Professional Documents

Culture Documents

Chimney Calculation Sheet

Uploaded by

Vinoth RajendraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chimney Calculation Sheet

Uploaded by

Vinoth RajendraCopyright:

Available Formats

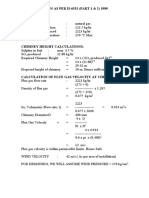

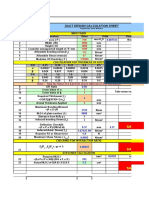

CHIMNEY DESIGN CALCULATION : I.S.

6533 CUSTOMER : CHIMNEY DIAMETER-TOP D1(IN cm) CHIMNEY DIA BOTTOM BD (IN cm) CHIMNEY HEIGHT TOTAL H( IN cm) CORROSION ALLOWANCE ALLOWABLE BEARING ON FOUNDATION Ff( IN KG/cm2) ALLOWABLE BENDING STRESS-BEARING PLATE Fbp( IN KG/cm2) DIA D1 ( IN cm) 132 132 132 132 176 CODE PAGE FIRST CARBON TECHNOLOGIES PVT LTD,INDIA : 132 : 220 : 4600 : MM 3 : 20 : 1650 DIA D1' (IN cm) 132 132 132 176 220 D AVG (IN cm) 132 132 132 154 198 SECTIONAL HEIGHT (IN cm) 960 960 920 880 880 SHELL THICKNESS (IN MM) ( IN cm) 10 1.00 12 1.20 16 1.60 20 2.00 22 2.20 1 OF 14

SEGMENT I SEGMENT II SEGMENT III SEGMENT IV SEGMENT V

DESIGN OF SEGMENT I DESIGN WIND SPEED (Vz)= WHERE Vb X K1 X K2 X K3 K1= K2= K3= VB= PROBABILITY FACTOR= TERRAIN FACTOR= TOPOGRAPHY FACTOR = BASIC WIND SPEED= Vz = DESIGN WIND PRESSURE PZ = PZ = PZ = WIND FORCE WHERE FL 0.6xVzxVz 1457.11104 N/M2 0.014862533 Kg/cm2 = Cf= Ae= Ae= 1.1 = WIND FORCE FL = Cf x Ae x Pz x 1.1 FORCE COEFFICIENT EFFECTIVE AREA = 49.28 METRES/SEC NOTE: I N/M2 CONVERSION FACTOR = 0.0000102 KG /cm2 -----IS 875(3)1 1.12 1 44 m/s 1987

98039.2157

(Pz= WIND PRESSURE) 1.2 AVG DIA x HEIGHT 126720 cm2

10% INCREASED TO TAKE CARE OF WIND PRESSURE ON CAGE AND LADDER 2486.061774 Kg

PAGE A) BENDING MOMENT Mx = Mx= B) MODULUS OF SECTION Z= WHERE .77T x D x D T= SHELL THICKNESS W/O CORROSION ALLOWANCE(in cm) = 132 0.7 FL(H-Y)/2 1193309.652 KG cm where, H= Y= HEIGHT OF CHIMNEY in cm SECTION HEIGHT in cm

2 OF 14

BOTTOM DIA(D) ( in cm)=

Z= C) ACTUAL BENDING STRESS FB= = = = D) ACTUAL COMPRESSION STRESS Fc= WHERE G= G= G/A Mx/Z

9391.536 cm^3

127.0622454 12457082.88 12.45708288

KG/cm^2 KG/cm^2 Pa Mpa

DEAD WEIGHT OF SEGMENT 3099.85824 KGS

D1= D2=

132 cm 130 cm

A=

AREA OF SECTION BOTTOM W/O CORROSION ALLOWANCE 288.5974 cm2

A=

FC = = =

10.74111631 KG/cm2 1053050.619 Pa 1.053050619 Mpa

E) TOTAL COMBINED STRESS

PAGE Sc = = REFER TABLE 3 he/D< 20 D/t<140 126 94.5 Fb+ Fc 13.5101335 Mpa : I.S. 6533

