Professional Documents

Culture Documents

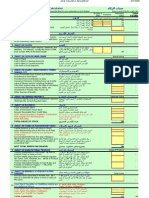

Design Calculation Sewage Pit

Uploaded by

M N HodaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Calculation Sewage Pit

Uploaded by

M N HodaCopyright:

Available Formats

EA for the Proposed STP

ANNEXURE III DESIGN CALCULATION

Present Sewage Flow

13.65 MLD = 569 m3/hr 2.25 30.71 MLD = 1279.58 m3/hr

Peak Factor Peak Flow

: :

Design Characteristics: BOD Total Suspended Solids Fecal Coliform : : : 170 370 mg/l 250 mg/l 5 x107 MPN/100ml

Total Sewage Characteristics: pH BOD COD Oil & Grease Total Suspended Solids Nitrate Nitrogen (as NO3) Ammonia Nitrogen (as N) Total Phosphorous (as PO4) Total Coliform : : : : : : : : : 5.5 9.0 20 mg/l 250 mg/l 5 mg/l 30 mg/l 5 mg/l 50 mg/l 5 mg/l 1000 no/100 ml

Dindigul Municipality

108

Pure Enviro

EA for the Proposed STP

Receiving Chamber 1 No Average Flow Design Flow (Considering Peak factor) Detention Time Volume Required : : : : 13.65 MLD 30.71 = 1279.58 m3/hr 120 sec (1279.58 / (60 x 60)) x 120 = 42.65 m3

Provide receiving chamber of size Provide Volume

: 6.0 m x 3.0 m x 2.5 m (SWD) + 0.5 (FB) : 45 m3 > 42.65 m3, OK

2. Coarse Screens 2 Nos (1 Mechanical + 1 Manual) 1 Working + 1 Standby: Design Flow : 30.71 MLD = 1279.58 m3/hr = 0.36 m3/sec 0.6 m/sec 25 mm 75 mm x 10 mm 0.36 / 0.6 1.0 m 1.2 m/sec 0.6 / (1.2 x Sin 600) = 0.58 m2 = 0.6 m2

Design Velocity at peak flow Clear Opening between bars Size of Bars Screen area required Width of Channel provided Velocity through screens at peak flow Clear Area

: : : : : : :

Clear Opening between bars No. of clear openings Dimension of bar Width of channel Width Provided

: : : : :

25 mm, 0.025m 24 75 mm x 10 mm (24 x 25) + (25 x 10) = 850 mm, 0.85m 1000 mm

Dindigul Municipality

109

Pure Enviro

EA for the Proposed STP

Provide a screen channel of size 1 m wide x 0.7 m (SWD) + 0.5 m (FB) Check for Approach Velocity at Average Flow Average Flow Channel Area Velocity : : : 13.65 MLD = 0.158 m3/sec 1 m wide x 0.7 m SWD = 0.7 m2 0.158 / 0.7 = 0.23 m/sec < 0.3 m/sec, ok.

3. Fine Screens 2 Nos (1 Mechanical + 1 Manual) 1 working + 1 standby Design Flow Design Velocity at ultimate flow Area required at Ultimate flow : : : 30.71 MLD = 0.36 m3/sec 0.6 m/sec 0.36 / 0.6 = 0.6 m2 0.7 m 1.0 m 1.2 m/sec 0.36 / 1.2 = 0.3 m2 400 0.3 / (1.2 x Sin 400) = 0.39 m2 0.8 m 0.39 m 6mm = 0.006 m 0.39 / 0.006 = 65 = 66 75 mm x 10 mm

SWD provided Width of channel Velocity through screen Clear Area

: : : :

Angle of inclination Net inclined screen area required SWD provided Net Clear width of channel Clear opening between bars No. of clear openings No. of bars Dimensions of bar

: : : : : : : :

Dindigul Municipality

110

Pure Enviro

EA for the Proposed STP

Width of channel Width provided

: :

