Professional Documents

Culture Documents

02 Samss 012

Uploaded by

slan79bisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02 Samss 012

Uploaded by

slan79bisCopyright:

Available Formats

Materials System Specification

02-SAMSS-012 Weld Overlayed Fittings, Flanges and Spool Pieces Document Responsibility: Materials and Corrosion Control Standards Committee 9 October 2010

Saudi Aramco DeskTop Standards

Table of Contents 1 Scope.............................................................. 2 2 Conflicts and Deviations.................................. 2 3 References...................................................... 2 4 Definition......................................................... 4 5 Information to be Supplied by the Purchaser.. 4 6 Manufacture.................................................... 4 7 Qualification of Welding Procedures............... 6 8 Pickling............................................................ 7 9 Non-Destructive Testing.................................. 8 10 Dimensional Requirements............................. 8 11 Inspection........................................................ 9 12 Marking........................................................... 9 13 Handling, Packing and Transportation............ 9 14 Certification..................................................... 9

Previous Issue: New Next Planned Update: 9 October 2015 Page 1 of 9 Primary contact: Rao, Sanyasi on 966-3-8760242

CopyrightSaudi Aramco 2010. All rights reserved.

Document Responsibility: Materials & Corrosion Control Standards Committee 02-SAMSS-012 Issue Date: 9 October 2010 Next Planned Update: 9 October 2015 Weld Overlayed Fittings, Flanges and Spool Pieces

Scope This Specification covers corrosion resistant alloy (CRA) clad (weld overlayed) fittings, flanges and spool pieces (pipes) intended for fabrication of clad pipe spools. This specification can also used for overlaying of valves and valve components. This specification does not apply for clad line pipe nor for girth welding of clad components for the purpose of fabrication of pipe spools.

Commentary Note: Procurement of Clad/Lined line pipe is covered in 01-SAMSS-048.

Conflicts and Deviations 2.1 Any conflicts between this specification and other applicable Saudi Aramco Materials System Specifications (SAMSSs), Engineering Standards (SAESs), or industry standards, codes, and forms shall be resolved in writing by the Company or Purchaser Representative through the Manager, Consulting Services Department of Saudi Aramco, Dhahran. Direct all requests to deviate from this specification in writing to the Company or Purchaser Representative, who shall follow internal company procedure SAEP-302 and forward such requests to the Manager, Consulting Services Department of Saudi Aramco, Dhahran.

2.2

References The manufacture and purchase of material covered by this specification shall comply with the latest edition (as per the purchase order date) of the references listed below, as noted. A. Saudi Aramco References Saudi Aramco Engineering Procedure SAEP-302 Instructions for Obtaining a Waiver of a Mandatory Saudi Aramco Engineering Requirement

Saudi Aramco Materials System Specifications 01-SAMSS-035 01-SAMSS-038 01-SAMSS-043 API Line Pipe Small Quantity Purchase of Pipe from Stockist Carbon Steel Pipes for On-Plot Piping

Page 2 of 9

Document Responsibility: Materials & Corrosion Control Standards Committee 02-SAMSS-012 Issue Date: 9 October 2010 Next Planned Update: 9 October 2015 Weld Overlayed Fittings, Flanges and Spool Pieces

02-SAMSS-001 02-SAMSS-005 02-SAMSS-011

Piping Components for Low Temperature Service Butt Welding Pipe Fittings Forged Steel and Alloy Flanges

Saudi Aramco Inspection Requirements Form 175-026600 B. Industry Codes and Standards American Petroleum Institute API SPEC 6A Specification for Wellhead and Christmas Trees Equipment Weld Overlayed Flanges, Fittings and Spool Pieces

American Society of Mechanical Engineers ASME SEC II Part C ASME SEC IX Specifications for Welding Rods, Electrodes, and Filler Metals Qualification Standard for Welding and Brazing Procedures, Welders, Brazers, and Welding and Brazing Operators

American Society for Testing and Materials ASTM A380 Standard Practice for Cleaning, Descaling, and Passivation of Stainless Steel Parts, Equipments, and Systems Standard test Methods for Detecting Detrimental Intermetallic in Duplex Austenitic/Ferritic Stainless Steel Standard Test Method for Vickers Hardness of Metallic Materials Standard Test Methods for Pitting and Crevice Corrosion Resistance of Stainless Steels and Related Alloys by Use of Ferric Chloride Solution

ASTM A923

ASTM E92 ASTM G48

International Standardization Organization ISO 9000 - 9004 Quality Management and Quality Assurance Standards