3 OF 14

MAXIMUM PERMISSIBLE COMBINED STRESS Mpa WITH TEMPERATURE CORRECTION FACTOR ALLOWABLE COMBINED STRESS a= STABILITY CHECK 1.6 (Fb+ Fc) - 0.9 xFc < 1.8 x a 20.66846804 (CALCULATED) < 170.1 Mpa (ALLOWABLE)

DESIGN OF SEGMENT II DESIGN WIND SPEED (Vz)= WHERE Vb X K1 X K2 X K3 K1= K2= K3= VB= PROBABILITY FACTOR= TERRAIN FACTOR= TOPOGRAPHY FACTOR = BASIC WIND SPEED= Vz = DESIGN WIND PRESSURE PZ = PZ = PZ = WIND FORCE WHERE F 0.6xVzxVz 1431.20736 N/M2 0.014598315 Kg/cm2 = Cf= Ae= Ae= 1.1 = WIND FORCE FL = Cf x Ae x Pz x 1.1 FORCE COEFFICIENT EFFECTIVE AREA = 48.84 METRES/SEC NOTE: I N/M2 CONVERSION FACTOR = 0.0000102 KG /cm2 -----IS 875(3)1 1.11 1 44 m/s 1987

(Pz= WIND PRESSURE) 1.2 AVG DIA x HEIGHT 253440 cm2

10% INCREASED TO TAKE CARE OF WIND PRESSURE ON CAGE AND LADDER 4883.732003 Kg

A)

BENDING MOMENT Mx = FL(H-Y)/2 4688382.723 KG cm where, H= Y= HEIGHT OF CHIMNEY in cm SECTION HEIGHT in cm

PAGE

4 OF 14

Mx= B) MODULUS OF SECTION Z= WHERE .77T x D x D

T=

SHELL THICKNESS W/O CORROSIONALLOWANCE(in cm) = 132.00

0.9

BOTTOM DIA(D) ( IN cm)=

Z= C) ACTUAL BENDING STRESS FB= = = = D) ACTUAL COMPRESSION STRESS Fc= WHERE G= G= G/A Mx/Z

12074.832 cm3

388.2772632 38066398.35 38.06639835

KG/cm2 KG/cm2 Pa Mpa

DEAD WEIGHT OF SEGMENT 6814.008998 KGS

D1= D2=

132 cm 129.6 cm

A=

AREA OF SECTION BOTTOM W/O CORROSION ALLOWANCE 370.4886 cm2 370.4886

PAGE

5 OF 14

A=

FC = = =

18.39195322 KG/cm2 1803132.668 Pa 1.803132668 Mpa

E) TOTAL COMBINED STRESS Sc = = REFER TABLE 3 he/D< 20 D/t<140 108 81 Fb+ Fc 39.86953102 Mpa : I.S. 6533

MAXIMUM PERMISSIBLE COMBINED STRESS Mpa WITH TEMPERATURE CORRECTION FACTOR ALLOWABLE COMBINED STRESS a= STABILITY CHECK 1.6 (Fb+ Fc) - 0.9 xFc < 1.8 x a 62.16843023 (CALCULATED) DESIGN OF SEGMENT III DESIGN WIND SPEED (Vz)= WHERE Vb X K1 X K2 X K3 K1= K2= K3= VB= PROBABILITY FACTOR= TERRAIN FACTOR= TOPOGRAPHY FACTOR = BASIC WIND SPEED= Vz = -----< 145.8 Mpa (ALLOWABLE)

IS 875(3)1 1.09 1 44 m/s

1987

47.96 METRES/SEC

DESIGN WIND PRESSURE PZ = PZ = PZ = WIND FORCE WHERE F

0.6xVzxVz 1380.09696 N/M2 0.014076989 Kg/cm2 = Cf= Ae= Ae= 1.1 = Cf x Ae x Pz x 1.1 FORCE COEFFICIENT EFFECTIVE AREA =

NOTE: I N/M2

CONVERSION FACTOR = 0.0000102 KG /cm2

PAGE

6 OF 14

(Pz= WIND PRESSURE) 1.2 AVG DIA x HEIGHT 374880 cm2

10% INCREASED TO TAKE CARE OF WIND PRESSURE ON CAGE AND LADDER 6965.879756 Kg

WIND FORCE

FL

A)

