Professional Documents

Culture Documents

Bulking of Sand

Uploaded by

Sougata DasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bulking of Sand

Uploaded by

Sougata DasCopyright:

Available Formats

The phenomena of bul ing of sand is discussed in the previous chapter.

The im portant facts in connection with the bul ing of sand are as follows: (1) When moisture content is increased by adding more water, the sand particles pac near each other and the amount of bul ing of sand is decreased. Thus the dr y sand and the sand completely flooded with water have practically the same volu me. (2) The coarse aggregate is little affected by the moisture content. (3) One of the reasons of adopting proportioning by weight is the bul ing of san d as proportioning by weight avoids the difficulty due to the bul ing of sand. (4) The bul ing of sand should be ta en into account when volumetric proportioni ng of the aggregates is adopted. Otherwise, less quantity of concrete per bag of cement will be produced, which naturally will increase the cost of concrete. Al so, there will be less quantity of line aggregate in the concrete mix which may ma e the concrete difficult to place. AIM To study the behaviour of sand grains under varying percentage of moisture conte nt . APPARATUES. 250 ml measuring cylinder ,weighing balance etc . PROCEDURE (i) Ta e 500gm (W1) of the aggregate. (ii) Keep the sample in an oven in a tray at a temperature of 100C-110 C for 24 0. 5 hours . (iii) Cool the sand in an air tight container and weight it (W2) Water content of the sample = (W1-W2)x 100/W1 (iv) Ta e out about 250gm of sand and pour it into a pan. (v) Add 2% (by weight) of water and mix well. (vi) Pour the sand sample into a 250 ml measuring cylinder and consolidate by sh a ing. (vii) Level the surface and read the volume in ml (Yi). (viii) Ta e out the whole quantity of sand and continue the experiment by adding 2% water more each time and note the corresponding volume of sand (Y2,Y3..) unti l the dump sand volume starts decreasing. (ix) Beyond this point, add 4% more water each time until the sample become full y saturated. (x) To the standard sample in the measuring cylinder, add about 50 ml water ore and stir the sample well. (xi) Note down the surface level of inundated sand (Y ml).

CALCULATIONS Bul ing =(Y1-Y)x100/Y GRAPH A graph drawn with % water content along X-mas and % bul ing along Y- axis. From the graph, pic out maximum % of bul ing occurred, % of water content at ma ximum bul ing , % of water content When bul ing is zero & % of bul ing for the i nitial water content (W) of the sample. RESULTS % of bul ing occurred = % of water content at maximum bul ing= % of water content when bul ing is zero= % of bul ing for the initial water content (W) of the sample = FIELD TEST FOR BULKING OF FINE AGGREGATES AIM To determine necessary adjustment for the bul ing of fine aggregate, in the fiel

d. APPARATUES 250 ml measuring cylinder PROCEDURE (I) Pour the dump sand in to a 250 ml measuring cylinder up to the 200 ml mar . (II) Fill the cylinder with water and stir well (sufficient water should be pour ed to submerge the sand compleately and it can be see that the sand surface is n ow below its original level) (III) Ta e the reading at the sand surface (Y ml) CALCULATIONS % of bul ing { (200/Y)- 1] x100 Report the percentage bul ing of the sand to the nearest whole number. RESULT Percentage bul ing of field sample= Related Tags: construction contracts sand bul ing testing, pdf presentation of bul ing of sand , factors affecting sand bul ing, sand bul ing test, testprocedure sand bul ing, note bul ing of sand, bul ing of sand limits, range and value ofbul ing of sand , bul ing of sand test procedure, concrete bul ing factor, as per is what is for mula for bul ing of sand, field moisture content test for fine aggregate by is s td,