Page 3 of 9

Document Responsibility: Materials & Corrosion Control Standards Committee 02-SAMSS-012 Issue Date: 9 October 2010 Next Planned Update: 9 October 2015 Weld Overlayed Fittings, Flanges and Spool Pieces

National Association of Corrosion Engineers NACE MR0175/ISO 15156 Petroleum and Natural Gas IndustriesMaterials for use in H2S-Containing Environments in Oil and Gas Production 4 Definition Spool Pieces: Double random length pipes or cut length of pipes intended for fabrication of clad pipe spools. 5 Information to be Supplied by the Purchaser a. If the weld overlayed piping components are intended for sour service, the following statement shall be included in the purchase order: The components shall be suitable for sour service and ISO 15156 shall apply. Type of corrosion resistant weld overlay

b. 6

Manufacture 6.1 Carbon steel fittings used for weld overlay shall meet the requirements of 02-SAMSS-005. Fittings intended for low temperature service shall meet the requirements of 02-SAMSS-001. Carbon steel fittings may either be procured by the manufacturer or can be free issue material provided by Saudi Aramco.

Commentary Note: Sour service requirements specified in 02-SAMSS-005 is not applicable even if the clad fittings are intended for sour service.

6.2

Carbon steel flanges used for weld overlay shall meet the requirements of 02-SAMSS-011. Carbon steel flanges may either be procured by the manufacturer or can be free issue material provided by Saudi Aramco.

Commentary Note: Sour service requirements specified in 02-SAMSS-011 is not applicable even if the clad fittings are intended for sour service.

6.3

Spool pieces used for weld overlay shall meet the requirements of 01-SAMSS-035 or 01-SAMSS-038 or 01-SAMSS-043. Spool pieces may either be procured by the manufacturer or can be free issue material provided by Saudi Aramco.

Commentary Note: Sour service requirements specified in 01-SAMSS-035, 01-SAMSS-038 and Page 4 of 9

Document Responsibility: Materials & Corrosion Control Standards Committee 02-SAMSS-012 Issue Date: 9 October 2010 Next Planned Update: 9 October 2015 Weld Overlayed Fittings, Flanges and Spool Pieces 01-SAMSS-043 are not applicable even if the clad pipe spool pieces are intended for sour service.

6.4

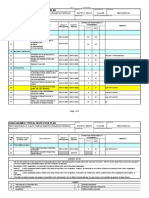

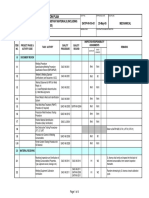

Weld overlay shall be carried out using automatic GTAW or GMAW process. Overlay by manual welding is not permitted except for repairs. Shielded Metal Arc Welding is an acceptable process for carrying out weld repairs. Other welding processes may be used if approved by Materials and Corrosion Control Standards Committee. Welding heads shall be equipped with automatic voltage control and high frequency or lift start facility (for GTAW only). Overlay thickness shall be 3.0 mm minimum and a minimum of two layers shall be applied. All welding consumables, including those used for repair, must have AWS classification. Alternative classification is acceptable, if approved by Materials and Corrosion Control Standards Committee. Selection of welding filler wire for weld overlays for any of the welding processes that use bare wire shall be as per Table 1 below. Table 1

Cladding 316L 347 321 904L S31254 S31803 S32205 S32750 N08825 N06625 N04400 C71500 Barrier Layer ER309L ER309L ER309Mo/ER309LMo ER309Mo/ER309LMo ERNiCrMo-3 ER309Mo/ER309LMo ER309Mo/ER309LMo ER309Mo/ER309LMo ERNiCrMo-3 ERNiCrMo-3 ERNiCu-7/ERNi-1 ERNiCu-7/ERNi-1 Rest of the Layers ER316L or ER317L ER347 ER321*/ER347 ER385 ERNiCrMo-3 ER2209 ER2209 ER2553 ERNiCrMo-3 ERNiCrMo-3 ERNiCu-7 ERCuNi/ERNiCu-7

6.5 6.6 6.7

6.8

*ER321 shall not be used for GMAW process.

Commentary Note: It is acceptable to use over alloyed welding consumables to obtain the required corrosion properties after dilution.