BENDING MOMENT Mx = FL(H-Y)/2 12259948.37 KG cm where, H= Y= HEIGHT OF CHIMNEY in cm SECTION HEIGHT in cm

Mx= B) MODULUS OF SECTION Z= WHERE .77T x D x D

T=

SHELL THICKNESS W/O CORROSION ALLOWANCE(in cm) = 132

1.3

BOTTOM DIA(D) ( IN cm)=

Z= C) ACTUAL BENDING STRESS FB= = = = D) ACTUAL COMPRESSION STRESS Fc= G/A Mx/Z

17441.424 cm3

702.9212965 68913852.6 68.9138526

KG/cm2 KG/cm2 Pa Mpa

WHERE G= G=

PAGE DEAD WEIGHT OF SEGMENT 11545.35497 KGS 0 D1= D2= 132 cm 128.8 cm

7 OF 14

A=

AREA OF SECTION BOTTOM W/O CORROSION ALLOWANCE 533.5174 cm2

A=

FC = = =

21.64007204 KG/cm2 2121575.69 Pa 2.12157569 Mpa

E) TOTAL COMBINED STRESS Sc = = REFER TABLE 3 he/D< 20 D/t<140 124 93 Fb+ Fc 71.03542829 Mpa : I.S. 6533

MAXIMUM PERMISSIBLE COMBINED STRESS Mpa WITH TEMPERATURE CORRECTION FACTOR ALLOWABLE COMBINED STRESS a= STABILITY CHECK 1.6 (Fb+ Fc) - 0.9 xFc < 1.8 x a 111.7472671 (CALCULATED) DESIGN OF SEGMENT IV DESIGN WIND SPEED (Vz)= WHERE Vb X K1 X K2 X K3 K1= K2= K3= VB= PROBABILITY FACTOR= TERRAIN FACTOR= TOPOGRAPHY FACTOR = BASIC WIND SPEED= -----< 167.4 Mpa (ALLOWABLE)

IS 875(3)1 1.06 1 44 m/s

1987

Vz = DESIGN WIND PRESSURE PZ = PZ = PZ = WIND FORCE WHERE F 0.6xVzxVz 1305.17376 N/M2 0.013312772 Kg/cm2 = Cf= Ae= Ae= 1.1 = WIND FORCE F = Cf x Ae x Pz x 1.1 FORCE COEFFICIENT EFFECTIVE AREA =

46.64 METRES/SEC NOTE: I N/M2 CONVERSION FACTOR = 0.0000102 KG /cm2

PAGE

8 OF 14

(Pz= WIND PRESSURE) 1.2 AVG DIA x HEIGHT 510400 cm2

10% INCREASED TO TAKE CARE OF WIND PRESSURE ON CAGE AND LADDER 8969.187491 Kg

A)

BENDING MOMENT Mx = FL(H-Y)/2 21517080.79 KG cm where, H= Y= HEIGHT OF CHIMNEY in cm SECTION HEIGHT in cm

Mx= B) MODULUS OF SECTION Z= WHERE .77T x D x D

T=

SHELL THICKNESS W/O CORROSION ALLOWANCE(in cm) = 176

1.7

BOTTOM DIA(D) ( IN cm)=

Z= C) ACTUAL BENDING STRESS FB= = = = D) ACTUAL COMPRESSION STRESS Fc= G/A Mx/Z

40547.584 cm3

530.6624629 52025731.66 52.02573166

KG/cm2 KG/cm2 Pa Mpa

WHERE G= G=

PAGE DEAD WEIGHT OF SEGMENT 18139.45545 KGS D1= D2= 154 cm 150 cm

9 OF 14

A=

AREA OF SECTION BOTTOM W/O CORROSION ALLOWANCE 812.9774 cm2

A=

FC = = =

22.31237357 KG/cm2 2187487.605 Pa 2.187487605 Mpa

E) TOTAL COMBINED STRESS Sc = = REFER TABLE 3 he/D< 30 D/t<140 108 81 Fb+ Fc 54.21321926 Mpa : I.S. 6533

MAXIMUM PERMISSBLE COMBINED STRESS Mpa WITH TEMPERATURE CORRECTION FACTOR ALLOWABLE COMBINED STRESS a= STABILITY CHECK 1.6 (Fb+ Fc) - 0.9 xFc < 1.8 x a 84.77241198 (CALCULATED) DESIGN OF SEGMENT V DESIGN WIND SPEED (Vz)= WHERE Vb X K1 X K2 X K3 K1= K2= K3= VB= PROBABILITY FACTOR= TERRAIN FACTOR= TOPOGRAPHY FACTOR = BASIC WIND SPEED= -----< 145.8 Mpa (ALLOWABLE)

IS 875(3)1 1.02 1 44 m/s

1987

Vz = DESIGN WIND PRESSURE PZ = PZ = PZ = WIND FORCE WHERE F 0.6xVzxVz 1208.52864 N/M2 0.012326992 Kg/cm2 = Cf= Ae= Ae= 1.1 = WIND FORCE FL = Cf x Ae x Pz x 1.1 FORCE COEFFICIENT EFFECTIVE AREA =

44.88 METRES/SEC NOTE: I N/M2 CONVERSION FACTOR = 0.0000102 KG /cm2

PAGE

10 OF 14

(Pz= WIND PRESSURE) 1.2 AVG DIA x HEIGHT 684640 cm2

10% INCREASED TO TAKE CARE OF WIND PRESSURE ON CAGE AND LADDER 11140.2085 Kg

A)

BENDING MOMENT Mx = Mx= FL(H-Y)/2 25622479.54 KG cm where, H= Y= HEIGHT OF CHIMNEY in cm SECTION HEIGHT in cm

MODULUS OF SECTION Z= WHERE .77T x D x D T= SHELL THICKNESS W/O CORROSION ALLOWANCE(in cm) = 220 1.9

BOTTOM DIA(D) ( IN cm)=

Z= C) ACTUAL BENDING STRESS FB= = = = D) ACTUAL COMPRESSION STRESS Fc= G/A Mx/Z

70809.2 cm3

361.8524082 35475726.29 35.47572629

KG/cm2 KG/cm2 Pa Mpa

WHERE G= G=

PAGE DEAD WEIGHT OF SEGMENT 27483.1223 KGS D1= D2= 198 cm 193.6 cm

11 OF 14

A=

AREA OF SECTION BOTTOM W/O CORROSION ALLOWANCE 1169.9326 cm2

A=

FC = = =

23.49120137 KG/cm2 2303058.958 Pa 2.303058958 Mpa

E) TOTAL COMBINED STRESS Sc = = REFER TABLE 3 he/D< 30 D/t<140 108 81 Fb+ Fc 37.77878525 Mpa : I.S. 6533

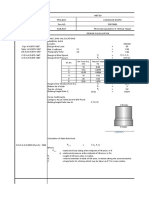

MAXIMUM PERMISSBLE COMBINED STRESS Mpa WITH TEMPERATURE CORRECTION FACTOR ALLOWABLE COMBINED STRESS a = STABILITY CHECK 1.6 (Fb+ Fc) - 0.9 xFc < 1.8 x a 58.37330333 (CALCULATED) FOUNDATION BOLTS MAXIMUM FORCE ON EACH BOLT WHERE P M n Ws D1 < 145.8 Mpa (ALLOWABLE)

= = = = =

(4M/nD1)-(Ws/n) B.M AT THE BASE OF CHIMNEY x NUMBER OF BOLTS WEIGHT OF THE CHIMNEY DIA OF BOLTCIRCLE pcd= 100000.00

PAGE M= BM= n= Ws= D1= P= NET AREA OF BOLT NOW BOLT DIA D2 NOW BOLT DIA D = SAY = = USE M50 DIA BOLT DESIGN OF BASE PLATE COMPRESSIVE FORCE Cf = WHERE D= = = = = = = = = 1.27*M/D*D+(Ws+W1)/3.142 D1 EXTERNAL DIA OF CHIMNEY BASE 275 cm WEIGHT OF THE CHIMNEY LINING 471.03 Kg / Sq.Cm 20 Cf/Ff 23.5513 cm 27.5 cm WIDE BEARING PALTE b/2 * sqrt (3* Ff)/Fbp = 0.036363636 0.190692518 2.62202 cm 3.2 cm 25622479.54 Kg cm 256.22 (x 100000 Kg cm) 32 32000 KGS 250 cm 11811.23977 KG 14.76404971 15 19.10219675 cm2 4.370605994 cm cm2 cm2

12 OF 14

W1 Cf Ff REQUIRED WIDTH OF BEARING PLATE B

WIDTH OF BEARING PLATE PROVIDED b THK OF BEARING PLATE t' =

((3*Ff)/Fbp) t' HENCE THICKNESS OF THE PLATE t' =

You might also like

- ChimneyDocument41 pagesChimneyhemantkle2u100% (2)

- NEO Steel Chimney DesignDocument8 pagesNEO Steel Chimney DesignAnil Pradeep100% (1)

- ASME STS-1Document19 pagesASME STS-1sivaraju1100% (4)

- Stack Design CalculationDocument27 pagesStack Design Calculationrupam dey100% (6)

- Design of Steel Chimney and RCC Foundation As Per Indian Code 22052014Document12 pagesDesign of Steel Chimney and RCC Foundation As Per Indian Code 22052014Ahmad Badsha Quadri58% (19)

- Chimney Design CalcDocument5 pagesChimney Design CalcYoga Sam100% (1)

- Chimney DesignDocument6 pagesChimney Designneel0% (1)

- Saddle v1-10: Fixed Saddle Sliding SaddleDocument30 pagesSaddle v1-10: Fixed Saddle Sliding SaddleidiazgNo ratings yet

- Boilers Chimney Draft and Breeching CalculationDocument15 pagesBoilers Chimney Draft and Breeching Calculationjoabjim8392No ratings yet

- Chimney CalculationsDocument2 pagesChimney CalculationsRamesh Kuppili75% (4)

- Air Coolers HeadsDocument30 pagesAir Coolers HeadsSergio PluchinskyNo ratings yet

- Chimney Design Guide LinesDocument9 pagesChimney Design Guide LinesluckynaveenrajNo ratings yet

- Chimney Calculations 800 Dia 35 M Ht-1Document9 pagesChimney Calculations 800 Dia 35 M Ht-1nilesh100% (2)

- Chimney/ring Fdn. DesignDocument3 pagesChimney/ring Fdn. Designmasum91032No ratings yet

- CH Design-R1 PDFDocument12 pagesCH Design-R1 PDFmazumdar_satyajitNo ratings yet

- Calculations Tank S6Document19 pagesCalculations Tank S6Joshue Adele100% (1)

- 32 Meter Chimney CalculationsDocument9 pages32 Meter Chimney Calculationsmazumdar_satyajitNo ratings yet

- Exhaust Gas Pressure Drop in DuctDocument6 pagesExhaust Gas Pressure Drop in DuctMyungkwan HaNo ratings yet

- Design of Const Dia RCC ChimneyDocument16 pagesDesign of Const Dia RCC ChimneyVadirajNHalgeri100% (3)

- Ibr CalDocument11 pagesIbr Calmailtosamraj100% (4)

- Chimney Calculations, Dia 400 MM, 30 M HeightDocument15 pagesChimney Calculations, Dia 400 MM, 30 M HeightMANOJNo ratings yet

- Leg CalculationDocument10 pagesLeg Calculationmashudi_fikriNo ratings yet

- Design Calculation Report-Steel ChimneyDocument15 pagesDesign Calculation Report-Steel ChimneyUJJWAL SUTHAR100% (2)

- Tank DesignDocument108 pagesTank DesignFRBM2No ratings yet

- HRSG stack design load calculation and analysisDocument35 pagesHRSG stack design load calculation and analysislightsons100% (1)

- Saddle CalculationDocument10 pagesSaddle Calculationpharis_chrisNo ratings yet

- 6 Design of Constant Dia RCC Chimney and Foundation 23052014Document16 pages6 Design of Constant Dia RCC Chimney and Foundation 23052014Ahmad Badsha Quadri0% (1)

