Professional Documents

Culture Documents

Nitrating Methyl Benzoate

Uploaded by

Ostap 奧斯塔普Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nitrating Methyl Benzoate

Uploaded by

Ostap 奧斯塔普Copyright:

Available Formats

Ostap Hlynskyy

CHM 3006

Nitrating Methyl Benzoate: Electrophilic Aromatic Substitution

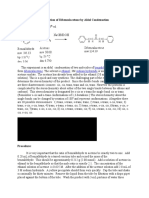

Abstract: The purpose of this experiment was to synthesize methyl nitro benzoate from methyl benzoate, concentrated HNO3, and concentrated H2SO4 via an electrophilic aromatic substitution reaction. The HNO3 and H2SO4 were combined to form a nitrating solution, which was mixed with a mixture of methyl benzoate and H2SO4. The product was then isolated and recrystallized using 95% ethanol. Following recrystallization, melting point was used to identify and characterize the product of the reaction. The melting point was determined to be 75C, which indicates metaregiochemistry. The percent recovery of this reaction for the recrystallized product was 26.42%. Introduction: Benzene rings are components of many important natural products and other useful organic compounds. Therefore, the ability to put substituents on a benzene ring, at specific positions relative to each other, is a very important factor in synthesizing many organic compounds. The two main reaction types used for this are both substitutions: Electrophilic Aromatic Substitution (EAS) and Nucleophilic Aromatic Substitution (NAS). The benzene ring itself is electron-rich, which makes NAS difficult, unless there are a number of strongly electron-withdrawing substituents on the ring. EAS, on the other hand, is a very useful method for putting many different substituents on a benzene ring, even if there are other substituents already present. In this experiment we will put a nitro (NO2) group on a benzene ring, which already has an ester group, attached to it (methyl benzoate). The actual electrophile in the reaction is the nitronium ion (NO2+), which is generated in the reaction mixture using concentrated nitric acid and concentrated sulfuric acid. Reaction scheme:

The electronic nature of the substituent also directs the position of electrophilic substitution. There are three different regioisomers for disubstituted aromatic rings: orth, meta, and para.

O C OCH3 HNO3 / H2SO4

O C OCH3

NO2

Methyl Benzoate MW = 136.15 g/mol Density = 1.0837 g/cm B.P. = 198-199 oC M.P. = -12 oC Methyl m-nitrobenzoate MW = 181.14 g/mol B.P. = 279 oC M.P. = 78-80 oC

Results and Discussion: Procedure Part 1 Place equal volumes of ice and tap water into a 400-mL beaker so that the beaker is approximately 75% full. Then, prepare chilled by pouring approximately 60 mL distilled water into a 125-mL Erlenmeyer flask. Place the flask into the ice-water bath. Part 2 Label two 15 x 125-mm test tubes nitric acid and sulfuric acid, respectively. Transfer 1 mL concentrated nitric acid into the tube labeled nitric acid. Then, transfer 1 mL concentrated sulfuric acid into the tube labeled sulfuric acid. Chill both the test tubes with the acids in them in the ice-water bath for 15 minutes. Then, use a Pasteur pipet to very slowly add the cold sulfuric acid drop by drop into the cold nitric acid. Swirl the reaction mixture after every three drops are added. After adding all the sulfuric acid to the nitric acid, allow the nitrating solution to stand in the ice-water bath for 10 minutes. Part 3 Place approximately 1 mL methyl benzoate into a 50-mL Erlenmeyer flask and add 2.0 mL concentrated sulfuric acid. Clamp the flask containing the mixture to a support stand. Lower the flask into the ice-water bath for 5 minutes, being sure to prevent the bath water from entering the reaction flask. After the 5 minutes are up, use a Pasteur pipet to slowly add the nitrating solution in the test tube to the Erlenmeyer flask containing the methyl benzoate and sulfuric acid. After all the nitrating solution has been added, allow the mixture to stand in the ice-water bath for 30-45 minutes. Make sure you swirl the flask every 5 minutes. After the 30-45 minutes are up, add 20 mL chilled water to a 100-mL beaker. Slowly and carefully add the cold reaction mixture, with stirring, to the chilled water. Then, allow the chilled solution to stand 5-10 minutes to complete crystal formation. Part 4 Isolating, Purifying, and Characterizing the Product Filter the reaction mixture via vacuum filtration. Wash the crystals with approximately 20 m L of chilled water in order to remove any residual acid. Then, allow your product to air dry in the filter funnel for 10 minutes. Then, put your product crystals into a 25-mL Erlenmeyer flask and add 10 mL of 95% ethanol. Swirl the flask to mix. Heat the flask in a steam bath until the crystals are in solution and the solution boils. Then remove the flask from the sand bath and allow it to cool to room temperature. Add ice-cold ethanol to the flask and swirl to loosen the crystals. Then filter the crystals using vacuum filtration. Part 5 Determine the melting point of recrystallized methyl nitrobenzoate. Data & Calculations Mass of crude methyl nitrobenzoate: 0.895g Mass of recrystallized methyl nitrobenzoate: 0.381g Percent yield: 26.42%