Page 5 of 9

Document Responsibility: Materials & Corrosion Control Standards Committee 02-SAMSS-012 Issue Date: 9 October 2010 Next Planned Update: 9 October 2015 Weld Overlayed Fittings, Flanges and Spool Pieces

Qualification of Welding Procedures 7.1 7.2 Welding procedures, including procedures for repair and welders / welding operators shall be qualified as per ASME SEC IX. The height of the overlay on the PQR test coupon shall not be more than 3.5 mm. It is acceptable to grind the final layer in order to reduce the height of the overlay. The brand name for nickel based and duplex/super duplex stainless steel filler wire shall be considered as an essential variable. Chemical analysis shall be carried out at a height of 2.0 mm form the base metal. The chemistry shall be within the range specified in ASME SEC II Part C or AWS classification. In the case of alloy N06625, the iron content shall not exceed 10%. The PREN (%Cr+3.3%Mo+16%N) value for the overlay shall be as per Table 2. Table 2

Grade 316/316L 317/317L N08904 S31254 S31803 S32205 S32750 N08825 N06625 PREN (min.) 24 29 34 42 35 35 42 42 45

7.3 7.4

7.5

Hardness testing shall be performed only if the material is intended for sour service. It shall be performed using the Vickers test in accordance with ASTM E92 using 5 kg or 10 kg load. A minimum of 5 indentations shall be taken on the heat affected zone (away from unmixed zone) of carbon steel and on weld overlay. Hardness on the carbon steel HAZ shall not exceed 248 HV. Hardness of the weld overlay shall meet the applicable requirements stated in ISO 15156. The following grades shall be subjected to the corrosion testing as specified in Table 3 below.

7.6

Page 6 of 9

Document Responsibility: Materials & Corrosion Control Standards Committee 02-SAMSS-012 Issue Date: 9 October 2010 Next Planned Update: 9 October 2015 Weld Overlayed Fittings, Flanges and Spool Pieces

Table 3

Steel Grade UNS N08904 (904L) UNS S31254 UNS S31803 UNS S32205 UNS S32750 UNS N08825 Corrosion Test ASTM G48 Method A ASTM G48 Method A

(a)(b)

Test Conditions Test temperature: 25C Test duration : 24 hours Test temperature: 50C Test duration : 48 hours As per ASTM A923 As per ASTM A923 As per ASTM A923 Test temperature: 22C Test duration : 72 hours Test temperature: 50C Test duration : 72 hours

Acceptance Criteria No pitting at 20X magnification.

(a)(b)

No pitting at 20X magnification As per ASTM A923 As per ASTM A923 As per ASTM A923 No pitting at 20X magnification

ASTM A923 Method C (a)(c) ASTM A923 Method C (a)(c) ASTM A923 Method C ASTM G48 Method A ASTM G48 Method A

(a)(b)

(a)(c)

(a)(b)

UNS N06625

Notes: a. b. c.

No pitting at 20X magnification

The surfaces of the specimens shall be pickled before testing. Cut edges shall be prepared according to ASTM G48. Rapid screening test (ASTM A923 Test Method A) shall not be used as an acceptance test.

7.7

Corrosion specimens shall be prepared by removing the backing carbon steel by milling or by other means. The thickness of the specimen shall not be less than 2.0 mm. All welding procedures, including procedures for repair, must be reviewed and approved by Materials and Corrosion Control Standards Committee.

7.8

Pickling Each overlayed component shall be pickled as per ASTM A380. Adequate precaution must be taken to prevent carbon steel form coming in contact with the pickling chemical.

Commentary Note: If the final commodity is a clad pipe spool, then pickling may be carried out after the fabrication of the spool.

Page 7 of 9

Document Responsibility: Materials & Corrosion Control Standards Committee 02-SAMSS-012 Issue Date: 9 October 2010 Next Planned Update: 9 October 2015 Weld Overlayed Fittings, Flanges and Spool Pieces

Non-Destructive Testing 9.1 9.2 9.3 NDT operators shall be qualified to ASNT level II or equivalent. Weld overlays shall be 100% inspected by dye penetrant testing. Acceptance criteria shall be in accordance with API SPEC 6A PSL3. Overlay thickness shall be measured for each component by taking wall thickness measurement by UT before and after the overlay at the same location. Thickness measurements shall be taken for each component at least three locations evenly distributed along the length of component. Ferrite content shall be measured on each component overlayed with austenintic stainless steel. The Ferrite content shall be between 3 to 8%. Positive Material Identification shall be carried on the weld overlay surface of each component. Acceptance criteria shall be as per the chemistry requirement stated in ASME SEC II Part C or applicable AWS standard with a tolerance of 10%. Visual inspection shall be carried out to ensure that the CRA weldoverlay is free of cracks and arc burns. Other imperfections in the CRA weld overlay shall not exceed 0.8 mm.