Fine Sand Fine sand should consist of natural sand or crushed stone sand. It should be har d, durable, clean and be free from organic matter etc.Fine Sand should not conta in any appreciable amount of clay balls and harmful impurities such as al alis, salts, coal, decayed vegetation etc. The silt contents should not exceed 4%. Classification of Sand Classification of sand is given below. 1. Fine sand = 0.075 to O.425 MM 2. Medium sand = 0.425 to 2 MM 3. Coarse Sand = 2.0 to 4.75 MM Various Types of Sand There are following three types of sand. 1. Pit Sand 2. River Sand 3. Sea Sand Pit Sand (Coarse Sand or Badarpur) Pit sand is obtained by forming pits into soil from Quarries. It consists of sharp angular grains which are free from salts. It is coarse sand which is usually us ed in concreting and has reddish yellow color normally. River Sand This sand is obtained from ban s or beds of rivers. River sand is fine and consi sts of fine rounded grains. The color of river sand is almost white and Grayish. River sand is usually available in clean condition and is used for plastering. Sea Sand This sand is obtained from sea shores. It has fine rounded grains and light brow n color. Sea sand contains salts which attract moisture from atmosphere. Such ab sorption causes dampness and disintegration of wor . Sea sand also retards setti ng action of cement. Due to these reasons, sea sand is generally avoided for eng ineering purposes. It is used only as a local material for nonstructural purpose s. Sand for Construction Wor s

Different construction wor s require different standards of sand for constructio n. Bric Wor s: finest modulus of fine sand should be 1.2 to 1.5 and silt contents should not be more than 4%. Plastering Wor s: finest modulus of fine sand should not be less than 1.5 and si lt contents should not be more than 4%. Concreting Wor s: coarse sand should be used with finest modulus 2.5 to 3.5 and silt contents should not be more than 4%. NOTE If the above quality of sand is not available due to any reason, the blending o f sand should be done by adding more coarse sand to achieve the required finest modulus. Washed sand should be used at site for getting more strength in construction wo r . Bul ing of Sand Due to moisture in each particle of sand, sand gets a coating of water due to su rface tension which eeps the particles apart. This causes an increment in volum e of sand nown as Bul ing.

You might also like

- NEC Course QuestionsDocument5 pagesNEC Course QuestionsLaiTinYat100% (1)

- Report Silt Test For SandDocument10 pagesReport Silt Test For SandZanne Rose100% (1)

- Test ProcedureDocument27 pagesTest ProcedureAjayNo ratings yet

- Bulking of Fine AggregateDocument7 pagesBulking of Fine AggregateDeep DebnathNo ratings yet

- Lab ReportDocument3 pagesLab Reportmuludibo7No ratings yet

- Concrete Laboratory Civil Engineering Department Polytechnic Kuching SarawakDocument6 pagesConcrete Laboratory Civil Engineering Department Polytechnic Kuching SarawakDdeqz Elina Bueno INo ratings yet

- CM 04 - SandDocument42 pagesCM 04 - SandVijayNo ratings yet

- 1.1 Expansive SoilDocument9 pages1.1 Expansive SoilYatin JethiNo ratings yet

- Construction Technology .KDocument247 pagesConstruction Technology .KHarshit Kumar SahuNo ratings yet

- Detailed Project Report - CsebDocument23 pagesDetailed Project Report - CsebdrlikhithrajNo ratings yet

- Experiment 2 Sand Segregation TestDocument3 pagesExperiment 2 Sand Segregation TestZul HaswalNo ratings yet

- Sand Lec5Document16 pagesSand Lec5232449045No ratings yet

- UNIT-1: Traditional Building Materials "SAND"Document49 pagesUNIT-1: Traditional Building Materials "SAND"Kyle SarmientoNo ratings yet

- Experiment No. 7 Bulking of SandDocument1 pageExperiment No. 7 Bulking of SandShubham GautamNo ratings yet

- Report Silt Test For SandDocument10 pagesReport Silt Test For SandDira Azman80% (5)

- Sand Casting TestingDocument5 pagesSand Casting TestingDumithJayathilaka100% (1)

- Sand Dams or Silt TrapsDocument6 pagesSand Dams or Silt TrapscherogonyaNo ratings yet

- Norah Final Project SlidesDocument17 pagesNorah Final Project Slidesiamkay665No ratings yet

- Bulkage & Silt Content of Fine Aggregate.Document1 pageBulkage & Silt Content of Fine Aggregate.XOXOXOXO XOXOXOXONo ratings yet

- BMC Question Answer Bank Explain The Composition of Ordinary CementDocument10 pagesBMC Question Answer Bank Explain The Composition of Ordinary Cementshenaz AfroseNo ratings yet

