Professional Documents

Culture Documents

Crossing Calculation API RP1102 (TEMPLATE)

Uploaded by

bebas_amarahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crossing Calculation API RP1102 (TEMPLATE)

Uploaded by

bebas_amarahCopyright:

Available Formats

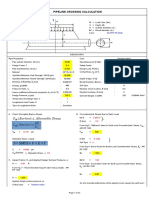

ATTACHMENT - X Document No.

XXXXX Uncased Track Crossing Design Calculation

36-inch Pipeline, API 5L X65 SAW

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84

As per API RP 1102

Input Data Pipe Material Pipeline design factor, D.F. pipe size, Outside Diam., D Pipe nominal thickness, t SMYS of linepipe material Longitudinal joint factor, Ej

Allow. design factor for Eff. Stress, Fa =

= = = = = = = = = = = = = = = = = = = = = =

API 5L X65 SAW 0.50

36 20.6 65300 1 0.72 1 19.6 70 65 13 2.07E+05 0.3 1.17E-05 1927 3.40E+06 6.90E+07 2000 914 112 112 144

in mm psi

914 mm

Corrosion allowance Corroded wall thickness, tw Design pressure, P Design temperature (U/G), T2 Installation (backfill) temp., T1 Youngs modulus of steel, E Poisson ratio, Thermal expansion coefficient, a Soil density, g Modulus of soil reaction, E' Soil resilient modulus, Er Depth of cover, H Bored diameter, Bd Tandem Axle Load, Pt Single Axle Load, Ps Wheel contact area, A

mm barg

deg C deg C Mpa

10197.16213

2 713801.3 kg/m

14.504

1015.26

psig

101971.6213

2 2.111E+10 kg/m

per deg C

kg/m3 N/m2 N/m2 18.9 3.47E+05 7.04E+06 kN/m3 Soil Type = Loose Sand

kg/m2 2 kg/m

mm mm kN kN Inch2

Construction type: Trenched Trenched 11428.57 kg 11428.57 kg 2 0.093 m

Check for Allowable stress Sh [ D.F x Ej x SMYS Hoop stress Shi(Barlow) = PD/2tw D.F x Ej x SMYS Circumferential stress due to earth load SHe tw/D Ref. Fig 3 = 0.021 Ref. Fig 4 H/Bd = 2.2 Ref. Fig 5 Bd/D = 1.00 SHe = KHe x Be x Ee x g x D Ref. Equation 1 Check critical axle configurations (figure A-1) Pavement type : No Pavement Pavement Critical Axle : Tandem Axles Impact factor and applied surface pressure w Ref. Fig 7 H = 2.00 Applied pressure (w) = Pt /A for Tandem Axles Cyclic circumferential stress SHh tw/D Ref fig 14 = 0.021 Ref fig 15 SHh = KHh x GHh x R x L x Fi x w Ref. Equation 5 Cyclic Longitudinal stress SLh tw/D Ref fig 16 = 0.021 Ref fig 17 SLh = KLh x GLh x R x L x Fi x w Ref. Equation 6 Circumferential Stress due to Internal Load, SHi SHi = P(D-tw)/2tw Ref. Equation 7 Principal stresses S1, S2, & S3 S1(max circum stress) = SHe + SHh + SHi Ref. Equation 9

= 23672.23 = 32650.00

psi psi

0.00689

= Hence

163.21 OK

MPa

KHe = Be = Ee = SHe =

2709 0.7 1.00 3340368

kg/m2

9.81E-06

32.76

MPa

R = 1.1

L = 1.00

(Refer table 2)

Fi = 1.45

2 w = 123016.1 kg/m

9.81E-06

1.21

MPa

KHh = GHh = SHh =

13.90 0.71 18.99

MPa

KLH = GLh = SLh =

9.70 0.73 13.63

MPa

SHi = 23164.60 psi S1 =

159.71

MPa

211.46

MPa

Ref. Equation 10, S2 = Maximum longitudinal stress S2 = SLh - Ea(T2-T1) + (SHe + SHi) S2 = Ref. Equation 11, Radial stress S3 = -P Ref. Equation 12, Effective stress Seff Allowable effective stress (SMYS x Fa) Ratio of Seff / Allowable

2

-54.57 -7

2

MPa MPa

S3 =

= [0.5 {(S1-S2) + (S2-S3) + (S3-S1)2}] 0.5 Seff = 245.73 MPa = 324.16 MPa = 0.758 Result Design OK