9.4 9.5

9.6

10

Dimensional Requirements 10.1 Dimensional tolerance at the ends of the component shall be as per Table 4 below: Table 4

Specified OD 323.9 >323.9 610 >610 End Tolerence (based on ID) 0.7 mm 1.0 mm 1.6 mm Our of Roundness 1.5% ID but not exceeding 1.5mm 0.75% ID but not exceeding 3.0mm 1% ID but not exceeding 4 mm

10.2

It is acceptable to correct the dimensions by pressing or my machining the inside overlayed surface provided the minimum required overlay thickness is not in violation.

Page 8 of 9

Document Responsibility: Materials & Corrosion Control Standards Committee 02-SAMSS-012 Issue Date: 9 October 2010 Next Planned Update: 9 October 2015 Weld Overlayed Fittings, Flanges and Spool Pieces

11

Inspection Pipes purchased in accordance with this Specification is subject to the requirements of Saudi Aramco Inspection Requirements Form 175-026600.

12

Marking 12.1 Each pipe component shall be marked Saudi Aramco, followed by the destination, Purchase Order number/Item number and the Saudi Aramco 9COM or 9CAT stock number, if applicable.

Commentary Note: If the final commodity is a clad pipe spool, then the marking requirements specified in the standard for spool only shall apply.

12.2 12.3 13

The marking shall include the specification number 02-SAMSS-012. Material ordered for sour service shall be marked with alphabet S.

Handling, Packing and Transportation The ends of the overlayed components should be suitably covered to prevent contamination from dust or moisture during storage and transportation.

14

Certification 14.1 14.2 14.3 The manufacturer shall furnish the mill test certificate of the carbon steel backing material if these commodities are procured by the manufacturer. All NDT results including dye penetrant test results and PMI shall be supplied. It shall be certified that the radioactivity level of the pipes is less than 0.05 Sv/hour. Certification can be based on measurements conducted by the backing carbon steel manufacturer and reported in the mill test certificates of the raw material.

9 October 2010

Revision Summary New Saudi Aramco Materials System Specification.

Page 9 of 9

You might also like

- 32 Samss 007Document38 pages32 Samss 007naruto256No ratings yet

- SAES-W-014 - Old SpecDocument12 pagesSAES-W-014 - Old SpecMichael TayactacNo ratings yet

- Saes L 109Document16 pagesSaes L 109Abdullah RiazNo ratings yet

- SAESL350Document14 pagesSAESL350Lester Dechavez100% (1)

- 04 SAMSS 005 Check ValvesDocument9 pages04 SAMSS 005 Check ValvesShino UlahannanNo ratings yet

- 04 Samss 055Document42 pages04 Samss 055nadeem shaikh100% (1)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- IIW Document No. IX-2165-05: Dnolan@uow - Edu.au Zoran@uow - Edu.auDocument28 pagesIIW Document No. IX-2165-05: Dnolan@uow - Edu.au Zoran@uow - Edu.aukatfy1No ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PeraneeshjokayNo ratings yet

- Materials System Specification: Saudi Aramco Desktop StandardsDocument14 pagesMaterials System Specification: Saudi Aramco Desktop StandardsMoustafa Bayoumi100% (1)

- 04 Samss 058 PDFDocument5 pages04 Samss 058 PDFbalajiNo ratings yet

- Welding For Sour ServiceDocument20 pagesWelding For Sour Serviceأحمد حسن100% (4)

- 04 Samss 003 PDFDocument4 pages04 Samss 003 PDFnadeem shaikhNo ratings yet

- Receiving Inspection of Pressure VesselsDocument5 pagesReceiving Inspection of Pressure Vesselsரமேஷ் பாலக்காடுNo ratings yet

- Materials System SpecificationDocument21 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- 04 Samss 002 PDFDocument8 pages04 Samss 002 PDFnadeem shaikhNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- SAES-L-132 PDF Download - Material Selection For Piping Systems - PDFYARDocument6 pagesSAES-L-132 PDF Download - Material Selection For Piping Systems - PDFYARZahidRafiqueNo ratings yet

- Active Doc ListDocument405 pagesActive Doc Listnadeem UddinNo ratings yet

- Saudi Aramco checklist for buttering jointsDocument1 pageSaudi Aramco checklist for buttering jointskarioke mohaNo ratings yet