(65 x 6 + 66 x 10) / 1000 = 1m 1000mm

Provide a screen channel size 1m wide x 0.8m SWD + 0.5m free board Check for Approach Velocity at Average Flow Average Flow Channel Area Velocity : : : : : 2 nos ( 1w + 1 s ): : : : : : : : : : 30.71 MLD 960 m3/m2/d 30.71 x 1000/960 31.99 m2 5.4m X 5.7 m 60 sec (30.71 x 1000/24 x 3600) x 60 21.33 m3 21.33 / 31.99 13.65 MLD = 0.158 m3/sec 1m wide x 0.8m SWD 0.8 m2 0.158/0.8 0.20 m/sec < 0.3m/sec

Degritting tank Design Flow

Surface loading rate Surface area

Dimensions of the Tank Detention time Volume required

Liquid depth required

Hence provide a Degritting tank with mechanism to fit in RCC chamber of size 5.7 m x 5.7 m x 0.66m (SWD) + 0.5 m free board 5 Primary Clarifier ----- 1 no Design flow Overflow Rate Clarifier area required : : : : : 13.65 MLD 25 m3/m2/day 13650/25 546 m2 26.4 m

Dia required

Dindigul Municipality

111

Pure Enviro

EA for the Proposed STP

Provided diameter Clarifier Area provided Retention time Volume required

: : : : : :

27.0m 572.3 m2 3 hrs 13650/24 x 3 1706.25 cum 1706.25/546 = 3.12, say 3 m

SWD required

Provide secondary clarifier of 27m dia x 3m SWD + 0.5m free board Check for overflow rate Surface area Overflow Rate : : : 546 m2 13650/546 25 m3/.2m/day , OK

Check for Weir loading

: 13650 ------------------------3.1412 x 25 : 173.8 m3/day/m, <300

Aeration Tank...1 No Design flow for each tank : : : 13.65 MLD = 569 m3/hr 0.158 m3/hr Diffused Aeration System

Type of Aeration

Inlet BOD to Aeration Tank : 0.8 x 300 (20% BOD removal in Degritting tank is assumed associated with grit) : 240 mg/l Outlet BOD Total BOD load removed : : 20 mg/l (240-20) x 13650 ---------------------1000 3003 kg/day

Dindigul Municipality

112

Pure Enviro

EA for the Proposed STP

MLSS F/M Ratio Volume of the tank required

: : :

2800 mg/l 0.4 13650 x220 -------------2800 x 0.4 2681.25 m3 30m x 20m x 4.5m SWD + 0.5m FB 2700 m3 2700/569 4.75 hrs, between 4 6 hrs,

: Size of the tank provided Volume provided Check for HRT : : :

Air Blower -- 3 Nos(2w+1s) Oxygen Requirement BOD destroyed Oxygen required : : : : : 0.9 kg / kg BOD destroyed 3003 kg/d 0.9 x 3003 2702.7 kg/d

Air required

2702.7 ------------------------------------------1.21 x 0.232 x 24 x 0.7 x 1 x (0.0625 x 4.5) : 2037.62 m3/hr

OR Air volume for mixing Air requirement/compartment : : : : : : 10 cum/min per 1000 cum of tank volume 10/1000 x 2702.7 27.03 m3/min 1621.8 m3/hr Higher of (1) & (2), 1020 m3/hr

Capacity of each blower i.e.,2037.62,say(2040/2)

Provide 3 Nos (2+1) blower, each of capacity 1020 m3/hr at 0.6 kg/cm2

Dindigul Municipality

113

Pure Enviro

EA for the Proposed STP

Secondary Clarifier ----- 1 no Design flow Overflow Rate Clarifier area required : : : : : : : : : : : : 13.65 MLD 25 m3/m2/day 13650/25 546 m2 26.4 m 27.0m 572.3 m2 3 hrs 13650/24 x 3 1706.25 cum 1706.25/546 3.12,say 3 m

Dia required Provided diameter Clarifier Area provided Retention time Volume required

SWD required

Provide secondary clarifier of 27m dia x 3m SWD + 0.5m free board Check for overflow rate Surface area Overflow Rate : : : 546 m2 13650/546 25 m3/2m/day, OK

Check for Weir loading

: 13650 ------------------------3.1412 x 25 : 173.8 m3/day/m, <300

Chlorine contact tank Flow Retention time Volume

---- 1 No : : : : 13.65 MLD 30 min (13650 x 30) / (24x60) 284.38 m3

Dindigul Municipality

114

Pure Enviro

EA for the Proposed STP

Provide Chlorine contact tank of 12 m x 8 m x 3.0 m SWD + 0.5m free board Provide Volume : 288 m3

Baffles shall be provided along length of the tank for better mixing

SLUDGE HANDLING SYSTEM: A. Return Activated Sludge: Total flow including recirculation MLSS in Aeration Tank Solids in recirculated flow : : : : : : : : 1.5 x 13650 = 20475 m3/day 2800 mg/l ((2800/1000) x 20475) 57330 m3/day 1% 57330/10 5733 m3/day 238.88, say 240 m3/hr

Consistency of solids Return Activated Sludge Quantity

B. Excess Secondary Sludge from Secondary Clarifier: Quantity of waste activated sludge,Q w MLSS concentration in Aeration Tank X : : V X / Oc Xs 2800 mg/L

MLSS concentration in waste activated sludge from secondary clarifier: 10000 mg/l Sludge Retention Time, Total Aeration Tank Volume Qc V Qw : : : 6 day 2700 m3 2700 x 2800 --------------------6 x 10000 126 m3/day

: 1 Sludge sump ---- 1 No Total sludge to sludge sump Size of the sump provided : :

126 m3/day 7m x 7m x 2.5 m SWD + 0.5 FB

Dindigul Municipality

115

Pure Enviro

EA for the Proposed STP

Volume of the sump provided:

122.5 m3

b) Air Blowers for sludge Mixing ------ 2 nos (1w+1s) Air volume for mixing Air requirment/compartment : : : : 10 m3/min per 1000 m3 of tank volume (10 / 1000) x 122.5 1.225 cum/min 73.5 cum/hr

Provide 2 nos.(1+1) blower,each of capacity 73.5 m3/hr at 0.4 kg/cm2

Thickener Feed Pumps ---- 2 nos (1w + 1s) Type Capacity Head : : : Horizontal, Centrifugal 60 cu.m/hr 10m

4. Return Activated Sludge Pumps --- 2 nos(1w + 1s) Type Capacity Head : : : Submersible, Non-clog impeller 15.0 cu.m/hr 10m

5 Sludge Thickener --- 1 no

Quantity of sludge Solids concentration in Total Solids Total solids in underflow Quantity of thickened sludge Thickener Overflow Solids Loading Rate Thickening Area required Thickener dia required Thickener dia provided Thickener dimension Centrifuge Feed Sump --- 1 No Thickened sludge consistency : : : : : : : : : : : : : 126 m3/day 1% 10000/1000 x 126 1260 kg/day 0.95 x 1260/36 33.25 cum/day 126 33.25 = 92.75 m3/ day 50 kg/m2/day 1260/50 25.2 m2 5.67m 5.7m 5.7m dia x 3m SWD + 0.5 m free board

3.6%

Dindigul Municipality

116

Pure Enviro

EA for the Proposed STP

Quantity of thickened sludge Retention time Volume of the sump required Sump provided board 7

: : : :

33.25 m3/day 10 hrs 13.85 m3 3.5m x 2m x 2.0m SWD + 0.5m free

Centrifuge Feed Pump --- 2 Nos (1w + 1s) Type Capacity Head : : : Progressive cavity screw 10 m3/hr 15 mwc

Centrifuge --- 2 Nos (1w+1s) Type Capacity Inlet consistency Outlet consistency : : : : Solid bowl type,co-current 10 m3/hr 3.6% 20%

