Professional Documents

Culture Documents

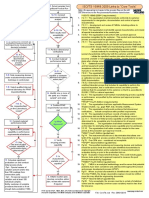

GAGE CALIBRATION PROCESS

Uploaded by

semaphore6Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GAGE CALIBRATION PROCESS

Uploaded by

semaphore6Copyright:

Available Formats

TURTLE DIAGRAM GAGE CALIBRATION

With what?

Machines/Equipment: Calibration lab equipment

Standards (trace to NIST) Computer, software, printer Hand tools

With whom?

People involved with this process:

Calibration Technician Quality Manager Tool crib Attendant

Materials: Gage

Cleaning supplies

Links/interfaces with involved parties:

Quality Engineering Process Engineering Purchasing Gage Supplier

Inputs? Customer wants:

Gage calibration per schedule CCAL-D03

Process Name Gage Calibration ___________________

Process Steps/Activities: Receive Gage and Clean _________________________ Verify and Adjust (if required) _________________________ Record Results _________________________ Release Gage _________________________

Outputs? Customer need is

fulfilled for:

Calibrated and recorded gage per schedule CCAL-D03

Input requirements. What are the inputs that determine what the process must produce?

Calibration schedule Production schedule Control plans Customer requirements

JAN ROOVERS ASSOCIATES, INC.

Output requirements. What output criteria are used to determine that the output meets the input requirements?

Calibration records Inspection and MSA results Int./Ext. Customer feedback

Measure?

With what key criteria? Measurements/Assessments:

Gage performance Gage availability Cost of calibration Audits Measurement System Analysis (MSA) records

How?

Support processes: (Who helps and how?)

Product Engineering Production Planning Training Calibration instructions Manufacturers manuals Process Engineering External Laboratory Maintenance Records, Database Control plans

Procedures/work instructions/control documents:

You might also like

- Turtle Diagram PPAPDocument1 pageTurtle Diagram PPAPDL50% (2)

- IATF Objective Data Analysis - Quality - ExampleDocument1 pageIATF Objective Data Analysis - Quality - ExampleSachin RamdurgNo ratings yet

- IATF 16949 2016 Mandatory ProcedureDocument1 pageIATF 16949 2016 Mandatory Procedureshivendrakumar100% (3)

- Turtle Diagram For AuditDocument5 pagesTurtle Diagram For AuditSelvaraj Simiyon100% (3)

- Process Audit Turtle DiagramDocument1 pageProcess Audit Turtle DiagramJoel Alcantara100% (3)

- Iatf ActivitiesDocument6 pagesIatf ActivitiesWizard tube and Engineered componentNo ratings yet

- Summary of New QMS Documents With References To ISO 9001 & IATF 16949 ClausesDocument8 pagesSummary of New QMS Documents With References To ISO 9001 & IATF 16949 ClausesStephen Lim Kean Jin100% (2)

- Turtle Diagram Manufacturing ProcedureDocument1 pageTurtle Diagram Manufacturing ProcedureBAla100% (2)

- IATF 16949 2016 Gap ToolDocument353 pagesIATF 16949 2016 Gap ToolOziel Cardenas33% (6)

- Iatf 3year Internal Audit PlanDocument6 pagesIatf 3year Internal Audit Planrajesh sharmaNo ratings yet

- Manufacturing Process Audit ScorecardDocument1 pageManufacturing Process Audit ScorecardSachin Kumbhar100% (1)

- C4 Turtle Diagram Process Design ProcessDocument1 pageC4 Turtle Diagram Process Design Processcao thanh quocNo ratings yet

- Process Audit Preparation GuideDocument5 pagesProcess Audit Preparation GuideNumpetch Somsw100% (6)

- Customer Specific Requirements MatrixDocument4 pagesCustomer Specific Requirements Matrixhmp9060% (5)

- 11.process Turtile DiagramDocument20 pages11.process Turtile DiagrammuthuselvanNo ratings yet