Melting point of recrystallized product: 75C Literature Value: 78 - 80C

Theoretical Yield Mass of methyl benzoate used = (1 mL methyl benzoate)(1.0837 g/cm)(1 cm3/mL) = 1.0837g Theoretic yield = [(1.0837g methyl benzoate)(1mol methyl benzoate)(1mol methyl nitrobenzoate)(181.13g methyl nitrobenzoate)]/[(136.15g methyl benzoate)(1mol methyl benzoate)(1 mol methyl nitrobenzoate)] = 1.442 g methyl nitrobenzoate Percent Yield For recrystallized product = (mass of recrystallized methyl nitrobenzoate)/(theoretical yield) 100% = (0.381g methyl nitrobenzoate)/(1.442g methyl nitrobenzoate) 100% = 26.42% Crystallization losses are one source of error. Nitrations are energetic reactions under harsh conditions. Consequently, by products can readily form which decrease the overall yield of the reaction. In this lab procedure one source of error is that not all of crude product was used in the recrystallization, because of transfer losses. Another source of error could have been that some impurities could have crystalized out of solution during recrystallization slightly lowering the melting point. Conclusion: The electrophilic aromatic substitution reaction between methyl benzoate and a nitrating solution of sulfuric and nitric acids was successful and yielded methyl m-nitrobenzoate. The percent yield of the recrystallized product was 26.42%. The melting point of the recrystallized product was 75C. This was then compared with a data table given in the experiment in order to determine the regiochemistry of the obtained product. The observed melting point was close to the literature value of 78 - 80C for the meta-substituted product. Therefore, analysis of the melting point determined that the product was methyl meta-nitrobenzoate, as could be predicted. Since the NO2 group t is meta-director.

Questions: 1. (a) The percent yield of my product was 26.42%. (b) The melting point of my product was 75C. (c) The observed melting point of 75C was most closely related to the literature melting point of 7880C for a meta substitututed product. Therefore, my product has a meta- regiochemistry. The meta-product forms because the ortho- and para- products both have very unstable resonance forms with 2 positive charges next to each other. The two positive charges right next to one another cause the resonance forms to be unstable, so ortho- and para- substituted products do not form in this reaction. The meta- position is electron-rich, and thus reacts best with the NO2 group to form methyl m-nitrobenzoate. (d) The structure of my product is:

2. The resonance forms for the arenium ion formed during this reaction are as follows:

3. The first nitration proceeds much faster than the second two because the first NO2 group to be added is added to the isolated toluene. The methyl group on the benzene ring is an activating group. It causes the benzene ring to be more electron rich and thus, have a high reactivity. CH3 is an ortho-para activator. So, the first NO2 group adds to the toluene in the para-position in

order to avoid steric crowding from the methyl group. The toluene has now been converted to para- nitrotoluene. The NO2 group that is now on the benzene ring is a deactivating group, and causes the benzene ring to be not nearly as reactive as it was.

You might also like

- Nitration of Methyl BenzoateDocument7 pagesNitration of Methyl Benzoateclcontact15100% (2)

- Nitration of Methyl BenzoateDocument3 pagesNitration of Methyl BenzoateDaniel McDermottNo ratings yet

- Nitration of Methyl BenzoateDocument7 pagesNitration of Methyl BenzoateJanel Pauline G. Chua100% (1)

- Nitration of Methyl Benzoate (Organic Chemistry)Document6 pagesNitration of Methyl Benzoate (Organic Chemistry)Run Xiang Ang100% (2)

- Nitration of Methyl BenzoateDocument4 pagesNitration of Methyl BenzoateMariel MendozaNo ratings yet

- ALDOL Synth - DibenzalacetoneDocument7 pagesALDOL Synth - DibenzalacetoneJames CookeNo ratings yet