Supernatant Collection Sump - 1 No Sludge flow to centrifuge : 33.25 cum/day Solids in the centrifuge feed : 1260 kg/day Solids in the under flow of centrifuge: 1197 kg/day Centrifuge sludge underflow : 5.43 cum/day Centrate floe from centrifuge : 33.25 5.43 : 27.82 m3/day Total supernatant from thickener¢rifuge: 92.75 + 27.82 : 120.57 m3/day Provide Supernatant collection sump of size 3.5 m x 3.5 m x 3m SWD + 0.5m free

board b)Supernatant transfer pumps ----- 2 nos(1w+1s) Type Capacity Head Chemical Handling System Polelectrolyte Dosing Tank------ 2 Nos(1w+1s) Polyelectrolyte at centrifuge Dry Solids at the centrifuge inlet Polelectrolyte required Solution Strength : : : Submersible, Non clog impeller 10 m3/hr 10m

: : : : :

1.5kg/ton of dry solids at centrifuge 1260 kg/d 1.26 ton/d 1.26 x 1.5 = 1.89 kg/d 0.1%

Dindigul Municipality

117

Pure Enviro

EA for the Proposed STP

Volume : provide 2 nos(1+1) HDPE tank, each of 2000 lit Dosing pumps ----- 2 nos(1w+1s) Type : Capacity : head : Chlorinator------ 2 Nos (1w+1s) Chlorine Dose Chlorine Requirment Chlorinator capacity provided Booster water pump----- 2 nos(1w+1s) Type Capacity Head Quantity of chlorine provided Chlorine concentration desired in the outlet Quantity of water required : : : :

1.89 / (0.1 x 10-2) = 1890 lit/day

Diaphram type 90 LPH 40 MWC

10 mg/L as 100% Cl2 10/1000 x 13650 136.5 kg/day 6 kg/hr

: : : : : : : :

Centrifugal, Horizontal 10 cum/hr 30 mwc 6 x 24 kg/d 1500 mg/l 1.5 kg/cum 144 /1.5 = 96 cum/day 4 cum/hr = say 5 cum/hr

MISCELLANEOUS UNITS: Centrifuge Shed 1 No Size of the room 9 m x 6 m Chlorination and Toner Room 1 No Size of the room 6.0 m x 5.0 m x 3.6 m (TH) Administration and Laboratory building 1 No Size of the room 10.0 m x 6.0 m x 3.6 m (TH) Motor Control Center (MCC) Room 1 No Size of the room 6.0 m x 4.0 m x 3.6 m (TH)

Dindigul Municipality

118

Pure Enviro

EA for the Proposed STP

ANNEXURE IV

Dindigul Municipality

119

Pure Enviro

You might also like

- Annex 31 Tool Design Extended AerationDocument5 pagesAnnex 31 Tool Design Extended AerationJong Dollente Jr.100% (1)

- Process Design Calculation3 - NDDocument14 pagesProcess Design Calculation3 - NDabhishek5810No ratings yet

- CalculationDocument5 pagesCalculationalok_rajpoot786100% (2)

- Grit Removal DesignDocument5 pagesGrit Removal Designnassif75No ratings yet

- Sewage Treatment PlantDocument9 pagesSewage Treatment PlantRohit NegiNo ratings yet

- Annex 31 Tool Design Extended AerationDocument5 pagesAnnex 31 Tool Design Extended AerationKalyca Nazhifa SalwaNo ratings yet

- Annex 30 Tool - Design - Waste Stabilization PondsDocument8 pagesAnnex 30 Tool - Design - Waste Stabilization Pondsmurkeking100% (1)

- Design of WTPDocument6 pagesDesign of WTPIbrahem Hamdy Naeem100% (4)

- Sewerage Treatment Plant Design TemplateDocument63 pagesSewerage Treatment Plant Design TemplateArvinthran Raja Kumaran92% (12)