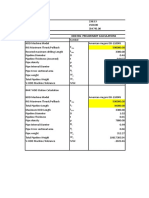

Check for Fatigue Girth weld fatigue endurance limit (SFG) = Allowable SFG = SFG x D.F = SLh < SFG x D.F Refer Equation 17 Ratio of Actual (SLh)/ Allowable = Longitudinal weld endurance limit (SFL) Allowable SFL = SFL x D.F. SHh < SFL x D.F. Refer Equation 18 Ratio of Actual (SHh) / Allowable SFL = = =

82.74 41.37 0.329 82.74 41.37 0.459

MPa (from table 3 of API 1102) MPa Result MPa (from table 3 of API 1102) MPa Result Design OK Design OK

\\vboxsrv\conversion_tmp\scratch_1\[134239044.xls.ms_office.xls]calculation

Page 1 of 1

You might also like

- Underground Pipe DesignDocument3 pagesUnderground Pipe Designjobees7850No ratings yet

- Crossing Calculation API RP1102 (TEMPLATE)Document1 pageCrossing Calculation API RP1102 (TEMPLATE)Hendra Yudistira100% (1)

- API RP 1102 SpreadsheetDocument5 pagesAPI RP 1102 Spreadsheetdrramsay100% (4)

- Road Crossing Pipeline Load CalculatorDocument7 pagesRoad Crossing Pipeline Load CalculatorZeeshan Ahuja100% (2)

- Bending Stress CalculationsDocument4 pagesBending Stress Calculationsschaali100% (5)

- HDD Design and MethodologyDocument14 pagesHDD Design and MethodologyVipin Gupta100% (4)

- 17-HDD Design CalculationDocument22 pages17-HDD Design CalculationAmit Shrivastava100% (6)

- Pipeline Sesmic CalculationDocument4 pagesPipeline Sesmic Calculationbaghelrohit100% (3)

- HDD Crossing Calculation 2Document26 pagesHDD Crossing Calculation 2Denstar Ricardo Silalahi93% (29)

- Elastic Bending Radius Calculation of PIPELINESDocument1 pageElastic Bending Radius Calculation of PIPELINESmailmaverick816777% (13)

- Buried PipeDocument11 pagesBuried PipePrashant Agrawal100% (4)

- API RP 1102 SpreadsheetDocument6 pagesAPI RP 1102 Spreadsheetm_michael_cNo ratings yet

- Crossing Calculation API 1102 8inch Sch40 Api5lbrg 1.3depthDocument12 pagesCrossing Calculation API 1102 8inch Sch40 Api5lbrg 1.3depthJoe Kyla83% (6)

- HDD Calculation (Template)Document4 pagesHDD Calculation (Template)bebas_amarah87% (15)

- 24in Pipeline Buoyancy CalculationDocument1 page24in Pipeline Buoyancy CalculationAdaghara67% (3)

- Pipe Lowering CalculationDocument8 pagesPipe Lowering CalculationMochamad Safarudin50% (4)

- Calculation Curvature HDDDocument1 pageCalculation Curvature HDDSeng HeangNo ratings yet

- Pipeline Anchor Length CalculationsDocument3 pagesPipeline Anchor Length Calculationslsatchithananthan100% (3)

- Hydraulic Fracturing in Soil During HDDDocument12 pagesHydraulic Fracturing in Soil During HDDamir_hayfaNo ratings yet

- HDDDocument13 pagesHDDAshok SwamiNo ratings yet

- HDD Calculation - CH 15Document23 pagesHDD Calculation - CH 15Binay Kumar100% (1)

- Upheaval Buckling CalculationDocument6 pagesUpheaval Buckling Calculationheldermanuel100100% (2)

- Upheval Bukling CalculationDocument2 pagesUpheval Bukling Calculationbaghelrohit100% (7)

- HDD CalculationDocument5 pagesHDD Calculationiwan100% (1)

- Pipeline Lowering CalculationDocument5 pagesPipeline Lowering CalculationRagh88% (16)

- HDD Calc As Per PRCDocument8 pagesHDD Calc As Per PRClive4sankar50% (2)

- HDD DesignDocument7 pagesHDD Designanon_824061466No ratings yet

- Buried Pipe Design (Flexible) 1Document9 pagesBuried Pipe Design (Flexible) 1Ah Leng Lau100% (2)

