Professional Documents

Culture Documents

Formulas

Uploaded by

sandeshbhavsar2281Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Formulas

Uploaded by

sandeshbhavsar2281Copyright:

Available Formats

FORMULAS

TO DETERMINE SELECTION

1) How to calculate torque when horsepower and speed are known 5252 x horsepower x service factor 5252 x hp x k torque ft lb = T= speed n 2) Inertia - How to determine inertia when material and shape are known. (Total system inertia is total inertia of all the components. If the components are not simple shafts or flanges, break down each of the components into its basic shape and calculate inertia of that individual component. When inertia is being calculated in relation to the clutch or brake, remember to adjust for reflected inertia amounts which may have a significant increase or decrease on the inertia that the clutch has to handle based upon a speed differential.) Formula to determine inertia of a solid shaft wk2 = .000681 x p x Length x Diameter4 wk2 = .000681 x p x L x D 4 Formula to determine inertia of a hollow shaft wk2 = .000681 x p x length x (outer diameter4 - inner diameter4) wk2 = .000681 x P x L x (DO4 -DI4 ) Reflected inertia via gears, chain or belt reflected inertia = load inertia divided by the square of the speed ratio 2 wk2R = wk L r2

(Inertia constants lb. in.3) (aluminum) = 0.0924 (bronze) = 0.321 (cast iron) = 0.26 (steel) = 0.282 Values wk2 = lb. ft.2 D, D0, D 1, L = in.

3) How to calculate the amount of torque required to accelerate or decelerate a load when inertia value is known (t = time to speed or time to stop depending if you are using a clutch or a brake.) (inertia x the change in rpm) wk2 x rpm torque ft lb = T= 308 x the time required 308t 4) Heat Dissipation Quick reference for determining slip watts for magnetic particle applications. (Magnetic particle clutches are normally limited to heat dissipation rather than torque when they are involved in a constant slip application.) watts = .0118 x torque in inch lbs. x the change in rpm 5) Linear Speed to Rotational Speed speed in feet per minute RPM = 3.14 x diam. in feet W = .0118 x t x rpm

RPM =

FPM 3.14 x D

You might also like

- Mechanical ShaftsDocument52 pagesMechanical ShaftsErnesto Elljr Landisan Locaben Jr.75% (16)

- 1 Worm GearDocument53 pages1 Worm GearMalay ShahNo ratings yet

- Lecture1-2 15852 SpringsDocument160 pagesLecture1-2 15852 SpringsL.K. Bhagi100% (1)

- Bearings ShaftsDocument74 pagesBearings ShaftsCik MinnNo ratings yet

- Vibration EngineeringDocument37 pagesVibration EngineeringAlen Benguit II0% (1)

- M 452 ContentDocument63 pagesM 452 ContentprasannaNo ratings yet

- 2 Way Slab Design - 31 Jul 13Document111 pages2 Way Slab Design - 31 Jul 13Vance Kang100% (1)

- Chapter 7Document39 pagesChapter 7Tejesh TutaramNo ratings yet

- Chapter 7Document39 pagesChapter 7SayeedIshtiaqueNo ratings yet

- EXP10MOM1252Document6 pagesEXP10MOM1252Sreevatsan M D 19BME1252No ratings yet

- Shaft Design: Design Against Static LoadingDocument6 pagesShaft Design: Design Against Static Loadingakshat singhNo ratings yet

- Dynamics ManualDocument30 pagesDynamics ManualRiyaz AhmedNo ratings yet

- 06 Practical Application Bolted Cylindrical VesselDocument12 pages06 Practical Application Bolted Cylindrical Vesselenrico.michelatoNo ratings yet

- Torque Shaft OptimisationDocument8 pagesTorque Shaft OptimisationJonathan CraigmileNo ratings yet

- Engineering Reference: Sizing and Selection of Exlar Linear and Rotary ActuatorsDocument8 pagesEngineering Reference: Sizing and Selection of Exlar Linear and Rotary ActuatorsJelena BauerNo ratings yet

- TorsionDocument3 pagesTorsionTannyVaneNo ratings yet

- Caculate Rotary LinearDocument3 pagesCaculate Rotary LinearTrinh Luong MienNo ratings yet

- Belt Drives and Chain DrivesDocument39 pagesBelt Drives and Chain DrivesSeparatorNo ratings yet

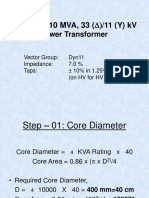

- Traditional Design of Cage Rotor Induction MotorsDocument35 pagesTraditional Design of Cage Rotor Induction MotorsMohammad Gulam AhamadNo ratings yet

- 200-Foot Simple Span Bridge Girder Design Using NU2000 V1Document50 pages200-Foot Simple Span Bridge Girder Design Using NU2000 V1Anthony GravagneNo ratings yet

- Problem FormulationDocument5 pagesProblem FormulationSudeesh SudevanNo ratings yet