- Process Design of A Complete Sewage Treatment PlantDocument10 pagesProcess Design of A Complete Sewage Treatment PlantSatish Charuvil100% (4)

- Sediment Tank Design Details - 2Document6 pagesSediment Tank Design Details - 2Ezdee100% (2)

- SBR Plant Design PDFDocument8 pagesSBR Plant Design PDFvishuNo ratings yet

- Design of WTP and STPDocument14 pagesDesign of WTP and STPVenu Ch100% (1)

- Design of STPDocument21 pagesDesign of STPMinTzHoNo ratings yet

- Cascade Aerator PDFDocument8 pagesCascade Aerator PDFPANKAJ TAMBAKHENo ratings yet

- Performance of Dual Media Downflow Rapid Gravity FiltersDocument7 pagesPerformance of Dual Media Downflow Rapid Gravity FiltersBasproNo ratings yet

- Process Design CalcDocument9 pagesProcess Design Calckiran raghukiranNo ratings yet

- Design Calculation - STPDocument23 pagesDesign Calculation - STPForam ParekhNo ratings yet

- Flash Mixer and FlocculationDocument13 pagesFlash Mixer and FlocculationPratik Kachalwar67% (3)

- Aeration and Sludge Drying BedDocument14 pagesAeration and Sludge Drying BedDavid Lambert100% (2)

- Annexure 15 - Tool For Water Treatment Plant DesignDocument3 pagesAnnexure 15 - Tool For Water Treatment Plant DesignMicheal Jackson100% (2)

- WTP (Water Treatment Plant) DesignDocument3 pagesWTP (Water Treatment Plant) DesignPratiksha Pawar100% (1)

- Design of Rapid Gravity Filter Design Criteria: (Rapid Sand Filter)Document4 pagesDesign of Rapid Gravity Filter Design Criteria: (Rapid Sand Filter)dpkNo ratings yet

- Cpheeo Manual Filter Bed and Sed. TankDocument9 pagesCpheeo Manual Filter Bed and Sed. TankChauhan UjjvalNo ratings yet

- Grit ChamberDocument29 pagesGrit Chamberazcomp100% (1)

- Annex 30 Tool - Design - Waste Stabilization PondsDocument9 pagesAnnex 30 Tool - Design - Waste Stabilization PondsAly AnisNo ratings yet

- 0.90 MLD MechanicalDocument8 pages0.90 MLD Mechanicalkiran raghukiranNo ratings yet

- Calculation Example of Extended AerationDocument30 pagesCalculation Example of Extended AerationHRK65100% (1)

- Interim Report 150 MLDDocument112 pagesInterim Report 150 MLDMaqsood Ibn Shaikhul ArfeenNo ratings yet

- 5m3d MBR Packaged STP 2017.3.28Document13 pages5m3d MBR Packaged STP 2017.3.28DevNo ratings yet

- Free Design Calculations For STP and ETP by Richa Environmental Services PVT LTD PDFDocument6 pagesFree Design Calculations For STP and ETP by Richa Environmental Services PVT LTD PDFmuradali01No ratings yet

- Sewagetreatmentplant Designcalculation 130528150104 Phpapp01Document8 pagesSewagetreatmentplant Designcalculation 130528150104 Phpapp01Muhammad IdrisNo ratings yet

- Tube Settler DesignDocument4 pagesTube Settler DesignKrishna Winx100% (1)

- 250mld WTPDocument6 pages250mld WTPeepmcjayal2No ratings yet

- Septic Tank SizingDocument1 pageSeptic Tank SizingManikumar CheboluNo ratings yet

- Design of Slow Sand Filter KinfraDocument2 pagesDesign of Slow Sand Filter KinframajeedctNo ratings yet

- Hopper Calulation For ClarifierDocument1 pageHopper Calulation For ClarifierHemantk8731100% (1)

- Primary TreatmentDocument22 pagesPrimary TreatmentEmil AbdoNo ratings yet

- Lecture 3 Screening and Grit ChambersDocument11 pagesLecture 3 Screening and Grit ChambersAs MihNo ratings yet