- Chap 7 SandDocument24 pagesChap 7 SandRiwaj PhuyalNo ratings yet

- Experiment No. 2.4 Sand Control Test: Compactibility Test: Aim: ApparatusDocument3 pagesExperiment No. 2.4 Sand Control Test: Compactibility Test: Aim: ApparatusDhananjay ShimpiNo ratings yet

- Experiment No. 2.4 Sand Control Test: Compactibility Test: Aim: ApparatusDocument3 pagesExperiment No. 2.4 Sand Control Test: Compactibility Test: Aim: ApparatusDhananjay ShimpiNo ratings yet

- Bituminous Soil StabilizationDocument30 pagesBituminous Soil StabilizationYathish14382% (11)

- Bulking of Sand TestDocument2 pagesBulking of Sand Testk_98196636867% (3)

- Bulking of SandDocument5 pagesBulking of SandOsama HassanNo ratings yet

- Sand ReplacementDocument14 pagesSand ReplacementMuniey Aziz75% (8)

- Moulding Sand Tesying - 11Document17 pagesMoulding Sand Tesying - 11firdoshansariNo ratings yet

- IMP PresentationDocument10 pagesIMP Presentationjai gaurNo ratings yet

- Casting and Casting Processes: Prof. (DR.) Dalgobind Mahto 3/10/2015Document28 pagesCasting and Casting Processes: Prof. (DR.) Dalgobind Mahto 3/10/2015keethanNo ratings yet

- Vishal Setting of CementDocument15 pagesVishal Setting of CementVishal ChamarthiNo ratings yet

- COMPARITIVE STUDY OF CONCRETE MADE OUT OF NATURAL SAND AND MANUFACTURED SAND SvitsDocument39 pagesCOMPARITIVE STUDY OF CONCRETE MADE OUT OF NATURAL SAND AND MANUFACTURED SAND SvitsMohammed Abdul RazzakNo ratings yet

- CHAPTER 2 - Selection of Fishfarm SiteDocument12 pagesCHAPTER 2 - Selection of Fishfarm SiteRay Lorenz OrtegaNo ratings yet

- 4ce7: Concrete Technology Lab: Experiment No.:-3Document3 pages4ce7: Concrete Technology Lab: Experiment No.:-3sita ram JatNo ratings yet

- Sang Semnr ReportDocument25 pagesSang Semnr Reportgreeshma cNo ratings yet

- Procedure For Using The Baroid Sand Content Set: PH MeasurementDocument4 pagesProcedure For Using The Baroid Sand Content Set: PH MeasurementJerryuk20No ratings yet

- LEC 6 AggregateDocument23 pagesLEC 6 AggregateMuhammad Irfan Khan100% (1)

- Presentation of CteDocument20 pagesPresentation of CteSamruddhi AnkalkhopeNo ratings yet

- Design & Layout of Solar Salt Works PDFDocument27 pagesDesign & Layout of Solar Salt Works PDFurmil_2_k100% (1)

- Net Content Purely Not My WorkDocument5 pagesNet Content Purely Not My WorkVķ MãħëšħNo ratings yet

- Chemical Properties of SandDocument5 pagesChemical Properties of SandTarunaiNo ratings yet

- Soil MechanicsDocument58 pagesSoil MechanicsNarte, Angelo C.No ratings yet

- Soil Properties and Their Influence On Design of DamsDocument15 pagesSoil Properties and Their Influence On Design of DamsHanniel Madramootoo100% (1)

- Improving The Surface Quality of Sand Castings Using Newly Invented Local Sand-Clay MixtureDocument48 pagesImproving The Surface Quality of Sand Castings Using Newly Invented Local Sand-Clay MixtureCharitha RanwalaNo ratings yet

- Sand& Cement TestsDocument6 pagesSand& Cement Testskaram amrNo ratings yet

- Sand Control 2. Introduction To Coiled Tubing: Damilola V. AinaDocument49 pagesSand Control 2. Introduction To Coiled Tubing: Damilola V. AinaAkande AyodejiNo ratings yet

- Lecture 1 - AggregateDocument9 pagesLecture 1 - AggregateDuronto Pothik100% (1)

- Bulking of Sand Test ProcedureDocument3 pagesBulking of Sand Test ProcedureA RaviNo ratings yet