- Alloy and Stainless Steel Forgings (Amendments/Supplements To Astm A182)Document13 pagesAlloy and Stainless Steel Forgings (Amendments/Supplements To Astm A182)Haresh Steel CentreNo ratings yet

- SAIC-L-2014 Flange Joint Insp PDFDocument7 pagesSAIC-L-2014 Flange Joint Insp PDFAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Saes H 200Document9 pagesSaes H 200راجہ شہزاد انورNo ratings yet

- Saudi Aramco Air Cooled Heat Exchanger Inspection PlanDocument2 pagesSaudi Aramco Air Cooled Heat Exchanger Inspection PlanAnonymous S9qBDVkyNo ratings yet

- Saes-A-206 DT 09 April 2020Document18 pagesSaes-A-206 DT 09 April 2020Kiran NikateNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- SAER1972Document9 pagesSAER1972zamil2008No ratings yet

- Saudi Aramco Typical Inspection PlanDocument2 pagesSaudi Aramco Typical Inspection PlanMAZHARULNo ratings yet

- 175 000003 PDFDocument1 page175 000003 PDFSohail TisekarNo ratings yet

- 20 - CCD Iow RefineryDocument2 pages20 - CCD Iow RefineryRASHEED YUSUFNo ratings yet

- 09-SAMSS-069 - Epoxy Coating For Atmospheric Service PDFDocument10 pages09-SAMSS-069 - Epoxy Coating For Atmospheric Service PDFsuresh_viki100% (1)

- Inspection & Testing Requirements: ScopeDocument1 pageInspection & Testing Requirements: ScopeAbu Anas M.SalaheldinNo ratings yet

- 01 Samss 042Document38 pages01 Samss 042বিপ্লব পালNo ratings yet

- 02 Samss 011Document36 pages02 Samss 011OMER ELFADILNo ratings yet

- Saep 1144Document23 pagesSaep 1144Amit shahNo ratings yet

- 04 Samss 048Document11 pages04 Samss 048SamiNo ratings yet

- Saep 311Document30 pagesSaep 311GulfamNo ratings yet

- Saep 347Document27 pagesSaep 347Qaiser Mahmood100% (2)

- Inspection Procedure EDRDocument8 pagesInspection Procedure EDRaamirtec301No ratings yet

- 76 204 16Document7 pages76 204 16finiteinjusticeNo ratings yet

- SAEP-316 Latest RevisionDocument25 pagesSAEP-316 Latest RevisionHabib RehmanNo ratings yet

- 09 Samss 071Document6 pages09 Samss 071inatt101100% (1)

- Welding Standards for Corrosion-Resistant Piping MaterialsDocument10 pagesWelding Standards for Corrosion-Resistant Piping MaterialsRaj AryanNo ratings yet

- GP-18!07!01 Welding ProceduresDocument21 pagesGP-18!07!01 Welding ProceduresFrancesco AvogadroNo ratings yet

- Materials System SpecificationDocument9 pagesMaterials System SpecificationFAPM1285No ratings yet

- Saudi Aramco Pipe Inspection RequirementsDocument2 pagesSaudi Aramco Pipe Inspection RequirementsAbu Anas M.Salaheldin100% (1)

- Active Doc ListDocument310 pagesActive Doc Listsalman1111aNo ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- Saes M 009Document55 pagesSaes M 009Shanmugapriya BalaramanNo ratings yet

- 1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1Document4 pages1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1JithuJohnNo ratings yet

- SATR-L-2001 Rev. 5Document10 pagesSATR-L-2001 Rev. 5Neelam AhmadNo ratings yet

- Satip D 001 01Document11 pagesSatip D 001 01Rijwan Mohammad0% (1)

- 74-002 Carbon Steel Pipe To Astm A106 2021 MESC 14DDocument9 pages74-002 Carbon Steel Pipe To Astm A106 2021 MESC 14Dkuttub28No ratings yet

- Spe 76-101 Sep 2012Document6 pagesSpe 76-101 Sep 2012akashdruva892No ratings yet

- 01 Samss 051 PDFDocument13 pages01 Samss 051 PDFnadeem shaikh100% (1)

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsFrom EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNo ratings yet

- Asset Integrity Management A Complete Guide - 2020 EditionFrom EverandAsset Integrity Management A Complete Guide - 2020 EditionNo ratings yet

- Corrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesFrom EverandCorrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesNo ratings yet

- 01-Samss-046 10302013Document11 pages01-Samss-046 10302013Anonymous jKuXWubR8No ratings yet