- VDA 6.3 Management: R. Dan ReidDocument61 pagesVDA 6.3 Management: R. Dan ReidAlpha Excellence consultingNo ratings yet

- Aum Prasad Casting PVT LTD: 1. Types of Audit 2. Objectives Overview 3. Introduction To Clauses. 4. Conducting AuditDocument24 pagesAum Prasad Casting PVT LTD: 1. Types of Audit 2. Objectives Overview 3. Introduction To Clauses. 4. Conducting AuditpraveenNo ratings yet

- Iso Iatf Quality System Manual PDFDocument53 pagesIso Iatf Quality System Manual PDFKrishnamoorthyNo ratings yet

- Attribute MSA 4th EditionDocument4 pagesAttribute MSA 4th EditionSachin RamdurgNo ratings yet

- IATF Quality Manual-GEC U-2 PDFDocument53 pagesIATF Quality Manual-GEC U-2 PDFNarendra100% (1)

- Required Documents For IATF - 16949Document5 pagesRequired Documents For IATF - 16949Rajesh Sahasrabuddhe0% (1)

- MSIL Audit Cheklist 16Document22 pagesMSIL Audit Cheklist 16Pravin Balasaheb GunjalNo ratings yet

- Annexure-1 Customer Specific Requirement MatrixDocument5 pagesAnnexure-1 Customer Specific Requirement MatrixSunil Shrivastava50% (2)

- SPC MSA GuidelinesDocument28 pagesSPC MSA Guidelinesbill100% (2)

- Turtle For Process MapDocument0 pagesTurtle For Process MapGhulam Mustafa100% (1)

- 03 (SQ) - Process Product Audit ReportDocument2 pages03 (SQ) - Process Product Audit ReportDEVENDERNo ratings yet

- Procedure: Measurement System Analysis ExecutionDocument1 pageProcedure: Measurement System Analysis Executionaslam100% (1)

- Core Tools PDFDocument1 pageCore Tools PDFsentrakerjaan100% (3)

- Internal Audit ChecklistDocument37 pagesInternal Audit ChecklistSumeet Rathee100% (5)

- Competence For Internal AuditorsDocument2 pagesCompetence For Internal AuditorsSachin Ramdurg100% (1)

- Layered Process Audit FormDocument3 pagesLayered Process Audit FormPawan Sehrawat100% (7)

- Attribute MSA TrainingDocument21 pagesAttribute MSA TrainingDisha ShahNo ratings yet

- QAF12 Process Audit Rev 09Document4 pagesQAF12 Process Audit Rev 09ukavathekarNo ratings yet

- TurtlesDocument15 pagesTurtlesshobhit2310100% (4)

- 94% Process Audit ChecklistDocument2 pages94% Process Audit ChecklistAshutosh Singh100% (2)

- Process Management for Quality AssuranceDocument22 pagesProcess Management for Quality AssuranceVikas0% (1)

- PURCHASING PROCESSDocument15 pagesPURCHASING PROCESSDuy Le100% (5)

- Internal Audit Checklist - Tool ManufacturingDocument1 pageInternal Audit Checklist - Tool ManufacturingSachin Ramdurg100% (2)

- QS - F-136 List of (Iatf) Internal AuditorsDocument1 pageQS - F-136 List of (Iatf) Internal AuditorsShaili SharmaNo ratings yet

- 4M Change Control Management Work InstructionDocument2 pages4M Change Control Management Work InstructionSameer Saxena100% (2)

- CS Customer - Plant Turtle Diagram 07Document1 pageCS Customer - Plant Turtle Diagram 07Alex100% (1)

- Iatf Gap Analysis ToolDocument100 pagesIatf Gap Analysis ToolKumaravel100% (3)

- Free Ts 16949 Audit ChecklistDocument8 pagesFree Ts 16949 Audit ChecklistKumaravel100% (1)

- Supplier Audit Check Sheet For New & NON ISO SupplierDocument7 pagesSupplier Audit Check Sheet For New & NON ISO SupplierManoj Kaushik100% (1)

- Internal Audit Checklist - Packing & DispatchDocument2 pagesInternal Audit Checklist - Packing & DispatchSachin Ramdurg100% (6)

- Iatf 16949Document27 pagesIatf 16949Shahrukh Patel100% (2)

- Blank Turtle DiagramDocument1 pageBlank Turtle Diagrammrtelephone1100% (2)

- 4M Change ProcedureDocument2 pages4M Change ProcedureKRISHAN KUMARNo ratings yet

- The Process Approach QuestionsDocument6 pagesThe Process Approach QuestionsDwinanda SeptiadhiNo ratings yet

- 3.6 Initial SupplyDocument2 pages3.6 Initial SupplySunil Kumar92% (12)

- Internal audit checklist for hot shop operationsDocument36 pagesInternal audit checklist for hot shop operationsDhinakaran100% (1)

- IATF 16949 - Internal Audit ChecksheetDocument11 pagesIATF 16949 - Internal Audit ChecksheetHem Upadhyay91% (11)

- PFMEA and Control Plan Linkage ExamplesDocument5 pagesPFMEA and Control Plan Linkage Exampleslittlekheong100% (1)

- Inputs Outputs: With Who? (Competence/skills/training) With What? (Materials and Equipment)Document2 pagesInputs Outputs: With Who? (Competence/skills/training) With What? (Materials and Equipment)azire carlos100% (1)

- Wi SPCDocument4 pagesWi SPCSujeet Kumar100% (1)

- NC Closure 5 Why AnalysiDocument26 pagesNC Closure 5 Why AnalysiKaran MalhiNo ratings yet

- IATF 16949 mandatory documentsDocument3 pagesIATF 16949 mandatory documentsOscar Solis MartirNo ratings yet

- Turtle Diagram (Calibration)Document1 pageTurtle Diagram (Calibration)DL100% (1)

- GLP Ipa Equipment Qualification - Final4Document35 pagesGLP Ipa Equipment Qualification - Final4عبدالعزيز بدرNo ratings yet

- 5 Steps Risk AssessmentDocument1 page5 Steps Risk AssessmentJayson V Caranto RNNo ratings yet

- Paroles Men Guell atDocument5 pagesParoles Men Guell atsemaphore6No ratings yet

- NormalDocument18 pagesNormalsemaphore6No ratings yet

- Calibration TablesDocument5 pagesCalibration Tablessemaphore6No ratings yet

- Internal Auditor Qualification - ExampleDocument2 pagesInternal Auditor Qualification - Examplesemaphore6No ratings yet

- Iso14000 ModelDocument1 pageIso14000 Modelsemaphore6No ratings yet

- Customer ComplaintDocument3 pagesCustomer Complaintsemaphore6No ratings yet

- Calibration PlanDocument1 pageCalibration Plansemaphore6No ratings yet

- Key Vocabulary For A Safe WorkplaceDocument109 pagesKey Vocabulary For A Safe WorkplaceAhmd_J_AbdellahNo ratings yet

- W3Schools Quiz Results - PythonDocument14 pagesW3Schools Quiz Results - PythonRicardo Deferrari0% (1)

- Sushant - CyberArk - Resume2024 - Vdart (Coforge)Document11 pagesSushant - CyberArk - Resume2024 - Vdart (Coforge)RAJINIKNTH REDDYNo ratings yet

- Introduction To C Part 1Document51 pagesIntroduction To C Part 1nitin rakhNo ratings yet

- Printers: Settings and Problems: HP Laserjet 5L, 5PDocument5 pagesPrinters: Settings and Problems: HP Laserjet 5L, 5PRodrigo Santos BrunaNo ratings yet

- How To Get A Product by Its ID Programmatically - Development - Magento 2Document3 pagesHow To Get A Product by Its ID Programmatically - Development - Magento 2m1k13No ratings yet