- 2.1 SoilTextureDocument41 pages2.1 SoilTexturerieNo ratings yet

- Factors Effecting Sand ProductionDocument24 pagesFactors Effecting Sand Production196463No ratings yet

- Experiment No 5-MKKDocument5 pagesExperiment No 5-MKKVivekumNo ratings yet

- .An Experimental Study On Different Properties of Sea Sand and River SandDocument4 pages.An Experimental Study On Different Properties of Sea Sand and River SandSantosh JayasavalNo ratings yet

- Sand Control TestsDocument7 pagesSand Control TestsAly MohamedNo ratings yet

- Referrence 11 PDFDocument11 pagesReferrence 11 PDFSagirul IslamNo ratings yet

- Chapter 7 Sand Control NewestDocument51 pagesChapter 7 Sand Control NewestVenny HelinaNo ratings yet

- Moulding & Moulding Materials: Casting ProcessesDocument97 pagesMoulding & Moulding Materials: Casting ProcessesTrung Quoc LeNo ratings yet

- The Chemistry of Soils - Including Information on Acidity, Nitrification, Lime Requirements and Many Other Aspects of Soil ChemistryFrom EverandThe Chemistry of Soils - Including Information on Acidity, Nitrification, Lime Requirements and Many Other Aspects of Soil ChemistryRating: 4 out of 5 stars4/5 (1)

- Sandcastles Made Simple: Step-by-Step Instructions, Tips, and Tricks for Building Sensational Sand CreationsFrom EverandSandcastles Made Simple: Step-by-Step Instructions, Tips, and Tricks for Building Sensational Sand CreationsRating: 4 out of 5 stars4/5 (6)

- Design Considerations and Important NotesDocument32 pagesDesign Considerations and Important NotesSougata DasNo ratings yet

- Effect of Admixtures On Properties of Alkali-Activated Slag ConcreteDocument8 pagesEffect of Admixtures On Properties of Alkali-Activated Slag ConcreteSougata DasNo ratings yet

- Structure Repairs & Rehabilitation Presentation No.3Document98 pagesStructure Repairs & Rehabilitation Presentation No.3Sougata DasNo ratings yet

- Design of Pile CapDocument6 pagesDesign of Pile CapJasy DasNo ratings yet

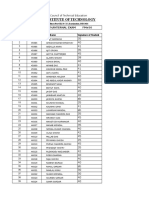

- Murshidabad Institute of Technology: Subject: Ce Project-I/Internal Exam FM 50Document3 pagesMurshidabad Institute of Technology: Subject: Ce Project-I/Internal Exam FM 50Sougata DasNo ratings yet

- Determinate Structures Are Analysed Just by The Use of Basic EquilibriumDocument10 pagesDeterminate Structures Are Analysed Just by The Use of Basic EquilibriumSougata DasNo ratings yet

- Strength and Flow 80316Document12 pagesStrength and Flow 80316Sougata DasNo ratings yet

- W/ggbs Wsub Wwet WD N%Document6 pagesW/ggbs Wsub Wwet WD N%Sougata DasNo ratings yet

- Calculation of Materials: ResultDocument6 pagesCalculation of Materials: ResultSougata DasNo ratings yet

- 1sd Dec 2015Document1 page1sd Dec 2015Sougata DasNo ratings yet

- Admix NIL: Strength and FlowDocument2 pagesAdmix NIL: Strength and FlowSougata DasNo ratings yet

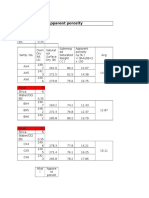

- Apparent Porosity: Alkali 6 Silica 6 Water/GG BSDocument4 pagesApparent Porosity: Alkali 6 Silica 6 Water/GG BSSougata DasNo ratings yet

- Din EquivalenteDocument66 pagesDin Equivalentemugiwara ruffyNo ratings yet

- Diósgyőri Stadion: A Case StudyDocument13 pagesDiósgyőri Stadion: A Case StudyKarthikeyan JagathesanNo ratings yet

- A 12 007 Garbage Chute DetailsDocument1 pageA 12 007 Garbage Chute DetailsMohammad UmmerNo ratings yet