- Tank SizingDocument2 pagesTank Sizingaike_5No ratings yet

- Water Balance Chart - Commercial Block Water Balance - Residential Block & ClubhouseDocument1 pageWater Balance Chart - Commercial Block Water Balance - Residential Block & ClubhouseRANJINI02VNo ratings yet

- ClarifierDocument1 pageClarifiergroup2sd1314No ratings yet

- MBR Membrane ComparisionDocument9 pagesMBR Membrane Comparisionyash_btech100% (1)

- Design Criteria SBRDocument8 pagesDesign Criteria SBRranbeer41100% (1)

- Equipment Design - Aeration TankDocument6 pagesEquipment Design - Aeration TankKENGERALDNo ratings yet

- SBR DesignDocument2 pagesSBR DesignHRK65100% (6)

- Annex 31 Tool Design Extended AerationDocument5 pagesAnnex 31 Tool Design Extended AerationAnonymous QiMB2lBCJLNo ratings yet

- Spreadsheet For Activated Sludge ProcessDocument31 pagesSpreadsheet For Activated Sludge ProcessHemantk8731100% (8)

- STP Calculation NS - 2200Document42 pagesSTP Calculation NS - 2200Anandaraju Saminathan67% (3)

- List of SymbolsDocument11 pagesList of SymbolsKaarthic EmayNo ratings yet

- Water Supply Scheme DesignDocument19 pagesWater Supply Scheme DesignOladunni Afolabi100% (1)

- Rapid Mix Design Calculation 1Document4 pagesRapid Mix Design Calculation 1Yang Ching HianNo ratings yet

- Trikling FiltersDocument16 pagesTrikling Filtersmosaad khadrNo ratings yet

- Design of Each Process of ETPDocument9 pagesDesign of Each Process of ETPFaisal Sr. ExecutiveNo ratings yet

- Design of Slow Sand Filter FinalDocument11 pagesDesign of Slow Sand Filter FinalHemant SonawadekarNo ratings yet

- Design Calculation of 61kld STPDocument4 pagesDesign Calculation of 61kld STPAminur Rahman100% (2)

- Coagulation Sanitary Engineering-Lecture3Document50 pagesCoagulation Sanitary Engineering-Lecture3motuz adamNo ratings yet

- Stress TransformationDocument22 pagesStress TransformationTran Manh HuyNo ratings yet

- Axial LoadingDocument20 pagesAxial LoadingM N HodaNo ratings yet

- Lecture4 TorsionDocument27 pagesLecture4 Torsionshilton1989No ratings yet

- Lecture2 Stress StrainDocument51 pagesLecture2 Stress StrainCarissa Eustaquio100% (1)

- Introducation Solid MechanicsDocument15 pagesIntroducation Solid MechanicsM N HodaNo ratings yet

- برنامج حساب زكاه المالDocument3 pagesبرنامج حساب زكاه المالnewlife4me100% (10)

- برنامج حساب زكاه المالDocument3 pagesبرنامج حساب زكاه المالnewlife4me100% (10)

- International BusinessDocument18 pagesInternational BusinessM N HodaNo ratings yet

- Pretest: Environmental Science Quarter 2 - Module 3 The Ecological Levels of Organization ObjectivesDocument10 pagesPretest: Environmental Science Quarter 2 - Module 3 The Ecological Levels of Organization ObjectivesPersonalNo ratings yet

- GreenDocument34 pagesGreenSiddharth Srivastava91% (11)

- Godrej's Sustainability Initiatives Towards SDGsDocument9 pagesGodrej's Sustainability Initiatives Towards SDGsAkanksha ChauhanNo ratings yet

- MC Mehta V Union of IndiaDocument18 pagesMC Mehta V Union of Indiagauravgupta3093No ratings yet