- AgitatorDocument6 pagesAgitatorSung Woong MoonNo ratings yet

- Clean Water Tank - Id - 7200x10900 HDocument208 pagesClean Water Tank - Id - 7200x10900 HWilly SastraleksanaNo ratings yet

- Chimney DesignDocument12 pagesChimney DesignVivek PremjiNo ratings yet

- Chimney DesignDocument13 pagesChimney DesignUhong Lai100% (1)

- Saddle Road Transportation Analysis 1Document2 pagesSaddle Road Transportation Analysis 1vpjagannaathNo ratings yet

- Steel Stacks Desing GuideDocument23 pagesSteel Stacks Desing GuideKhaled Eid100% (5)

- 100cub API 650 STEEL SiloDocument19 pages100cub API 650 STEEL SiloUDayNo ratings yet

- Longitudinal Deflection Calculation SheetDocument8 pagesLongitudinal Deflection Calculation SheetXplore Engg100% (1)

- KONARK CHIMNEY Chimney Calculation SheetDocument18 pagesKONARK CHIMNEY Chimney Calculation SheetBimal DeyNo ratings yet

- Chimney Calculation SheetDocument14 pagesChimney Calculation SheetSrinivasa Rao VenkumahanthiNo ratings yet

- Saddle Support Calculation PD 5500,2000 Annex.G)Document26 pagesSaddle Support Calculation PD 5500,2000 Annex.G)Neeraj Kumar33% (3)

- Design of Steel Chimney According to IS StandardsDocument24 pagesDesign of Steel Chimney According to IS StandardsG S Deshpande100% (1)

- Draft Code for Design of Reinforced Concrete ChimneysDocument54 pagesDraft Code for Design of Reinforced Concrete Chimneysakshay chauhan67% (3)

- SEISMIC AND WIND LOAD CALCULATIONS FOR VERTICAL VESSELDocument14 pagesSEISMIC AND WIND LOAD CALCULATIONS FOR VERTICAL VESSELronnie_syncinNo ratings yet

- Duct Design Calculation Sheet: Note:-Take the Value of α & β from above table use in the calculationDocument9 pagesDuct Design Calculation Sheet: Note:-Take the Value of α & β from above table use in the calculationchagar_harshNo ratings yet

- Heat Transfer in Jacketed VesselDocument2 pagesHeat Transfer in Jacketed VesselMuthuKumar Arunachalam0% (1)

- Sample Design Calculation - Vessel Supported On LugsDocument4 pagesSample Design Calculation - Vessel Supported On LugsAbhay Upadhyay0% (1)

- Thermal 3TPH 12Kg FO Fired Boiler R0Document6 pagesThermal 3TPH 12Kg FO Fired Boiler R09913489806No ratings yet

- Ibr CalcDocument4 pagesIbr CalcUmesh Kondkar100% (7)

- Sizing Stack HeightDocument1 pageSizing Stack Heightashwini_kumar19840% (1)

- Wind & Seismic CalculationsDocument3 pagesWind & Seismic CalculationsSajal Kulshrestha33% (3)

- ChimneyDocument42 pagesChimneyAnand SwamiNo ratings yet

- Analysis of RCC ChimneyDocument26 pagesAnalysis of RCC ChimneynaveenaeeNo ratings yet

- Design of ChimneyDocument39 pagesDesign of ChimneyVenkatesha Hebbar100% (2)

- Chequered PlateDocument23 pagesChequered Platesaravanan428680% (10)

- Wind Coefficient Calculation1Document29 pagesWind Coefficient Calculation1Hemant Sonawadekar0% (1)

- 35 KL DesignDocument10 pages35 KL DesigneduardoambientalNo ratings yet

- Page 3Document2 pagesPage 3Dhvanit JoshiNo ratings yet

- Combine Footing by IS 456:2000Document18 pagesCombine Footing by IS 456:2000Huzaifa NakhwaNo ratings yet

- D132a1 +3 D132a1 +15 D132C1 +6Document15 pagesD132a1 +3 D132a1 +15 D132C1 +6Rhonzkie GapuzNo ratings yet

- Design of FoundationDocument66 pagesDesign of FoundationShaikh Muhammad Ateeq100% (2)

- Combined PAD Footing DesignDocument3 pagesCombined PAD Footing Designarshad aliNo ratings yet