- 3TEMPORARY STRUCTURE Fall Protection Working at HeightsDocument85 pages3TEMPORARY STRUCTURE Fall Protection Working at HeightsEunice GayetaNo ratings yet

- 958101tender PDFDocument120 pages958101tender PDFSandeep Saini100% (1)

- Space Frame: Navigation SearchDocument14 pagesSpace Frame: Navigation SearchDaniel Tejedor Ramos100% (1)

- Seismic Retrofitting Techniques PDFDocument42 pagesSeismic Retrofitting Techniques PDFAB100% (1)

- Sunidhi Rathore: Building Construction-VDocument20 pagesSunidhi Rathore: Building Construction-VSunidhi rathore100% (1)

- Expansion Joints hoses-KLINGER AUDocument7 pagesExpansion Joints hoses-KLINGER AUMichael PhamNo ratings yet

- The Complete Flight Pen Construction Manual: 2821 South U.S. Hwy 51 - Janesville, WI USA 53546Document11 pagesThe Complete Flight Pen Construction Manual: 2821 South U.S. Hwy 51 - Janesville, WI USA 53546FernandinigranNo ratings yet

- Advantages and Disadvantages of Timber Frame ConstructionDocument7 pagesAdvantages and Disadvantages of Timber Frame ConstructionViewingFreePDFSShouldNotBeChargedFuckYouSCRIBD100% (1)

- Dewanshu Srivastava Planning, Scheduling & Cost Engineer: Experience SkillsDocument2 pagesDewanshu Srivastava Planning, Scheduling & Cost Engineer: Experience Skillsअदभुत राजसिक साधनायेNo ratings yet

- Rigid PavementDocument20 pagesRigid PavementsknagarNo ratings yet

- Tal Eng Tec TP I FWC 2015Document8 pagesTal Eng Tec TP I FWC 2015Abcd AbcdNo ratings yet

- Activity Center Front Elevation: Esj and Sons Construction and Construction Supply, IncDocument1 pageActivity Center Front Elevation: Esj and Sons Construction and Construction Supply, IncGerard Paul CusiNo ratings yet

- History of Architecture: Michael GravesDocument19 pagesHistory of Architecture: Michael GravesrakeshNo ratings yet

- Fas-11 Typical Device Equipment Installation PDFDocument1 pageFas-11 Typical Device Equipment Installation PDFMØhãmmed ØwięsNo ratings yet

- Tile Adhesive Production by Inorganic Materials: International Journal of Innovation and Applied Studies July 2013Document6 pagesTile Adhesive Production by Inorganic Materials: International Journal of Innovation and Applied Studies July 2013Akshay RajNo ratings yet

- Standard Bracing of Simple Duopitched Trussed Rafter Roofs For Dwellings PublicDocument4 pagesStandard Bracing of Simple Duopitched Trussed Rafter Roofs For Dwellings PublicDavid O'MearaNo ratings yet

- ACB Installation Checklist 1Document8 pagesACB Installation Checklist 1Adnan AhmadNo ratings yet

- Pud 21-01 Batton RV Park Staff ReportDocument10 pagesPud 21-01 Batton RV Park Staff ReportActionNewsJaxNo ratings yet

- Engineering Drawing Meng 2203: Teshome Bogale May 2021Document41 pagesEngineering Drawing Meng 2203: Teshome Bogale May 2021Abdi ZerihunNo ratings yet

- Design of Gantry Girder MCQDocument2 pagesDesign of Gantry Girder MCQAvinash Kumar (RA1911001030001)No ratings yet

- SOR2023 RoadDocument279 pagesSOR2023 RoadccykdhamNo ratings yet

- Example 3Document12 pagesExample 3iknowvictoriassecret49No ratings yet

- GD 4Document46 pagesGD 4Moh Rofi'eNo ratings yet

- Mkii Soldiers: FormworkDocument2 pagesMkii Soldiers: FormworkHummadNo ratings yet

- Fountain EstimateDocument3 pagesFountain EstimateDeepak ChhuganiNo ratings yet

- Epcc-2 Package (RFCC Unit) ) For Petrochemical and Lube Integration Project "Lupech" (J-18)Document8 pagesEpcc-2 Package (RFCC Unit) ) For Petrochemical and Lube Integration Project "Lupech" (J-18)phanikrishnabNo ratings yet