- Learn All PC Tips and Tricks - CrackingDocument5 pagesLearn All PC Tips and Tricks - CrackingSrinivas KaratlapelliNo ratings yet

- The OpsRamp Platform Security and ComplianceDocument9 pagesThe OpsRamp Platform Security and ComplianceJesus Huerta VilchisNo ratings yet

- Website Assignment RDocument4 pagesWebsite Assignment Rapi-568464744No ratings yet

- Handbook of Data Center ManagmentDocument801 pagesHandbook of Data Center ManagmentHusam SalehNo ratings yet

- SQE Assignment 04 - Login Test CasesDocument4 pagesSQE Assignment 04 - Login Test CasesM.Abdullah GulNo ratings yet

- Insert Tab in MS WordDocument8 pagesInsert Tab in MS WordABIGAEL FRANINo ratings yet

- PC Transfer Tool Operation Manual: Digital Electronics CorporationDocument35 pagesPC Transfer Tool Operation Manual: Digital Electronics CorporationPapahnya Qiana MaulinaNo ratings yet

- AWS 101 Next Steps GuideDocument3 pagesAWS 101 Next Steps GuidejeffersonNo ratings yet

- Flags and Flow Control StructureDocument19 pagesFlags and Flow Control StructureMuhammad UmerNo ratings yet

- Controllogix Ethernet Manual KEPServerEXDocument200 pagesControllogix Ethernet Manual KEPServerEXIngeniería 2 ICMANo ratings yet

- CH 3Document22 pagesCH 3Bereket AlemuNo ratings yet

- 03 - A Performance Modeling Framework For Microservices-Based Cloud InfrastructuresDocument12 pages03 - A Performance Modeling Framework For Microservices-Based Cloud InfrastructuresCayo OliveiraNo ratings yet

- Smsplace Bulksms HTTP APIDocument17 pagesSmsplace Bulksms HTTP APICHIAMBAH ENDURANCENo ratings yet

- Lecture 22 - TriggersDocument19 pagesLecture 22 - TriggersHiba AzeemNo ratings yet

- CSE325 - A1 - G2 - Lecture2 NotesDocument39 pagesCSE325 - A1 - G2 - Lecture2 Notesislam2059No ratings yet

- Calculating Selectivity: Whoami?Document15 pagesCalculating Selectivity: Whoami?kruemeL1969No ratings yet

- Ib 1500904 EngmDocument42 pagesIb 1500904 EngmKING Rooster PlayNo ratings yet

- Lock Picking Hotel RoomsDocument22 pagesLock Picking Hotel Roomsbiffbuff99No ratings yet

- BLISS 03-T3 Unit 1 Slides v3.0 Final ControledDocument72 pagesBLISS 03-T3 Unit 1 Slides v3.0 Final ControledNedra BenletaiefNo ratings yet

- Yonatan Andreas Parsaoran Lumban Tobing - ResumeDocument2 pagesYonatan Andreas Parsaoran Lumban Tobing - ResumeChrisma Lumban TobingNo ratings yet

- Required MOVs On CBFMA, TIs, CSCDocument25 pagesRequired MOVs On CBFMA, TIs, CSCAlga Zalli Datu-daculaNo ratings yet

- Data Center Airflow MGMT Basics WPDocument15 pagesData Center Airflow MGMT Basics WPZafya NadhiraNo ratings yet

- Terra Model ConstructionDocument6 pagesTerra Model ConstructionOjeleke TundeNo ratings yet

- 4.-Revised-Tle-As-Css10-Q3-Disk ManagementDocument5 pages4.-Revised-Tle-As-Css10-Q3-Disk ManagementJonald SalinasNo ratings yet

- Canon imageRUNNER ADVANCE 4525i BrochureDocument4 pagesCanon imageRUNNER ADVANCE 4525i BrochurePuwanat6945 6945No ratings yet