- HDD Capacity CalculationDocument2 pagesHDD Capacity CalculationUghojor ElohoNo ratings yet

- Pipeline Buoyancy AnalysisDocument12 pagesPipeline Buoyancy AnalysisbonnicoNo ratings yet

- Upheaval Buckling PipelineDocument11 pagesUpheaval Buckling PipelineRYZKI EFENDI SIMANULANGNo ratings yet

- Elastic Bend Calculation-CR4Document8 pagesElastic Bend Calculation-CR4Sankar CdmNo ratings yet

- Permissible Elastic Bend Limit CalculationDocument4 pagesPermissible Elastic Bend Limit Calculationheldermanuel100No ratings yet

- Buried PipelinesDocument93 pagesBuried PipelinesVasant Kumar VarmaNo ratings yet

- Buoyancy CalculationDocument2 pagesBuoyancy CalculationHerruSetiawanNo ratings yet

- Buried Pipe Analysis PDFDocument6 pagesBuried Pipe Analysis PDFPer Bagus Handoko50% (2)

- HDD Installation CalculationsDocument4 pagesHDD Installation Calculationslive4sankar100% (1)

- Pipeline Stability and Weight Coating CalculationDocument4 pagesPipeline Stability and Weight Coating CalculationAdaghara67% (3)

- Sample Report - API RP 1102 - HighwayDocument5 pagesSample Report - API RP 1102 - Highwayaliyildizx17730No ratings yet

- Horizontal Directional Drilling ToolboxDocument2 pagesHorizontal Directional Drilling Toolboxravneet7750% (4)

- Pipeline Design Calculations PDFDocument21 pagesPipeline Design Calculations PDFjimallen21281% (21)

- Wheel Load AnalysisDocument8 pagesWheel Load Analysistsoheil100% (2)

- Design Radius of Curvature - Horizontal Directional DrillingDocument6 pagesDesign Radius of Curvature - Horizontal Directional DrillingBenaknaik S GajannavarNo ratings yet

- River Crossing Pipeline - PaperDocument6 pagesRiver Crossing Pipeline - PaperJoko NugrohoNo ratings yet

- Virtual Anchor Length - KBRDocument22 pagesVirtual Anchor Length - KBRSammar Adhikari100% (2)

- Buried Pipe Analysis Based On ALADocument6 pagesBuried Pipe Analysis Based On ALADonald.K0% (1)

- Skirt Support TrialDocument11 pagesSkirt Support TrialAbhishek Nag0% (1)

- Estimation Software For Presure VesselDocument36 pagesEstimation Software For Presure VesselKarthikeyan Shanmugavel0% (1)

- Lifting LugDocument8 pagesLifting LugAzwan ShahNo ratings yet

- Estimation Software For Presure VesselDocument37 pagesEstimation Software For Presure VesselalexnomitaNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsIbrahim El SharNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsAnonymous 9iK0i8h0dPNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsAnonymous nwByj9L100% (2)

- Wall THK Calculation Asme b31.4Document5 pagesWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- Foot Design (Amine Absorber) Rev.0Document9 pagesFoot Design (Amine Absorber) Rev.0taz_taz3No ratings yet

- Weight Estimation of Vessels AppsDocument28 pagesWeight Estimation of Vessels AppsAlvin Smith60% (5)

- Davit CalcDocument6 pagesDavit Calcrustamriyadi100% (1)

- 6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3Document8 pages6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3abdulNo ratings yet

- E4.5 Flange Cover CalcDocument10 pagesE4.5 Flange Cover CalcTanCM100% (1)

- Combine Footing by IS 456:2000Document18 pagesCombine Footing by IS 456:2000Huzaifa NakhwaNo ratings yet

- Why Coiled Tubing Fails and HowDocument56 pagesWhy Coiled Tubing Fails and HowArdita S IrwanNo ratings yet

- DRAFT - : Fracture Properties and Fatigue Cracking Resistance of Asphalt BindersDocument58 pagesDRAFT - : Fracture Properties and Fatigue Cracking Resistance of Asphalt BindersEsra'a AlhajNo ratings yet

- Horizontal Distribution of TemperatureDocument12 pagesHorizontal Distribution of TemperatureS.H EnterpriseNo ratings yet

- Simple Procedure For Seismic Analysis of Liquid-Storage TanksDocument5 pagesSimple Procedure For Seismic Analysis of Liquid-Storage TanksbcvdocuNo ratings yet

- Liquid-Liquid Phase Equilibria For Soybean Oil MethanolysisDocument6 pagesLiquid-Liquid Phase Equilibria For Soybean Oil Methanolysisbrambrams98264No ratings yet

- A Novel Forming Technology For Tailor-Welded BlanksDocument9 pagesA Novel Forming Technology For Tailor-Welded BlanksGabipmNo ratings yet

- SBT 200 Plant Ecologykenyatta UniversityDocument85 pagesSBT 200 Plant Ecologykenyatta Universityvincent onsaseNo ratings yet

- FRC1Document49 pagesFRC1Pavan Kalyan YadavNo ratings yet

- EnergySRP Forms MatchingDocument2 pagesEnergySRP Forms Matchingeiad-mahmoudNo ratings yet

- Unclassified Ad Number Limitation Changes TODocument36 pagesUnclassified Ad Number Limitation Changes TORuben's OscarNo ratings yet

- Shrijee Fluidized Bed Sugar Dryer (FBD) Flyer-NewDocument2 pagesShrijee Fluidized Bed Sugar Dryer (FBD) Flyer-NewbkarakoseNo ratings yet

- Mechanics of Deformable BodiesDocument106 pagesMechanics of Deformable Bodiesgilbert casinoNo ratings yet

- C-SCP360H38B R410aDocument8 pagesC-SCP360H38B R410aRaúl RodríguezNo ratings yet

- Skin Friction and Pile DesignDocument7 pagesSkin Friction and Pile DesignNaveen RNo ratings yet

- Photometry Training EnglishDocument79 pagesPhotometry Training EnglishkholisenangNo ratings yet

- Lesson 1 - Solid, Liquid, and Gas (Grade 3)Document26 pagesLesson 1 - Solid, Liquid, and Gas (Grade 3)Christian TabalanNo ratings yet

- CH 7.4 - PPT - To Students - 25-3-2023Document13 pagesCH 7.4 - PPT - To Students - 25-3-2023jujuNo ratings yet

- Night Vision SystemDocument12 pagesNight Vision SystemAnshul Aggarwal100% (1)

- Pinnacle Alloys E9018-M Code and Specification DataDocument2 pagesPinnacle Alloys E9018-M Code and Specification DataPutra Panca WardhanaNo ratings yet

- Primal Et Al. 2004Document13 pagesPrimal Et Al. 2004Francisco OppsNo ratings yet

- API 570 API 571 QuestionsDocument4 pagesAPI 570 API 571 QuestionsThomas Tucker100% (1)

- Preformulati ON: By: Abhishek D. DeshmukhDocument33 pagesPreformulati ON: By: Abhishek D. DeshmukhSuraj WasankarNo ratings yet

- Euler-Bernoulli Beam Theory - Simple English Wikipedia, The Free EncyclopediaDocument2 pagesEuler-Bernoulli Beam Theory - Simple English Wikipedia, The Free EncyclopediaCordy Jourvel Itoua-TseleNo ratings yet

- Atomic Force Microscopy: Basic PrinciplesDocument10 pagesAtomic Force Microscopy: Basic PrinciplesGiovanni DoveNo ratings yet

- 02.01.24 SR - Star Co-Sc (Model A, B&C) Jee Main Gtm-5 (N) - QPDocument20 pages02.01.24 SR - Star Co-Sc (Model A, B&C) Jee Main Gtm-5 (N) - QPReddyNo ratings yet

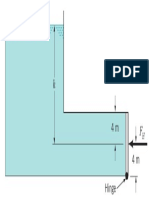

- Fluid Statics: F I G U R E P2.69Document1 pageFluid Statics: F I G U R E P2.69andres bernalNo ratings yet

- Observation On Design and Drawing of Widening Box Culverts (Straight & Skew) and Miscellaneous Drawings Reg LTR DT - 31-07-2020Document14 pagesObservation On Design and Drawing of Widening Box Culverts (Straight & Skew) and Miscellaneous Drawings Reg LTR DT - 31-07-2020Vikas SharmaNo ratings yet

- FEM Question Bank PDFDocument23 pagesFEM Question Bank PDFedla rajuNo ratings yet

- CH - 12 ElectricityDocument24 pagesCH - 12 ElectricityJency JohnsonNo ratings yet

- Fenomenos SuperficieDocument2 pagesFenomenos SuperficieSimón CalderaNo ratings yet