- 02-Samss-013 2020Document16 pages02-Samss-013 2020slan79bisNo ratings yet

- JoiningDocument52 pagesJoiningJade Al BoodoosinghNo ratings yet

- Direttiva 99 92 CEDocument8 pagesDirettiva 99 92 CEslan79bisNo ratings yet

- Product Guide TechalloyDocument12 pagesProduct Guide Techalloyslan79bisNo ratings yet

- Daiko 625Document2 pagesDaiko 625slan79bisNo ratings yet

- Final 401Document8 pagesFinal 401Hong Chul NamNo ratings yet

- Enzymatic Browning and Its Prevention-American Chemical Society (1995)Document340 pagesEnzymatic Browning and Its Prevention-American Chemical Society (1995)danielguerinNo ratings yet

- TDS - RheoFIT 762Document2 pagesTDS - RheoFIT 762Alexi ALfred H. TagoNo ratings yet

- TTBR 10 January 2024 LDocument22 pagesTTBR 10 January 2024 Lfossil.tractor0sNo ratings yet

- In Situ Combustion: Amit Kumar Singh R270307004 Integrated (Ape) +mba (Uam) Semester: VIIIDocument17 pagesIn Situ Combustion: Amit Kumar Singh R270307004 Integrated (Ape) +mba (Uam) Semester: VIIISmita SharmaNo ratings yet

- CPE PRACTICE TEST 2 READINGDocument4 pagesCPE PRACTICE TEST 2 READINGHong Anh0% (1)

- Ashrae 62.1-2019Document92 pagesAshrae 62.1-2019Alejandro Castillo100% (16)

- SynopsisDocument13 pagesSynopsisharivijay ranmaleNo ratings yet

- NSBI 2022-2023 FormsDocument16 pagesNSBI 2022-2023 FormsLove MaribaoNo ratings yet

- Premchand Deliverance Download in PDFDocument4 pagesPremchand Deliverance Download in PDFRiya W100% (3)

- Overview of US Investment in NanotechnologyDocument19 pagesOverview of US Investment in NanotechnologyMaterials Research InstituteNo ratings yet

- Alimak AustraliancontractminingDocument5 pagesAlimak AustraliancontractminingmanudemNo ratings yet

- Mcu-R4nek0n+submittal 04212020Document2 pagesMcu-R4nek0n+submittal 04212020Jaime A. AlvarezNo ratings yet

- Galaxy NanoporeDocument11 pagesGalaxy NanoporeDeborah ShirleenNo ratings yet

- FMDocument12 pagesFMGajera HarshadNo ratings yet

- Tivax STB-T12 Owners ManualDocument32 pagesTivax STB-T12 Owners ManualJesseNo ratings yet

- 02 - AFT - Know Your Pump & System Curves - Part 2ADocument8 pages02 - AFT - Know Your Pump & System Curves - Part 2AAlfonso José García LagunaNo ratings yet

- Esquematicos CaterpillarDocument9 pagesEsquematicos Caterpillarluis alberto rodriguez100% (1)

- Techint Group Brochure 2013Document100 pagesTechint Group Brochure 2013MD AFROZ RAZANo ratings yet

- EM 385-1-1 Chapters 20-26Document179 pagesEM 385-1-1 Chapters 20-26MusabNo ratings yet

- Simple LED Flasher CircuitsDocument5 pagesSimple LED Flasher CircuitsVivek BNo ratings yet

- (MITSUBISHI) Manual de Taller Mitsubishi Montero 2002Document21 pages(MITSUBISHI) Manual de Taller Mitsubishi Montero 2002wnsdNo ratings yet

- Therapeutic Drug Monitoring GuideDocument12 pagesTherapeutic Drug Monitoring GuidePromise NcubeNo ratings yet

- GRT9165 Product GuideDocument23 pagesGRT9165 Product GuideEslamAldenAbdoNo ratings yet

- Environmental Law Handbook ExampleDocument20 pagesEnvironmental Law Handbook ExampleThomson Reuters Australia100% (5)

- Caffeine Extraction 1 PDFDocument25 pagesCaffeine Extraction 1 PDFShanay ShahNo ratings yet

- Co2 OrderDocument2 pagesCo2 OrderRamakant PatelNo ratings yet

- ImmortalDocument4 pagesImmortalMaNithyaVishalanandaNo ratings yet

- Chemistry PropertiesDocument14 pagesChemistry PropertiesconchoNo ratings yet