Professional Documents

Culture Documents

5 S Awarness Questions 1 1

Uploaded by

ashish.ojha1590%(21)90% found this document useful (21 votes)

19K views2 pagesKaizen is part of 5s principle, it means change for good. It refers to small changes that lead to large improvement. What do you mean by Red Tag? It is a tool to mark any abnormality which needs to be addressed in order to do Five S. What does the first page of the Red Tag register contain? it should indicate the start date and the name, designation of the person responsible for maintain the register.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentKaizen is part of 5s principle, it means change for good. It refers to small changes that lead to large improvement. What do you mean by Red Tag? It is a tool to mark any abnormality which needs to be addressed in order to do Five S. What does the first page of the Red Tag register contain? it should indicate the start date and the name, designation of the person responsible for maintain the register.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC or read online from Scribd

90%(21)90% found this document useful (21 votes)

19K views2 pages5 S Awarness Questions 1 1

Uploaded by

ashish.ojha15Kaizen is part of 5s principle, it means change for good. It refers to small changes that lead to large improvement. What do you mean by Red Tag? It is a tool to mark any abnormality which needs to be addressed in order to do Five S. What does the first page of the Red Tag register contain? it should indicate the start date and the name, designation of the person responsible for maintain the register.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC or read online from Scribd

You are on page 1of 2

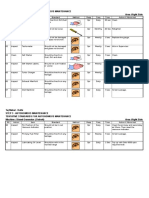

1) What is 5S?

S1 Sorting

S2 Sys Arrangement

S3 Spic N Span

S4 Standardisation

S5 Self Discipline

2) What is the goal of 5s principle?

To make the workplace productive and efficient,by its own people and with

the help of management in a short span of 2 or 3 days.

3) What is kaizen?

It is part of 5S, it means change for good. It refers to small changes that lead

to large improvement.

4) What do you understand by sorting?

It means dividing the object into two groups That are Needed and Those that

are Wanted.

5) What do you mean by Red Tag?

It is a tool to mark any abnormality which needs to be addressed in order to

do Five S

6) When is Red Tag applied?

It is applied in following situations:---

a) Wanted but not needed, which cannot be disposed of during the

workshop.

b) In case of doubt about the status of the item.

c) Observed abnormality, which may be the root cause for disorganisation.

7) In what step of 5S is the Red tag register used?

It is a two portion register used during S1.

8) What does the first page of the Red Tag register contain?

It should indicate the start date and the name, designation of the person

responsible for maintain the register. 5WH What, where,why,when, who, How

& Remarks

9) How often should the red tag register be reviewed?

At least once in 15days. It should indicate the review date and the name of

teh person responsible to review the same.

10) What is systematic arrangement?

It means Place for everything and everything in its place(PEEP).

11) Steps in systematic arrangement?

- Make a Layout of the workplace

- Decide on what item to be place where

- Put all the things in their identified place.

12) What do you mean by Poka yoke?

It is a mistake proofing device which ensures faster retrival of files and also it

makes sure that the files are kept back in the proper place everytime.

13) What info does the file label contain?

1) Name of the file.

2) Start date and End date.

3) Retention Time.

4) Owner of th2 file and Dept.

14) What do you mean by Spic N Span?

It is check whether S1 and S2 are done on regular basis and properly. It is

abt keeping things clean and in order .It means Cleaning with Meaning.

15) What do you mean by AMC?

Autonomous Maintenance Calender.

16) What information does AMC contain?

What: What task needs to be performed and when.

Who: Name of the person responsible for doing the activity.

When: When the task needs to be performed.

Frequency: Enter the optimum frequency of doing the particular task to

sustain the gain.

17) What is Standarization?

This is a step for creating rules,procedure, policies and standards,which are

necessary to sustain the 5S movement.

18) What is sorting?

Sorting is dividing the objects into 2 groups – needed & wanted.

19) What are needed items?

- Needed regularly (Pen, Pencil etc frequently needed)

- Needed but not regularly (Audit files,Vendor files etc.)

- Needed but not much in quantity (Excess stationary)

20) What are the wanted items?

•Wanted but not needed.(Cash reports)

•Scrap (old items,product brochure)

You might also like

- 15 Best Education Apps For TeachersDocument15 pages15 Best Education Apps For TeachersJasper YogcayogNo ratings yet

- Question Paper For MSA: Magnifico Training and Consulting ServicesDocument2 pagesQuestion Paper For MSA: Magnifico Training and Consulting ServicesRajesh SahasrabuddheNo ratings yet

- Quiz 4 (Ict)Document3 pagesQuiz 4 (Ict)GILBERT P. CAOILI100% (1)

- CHRO 3.0 Lead Future HR Function India PDFDocument40 pagesCHRO 3.0 Lead Future HR Function India PDFpriteshpatel103100% (1)

- 5s ImplementationDocument20 pages5s ImplementationHerry Prakoso100% (1)

- 5S - Final PPDocument71 pages5S - Final PPSiti Sara Rahim100% (1)

- Sample Questions For Chapter 8:: Answer: BDocument3 pagesSample Questions For Chapter 8:: Answer: BMusaba BabaNo ratings yet

- Auditor Auditee Audit Zone: Audit Date: 5S Audit Check List - Scoring GuidelinesDocument2 pagesAuditor Auditee Audit Zone: Audit Date: 5S Audit Check List - Scoring GuidelinesRishi Gautam100% (2)

- Question Answer FolioDocument13 pagesQuestion Answer FolioMY NAME IS NEERAJ..:):)96% (25)

- Lean Manufacturing QuizDocument6 pagesLean Manufacturing QuizSajib Mahmud Shahriar67% (9)

- 5S Checklist OkDocument2 pages5S Checklist Okmichelle ann100% (1)

- Sample Questions-WCM-WORLD CLASS MANUFACTURINGDocument7 pagesSample Questions-WCM-WORLD CLASS MANUFACTURINGChavan Vivek100% (5)

- MCQs - CompiledDocument11 pagesMCQs - Compiledfahadkhanffc100% (1)

- 5S QuizDocument2 pages5S QuizSehabom Geberhiwot100% (1)

- Autonomous Maintenance Standards & ChecklistDocument4 pagesAutonomous Maintenance Standards & ChecklistPanch BNo ratings yet

- Questions and Answers on Lean ConceptsDocument23 pagesQuestions and Answers on Lean ConceptsEng-Ahmed Baasaay100% (2)

- 8D Problem Solving Training - SOLUTIONS - OKDocument2 pages8D Problem Solving Training - SOLUTIONS - OK57641100% (2)

- Aventador Racer InstructionsDocument51 pagesAventador Racer InstructionsMario Cembellin Ferreiro100% (1)

- Question Bank No 2. For Second MCQDocument24 pagesQuestion Bank No 2. For Second MCQUnknown Laapta50% (2)

- FMEA Question PaperDocument2 pagesFMEA Question PaperKarthi Thiyagarajan33% (3)

- Question Paper SPC - MSTCDocument11 pagesQuestion Paper SPC - MSTCRajesh SahasrabuddheNo ratings yet

- Autonomous Maintenance Standards & Checklist For Chiller PlantDocument7 pagesAutonomous Maintenance Standards & Checklist For Chiller PlantPanch B100% (1)

- 4M ManagementDocument5 pages4M ManagementSachin YadavNo ratings yet

- Orlando Plant Vision Great Place WorkDocument2 pagesOrlando Plant Vision Great Place WorkRavi Sankar Venkatesan80% (5)

- Test Your Knowledge of VSM QuizDocument2 pagesTest Your Knowledge of VSM Quizkishkar100% (3)

- Daily Management Quiz: 2007: SN Question Option A Option B Option C Option D AnswerDocument5 pagesDaily Management Quiz: 2007: SN Question Option A Option B Option C Option D AnswerPrakash Kumar50% (2)

- Lean Manufacturing Quiz IDocument18 pagesLean Manufacturing Quiz IDiệp Nguyễn67% (6)

- Quiz Answers KaizenDocument2 pagesQuiz Answers KaizenJose Ortega100% (1)

- Question and Answer 7QC ToolsDocument2 pagesQuestion and Answer 7QC ToolsDFLQMS100% (1)

- 5S Roles and ResponsibilitiesDocument5 pages5S Roles and Responsibilitiessenk197100% (1)

- Knowledge Test Questions Based On Quality Circle Concept - Q-EdgeDocument2 pagesKnowledge Test Questions Based On Quality Circle Concept - Q-Edgepramod50% (2)

- 5S Audit ChecksheetDocument1 page5S Audit ChecksheetIB Ismady68% (19)

- Lean Manufacturing Quiz GuideDocument6 pagesLean Manufacturing Quiz GuideMusical Corruption100% (1)

- TPM QuizDocument2 pagesTPM QuizSrinathChakravarthy100% (6)

- Quality Circle (Hindi) 14 - 05 - 2011 (Read-Only)Document40 pagesQuality Circle (Hindi) 14 - 05 - 2011 (Read-Only)Atul Sharma100% (1)

- Quiz Kaizen Leadership PDFDocument5 pagesQuiz Kaizen Leadership PDFJose OrtegaNo ratings yet

- Industrial House Keeping and 5S Technique HINDIDocument79 pagesIndustrial House Keeping and 5S Technique HINDIDeepak Sharma84% (31)

- Question Paper - APQP MTCSDocument3 pagesQuestion Paper - APQP MTCSRajesh Sahasrabuddhe100% (1)

- Pre Post Test Questionaires - Autonomous MaintenanceDocument2 pagesPre Post Test Questionaires - Autonomous MaintenanceNurul Zawani Hambali50% (2)

- 5S Quiz PDFDocument1 page5S Quiz PDFAnonymous KeBaAOY3TNo ratings yet

- Costing Mcqs - 4: Just-In-Time (Jit) NeededDocument3 pagesCosting Mcqs - 4: Just-In-Time (Jit) Neededshivam kumar100% (1)

- Practice Questions For Quality CircleDocument2 pagesPractice Questions For Quality CircleShyamal Kumar100% (1)

- NCQCDocument73 pagesNCQCSaurabh Jaiswal JassiNo ratings yet

- NCQC Answer Paper-1Document4 pagesNCQC Answer Paper-1Shyamal KumarNo ratings yet

- 5S Post - Test 0219 001Document1 page5S Post - Test 0219 001Mau TauNo ratings yet

- QCC Question BankDocument14 pagesQCC Question BankAnonymous Sp3XzoSNo ratings yet

- WCM Quiz For StudentsDocument6 pagesWCM Quiz For StudentsGujar DwarkadasNo ratings yet

- NCQC Answer Paper-1Document4 pagesNCQC Answer Paper-1Shyamal Kumar100% (1)

- NCQC Answer Paper-1Document4 pagesNCQC Answer Paper-1Shyamal KumarNo ratings yet

- Knowledge Test Question Bank For NCQC - Q-EdgeDocument5 pagesKnowledge Test Question Bank For NCQC - Q-EdgeAjit Shivaji Mokal50% (2)

- Quiz-1 MM ZG 537Document10 pagesQuiz-1 MM ZG 537xavieraja100% (1)

- 5S QuizDocument7 pages5S Quizdhillon63No ratings yet

- 100 Questions - Knowledge Test 49 - For NCQC 2017 - Q-EdgeDocument23 pages100 Questions - Knowledge Test 49 - For NCQC 2017 - Q-EdgeShankar KalagiNo ratings yet

- NCQC Answer Paper-1Document4 pagesNCQC Answer Paper-1Shyamal KumarNo ratings yet

- 16 - NCQC 2019 Knowledge Test - Practice PaperDocument3 pages16 - NCQC 2019 Knowledge Test - Practice Papervitthal01No ratings yet

- 12 Steps of QCCDocument16 pages12 Steps of QCCRicky Mark100% (4)

- ABC Type DefectsDocument17 pagesABC Type DefectsMayank Dadhich100% (2)

- 5s As A Tool and Strategy For Improvising The Work PlaceDocument3 pages5s As A Tool and Strategy For Improvising The Work PlaceOscar PedrozaNo ratings yet

- 5s ImplementationDocument22 pages5s Implementationah antarNo ratings yet

- Republic of The Philippines1Document7 pagesRepublic of The Philippines1Clyde X2600No ratings yet

- People Soft FAQ'sDocument45 pagesPeople Soft FAQ'sHidayathulla MohammedNo ratings yet

- Implementing 5S at UCO Bank Pilani campusDocument2 pagesImplementing 5S at UCO Bank Pilani campusJilShahNo ratings yet

- 5S Methodology for Workplace OrganizationDocument26 pages5S Methodology for Workplace OrganizationpetcutpaulNo ratings yet

- Fu Look Closer To CVPR 2017 PaperDocument9 pagesFu Look Closer To CVPR 2017 PaperMahmoudNo ratings yet

- 18IE10019 Rajarshi SahaDocument1 page18IE10019 Rajarshi SahaRajarshi SahaNo ratings yet

- Marina Mall Work Permit (20369)Document1 pageMarina Mall Work Permit (20369)Shahid FarooqNo ratings yet

- F4-VB Spray Gun Plasma Spraying: Parts List PL 40333 EN 07Document12 pagesF4-VB Spray Gun Plasma Spraying: Parts List PL 40333 EN 07a.n.87711990No ratings yet

- Database Management System Lab Course Code: CSE 312: Instructor: Tasnim Tarannum Lecturer CSE DepartmentDocument15 pagesDatabase Management System Lab Course Code: CSE 312: Instructor: Tasnim Tarannum Lecturer CSE DepartmentNirban MitraNo ratings yet

- Fourier Transform (For Non-Periodic Signals)Document27 pagesFourier Transform (For Non-Periodic Signals)hamza abdo mohamoudNo ratings yet

- Complete PEZA Citizen CharterDocument41 pagesComplete PEZA Citizen CharterAngelica MacatangayNo ratings yet

- Software Testing Methodologies LabDocument155 pagesSoftware Testing Methodologies LabjessiNo ratings yet

- Different Version of Social Networking PlatformDocument4 pagesDifferent Version of Social Networking PlatformHarshita SinghNo ratings yet

- Elevator Case StudyDocument8 pagesElevator Case StudyUrja Shrestha0% (1)

- Sheet 4Document5 pagesSheet 4vector mosesNo ratings yet

- Computer Graphics - Ugc Net Solved Paper PDFDocument119 pagesComputer Graphics - Ugc Net Solved Paper PDFChandana Swathi100% (1)

- SNT Notes 2022Document7 pagesSNT Notes 2022OrlinNo ratings yet

- SQL Cheat Sheet 2Document4 pagesSQL Cheat Sheet 2sahil sharmaNo ratings yet

- KUIZ ICT - 50 questions on computer technologyDocument2 pagesKUIZ ICT - 50 questions on computer technologyTanicshaNo ratings yet

- Power Relay LZ Series: 1 POLE - 1/3/5/10ADocument11 pagesPower Relay LZ Series: 1 POLE - 1/3/5/10AElect Yan LumosoNo ratings yet

- Chinese Finite Element Human Body Model Development Based On THUMS Occupant v402Document4 pagesChinese Finite Element Human Body Model Development Based On THUMS Occupant v402DeepsNo ratings yet

- Wu - Terms and ConditionsDocument14 pagesWu - Terms and ConditionsMaria DharyasaNo ratings yet

- Tecewn 3002Document589 pagesTecewn 3002Cristea CalinNo ratings yet

- Modelado y Co-Simulación de Vehículos Híbridos Una Gestión TérmicaDocument18 pagesModelado y Co-Simulación de Vehículos Híbridos Una Gestión TérmicaSantiiGonzalezNo ratings yet

- Volvo control system 22517, 22546, 22640, 22650 partsDocument3 pagesVolvo control system 22517, 22546, 22640, 22650 partsElie AbisaadNo ratings yet

- ReadmeDocument10 pagesReadmeИлиан ИлиевNo ratings yet

- KeyFinder LogDocument22 pagesKeyFinder LogdsdsdsdsdaNo ratings yet

- Air Gap Installation InstructionsDocument2 pagesAir Gap Installation InstructionsWattsNo ratings yet

- Kidney Exchange Program Modernization Using Machine Learning AlgorithmsDocument65 pagesKidney Exchange Program Modernization Using Machine Learning Algorithmsimmi1989No ratings yet

- Model Mediasi Erp, SPM, SCM Dan Kinerja Perusahaan: Muhammad NawawiDocument22 pagesModel Mediasi Erp, SPM, SCM Dan Kinerja Perusahaan: Muhammad Nawawiandi nurhidayatul islamiyahNo ratings yet

- CH 5 Test BankDocument3 pagesCH 5 Test BankYasser BadrNo ratings yet