- Column Skirt Support Design CalculationDocument5 pagesColumn Skirt Support Design CalculationRitesh VishambhariNo ratings yet

- Weld Defects - RepairsDocument48 pagesWeld Defects - RepairsVinoth Rajendra100% (4)

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design CalculationsVinoth Rajendra50% (4)

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsVinoth Rajendra100% (3)

- Basic HydraulicsDocument916 pagesBasic Hydraulicsabraham_ginNo ratings yet

- CSWIP 3.2 Preparation Course MaterialDocument214 pagesCSWIP 3.2 Preparation Course MaterialVinoth Rajendra81% (21)

- CSWIP 3.2 Preparation Course MaterialDocument214 pagesCSWIP 3.2 Preparation Course MaterialVinoth Rajendra81% (21)

- Welding Notes of CSWIP3.2 - Senior Welding InspectorDocument584 pagesWelding Notes of CSWIP3.2 - Senior Welding InspectorVinoth Rajendra100% (1)

- Fabrication and Processing of Grade 91 MaterialDocument376 pagesFabrication and Processing of Grade 91 MaterialVinoth Rajendra100% (2)

- Fabrication CalculationDocument73 pagesFabrication CalculationVinoth Rajendra100% (1)

- Filler Material Selection GuideDocument32 pagesFiller Material Selection GuidemaknileNo ratings yet

- Piping DownloadsDocument11 pagesPiping DownloadsAnkit ChughNo ratings yet

- Welding 'Document515 pagesWelding 'Gopu Pushpangadhan67% (3)

- Fabrication CalculationDocument73 pagesFabrication CalculationVinoth Rajendra100% (1)

- Using Welding Inspection ToolsDocument9 pagesUsing Welding Inspection ToolsVinoth RajendraNo ratings yet

- Eng Ref BookDocument241 pagesEng Ref BookVinoth RajendraNo ratings yet

- Common Materials & Welding Codes A5Document1 pageCommon Materials & Welding Codes A5Vinoth RajendraNo ratings yet

- Base Metal and IronDocument5 pagesBase Metal and IronVinoth RajendraNo ratings yet

- SmagDocument28 pagesSmagcsvasukiNo ratings yet

- Disaster Recovery Homeowner Rehab Quality Assurance Quality Control ProceduresDocument4 pagesDisaster Recovery Homeowner Rehab Quality Assurance Quality Control ProceduresVinoth RajendraNo ratings yet

- Chapter 7: Inspection, Evaluation, and Testing ProceduresDocument42 pagesChapter 7: Inspection, Evaluation, and Testing ProceduresVinoth RajendraNo ratings yet

- Pressure Vessels PDFDocument9 pagesPressure Vessels PDFVinoth RajendraNo ratings yet

- Thisai Kanden Vaan Kanden - Sujatha NovelDocument83 pagesThisai Kanden Vaan Kanden - Sujatha NovelVinoth Rajendra100% (2)

- Mandatory DisclosureDocument11 pagesMandatory DisclosureVinoth RajendraNo ratings yet

- Multi+Choice QuestionsDocument40 pagesMulti+Choice QuestionsVikas Lk100% (18)

- 36-775 Control of Plant Construction Repair and Maintenance Welding Activities (Rev 1)Document22 pages36-775 Control of Plant Construction Repair and Maintenance Welding Activities (Rev 1)Vinoth Rajendra100% (1)

- ASTI - Boiler Tube Failure Investigation & Prevention - NACE - ForDocument9 pagesASTI - Boiler Tube Failure Investigation & Prevention - NACE - ForVinoth RajendraNo ratings yet

- GtawbookDocument24 pagesGtawbooksamuelherbasNo ratings yet

- GWS 1 04 Procedure R1Document4 pagesGWS 1 04 Procedure R1Vinoth RajendraNo ratings yet

- ACAS II Operations in The European RVSM EnvironmentDocument45 pagesACAS II Operations in The European RVSM Environmentali4957270No ratings yet

- Datasheet TachogeneratorDocument4 pagesDatasheet TachogeneratorNurulHidayatNo ratings yet