- Geography For Cambridge International As & A Level - Revision GuideDocument216 pagesGeography For Cambridge International As & A Level - Revision GuideNana Budu Kofi HAYFORDNo ratings yet

- Research Paper In-Vessel Co-Composting - A Rapid Resource Recovery Option For Septage Treatment in Indian CitiesDocument10 pagesResearch Paper In-Vessel Co-Composting - A Rapid Resource Recovery Option For Septage Treatment in Indian CitiesAregaNo ratings yet

- MANUSCRIPT (Eboy)Document16 pagesMANUSCRIPT (Eboy)Niña AntopinaNo ratings yet

- Waste Management ArticleDocument7 pagesWaste Management Articleapi-312441438No ratings yet

- Balili ResearchDocument14 pagesBalili ResearchFaith G. TayabanNo ratings yet

- Bridge Scoping Checklist: NAME: HAMZA MINHAS & Mohsin ManzoorDocument5 pagesBridge Scoping Checklist: NAME: HAMZA MINHAS & Mohsin Manzoorhamza minhasNo ratings yet

- Resources (Assignment - 1)Document4 pagesResources (Assignment - 1)gobinda prasad barmanNo ratings yet

- Belonio, Roi Emman E.Document4 pagesBelonio, Roi Emman E.Adrian Nazrene BitoonNo ratings yet

- Green Building Research PaperDocument12 pagesGreen Building Research PaperBianca PlabasanNo ratings yet

- Biogas: Alix Simnock Brooke Myones Carrie Senft Dan CohnDocument21 pagesBiogas: Alix Simnock Brooke Myones Carrie Senft Dan CohnNguyênVũXuânNo ratings yet

- Water Pollution Control Program (WPCP) : Title PageDocument32 pagesWater Pollution Control Program (WPCP) : Title Pageapi-19990262No ratings yet

- dHEqRC HMW 1675997116 Grade5 PA 3 SST CH-12 Environmental Pollution Notes 1Document3 pagesdHEqRC HMW 1675997116 Grade5 PA 3 SST CH-12 Environmental Pollution Notes 1juncNo ratings yet

- Air Pollution PDFDocument353 pagesAir Pollution PDFrekhaNo ratings yet

- Urban Problems Related To EnergyDocument33 pagesUrban Problems Related To EnergyJobin Varghese80% (5)

- UntitledDocument3 pagesUntitledShivam GoyalNo ratings yet

- Land Pollution - Mapua Pollution New ZealandDocument10 pagesLand Pollution - Mapua Pollution New ZealandOPGJrNo ratings yet

- Determination of Total Solids in Water SamplesDocument9 pagesDetermination of Total Solids in Water SampleskhujastakhanNo ratings yet

- Activity 9 - Design Principles of Wastewater TreatmentDocument8 pagesActivity 9 - Design Principles of Wastewater TreatmentAnne Maureen MasangcayNo ratings yet

- Math MT Midterm ExamsDocument3 pagesMath MT Midterm ExamsEddie Angco TorremochaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityfeyayel990No ratings yet

- Anaerobic Digestion of Pulp and Paper Mill Wastewater and SludgeDocument29 pagesAnaerobic Digestion of Pulp and Paper Mill Wastewater and SludgeAndres MilquezNo ratings yet

- 3 4 5 A StormwatermanagementDocument4 pages3 4 5 A Stormwatermanagementapi-2609403590% (1)

- Physics Coursework: Alternative Energy SourcesDocument4 pagesPhysics Coursework: Alternative Energy SourcesJANE BALBOSA MOHAMMEDNo ratings yet

- A Review of Energy Recovery From Waste in ChinaDocument10 pagesA Review of Energy Recovery From Waste in ChinaWeiller Rafael Galli SilvaNo ratings yet

- Thailand Ultimate DaimondDocument15 pagesThailand Ultimate DaimondJenn TajanlangitNo ratings yet

- Module 3 Lesson 1Document2 pagesModule 3 Lesson 1Celine Marie CervantesNo ratings yet