- Nitration of Methyl BenzoateDocument3 pagesNitration of Methyl BenzoateKarlo PintorNo ratings yet

- NITRATION OF METHYL BENZOATE (ELECTROPHILIC AROMATIC SUBSTITUITION - Idayu Razali - Academia - Edu PDFDocument7 pagesNITRATION OF METHYL BENZOATE (ELECTROPHILIC AROMATIC SUBSTITUITION - Idayu Razali - Academia - Edu PDFyawsNo ratings yet

- Aldol Condensation Reaction Lab ReportDocument4 pagesAldol Condensation Reaction Lab ReportAvril Watson100% (3)

- Aldol CondensationDocument10 pagesAldol CondensationVanessa Nguyen0% (1)

- Experiment 32Document14 pagesExperiment 32Morgan Elizabeth Lepley100% (6)

- Organic Chemistry Practical 301Document22 pagesOrganic Chemistry Practical 301geetesh waghela100% (1)

- Formal Report Synthesis of An Alkyl HalideDocument7 pagesFormal Report Synthesis of An Alkyl HalideFerdinand Tamayo Cayabyab Jr.No ratings yet

- Chemistry Lab Report: III Formation and Use of An Organometallic Reagent: Synthesis of Triphenylmethanol. " The Grignard's Reaction "Document5 pagesChemistry Lab Report: III Formation and Use of An Organometallic Reagent: Synthesis of Triphenylmethanol. " The Grignard's Reaction "Rajat NairNo ratings yet

- Aldol Condensation LabDocument6 pagesAldol Condensation LabChristian AmpeNo ratings yet

- Objectives: FIGURE A: Example of Coordination CompoundsDocument7 pagesObjectives: FIGURE A: Example of Coordination CompoundsNurul izzatiNo ratings yet

- Sodium Borohydride Reduction of Cyclohex PDFDocument8 pagesSodium Borohydride Reduction of Cyclohex PDFhahadindongNo ratings yet

- NaBH4 Reduction of CyclohaxanoneDocument5 pagesNaBH4 Reduction of Cyclohaxanonenurul1110No ratings yet

- Aldol Condensation DiscussionDocument3 pagesAldol Condensation DiscussionDenisse Watt Cuarteros100% (8)

- CHY449 Synthesis of Metal AcacsDocument10 pagesCHY449 Synthesis of Metal Acacsoogulay100% (1)

- The Friedel-Crafts Reaction PDFDocument7 pagesThe Friedel-Crafts Reaction PDFIsaac Nicholas NotorioNo ratings yet

- CHM557 Exp 3Document22 pagesCHM557 Exp 3syafNo ratings yet

- Experiment 8 The Preparation of AcetanlideDocument12 pagesExperiment 8 The Preparation of AcetanlideRadhwanNo ratings yet

- Organic ChemistryDocument8 pagesOrganic ChemistryAndré Brincat100% (1)

- Aldol CondensationDocument5 pagesAldol CondensationKatherine McLarneyNo ratings yet

- Robinson Annulation Reaction of NItrochalconeDocument10 pagesRobinson Annulation Reaction of NItrochalconeMohd Nakirudin Muhamad NorNo ratings yet

- Experiment 2 Sodium Borohydride Reduction of CyclohexanoneDocument6 pagesExperiment 2 Sodium Borohydride Reduction of CyclohexanoneSarah HannisNo ratings yet

- Exercise No. 8Document11 pagesExercise No. 8Charlez UmerezNo ratings yet

- Preparation of Mono-Nitro TolueneDocument6 pagesPreparation of Mono-Nitro TolueneMuhammad Shahood JamalNo ratings yet

- Preparation of DibenzalacetoneDocument4 pagesPreparation of DibenzalacetoneMichael E G Byers100% (1)

- Formal LabDocument4 pagesFormal Labljeanja2100% (1)

- Di Benz Al AcetoneDocument12 pagesDi Benz Al Acetonevicky_law_2No ratings yet

- FAR 113 Organic Chemistry: Practical 1 Preparation of P-NitroacetanilideDocument10 pagesFAR 113 Organic Chemistry: Practical 1 Preparation of P-NitroacetanilideHuii Jiing Wong100% (2)

- 2 BenzophenoneDocument3 pages2 BenzophenoneElizabeth LawsonNo ratings yet

- Lab C-Methyl OrangeDocument4 pagesLab C-Methyl Orangetopikamew100% (1)

- Determination of Fluoride Ion Using An Ion Selective ElectrodeDocument4 pagesDetermination of Fluoride Ion Using An Ion Selective ElectrodeHuyentrang Nguyen100% (1)

- Exp 55 Lab ReportDocument8 pagesExp 55 Lab Reportkarlymae67% (6)

- Experiment 3 Redox Titration Percent Purity AnalysisDocument5 pagesExperiment 3 Redox Titration Percent Purity AnalysisnanaNo ratings yet

- CE - Experiment 2 Extraction With Acid and AlkalineDocument8 pagesCE - Experiment 2 Extraction With Acid and AlkalineWeiChingNo ratings yet

- Oxidation of Cyclohexanol To CyclohexanoneDocument5 pagesOxidation of Cyclohexanol To CyclohexanoneChandrani Chakraborti100% (1)

- The Nitration of AcetanilideDocument2 pagesThe Nitration of AcetanilideSashaNo ratings yet

- Preparation of P-Nitroacetanilide - Dotsha J. RaheemDocument13 pagesPreparation of P-Nitroacetanilide - Dotsha J. RaheemDotsha Raheem83% (12)

- EXPERIMENT 5 Robinson Annulation ReactionDocument13 pagesEXPERIMENT 5 Robinson Annulation ReactionMuhammad Amirul Afifi100% (1)

- Experiment 1 OrgChem Lab 2Document5 pagesExperiment 1 OrgChem Lab 2John Harvey Santos100% (2)

- Determination of Fluoride Concentration Using Ion Selective ElectrodeDocument7 pagesDetermination of Fluoride Concentration Using Ion Selective ElectrodeAmanda WangNo ratings yet

- Lab 1 Report - Diels-Alder ReactionDocument3 pagesLab 1 Report - Diels-Alder Reactionlucyli115100% (2)

- Determination of Acid Content of Vinegars and Wines Lab ReportDocument3 pagesDetermination of Acid Content of Vinegars and Wines Lab ReportAlleia Mae Urbano MazoNo ratings yet

- Formal Report For Synthesis of An Alkyl HalideDocument5 pagesFormal Report For Synthesis of An Alkyl HalideLovelyn Marie Morada Nievales80% (5)

- Experiment 2 chm556 Organic ChemistryDocument8 pagesExperiment 2 chm556 Organic ChemistryAmar SafwanNo ratings yet

- CHEM 334L - Conductance of Solutions - Estimating K For A Weak AcidDocument4 pagesCHEM 334L - Conductance of Solutions - Estimating K For A Weak Acidfdobonat613100% (1)

- Factors Affecting The Relative Rates of Electrophilic Aromatic Substitution ReactionsDocument5 pagesFactors Affecting The Relative Rates of Electrophilic Aromatic Substitution ReactionsXyrell Claude Monta100% (2)

- Unit 5 Formal Lab ReportDocument5 pagesUnit 5 Formal Lab Reportapi-359422860No ratings yet

- Lab+Manual+2014 Cbe 2207Document63 pagesLab+Manual+2014 Cbe 2207Krishnan MohanNo ratings yet

- Grinard Reagent LabDocument4 pagesGrinard Reagent LabZach McCartyNo ratings yet

- EXP4 The Diels Alder ReactionsDocument3 pagesEXP4 The Diels Alder ReactionsLaura GuidoNo ratings yet

- Lab Activity 5Document5 pagesLab Activity 5Jasmin CeciliaNo ratings yet

- Aldol CondensationDocument2 pagesAldol CondensationGian Wyatt Gamboa100% (1)

- Experimental Inorganic/Physical Chemistry: An Investigative, Integrated Approach to Practical Project WorkFrom EverandExperimental Inorganic/Physical Chemistry: An Investigative, Integrated Approach to Practical Project WorkNo ratings yet

- Experiment 6: Nitration of Methyl Benzoate (Electrophilic Aromatic Substitution)Document5 pagesExperiment 6: Nitration of Methyl Benzoate (Electrophilic Aromatic Substitution)Noor Azizah ZakariaNo ratings yet

- Methyl BenzoateDocument6 pagesMethyl BenzoateAnthony Lazarus MassaNo ratings yet

- دهانات الإيبوكسي الخالي من المذيب لخزانات ومواسير مياه الشرب-eDocument9 pagesدهانات الإيبوكسي الخالي من المذيب لخزانات ومواسير مياه الشرب-eabdelnasser hasanNo ratings yet

- Lesson - 03 - Focus On Plastic FootprintsDocument59 pagesLesson - 03 - Focus On Plastic FootprintsMariaNo ratings yet

- Edit Resume - My Perfect Resume 1Document1 pageEdit Resume - My Perfect Resume 1Ferid MemmedzadeNo ratings yet

- Employee Engagement - Korn - Ferry InternationalDocument2 pagesEmployee Engagement - Korn - Ferry InternationalЯрослава ЛояничNo ratings yet

- Prac Res Q2 Module 8Document12 pagesPrac Res Q2 Module 8Benicel Lane De VeraNo ratings yet

- Prospectus: 1 ReservationsDocument8 pagesProspectus: 1 ReservationsvarunNo ratings yet

- Lesson From Seveso ItalyDocument48 pagesLesson From Seveso ItalyBilal ZamanNo ratings yet

- Week 4 and 5 Non-Verbal Communication: 4.1 The Importance of Nonverbal CommunicationDocument8 pagesWeek 4 and 5 Non-Verbal Communication: 4.1 The Importance of Nonverbal CommunicationNovilia FriskaNo ratings yet

- BYRGMv 3Document30 pagesBYRGMv 3tajsisNo ratings yet

- Practice For Group Work Week 2 Case 2.1 - Assigning Plants To Products (Better Products Company)Document2 pagesPractice For Group Work Week 2 Case 2.1 - Assigning Plants To Products (Better Products Company)Thu TrangNo ratings yet

- 6480 49 35800 2 10 20230801Document12 pages6480 49 35800 2 10 20230801samsidar nidarNo ratings yet

- Word Formation - Open Cloze Exercises Unit 1Document2 pagesWord Formation - Open Cloze Exercises Unit 1Fatima Luz RuizNo ratings yet

- Research Methodology and Biostatistics - Syllabus & Curriculum - M.D (Hom) - WBUHSDocument5 pagesResearch Methodology and Biostatistics - Syllabus & Curriculum - M.D (Hom) - WBUHSSumanta KamilaNo ratings yet

- 30 Tips For Indesign Users enDocument38 pages30 Tips For Indesign Users enMoo MNo ratings yet

- Generative NLP Robert Dilts PDFDocument11 pagesGenerative NLP Robert Dilts PDFCristina LorinczNo ratings yet

- Topic 2.9 WorksheetDocument3 pagesTopic 2.9 WorksheethaniaNo ratings yet

- Baylan: Water Meters With M-BusDocument2 pagesBaylan: Water Meters With M-Busamr ibrahimNo ratings yet

- Compare and ContrastDocument9 pagesCompare and Contrastmai mohamedNo ratings yet

- Test - Reading Explorer 3 8A - QuizletDocument4 pagesTest - Reading Explorer 3 8A - QuizletTatjana Modea SibulNo ratings yet

- Abstract On Face Recognition TechnologyDocument1 pageAbstract On Face Recognition TechnologyParas Pareek60% (5)

- What Is Emergency Lighting Circuit DiagramDocument14 pagesWhat Is Emergency Lighting Circuit DiagramjackNo ratings yet

- Gravity Distribution Systems: A System Design and ConstructionDocument40 pagesGravity Distribution Systems: A System Design and ConstructionTooma DavidNo ratings yet

- Strategic Management Text and Cases 7th Edition Dess Solutions ManualDocument25 pagesStrategic Management Text and Cases 7th Edition Dess Solutions ManualNataliePowelljdmb100% (32)

- Basic Science AssigDocument5 pagesBasic Science AssigdomromeoNo ratings yet

- Weekly Home Learning Plan (Q3) Self-Learning Module 4 (Week 5)Document2 pagesWeekly Home Learning Plan (Q3) Self-Learning Module 4 (Week 5)Richie MacasarteNo ratings yet

- NDX DolsonDocument67 pagesNDX DolsonMahanta BorahNo ratings yet

- GE 4 MMW in A NutshellDocument7 pagesGE 4 MMW in A NutshellPEACH CATHERINE MANOTANo ratings yet

- Venkateshetal 2003Document56 pagesVenkateshetal 2003Gilang KemalNo ratings yet

- Reduced Adjective ClausesDocument1 pageReduced Adjective Clausesmetoeflgrammar100% (1)

- 302 Decision Science Question - PaperDocument3 pages302 Decision Science Question - Paperajay taleNo ratings yet