- Basics of Squirrel Cage Induction Motor DesignDocument29 pagesBasics of Squirrel Cage Induction Motor Designरमेश सिंह100% (1)

- Aluminium Conductor Sag & Tension Calculation Inclined SpanDocument5 pagesAluminium Conductor Sag & Tension Calculation Inclined Spansitifarhani100% (1)

- Design Case StudyDocument14 pagesDesign Case Studyp m yadavNo ratings yet

- Board Solved Problems & FormulasDocument6 pagesBoard Solved Problems & FormulasJC YabisNo ratings yet

- Torque Sensors: Common Sensing MethodsDocument32 pagesTorque Sensors: Common Sensing MethodsvishiwizardNo ratings yet

- Mee2004 Exp 9Document6 pagesMee2004 Exp 9Raja RajaNo ratings yet

- Belt and Chain Drive With Pics and ExampleDocument39 pagesBelt and Chain Drive With Pics and ExampleTheodoric Bravo Martinez100% (1)

- SPL Bsts Jandaha Earthmat - Cal 005Document11 pagesSPL Bsts Jandaha Earthmat - Cal 005rahulnegi19170% (1)

- Thickener Presentation ScreenDocument10 pagesThickener Presentation ScreenArdian20100% (1)

- Motion Control Basics by John Mazurkiewicz Baldor Electric: Part 1 - Drive MechanicsDocument8 pagesMotion Control Basics by John Mazurkiewicz Baldor Electric: Part 1 - Drive MechanicsBob JonesNo ratings yet

- Torsional Vibration of Long Uniform ShaftDocument3 pagesTorsional Vibration of Long Uniform Shaftdaongocha108No ratings yet

- 4 Lecture Notes-4 BEM2053 EM218 - Additional NotesXDocument26 pages4 Lecture Notes-4 BEM2053 EM218 - Additional NotesXMuhammad Abdullah ImranNo ratings yet

- DOM Manual ACTDocument21 pagesDOM Manual ACTErin BarryNo ratings yet

- Mechanical Engineering TestDocument19 pagesMechanical Engineering TestKevin OnyangoNo ratings yet

- Whirling of ShaftsDocument16 pagesWhirling of ShaftsAshok JohnNo ratings yet

- Shafts With SampleDocument6 pagesShafts With Samplewaar lockNo ratings yet

- General Criteria For Design Steel StructureDocument12 pagesGeneral Criteria For Design Steel StructureSurat WaritNo ratings yet

- Connecting Rod DesignDocument16 pagesConnecting Rod Designashok_mangina0% (1)

- Design Analysis of Spur Gear With The Usage of The Advanced ComputerDocument6 pagesDesign Analysis of Spur Gear With The Usage of The Advanced ComputerPradeep AdsareNo ratings yet

- Muthu Cad 2Document8 pagesMuthu Cad 2Sagarias AlbusNo ratings yet

- Earthing CalculationDocument14 pagesEarthing CalculationNatarajan Ramakrishnan100% (18)

- Clutches and BrakesDocument77 pagesClutches and BrakesKaushikUpadyaNo ratings yet

- Design of Multi-Axis Welding Positioner WithDocument7 pagesDesign of Multi-Axis Welding Positioner Withsuraj dhulannavarNo ratings yet

- Belt Drives and Chain DrivesDocument39 pagesBelt Drives and Chain Drivesjaycee68No ratings yet

- Connecting Rod AnalysisDocument36 pagesConnecting Rod AnalysissayedNo ratings yet

- Belt Friction and Belt Drives-2022 NitDocument59 pagesBelt Friction and Belt Drives-2022 NitVimukthi LakshanNo ratings yet

- Dhanalakshmi College of Engineering: (DR - VPR Nagar, Manimangalam, Tambaram) Chennai - 601 301Document26 pagesDhanalakshmi College of Engineering: (DR - VPR Nagar, Manimangalam, Tambaram) Chennai - 601 301sajal agarwalNo ratings yet

- 3 Rig ComponentsDocument49 pages3 Rig ComponentsĐỗ AnhNo ratings yet

- Mechanics of DB PDF 3Document6 pagesMechanics of DB PDF 3eysNo ratings yet

- Calculation of Torque For Selection of MotorDocument6 pagesCalculation of Torque For Selection of Motoratanughosh125100% (6)

- M 452 ContentDocument84 pagesM 452 ContentSureshNo ratings yet

- Guid For The Selection of Agitator, Design Formula and Scale UpDocument60 pagesGuid For The Selection of Agitator, Design Formula and Scale Upscranderi100% (1)

- Dr. Suvandan Saraswat: Machine Design I (EME-501)Document67 pagesDr. Suvandan Saraswat: Machine Design I (EME-501)Suvandan SaraswatNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Differential Forms on Electromagnetic NetworksFrom EverandDifferential Forms on Electromagnetic NetworksRating: 4 out of 5 stars4/5 (1)

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet