Professional Documents

Culture Documents

Wartsila O E RT Flex96C B MIM Part C

Uploaded by

Uhrin ImreCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wartsila O E RT Flex96C B MIM Part C

Uploaded by

Uhrin ImreCopyright:

Available Formats

19.

General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-116

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-117

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-118

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-119

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-120

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-121

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-122

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

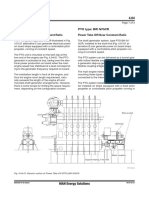

19.5 Engine coupling

Figure 19.3: Engine coupling, fitted bolt arrangement

WARNING The illustrations above and below do not necessarily represent the actual configuration or the stage of development, nor the type of your engine. In order to have all the relevant and prevailing information available, please consult the drawings in the section "Drawings" at the end of present chapter.

19.5.1 Fitting of coupling bolts

Drilling and reaming of the engine and shaft couplings is to be carried out using a computer controlled drilling machine or an accurately centred jig. Great care is to be taken in matching and machining mating flanges together. Fitted bolt hole tolerances are to be H7 and fitted bolts are to be available for inserting in the holes on completion of reaming. Each fitted bolt is to be stamped with its position in the coupling, with the same mark stamped adjacent to the hole. In the event of a pitch circle error leading to a misalignment of bolt holes, the situation has to be remedied by applying joint cylindrical reaming to an oversize hole and fitting an individually machined fitted bolt. Fitted bolts are to locate with a slight interference fit, but not requiring heavy hammer blows. If there is any doubt that a fitted bolt is too slack or too tight, refer to the classification society surveyor and a representative of the engine builder.

Version a1

19-123

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

Figure 19.4: Details of coupling bolt and nut

When tightening the coupling bolts it is essential to work methodically, taking up the threads on opposite bolts to hand-tight, followed by sequential torque tightening.

19-124

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Mark each bolt head in turn, 1, 2, 3, etc., and tighten opposite nuts in turn to an angle of 55, making sure the bolt head is securely held and unable to rotate with the nut. Castellated nuts are to be locked according to the requirements of class with either locking wires or split pins. Use feeler gauges during the tightening process to ensure that the coupling faces are properly mated with no clearance. Drawings 107.298.385 a Connection Crank/Propeller Shaft, On Crankshaft .............................1 - 2 91 6

Version a1

19-125

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-126

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

19.6 Engine earthing

Electric current flows when a potential difference exists between two materials. The creation of a potential difference is associated with thermoelectric by the application of heat, tribo-electric between interactive surfaces, electrochemical when an electrolytic solution exists, and electromagnetic induction when a conducting material passes through a magnetic field. Tracking or leakage currents are created in machinery by any of the above means and, if they are not adequately directed to earth, can lead to component failures or in some cases result in fires and interference with control and monitoring instrumentation.

19.6.1 Preventive action

Using earthing brushes in contact with slip-rings and bonding the chassis by braided copper wire are common ways of protecting electric machines. Where operating loads and voltages are comparatively low, then the supply is isolated from the machine by an isolating transformer, often with handheld power tools. The build specification dictates the earthing procedure to be followed and the classification society is to approve the final installation. On vessels with star-wound alternators the neutral is considered to be earth, and electrical devices are protected by automatic fuses. Ensure that instrument wiring meets the building and classification society specifications and that it is shielded and isolated to prevent induced signal errors and short circuits. In certain cases large items of machinery are isolated from their foundations, and couplings are isolated to prevent current flow, e.g. when electric motors are connected to a common gear box. Retrospective fitting of earthing devices is not uncommon, but due consideration is to be given at the design stage to adequate shielding of control equipment and earthing protection where tracking and leakage currents are expected. Magnetic induction and polarisation are to be avoided and degaussing equipment incorporated if there is likely to be a problem.

Version a1

19-127

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19.6.2 Main shaft earthing system

Figures 19.6 and 19.5 show a typical shaft earthing system. The slip-ring (1) is supplied as matched halves to suit the shaft and secured by two tension bands (2) using clamps (12). The slip-ring mating faces are finished flush and butt jointed with solder. The brushes (4) are housed in the twin holder (3) clamped to a stainless steel spindle (6) and there is a monitoring brush (11) in a single holder (10) clamped to an insulated spindle (9). Both spindles are attached to the mounting bracket (8). The electric cables are connected as shown in figure 19.7 with the optional voltmeter. This instrument is at the discretion of the owner but it is useful to observe that the potential to earth does not rise above 100 mV. Different combinations of conducting material are available for the construction of the slip-rings. However, alloys with a high silver content are found to be efficient and hard wearing. Wrtsil Switzerland Ltd. recommends installing a shaft earthing device on the intermediate shafting as illustrated in figure 19.5.

Figure 19.6: Shaft earthing arrangement

Figure 19.5: Shaft earthing slip-ring arrangement

19-128

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Figure 19.7: Shaft earthing with condition monitoring facility

Version a1

19-129

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19.7 Engine stays

Ship vibrations and engine rocking caused by the engine behaviour (as described in chapter 6. Engine Dynamics) are reduced by fitting lateral and longitudinal and stays.

19.7.1 Stays arrangement

Installation of lateral stays - hydraulic and friction types Fitting of lateral stays between the upper platform level and the hull reduces transmitted vibration. Two types of stays can be considered: Hydraulic stays: ................. two by two installed on the exhaust and on the fuel side of the engine. Friction stays: .................... installed on the engine exhaust side. Table Countermeasures for lateral and longitudinal rocking indicates in which cases the installation of lateral stays is to be considered.

19-130

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

19.7.2 Drawings

107.333.483 c 107.165.800 g 107.165.801 f 107.165.802 a 107.165.803 d 107.165.804 b 107.165.808 a 107.165.806 a 107.165.809 107.165.810 a 107.165.815 107.165.821 a 107.245.489 107.165.811 107.165.812 107.329.413 a 107.165.814 107.165.820 b 107.165.818 b 107.165.817 a 107.165.822 107.165.813 b 107.338.178 b 107.353.629 107.246.735 107.246.436 a 107.246.732 107.246.730 107.246.439 b 107.246.731 107.246.650 a 107.246.429 c Engine Stays ........................................................................................1 - 3 91 2 Hydraulic Cylinder, To Engine Stays ....................................................1 - 3 91 3 Cylinder ................................................................................................1 - 3 91 4 Piston ...................................................................................................1 - 3 91 5 Cover ...................................................................................................1 - 3 91 6 Valve Spindle .......................................................................................1 - 3 91 7 Connecting Piece (Sw41) .....................................................................1 - 3 91 8 Pointer ..................................................................................................1 - 3 91 9 Bearer ..................................................................................................1 - 4 91 0 Treaded Sleeve, Engine Stays .............................................................1 - 4 91 1 Support ................................................................................................1 - 4 91 2 Ring ......................................................................................................1 - 4 91 3 Ball Valve, Order Drawing ....................................................................1 - 4 91 4 Piston Guide, Order Drwg. ...................................................................1 - 4 91 5 Pressure Gauge, Order Dr. ...................................................................1 - 4 91 6 Bladder Accumulator, Order Drawing ..................................................1 - 4 91 7 Plug, Order Drwg. ................................................................................1 - 4 91 8 Hydraulic Lateral Device, For Main Engine ..........................................1 - 6 91 0 Testing And Filling Device, Order Drwg. ..............................................1 - 6 91 1 Instruction For Pressure Test, 250 Bar ................................................1 - 6 91 2 Male Union, Order Drwg. .....................................................................1 - 6 91 3 Prec. Seamless Pipe, Order Drwg. ......................................................1 - 6 91 4 Engine Stays ........................................................................................1 - 6 91 5 Engine Stays/ Friction Type, Assembly Drawing .................................1 - 6 91 6 Stay, To Engine Stays, Frictio ..............................................................1 - 6 91 7 Support, To Engine Stays, Frictio ........................................................1 - 6 91 8 Clamping Part, To Engine Stays, Frictio ..............................................1 - 6 91 9 Disc Spring, To Engine Stays, Frictio ...................................................1 - 7 91 0 Bolt, To Engine Stays, Frictio ...............................................................1 - 7 91 1 Friction Shim, Ordering Drawing .........................................................1 - 7 91 2 Centring Sleeve, To Engine Stays, Friction ..........................................1 - 7 91 3 Assembly Instructions, To Engine Stays Friction .................................1 - 7 91 7

Version a1

19-131

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-132

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-133

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-134

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-135

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-136

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-137

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-138

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-139

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-140

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-141

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-142

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-143

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-144

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-145

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-146

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-147

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-148

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

1.

General

Installation drawing Sectional view drawing see page 2 see page 3

Hydraulic transverse stays are used to shift the natural frequency when resonance can be expected in the normal operating range of the engine. The applied arrangement enables: - The adjustability of the pretension force. - The adaptability to the slow movement of the ship's hull when loading or unloading the ship.

2.

Description

The hydraulic lateral fixation device consists of: - Hydraulic cylinder with differential piston, fitted with hydro accumulator and pressure gauge. - Stays for lateral fixation of the engine to the ship's structure. - Adjusting screw, fixed to the engine. Accessories per ship for single main engine installation (for multiple main engine installation the engine supplier is to be consulted) - Hydraulic cylinders either to design 200 or 201 with adjusting screw (stays are yard delivery) Design 200: Compact execution Design 201: Hydro accumulator detached for separate installation (Fittings included, but connection steel pipe 10 x 2 is yard delivery) - Tester and pressurizer VGU - 250 - TS3 for nitrogen (for details see page 9) - Hand pump for hydraulic oil (contained in the standard engine tool set)

Replaced by:

Substitute for:

1

Design group

RTA-Engines

Wrtsil Switzerland Ltd.

HYDRAULIC LATERAL DEVICE FOR MAIN ENGINE

9715

Page

Created: 23.8.1984

4-107.165.820

1/12

Version a1

19-149

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

Replaced by:

Substitute for:

2

Design group

RTA-Engines

Wrtsil Switzerland Ltd.

HYDRAULIC LATERAL DEVICE FOR MAIN ENGINE

9715

Page

Created: 23.8.1984

4-107.165.820

2/12

19-150

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

I II III IV V VI VII

Set bolt Plug Throttling valve Filling valve Vent screw Vent screw Adjusting screw

Replaced by:

Substitute for:

3

Design group

RTA-Engines

Wrtsil Switzerland Ltd.

HYDRAULIC LATERAL DEVICE FOR MAIN ENGINE

9715

Page

Created: 23.8.1984

4-107.165.820

3/12

Version a1

19-151

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

Free end

Cyl. No.1

Driving end

For details see drawing "Engine stays, hydraulic type" of the relevant engine.

3.

Function

Transverse vibrations of the engine cause rapid pressure fluctuations in the hydraulic cylinder. Thereby the unit behaves like a strong spring. By using the throttling valve III (page 3), the spring rate can be adjusted such that the rapid pressure fluctuations are practically filtered off and do not continue into the hydro accumulator. The hydraulic cylinder nevertheless adjusts itself to the slow deformations of the ship's hull.

4.

Installation

The hydraulic cylinders are to be bolted to the reinforced attachment points on the ship structure. The adjustments screws are welded on the engine at position shown on the relevant arrangement drawing from the engine builder. Stay length "L" shown on page 2 is to be determined and the diameter "D" taken from the table or from the arrangement drawing.

5.

Commissioning

Commissioning of the hydraulic cylinders should be carried out shortly before the sea trial as follows:

5.1.

The stay is to be fitted between the hydraulic cylinder and the adjusting screw on engine side and secured against dropping. The adjusting screw is to be set as shown on page 2 (axially: piston face and indicator pin to be on same plane; radially: pin and holes in line). Set bolt pos. I to be secured. The hydro accumulator will be delivered pre-pressurised to 10 bar. The pressure is to be raised to the figure shown on page 7 with the help of the tester pressurizer (see page 9).

5.2.

5.3.

Plug pos. II is to be removed for filling of the hydraulic oil and the flexible hose connected to the hand pump. Throttling valve pos. III and filling valve pos. IV must be open (throttling valve switched to mark "1") as well as vent screws pos. V on the hydro accumulator and pos. IV on the hydraulic cylinder. Hydraulic oil to be pumped slowly into the hydr. cylinder (oil to be warmed when engine room is cold). After perfect venting, first close vent screw pos. IV on the hydr. cylinder and then vent screw pos. V on the hydro accumulator. The 4 hydr. cylinders must then be pumped up to service pressure as follows:

5.4.

Replaced by:

Substitute for:

4

Design group

RTA-Engines

Wrtsil Switzerland Ltd.

HYDRAULIC LATERAL DEVICE FOR MAIN ENGINE

9715

Page

Created: 23.8.1984

4-107.165.820

4/12

19-152

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

(Attention: Check that pump is always full and the filling hose completely filled before connecting up).

B

Cyl. No. 1

Driving end

Free end

5.4.1.

On cylinder A the oil pressure is to be raised to half the nominal pressure shown on page 7. (Pressure to be checked at the built on pressure gauge below the hydro accumulator). Filling valve pos. IV is to be closed and the hand pump disconnected. On cylinder B the same preparatory work can be carried out, however, the pressure can be raised to 10 bar above the nominal pressure. Filling valve pos. IV is to be closed and the plug (II) fitted. The hand pump is to be reconnected to cylinder A and the pressure increased to 10 bar above the nominal pressure. Filling valve pos. IV is to be closed and the plug (II) fitted. The procedure for cylinders C and D is the same as for cylinders A and B. After several hours, all hydraulic cylinders must be vented carefully at valves V and VI so as not to loose too much pressure. It must not sink below the nominal value.

5.4.2.

5.4.3.

5.4.4. 5.4.5.

5.5.

The throttling valve pos. III is to be adjusted to mark "A" and secured on all cylinders. Mark "B" is used for reduced stiffness. At Mark "1" the function is practically ineffective. Attention The throttling valve pos. III must never be closed (Mark "0") in service because in this position the hydraulic piston cannot adjust itself to the movement of the ship's hull.

Replaced by:

Substitute for:

5

Design group

RTA-Engines

Wrtsil Switzerland Ltd.

HYDRAULIC LATERAL DEVICE FOR MAIN ENGINE

9715

Page

Created: 23.8.1984

4-107.165.820

5/12

Version a1

19-153

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

6.

Sea trial

The hydraulic cylinders must be checked frequently for oil pressure and general soundness.

6.1.

At the end of the sea trial the following must be checked: - "0" position of the piston according to page 2 - pressure to be the nominal value as shown on page 7. If the pressure is too high it can be corrected with careful opening of the vent screw pos. V. Where the pressure is too low, it has to raised with the hand pump.

7.

Check when loading the ship fully for the first time

The position of the piston relative to the cylinder is to be checked when the ship is fully laden. Should it occur that the piston is almost touching the bottom of the cylinder (this situation must not be allowed to occur, but it will happen when the piston is 15 mm on the inside of the "0" position) then the hydraulic lateral fixation device is to be shortened by about 7 mm with the adjusting screw pos. VII.

8.

Regular checks

The oil pressures on the pressure gauges of the hydraulic cylinders are to be compared with each other at regular intervals. (The shown oil pressure may not be identical with the nominal pressure, because it varies according to the loading of the ship). If one of the cylinders shows a considerably lower pressure, which could be caused by a leaking seal, the opposite hydraulic cylinder must be released of its pressure until the leaking seal has been replaced. Afterwards both cylinders are to be put into service as mentioned under commissioning.

9.

Spares

For spares see the following pages: Pneumatic accumulator Tester pressurizer Hydraulic cylinder page 8 page 11 page 12

Safety regulations regarding pressure vessels have to be adhered to

Replaced by:

Substitute for:

6

Design group

RTA-Engines

Wrtsil Switzerland Ltd.

HYDRAULIC LATERAL DEVICE FOR MAIN ENGINE

9715

Page

Created: 23.8.1984

4-107.165.820

6/12

19-154

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Technical data

Hydraulic cylinder 200/160 Mass: Piston stroke: Oil Content: Oil Type: Viscosity grade: Hydropneumatic accumulator type: Engine type about 138 kg 15 mm about 2,5 l Hydraulic oil HL or HLP ISO VG 32/46 (20 - 30 mm/s at 50 C) IHV 2,5 - 330/05 with bladder ref.: 105644-01120 RTA 68T-B, RTA72U/-B, RTA84T/-B/-D, RTA84C, RTA96C 40 bar 80 bar 160 kN about 320 kN/mm Throttl.valve pos."A" about 60 bar when piston is protruding 15 mm in cylinder about 115 bar when piston is recessed 15 mm in cylinder. Pomax = Po + 10 bar Po = above given nominal pressure RTA52U/-B, RTA62U/-B, RTA48T/-B, RTA58T/-B RTA60C 20 bar 50 bar 100 kN about 270 kN/mm

Pre-pressurising pressure (gas) Nominal oil pressure 1) Nominal pre-tensioning force Fvo Dynamic spring rate

Minimum oil pressure

about 37 bar

Maximum oil pressure

about 80 bar

1)

piston in position "0" (see sketch on page 2):

Replaced by:

Substitute for:

7

Design group

RTA-Engines

Wrtsil Switzerland Ltd.

HYDRAULIC LATERAL DEVICE FOR MAIN ENGINE

9715

Page

Created: 23.8.1984

4-107.165.820

7/12

Version a1

19-155

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

Hydropneumatic accumulator

P0 = nitrogen pressurising pressure P1 = minimum working pressure P2 = maximum working pressure V0 = total nitrogen volume in the accumulator V1 = nitrogen volume at P1 V2 = nitrogen volume at P2 V = volume absorbed and/or returned beween P1 and P2

(1)

P0V0 state

(2)

P1V1 state

(3)

P2V2 state

The bladder, enclosed in the accumulator body is pre-pressurised by means of an inert gas (nitrogen), capable of great compression, to a pressure determined by the needs of the work to be done. During this pressurising operation, the bladder expands, progressively approaches the lower part of the accumulator, and presses against its sides, so occupying the entire volume of the chamber (1). When the circuit pressure generator causes the liquid to penetrate into the shell of the accumulator (2) the gas enclosed in the bladder is compressed and increases the pressure. The process comes to an end when the pressure of the liquid and of the gas reach equilibrium (3). In the reverse process, the return commences when the resisting pressure of the liquids is less than the pressure of the gas in the bladder. The lateral deformation of the latter in three lobes, forming a shamrock shape with three promontories excludes rubbing and inertia, and enables an efficiency of nearly 100% to be attained.

Spare Parts

1. Valve cap and gasket 2. Nut 3. Bladder 4. Bladder assembly 5. Anti-extrusion ring 6. Washer 7. Gland-ring 8. Ring nut 9. Venting screw and gasket 10. Fluid port sub-assembly 11. Fluid port assembly complete 12. Set of gaskets

Replaced by:

Substitute for:

8

Design group

RTA-Engines

Wrtsil Switzerland Ltd.

HYDRAULIC LATERAL DEVICE FOR MAIN ENGINE

9715

Page

Created: 23.8.1984

4-107.165.820

8/12

19-156

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

TESTER AND PRESSURIZER VG U DESCRIPTION

The VG U tester and pressurizer is used for charging of bladder, piston and membrane accumulators with nitrogen, and for testing or changing the pre-charge pressure. The instrument is suitable for all OLAER 5 accumulators with /8" flap valves, Schrder valves or screw plugs. It is screwed onto the gas inlet valve of the hydropneumatic accumulator, and connected to a standard nitrogen flask via a hose. If only the precharge pressure needs to be checked, the connection of the charging hose is not necessary. Each unit comprises of: - Tester and pressurizer with manometer, return valve on the charging hose, built-in release valve, valve spindle for opening the gas inlet valve on the accumulator. - Charging hose, length 2.5m - Connections for the accumulator 7 /8" - 14 UNF 5 /6" - 18 UNF 0.305" - 32 NFT M28 x 1,5 - Plastic protective case

KEY TO MODEL DESIGNATION

VG U 250 TS 3

Charging hose TS 3: for Ch, D, N, S, A, FL, NL, DK, GUS Connector W24,32 x 1,814 245 bar (for other countries, see part no. 40 on page 11)

Model Tester and Pressurizer Manometer 6, 10, 25, 60, 100, 250, 400 bar

Replaced by:

Substitute for:

9

Design group

RTA-Engines

Wrtsil Switzerland Ltd.

HYDRAULIC LATERAL DEVICE FOR MAIN ENGINE

9715

Page

Created: 23.8.1984

4-107.165.820

9/12

Version a1

19-157

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

INSTALLATION AND USE

Setting up (see figure on page 11) Before any pre-charge checks and/or nitrogen pressurizing, the hydraulic fluid of the hydro-pneumatic accumulator must be discharged. Accumulator with hydraulic valve: - Completely screw the lobed hand-wheel (no. 6) outwards - Unscrew the protective cap(s) of the accumulator gas inlet valve. - Screw pressurizer with intermediary no. 23 or 26 (+ connector no. 30 for Schrder valves) onto the hydraulic valve. Move the manometer into a convenient position for reading, and tighten the intermediary (no. 5) by hand. - Check that the release valve is closed. (close the lobed hand-wheel no. 18 in an clockwise direction). Checking the charge pressure: - Turn the lobed hand-wheel (no. 6) in an anti-clockwise direction. This causes the gas inlet valve or allen screw to open. The pressure may now be read on the manometer. Reducing the charge pressure: - Rotate the lobed hand-wheel (no. 18) of the release valve slowly in an anti-clockwise direction. The nitrogen is released into the surrounding air. Pressurizing/raising the charge pressure: - Connect the charging hose: one end to the return valve (no. 7) and the other to a standard nitrogen flask. - Open the stop valve on the nitrogen flask carefully. Allow the nitrogen to flow into the accumulator slowly, till the desired pre-charge pressure is reached. - Close the stop valve on the nitrogen flask. After 5-10 minutes (temperature stabilisation), check the charge pressure again and correct where necessary. Dismantling: - Turn the lobed hand-wheel (no. 6) back. - Screw the lobed hand-wheel (no. 18) outwards - Unscrew instrument. - Tighten screw valve with allen key SW6. - Check the gas inlet valve seal with a foam-forming substance. - Screw the protective cap(s) back on and tighten by hand. Caution: - Never use oxygen to inflate the accumulator. - Where the nitrogen flask pressure is higher than the permitted accumulator working pressure, a pressure limitation valve must be fitted.

Replaced by:

Substitute for:

10

Design group

RTA-Engines

Wrtsil Switzerland Ltd.

HYDRAULIC LATERAL DEVICE FOR MAIN ENGINE

9715

Page

Created: 23.8.1984

4-107.165.820

10/12

19-158

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

SPARE PARTS LIST FOR VG U TESTER AND PRESSURIZER Spares

Part No: Quantity 1 1 2 1 3 1 4 1 5 1 6 1 7 1 8 1 9 1 10 1 11 1 12 1 13 1 14 1 15 1 16 1 17 1 18 1 19 1 20 1 21 1 22 1 23 1 24 1 25 1 26 1 27 1 28 1 29 1 30 1 31 1 Description Valve body Valve spindle Bolts Split ring Spigot nut Lobed hand-wheel Return valve Hexagon nut Snap ring Stand. press. spring Retaining ring O-Ring O-Ring Centre-grooved dowel pin Name plate Connect. for manom. G " Copper seal Lobed hand-wheel Gland Valve spindle Valve ball Knurled cap 7 Adapter SAE /8" - 14UNF Valve spindle O-Ring 5 Adapter SAE /8" - 18UNF Valve spindle O-Ring Flat seal Connect. 0.305" - 32NFT Gasket assembly (complete set) 32 1 Charging hose 40 1 Connections for foreign nitrogen flasks 5 GB/AUS 40b R /8" external 1 USA 40c 24.51 x /14" external 1 Italy 40d 21.7 x /14" external 1 Japan 40e 22 x /14" internal 1 Japan 40f W23 x /14" external Brazil 40g R " internal 1 F, B, E 40h 21.7 x /14" internal China 40i M22 x 1.5 internal 5 China 40k /8" internal 7 Malaysia 40l G /8" external 7 Trinidad 40m /8" - 14UNF external Bulgaria 40n " internal 1 40o Philippines W23 x /14" left Rec'd spares

x x

x x x

Replaced by:

Substitute for:

11

Design group

RTA-Engines

Wrtsil Switzerland Ltd.

HYDRAULIC LATERAL DEVICE FOR MAIN ENGINE

9715

Page

Created: 23.8.1984

4-107.165.820

11/12

Version a1

19-159

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

Spares (When ordering, please state complete serial No.!)

Pos. 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 No. off 1 1 1 1 1 1 1 1 1 1 1 2 6 2 1 1 1 2 8 1 Item Cylinder Piston Cover Valve spindle Connecting piece Pointer Bearer Threaded sleeve Support Ring Ball valve Bolt Bolt Bolt Bolt Shoulded nut Nut Nut Spring washer Spring washer Pos. 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 No. off 2 2 1 1 1 1 2 1 1 1 1 1 1 1 1 1 1 1 1 1 Item Spring washer O-Ring Sealing ring Sealing ring Sealing ring Sealing ring Piston guide Guide tape Grooved ring Scraper O-Ring Pressure gauge Reduction Joint Bladder accumulator Reduction Clamping strap Vent screw with joint Plug Male union Pos. 41 44 No. off 1 1 Item Female union Prec. seamless pipe

Replaced by:

Substitute for:

12

Design group

RTA-Engines

Wrtsil Switzerland Ltd.

HYDRAULIC LATERAL DEVICE FOR MAIN ENGINE

9715

Page

Created: 23.8.1984

4-107.165.820

12/12

19-160

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

ORDER SHEET TESTER PRESSURIZER

VG U - 250 - TS3 Ref. 202 182-07733 Comprises of: - Tester and pressurizer with manometer, return valve on the charging hose, built-in release valve, valve spindle for opening the gas inlet valve on the accumulator. - Charging hose, length 2.5m - Connections for the accumulator 7 /8" - 14 UNF 5 /6" - 18 UNF 0.305" - 32 NFT M28 x 1,5 - Plastic protective case

- Additional nitrogen flasks connections for the following countries: 1) GB, AUS, NZ: R5/8" external Part No. 993507-02800 2) F, B, E: 21.7 x 1/14" internal Part No. 993513-02800 3) Italy: 21.7 x 1/14" external Part No. 993509-02800 4) USA: 24.51 x 1/14" external Part No. 993508-02800 5) Brazil: R" internal Part No. 993512-02800 6) Japan: 22 x 1/14" internal Part No. 993510-02800 7) Japan: W 23 x 1/14" external Part No. 993511-02800

KEY TO MODEL DESIGNATION

VG U 250 TS 3

Model Tester and Pressurizer

Charging hose TS 3: for Ch, D, N, S, Manometer A, FL, NL, DK, GUS 6, 10, 25, 60, 100, 250, 400 bar Connector W24,32 x 1,814 245 bar

SUPPLIER:

OLAER (SUISSE) SA Bonnstrasse 3 CH- 3186 Duedingen e-mail: info@olaer.ch

21.08.84 10.11.99

Replaced by: Substitute for:

a b

Pipa 7-14.418

TEST AND FILLING UNIT RTA-Engines

Wrtsil Switzerland Ltd.

Design group

TO ENGINE STAYS (HYDRAULIC TYPE)

9715

Page

Created: 28.10.82

4-107.165.818

Version a1

19-161

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-162

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-163

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-164

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-165

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-166

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-167

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-168

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-169

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-170

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-171

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19-172

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Version a1

19-173

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

Fitting instructions for engine stays (friction type)

for lateral and longitudinal application

1. Introduction

Lateral and longitudinal stays are installed where countermeasures for dynamic effects are to be taken (for indication refer to Marine Installation Manual, chapter E or to Engine Selection and Project Manual). For stay arrangement and details refer also to the relevant installation drawings of the corresponding design group 9715. It is vital that the stays are fitted correctly to ensure proper operation and to prolong lifetime of the components.

2. Description and function

According to WNS standard design two stays are fitted between the engine and the ship's hull. They transmit lateral or longitudinal forces from the engine body attachment (pos. 1) via the friction shims and the sheet metal girders (pos. 2) to the ships attachment (pos. 3). The clamping force of the two elastic bolts is adjusted so that during service the engines pulsating forces are transmitted to the ships hull. During loading and unloading however, the stay is able to adapt to deformations of the ships hull within its stroke. To reduce material stress in the stay itself and also in the attachment points hinge pins are provided to allow movements in both vertical and longitudinal direction.

3

Pos.1 Engine side attachment device with latch and hinge pin Pos.2 Sheet metal girders with friction shims and elastic bolts

Engine side

Ship side

Pos.3 Ship side attachment device with hinge pin

Scavenge air receiver box or upper platform support

Fig.1 Principle arrangement

For lateral application the stays are welded on the exhaust side just below the upper platform onto the scavenge air receiver box or in exceptional cases onto the turbocharger support. For longitudinal application they are welded at the engine free end onto the upper platform supports where special attachment plates are provided by the engine builder. For examples of stay arrangement see figures No. 2, 3 and 4. As the design of the elastic bolts is similar to that applied for the engine holding down studs, the same hydraulic tool (design group 9411-06) is used for pretensioning.

a 7-28.674 12.12.02 c EAAD082173 b 7-67.959 07.04.09 RT84T B

Drawn: T. Landert Verif: T. Landert

27.01.98 30.01.98

Replaced by: Substitute for:

PC

Fitting instructions

to engine stays, friction type

Group

9715

Wrtsil Switzerland Ltd.

4-107.246.429

1/4

ISO-Basic Document Nr.X-107.246.429 / 12.02.96 / Rev. 1.0 File name: 107_246_429__c.doc /

19-174

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Lateral arrangement with attachment on scavenge air receiver box (RTA84T-B/96C-B)

Lateral arrangement with attachment on scavenger air receiver box (RTA84CU only)

Longitudinal arrangement with attachment on platform support (RTA84T-B only)

Fig. 2

Fig. 3

Fig. 4

3. Fitting of the stays

3.1 Starting conditions Before the stays are fitted, following conditions must be fulfilled: Ship afloat Engine aligned and chocked Engine coupled to intermediate shaft Engine holding down studs fully tightened Side stoppers fitted Engine preheated to starting condition Relevant installation drawings available Hydraulic tensioning device ready to use (engine builders tool kit, code-No. 94145) Note: When fitting the stays it is very important that the engine is preheated to starting condition. This is to reduce any possible misalignment of the stay due to engine thermal expansion between fitting and service condition. Excessive horizontal and vertical misalignment of the stay between the engines and the ships attachment point may restrict the stay function. It may even lead to buckling or cracking of the stay. For admissible tolerances refer to table 2. When positioning and fitting use crane to avoid overstress to the stay. 3.2 Sequence of operations 1.) Check whether the stays are completely and correctly assembled according to the relevant assembly drawing. Observe that the two elastic bolts are concentric with the holes of the attachment device (nominal position). The bolts are not tightened with the final hydraulic tensioning pressure but sufficiently so that no shifting within the stroke is possible when handling the stay.

RT84T

Wrtsil Switzerland Ltd.

B

27.01.98 30.01.98

Fitting instructions

to engine stays, friction type

Group

9715

Drawn: T. Landert Verif.: T. Landert

4-107.246.429

2/4

ISO-Basic Document Nr.X-107.XXX.XXX / 12.02.96 / Rev. 1.0 File name: 107_246_429__c.doc

Version a1

19-175

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

2.) Check that there is no platform support, piping or else which could collide with the stay. In particular pay attention to the space requirements of the hydraulic tensioning device in order to allow proper tightening of the elastic bolts. 3.) Measure the actual stay length X and compare it to the effective clear width between the previously determined attachment points on engine and ship side. As foreseen in the design the stay length may, when assembled correctly, exceed the clear width slightly due to the over measure of the latch of the engine side attachment device (fig.1/pos.1 and fig.5). 4.) Shorten then the stay at the latch to the required length X while observing table 1 as a guideline. A tolerance of the stays length is allowed, however, ensure that the actual stay length X does not exceed the clear width by more than 5mm and that the gap is no more than 10mm. At the same time prepare the edges for welding. Note: During loading the ships hull is supposed to deform towards the ships centre line or engine side respectively. It is therefore preferable fitting a stay with a length just correct or rather too short than with an over length as an extra stroke in the relevant direction can be realised (see table 1). 5.) Make sure that the surfaces of the receiver box/platform support and the ship side attachment points are clean. Position the stay to the foreseen attachment points and compensate the a.m. possible deviation in length by loosening the elastic bolts and shifting the stay accordingly. After shifting retighten the bolts. 6.) Then align the stay in all planes within the given tolerances (see table 2) and fix it by spot welding starting on engine side. 7.) Before commencing the final welding, loosen the elastic bolts in order to avoid material stress due to thermal expansion. When welding, pay attention that no deviation in the stay alignment occurs. When fitting longitudinal stays after welding, overlapping parts of the latch may be cut off if required (see fig. 4). 8.) After welding, when all parts have cooled down make sure the stay is free of any tension. Retighten the elastic bolts by means of the tensioning device with the hydraulic pressure given in table 4.

Engine side Ship side

Driving end

Fig. 5

RT84T

Wrtsil Switzerland Ltd.

B

27.01.98 30.01.98

Fitting instructions

to engine stays, friction type

Group

9715

Drawn: T. Landert Verif.: T. Landert

4-107.246.429

3/4

ISO-Basic Document Nr.X-107.XXX.XXX / 12.02.96 / Rev. 1.0 File name: 107_246_429__c.doc

19-176

Version a1

RT-flex96C-B Marine Installation Manual

19. General Installation Aspects

Table 1: Admissible deviation for stay length when commissioning (in mm) Deviation of stay Reference Resulting stroke length X related to clear width

M

Nominal position Stay too long (max. over length) Stay too short (max. gap) 0 +5 - 10 25 30 15

-S

24.5 29.5 14.5

+S

24.5 19.5 34.5

Table 2: Admissible vertical and horizontal deviation (in mm) Clear width Lateral application Longitudinal application

X

2000 to 2280 2281 to 2560 2561 to 3120 3121 to 3400

+V

2 2 4 4

-V

0 0 0 0

+H

1.5 2 3 4

-H

0 0 0 0

+V

2 2 4 4

-V

0 0 0 0

+H

1.5 2 3 4

-H

1.5 2 3 4

4. Operational check and final adjustment

4.1 During sea trial During service check whether relative movements between the ship side attachment device (fig.1/pos. 3) and the sheet metal girders (fig.1/pos. 2) occur. If this is the case, following might be the cause: Insufficient or incorrect tightening of the elastic bolts Dirty or damaged friction shims Material or quality of friction shims not according to WNS specification Incorrect assembly of the stays Incorrect fitting or alignment, i.e. welding 4.2 After sea trial After sea trial, when the engine and machinery space still are in hot condition, check whether measure M remained within the limits given in table 3 and check also whether the stays are still in line with the engine (horizontally and vertically). If not, it may help to loosen the elastic bolts. The sheet metal girders can then move within the clearance of the through holes of the ship side attachment device. Undesirable tension in the stay can release and possible misalignment may be compensated. At a latter stage, when the vessel has been loaded and unloaded, check whether displacement between engine and ship hull has taken place to make sure the stays work properly. Check also whether measure M remained within the limits given in table 3. If this is not the case, refer to the possible causes listed under 4.1. For maintenance repeat the above mentioned checks i.e. check the pretension of the bolts at intervals as foreseen for the maintenance of the engine holding down studs. Table 3: Admissible values for M in service (in mm) Table 4: Pretensioning pressure Reference Loaded state Engine type Hydr. Pressure

For lateral and longitudinal application

M

absolute minimum absolute maximum 2 48 ballast condition fully loaded RTA84T-B/-D RTA/-flex96C-B RTA/-flex82C/T RTA/-flex68-D

bar

150 200 170 120 2 48

RT84T

Wrtsil Switzerland Ltd.

B

27.01.98 30.01.98

Fitting instructions

to engine stays, friction type

Group

9715

Drawn: T. Landert Verif.: T. Landert

4-107.246.429

4/4

ISO-Basic Document Nr.X-107.XXX.XXX / 12.02.96 / Rev. 1.0 File name: 107_246_429__c.doc

Version a1

19-177

19. General Installation Aspects

RT-flex96C-B Marine Installation Manual

19.8 Fire protection

Fires may develop in areas such as under-piston spaces and scavenge air receiver. The engine is fitted with a piping system which leads the fire extinguishing agent into the mentioned areas. Where fire protection is required, the final arrangement of the fire extinguishing system is to be submitted for approval to the relevant classification society.

19.8.1 Extinguishing agents

Various extinguishing agents can be considered for fire fighting purposes. Their selection is made either by the shipbuilder or the shipowner in compliance with the rules of the classification society involved. Table gives the recommended quantity of 45 kg bottles of CO2 for each engine. Steam as an alternative fire extinguishing medium is permissible for the scavenge air spaces of the piston underside, but may cause corrosion if countermeasures are not taken immediately after its use. These countermeasures comprise: opening scavenge spaces and removing oil and carbon deposits drying all unpainted surfaces and applying rust protection (i.e. lubricating oil). NOTICE Steam is not suitable for fire extinguishing under-piston spaces, as this may result in damage to vital parts such as the crankshaft. If steam is used for the scavenge spaces at piston underside, a water trap is recommended to be installed at each entry to the engine and assurance obtained that steam shut-off valves are tight when not in use. Recommended quantities of fire extinguishing medium

Piston underside at bottom dead centre including Bottle common section of cylinder jacket Volume Mass Size [m3/cyl.] [kg/cyl.] [kg] Carbon dioxide 8 30 45 Recommended total number of fire extinguishing bottles Number of cylinders 6 4 7 5 8 6 9 6 10 7 11 8 12 8 13 9 14 10

Extinguishing medium

The indicated numbers of bottles are provisional, will be checked by Wrtsil Switzerland Ltd.

19-178

Version a1

RT-flex96C-B Marine Installation Manual

20. Engine Emissions

20. Engine Emissions

The International Maritime Organisation (IMO) is a specialized agency of the United Nations (UN), dealing with technical aspects of shipping. For more information see http://www.imo.org.

20.1 Exhaust gas emissions

20.1.1 Establishment of emission limits for ships

In 1973 an agreement on the International Convention for the Prevention of Pollution from ships was reached. It was modified in 1978 and is now known as MARPOL 73/78. The Annex VI to MARPOL 73/78, entered into force in 2005, contains regulations limiting or prohibiting certain types of emissions from ships, including limitations with respect to the allowed air pollution. Following the entry into force of the annex, a review process was started, resulting in an amended Annex IV, which was adopted by the IMO in October 2008 and entered into force in July 2010. This amended Annex IV includes provisions for the further development of the emissions regulations until 2020.

20.1.2 Regulation regarding NOx emissions of diesel engines

Regulation 13 of Annex IV specifies a limit for the nitrogen oxide (NOx) emissions of engines installed on ships, which has a direct implication on propulsion engine design. Depending on the rated speed of the engine and the date of keel-laying of the vessel, the weighted average NOx emission of that engine must not exceed the maximum allowable value as indicated by the respective curves in the following diagram.

Figure 20.1: Speed dependent maximum average NOx emissions by engines

Version a1

20-1

20. Engine Emissions

RT-flex96C-B Marine Installation Manual

The rules and procedures for demonstrating and verifying compliance with this regulation are laid down in the NOx Technical Code, which is part of Annex VI and is largely based on the latest revision of ISO 8178.

20.1.3 Measures for compliance with the IMO regulation

The rating field is divided in two areas as shown in figure 20.2, and comprises the following measures: Low NOx Tuning In the upper part of the rating field the IMO regulation is fulfilled by the use of the Low NOx Tuning concept. Low NOx Tuning includes well tested measures, which lead to lowest disadvantage in engine costs and fuel consumption while maintaining the high reliability levels of pre-IMO tuned engines. Extended measures In the lower part of the rating field, fulfilling the IMO NOx regulation requires the application of extended measures. For further information please do not hesitate to contact one of our offices.

Figure 20.2: Compliance with IMO regulations

20-2

Version a1

RT-flex96C-B Marine Installation Manual

20. Engine Emissions

20.2 Engine noise

It is necessary to protect the ships crew/passengers from the effects of machinery space noise. Therefore the scavenge air ducts and the exhaust duct system (both expansion joints of gas outlet and gas inlet of turbocharger) should be equipped with the standard insulation and the turbocharger with the standard intake silencer.

20.2.1 Engine surface sound pressure level

Figure 20.3 shows the average air borne noise level, measured at 1 m distance and at nominal MCR. Near the turbocharger (air intake), the maximum measured noise level will normally be about 3-5 dB(A) higher than the average noise level of the engine.

Figure 20.3: Engine sound pressure level at 1 m distance

Average values Lp in dB in comparison with the ISO NR-curves and overall average values LpA in dB(A), at nominal MCR under free field conditions.

Version a1

20-3

20. Engine Emissions

RT-flex96C-B Marine Installation Manual

20.2.2 Engine exhaust sound pressure level at funnel top

The sound pressure level from the engine exhaust gas system without boiler and silencer (given in figure 20.4) is related to: a distance of one metre from the edge of the exhaust gas pipe opening (uptake) an angle of 30 to the gas flow direction nominal MCR. Each doubling of the distances reduces the noise level by about 6 dB. Depending on the actual noise level allowed on the bridge wing - which is normally maximum 60-70 dB(A) - a simple flow silencer of the absorption type may be necessary and placed after the exhaust gas boiler. The silencer is dimensioned for a gas velocity of approximately 35 m/s with a pressure loss of approx. 2 mbar at specified MCR.

Figure 20.4: Sound pressure level at funnel top of engine exhaust gas system

Average values Lp in dB in comparison with the ISO NR-curves and overall average values LpA in dB(A), at nominal MCR; at 1 m distance from the edge of the exhaust gas pipe opening at an angle of 30 to the gas flow. Exhaust gas system without boiler and silencer.

20-4

Version a1

RT-flex96C-B Marine Installation Manual

20. Engine Emissions

20.2.3 Engine structure borne noise

The vibrational energy is propagated via engine structure, bedplate flanges and engine foundation to the ships structure, which starts to vibrate and thus emits noise. The sound pressure levels in the accommodations can be estimated with the aid of standard empirical formulas and the vibration velocity levels given in figure 20.5.

Figure 20.5: Structure borne noise level at engine feet vertical

Structure borne noise level Lv in dB at nominal MCR.

Version a1

20-5

This page intentionally left blank

RT-flex96C-B Marine Installation Manual

21. Tools

21. Tools

21.1 Group 1

21.1.1 Drawings

107.358.974 a 107.272.878 g 107.298.695 a 107.298.697 a 107.074.837 f 107.335.260 107.235.317 h 107.361.706 b 107.298.699 a 107.298.721 b 107.352.530 a 107.201.192 a 107.156.875 a 107.338.980 107.338.944 a 107.312.462 d 107.338.591 107.354.656 107.338.924 Tool Instructions ...................................................................................21-2 Tool General Combination Wrench ......................................................21-3 Tools For Group:08, General ................................................................21-4 Tools For Group:08, General ................................................................21-5 Tool General Allan Key .........................................................................21-6 Tool General Rods, General .................................................................21-7 Tool General Wrenches ........................................................................21-8 Tool General Pliers ...............................................................................21-9 Tools For Group:08, General ................................................................21-10 Tool General Withdrawing Gear, General .............................................21-11 Tool General Jacks/Pumps ..................................................................21-12 Tool General Cupboard ........................................................................21-13 Tool General Grease Gun .....................................................................21-14 Tool General Torque Wrenches ............................................................21-15 Tool General Spanners .........................................................................21-16 Tool General Pressure Measurement ...................................................21-17 Tool General Chain Block ....................................................................21-18 Tool General Chain Block ....................................................................21-19 Tool Open End Torque Wrench ............................................................21-20

Version a1

21-1

21. Tools

RT-flex96C-B Marine Installation Manual

21-2

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-3

21. Tools

RT-flex96C-B Marine Installation Manual

21-4

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-5

21. Tools

RT-flex96C-B Marine Installation Manual

21-6

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-7

21. Tools

RT-flex96C-B Marine Installation Manual

21-8

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-9

21. Tools

RT-flex96C-B Marine Installation Manual

21-10

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-11

21. Tools

RT-flex96C-B Marine Installation Manual

21-12

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-13

21. Tools

RT-flex96C-B Marine Installation Manual

21-14

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-15

21. Tools

RT-flex96C-B Marine Installation Manual

21-16

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-17

21. Tools

RT-flex96C-B Marine Installation Manual

21-18

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-19

21. Tools

RT-flex96C-B Marine Installation Manual

21-20

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

21.2 Group 2

21.2.1 Drawings

107.298.340 a 107.346.168 a 107.346.516 a 107.381.504 107.330.553 a 107.297.858 b 107.297.363 d 107.297.508 a 107.297.509 b 107.297.836 a 107.298.348 d 107.335.020 Tools For Group:11, Bedplate ..............................................................21-22 Tool Main Bearing Assembly ...............................................................21-23 Tool Main Bearing Assembly ...............................................................21-24 Tool Main Bearing Measuring ..............................................................21-25 Tool Main Bearing Pre-Tensioning .......................................................21-26 Tool Main Bearing Shell Assembly, Bedplate ......................................21-27 Tool Foundation Pre-Tensioning, Foundation ......................................21-28 Tools For Group:12, Thrust Bearing .....................................................21-29 Tool Thrust Bearing Assembly .............................................................21-30 Tools For Group:12, Thrust Bearing/Spare Wheel ...............................21-31 Tool Column Working Support, Tool Column Working Supp ...............21-32 Tool Tie Rod Pre-Tensioning, Tie Rod .................................................21-33

Version a1

21-21

21. Tools

RT-flex96C-B Marine Installation Manual

21-22

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-23

21. Tools

RT-flex96C-B Marine Installation Manual

21-24

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-25

21. Tools

RT-flex96C-B Marine Installation Manual

21-26

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-27

21. Tools

RT-flex96C-B Marine Installation Manual

21-28

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-29

21. Tools

RT-flex96C-B Marine Installation Manual

21-30

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-31

21. Tools

RT-flex96C-B Marine Installation Manual

21-32

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-33

21. Tools

RT-flex96C-B Marine Installation Manual

21.3 Group 3

21.3.1 Drawings

107.298.477 c 107.340.948 107.343.555 a 107.298.317 b 107.372.939 107.335.612 b 107.336.301 a 107.336.877 DAAD010231 DAAD010277 107.298.749 a 107.337.404 b 107.367.744 b 107.385.159 107.298.471 a 107.298.677 a 107.337.284 a 107.427.693 107.426.833 107.298.644 d 107.337.506 c Tool Cylinder Liner Assembly, For Cylinder Liner ................................21-35 Tool Cylinder Liner Assembly, For Cylinder Liner ................................21-36 Tool Cylinder Liner Assembly, For Cylinder Liner-Removal .................21-38 Tool Cylinder Liner Measuring, For Cylinder Liner ...............................21-39 Tool Cylinder Liner Grinding ................................................................21-40 Tool Gland Box Assembly ....................................................................21-41 Tool Gland Box Assembly Platform .....................................................21-42 Tool Cyl. Cover/Exh. Valve Assembly ..................................................21-43 Tool Cyl. Cover/Exh. Valve Assy. .........................................................21-44 Tool Cyl. Cover/Exh. Valve Assy. .........................................................21-45 Tools For Group:27, Fuel Valve ............................................................21-46 Tool Injector Test Bench, Fuel Valve And Safety Valve ........................21-47 Tool Injector Test Bench .......................................................................21-48 Tool Cylinder Cover Pre-Tensioning .....................................................21-49 Tools For Group:27, Valve Cage ..........................................................21-50 Tools For Group:27, Exhaust Valve ......................................................21-51 Tool Exhaust Valve Failure ...................................................................21-52 Tool Valve Seat Machining ...................................................................21-53 Tool Valve Spindle Grinding .................................................................21-54 Tool Injection Valve Protection .............................................................21-55 Tool Cylinder Pressure Measuring .......................................................21-56

21-34

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-35

21. Tools

RT-flex96C-B Marine Installation Manual

21-36

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-37

21. Tools

RT-flex96C-B Marine Installation Manual

21-38

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-39

21. Tools

RT-flex96C-B Marine Installation Manual

21-40

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-41

21. Tools

RT-flex96C-B Marine Installation Manual

21-42

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-43

21. Tools

RT-flex96C-B Marine Installation Manual

21-44

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-45

21. Tools

RT-flex96C-B Marine Installation Manual

21-46

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-47

21. Tools

RT-flex96C-B Marine Installation Manual

21-48

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-49

21. Tools

RT-flex96C-B Marine Installation Manual

21-50

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-51

21. Tools

RT-flex96C-B Marine Installation Manual

21-52

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-53

21. Tools

RT-flex96C-B Marine Installation Manual

21-54

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-55

21. Tools

RT-flex96C-B Marine Installation Manual

21-56

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

21.4 Group 4

21.4.1 Drawings

107.074.657 b 107.297.377 a 107.298.182 b 107.411.874 107.297.907 a 107.298.859 a 107.364.418 107.297.536 b 107.298.428 b 107.298.872 c 107.412.617 107.299.976 a 107.338.328 107.394.549 b 107.394.552 a 107.394.553 a 107.333.474 a 107.298.727 a 107.347.781 a 107.298.617 b 107.298.662 a 107.374.933 Tool Crankshaft Measuring ..................................................................21-58 Tools For Group:33, Connecting Rod ..................................................21-59 Tool Con. Rod/Crosshead Assembly ...................................................21-60 Tool Con. Rod/Crosshead Assembly ...................................................21-61 Tools For Group:33, Crosshead Pin Bearing .......................................21-62 Tools For Group:33, Connecting Rod ..................................................21-63 Tool Connecting Rod Assembly, Connecting Rod ..............................21-64 Tools For Group:33, Piston Rod-Screw Connect ................................21-65 Tools For Group:33, Guide Shoe .........................................................21-66 Tool Connec. Rod Bearing Inspection .................................................21-67 Tool Connec. Rod Bear. Inspect. .........................................................21-68 Tool Connec. Rod Bearing Assembly ..................................................21-69 Tool Bearing Shell Crank Pin Assy .......................................................21-70 Tool Piston Assembly ...........................................................................21-71 Tool Piston Assembly ...........................................................................21-72 Tool Piston Assembly ...........................................................................21-73 Tool Piston Head Pre-Tensioning .........................................................21-74 Tools For Group:34, Piston ..................................................................21-75 Tool Piston Ring Assembly ..................................................................21-76 Tool Piston Rod Shim Assembly ..........................................................21-77 Tools For Group:34, Working Piston ....................................................21-78 Tool Piston Ring Measuring, Leptoskop ..............................................21-79

Version a1

21-57

21. Tools

RT-flex96C-B Marine Installation Manual

21-58

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-59

21. Tools

RT-flex96C-B Marine Installation Manual

21-60

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-61

21. Tools

RT-flex96C-B Marine Installation Manual

21-62

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-63

21. Tools

RT-flex96C-B Marine Installation Manual

21-64

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-65

21. Tools

RT-flex96C-B Marine Installation Manual

21-66

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-67

21. Tools

RT-flex96C-B Marine Installation Manual

21-68

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-69

21. Tools

RT-flex96C-B Marine Installation Manual

21-70

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-71

21. Tools

RT-flex96C-B Marine Installation Manual

21-72

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-73

21. Tools

RT-flex96C-B Marine Installation Manual

21-74

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-75

21. Tools

RT-flex96C-B Marine Installation Manual

21-76

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-77

21. Tools

RT-flex96C-B Marine Installation Manual

21-78

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-79

21. Tools

RT-flex96C-B Marine Installation Manual

21.5 Group 5

21.5.1 Drawings

107.296.738 b 107.364.709 107.387.741 Tool Intermediate Wheel Assembly, Intermediate Wheel .....................21-81 Tool Intermediate Wheel Assembly ......................................................21-82 Tool Gear Wheel Crankshaft Assembly ...............................................21-83

21-80

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-81

21. Tools

RT-flex96C-B Marine Installation Manual

21-82

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-83

21. Tools

RT-flex96C-B Marine Installation Manual

21.6 Group 6

21.6.1 Drawings

107.377.552 a 107.377.555 a 107.377.556 a 107.377.557 a 107.373.919 b 107.385.874 107.399.193 107.352.049 d 107.352.844 d 107.355.652 d 107.391.778 107.391.816 107.401.617 107.337.094 d 107.370.714 107.335.628 a 107.375.166 107.375.167 107.375.168 107.381.986 107.391.581 107.406.748 107.336.253 a 107.344.953 c 107.350.285 b 107.337.208 a 107.359.983 107.360.599 107.360.603 107.360.607 107.360.610 Tool Supply Unit Assembly ..................................................................21-85 Tool Supply Unit Assembly ..................................................................21-86 Tool Supply Unit Assembly ..................................................................21-87 Tool Supply Unit Assembly ..................................................................21-88 Tool Supply Unit Assembly, Retrofit ....................................................21-89 Tool Supply Unit Assembly ..................................................................21-90 Tool Supply Unit Assembly ..................................................................21-91 Tool Fuel Pump Assembly ...................................................................21-92 Tool Fuel Pump Assembly ...................................................................21-93 Tool Fuel Pump Assembly ...................................................................21-94 Tool Fuel Pump Assembly, Guide Pin ..................................................21-95 Tool Fuel Pump Assembly, Press-Off Device ......................................21-96 Tool Fuel Pump Assembly ...................................................................21-97 Tool Rail Unit Maintenance ..................................................................21-98 Tool Supply Unit Maintenance .............................................................21-99 Tool Supply Unit Pre-Tensioning ..........................................................2 - 0 11 0 Tool Cams Gear Wheel Assembly .......................................................2 - 0 11 1 Tool Cams Gear Wheel Assembly .......................................................2 - 0 11 2 Tool Cams Gear Wheel Assembly .......................................................2 - 0 11 3 Tool Cams Gear Wheel Assembly .......................................................2 - 0 11 4 Tool Cams Gear Wheel Assembly, Hydraulic Jack 2-Parts .................2 - 0 11 5 Tool Cams Gear Wheel Assembly .......................................................2 - 0 11 6 Tool Supply Unit Transport ..................................................................2 - 0 11 7 Tool Supply Unit Transport ..................................................................2 - 0 11 8 Tool Supply Unit Transport ..................................................................2 - 0 11 9 Tool Supply Unit Interm. Gear Wheel ...................................................2 - 1 11 0 Tool Supply Unit Interm. Gear Wheel, Dismantling Rail Retrofit ..........2 - 1 11 1 Tool Rail Unit Transport ........................................................................2 - 1 11 2 Tool Rail Unit Transport ........................................................................2 - 1 11 3 Tool Rail Unit Transport ........................................................................2 - 1 11 4 Tool Rail Unit Transport ........................................................................2 - 1 11 5

21-84

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-85

21. Tools

RT-flex96C-B Marine Installation Manual

21-86

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-87

21. Tools

RT-flex96C-B Marine Installation Manual

21-88

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-89

21. Tools

RT-flex96C-B Marine Installation Manual

21-90

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-91

21. Tools

RT-flex96C-B Marine Installation Manual

21-92

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-93

21. Tools

RT-flex96C-B Marine Installation Manual

21-94

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-95

21. Tools

RT-flex96C-B Marine Installation Manual

21-96

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-97

21. Tools

RT-flex96C-B Marine Installation Manual

21-98

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-99

21. Tools

RT-flex96C-B Marine Installation Manual

21-100

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-101

21. Tools

RT-flex96C-B Marine Installation Manual

21-102

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-103

21. Tools

RT-flex96C-B Marine Installation Manual

21-104

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-105

21. Tools

RT-flex96C-B Marine Installation Manual

21-106

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-107

21. Tools

RT-flex96C-B Marine Installation Manual

21-108

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-109

21. Tools

RT-flex96C-B Marine Installation Manual

21-110

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-111

21. Tools

RT-flex96C-B Marine Installation Manual

21-112

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-113

21. Tools

RT-flex96C-B Marine Installation Manual

21-114

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-115

21. Tools

RT-flex96C-B Marine Installation Manual

21.7 Group 7

21.7.1 Drawings

107.337.646 107.283.637 a 107.319.964 a DAAD005964 DAAD005969 107.338.565 b 107.356.777 107.362.647 107.362.648 107.409.642 107.409.787 107.409.823 107.409.824 107.338.539 Tool Auxiliary Blower Assembly ...........................................................2 - 1 11 7 Tool Tc Failure ......................................................................................2 - 1 11 8 Tool Tc Failure ......................................................................................2 - 1 11 9 Tool Tc Failure ......................................................................................2 - 2 11 0 Tool Tc Failure ......................................................................................2 - 2 11 1 Tool Sac Assembly ...............................................................................2 - 2 11 2 Tool Sac Assembly ...............................................................................2 - 2 11 3 Tool Sac Assembly ...............................................................................2 - 2 11 4 Tool Sac Assembly ...............................................................................2 - 2 11 5 Tool Sac Assembly ...............................................................................2 - 2 11 6 Tool Sac Assembly ...............................................................................2 - 2 11 7 Tool Sac Assembly ...............................................................................2 - 2 11 8 Tool Sac Assembly ...............................................................................2 - 2 11 9 Tool Water Separator Assembly ..........................................................2 - 3 11 0

21-116

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-117

21. Tools

RT-flex96C-B Marine Installation Manual

21-118

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-119

21. Tools

RT-flex96C-B Marine Installation Manual

21-120

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-121

21. Tools

RT-flex96C-B Marine Installation Manual

21-122

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-123

21. Tools

RT-flex96C-B Marine Installation Manual

21-124

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-125

21. Tools

RT-flex96C-B Marine Installation Manual

21-126

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-127

21. Tools

RT-flex96C-B Marine Installation Manual

21-128

Version a1

RT-flex96C-B Marine Installation Manual

21. Tools

Version a1

21-129

21. Tools

RT-flex96C-B Marine Installation Manual