- Performance Appraisal Form From IndustryDocument2 pagesPerformance Appraisal Form From IndustryJaspal SinghNo ratings yet

- GRT8100 Product Guide Imperial PDFDocument32 pagesGRT8100 Product Guide Imperial PDFSijumon sijuNo ratings yet

- 3D PrintingDocument32 pages3D Printing9700216256No ratings yet

- Power-Master III Drum PumpsDocument5 pagesPower-Master III Drum PumpsGuntur SoebankNo ratings yet

- DA 65we EnglishDocument2 pagesDA 65we EnglishAlvin NguyenNo ratings yet

- Electronically Controlled On-Demand 4WDDocument32 pagesElectronically Controlled On-Demand 4WDjulio797No ratings yet

- What is a Gear Motor? - An In-Depth GuideDocument15 pagesWhat is a Gear Motor? - An In-Depth GuidePuneet KumarNo ratings yet

- X-Arcade Tankstick Manual USADocument13 pagesX-Arcade Tankstick Manual USAmight69No ratings yet

- Bs1030 BrochureDocument2 pagesBs1030 BrochuremgvuleNo ratings yet

- Engine and vehicle parameter monitoringDocument170 pagesEngine and vehicle parameter monitoringAlejandro Samuel100% (2)

- ParkerOriga PDFDocument338 pagesParkerOriga PDFilyesNo ratings yet

- True/False: List of Attempted Questions and AnswersDocument15 pagesTrue/False: List of Attempted Questions and AnswersDeepak Kumar VermaNo ratings yet

- AbaqusCAE FSI Module Users GuideDocument21 pagesAbaqusCAE FSI Module Users GuideZenghu Han100% (1)

- ZZZXDocument14 pagesZZZXJay R DenostaNo ratings yet

- Kurnool - 30 NM - RWY 2000Document1 pageKurnool - 30 NM - RWY 2000aeeNo ratings yet

- THE PASSION AND GLOBAL APPROACH DRIVING HONDA MOTORCYCLES TO SUCCESSDocument11 pagesTHE PASSION AND GLOBAL APPROACH DRIVING HONDA MOTORCYCLES TO SUCCESSjatinag990No ratings yet

- GENRE DocumentaryDocument10 pagesGENRE Documentaryemilyweal123No ratings yet

- 9303 Part 1 Vol 1 PDFDocument99 pages9303 Part 1 Vol 1 PDFrexthrottleNo ratings yet

- Camden CM-30EE-LED Data SheetDocument2 pagesCamden CM-30EE-LED Data SheetJMAC SupplyNo ratings yet

- 30x173 - TPDS-T - MK317 Mod0 - NAVSEA - 2011Document16 pages30x173 - TPDS-T - MK317 Mod0 - NAVSEA - 2011Anonymous jIzz7woS6No ratings yet

- SWOT) Analysis, Marketing Process, Marketing PlanDocument24 pagesSWOT) Analysis, Marketing Process, Marketing PlanSagar Patil100% (2)

- Microstation GuideDocument158 pagesMicrostation GuideMishra KirtiwardhanNo ratings yet

- BS 5950-4-1994 (Englezesc) PDFDocument38 pagesBS 5950-4-1994 (Englezesc) PDFYannis Alexandru100% (4)

- Usb Modem 2Document4 pagesUsb Modem 2emadNo ratings yet

- TM 1001 AVEVA Plant 12 1 PDMS Foundations Rev 3 0 PDFDocument153 pagesTM 1001 AVEVA Plant 12 1 PDMS Foundations Rev 3 0 PDFPolarogramaNo ratings yet

- Telepo SDK Develop Guide (Linux For TPS300) - v1.0Document10 pagesTelepo SDK Develop Guide (Linux For TPS300) - v1.0VKM2013No ratings yet

- Medonic M-Series M32 Innovation Built On Total Quality: For Today'S Hematology LabsDocument6 pagesMedonic M-Series M32 Innovation Built On Total Quality: For Today'S Hematology LabsSubhanullah JalalNo ratings yet

- InRoom Tech Data 31010 ApcDocument92 pagesInRoom Tech Data 31010 ApcRolandoNo ratings yet