Professional Documents

Culture Documents

Design of Flexible Pavements For Low Volume Rural Roads

Uploaded by

Vizag RoadsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Flexible Pavements For Low Volume Rural Roads

Uploaded by

Vizag RoadsCopyright:

Available Formats

D.V .Bhavanna Rao M.Tech., F.I.E., Retired R&B Chief Engineer E-mail: bhavannarao@yahoo.co.

in Phone: +919494440202 Egis-india consulting engineers pvt ltd.

for all my presentations, please visit http://aproadbuildqa.blogspot.com

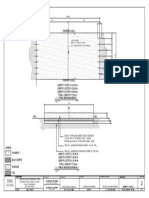

shoulder

Base Sub base eeeeEeeee Sub-Grade (300mm)

shoulder

Embankment

Typical Pavement Cross Section

Earlier Design Approach as per IRC:SP:20-2002

As per IRC: SP:20-2002, traffic is evaluated in Commercial Vehicles Per Day grouping together all types of vehicles weighing 3.0t or more. The percentage of laden, un-laden or over loaded vehicles was not considered. sub-Grade strength is evaluated in terms of 4-day soaked CBR values except in areas with annual rainfall less than 500mm and where the water table is too deep.

Pavement thickness chart as per IRC: SP 20 2002

Pavement thickness as per IRC: SP 20 2002

CBR Crust Base 2% Sub base Base 3% Sub base Base 4% Sub base 0 to 15 CVPD 150 275 150 200 150 125 15 to 45 CVPD 150 365 150 265 150 200 45 to 150 CVPD 225 370 150 330 150 260 150 to 450 CVPD 225 455 225 320 150 315

Base

5%

150 100

150 60

150 165

150 115

150 210

150 150

150 260

150 175

Sub base

Base

6%

Sub base

Pavement thickness as per IRC: SP 20 2002

CBR Crust Base 7 Sub base Base 0 to 15 CVPD 150 60 150 30 150 nil 150 15 to 45 CVPD 150 115 150 70 150 30 150 45 to 150 CVPD 150 150 150 85 150 50 150 150 to 450 CVPD 150 175 150 125 150 75 150

10%

Sub base Base

15%

Sub base Base

20%

Sub base

nil

nil

30

50

Recommended Design Approach as per IRC:SP:72-2007 Low volume roads are divided into three categories 1) Gravel/Aggregate surfaced (Un-paved) roads

2) Flexible Pavements (Paved roads)

3) Rigid Pavements

note: AASHTO guide for Design of Pavement structures was considered in this publication.

Recommended Design features in IRC:SP:72-2007

Pavement design for new roads as well as for the up gradation/rehabilitation of existing roads have been included. Maximising the use of localised materials. Simple procedures for traffic counts, computing ADT(Average Daily Traffic) and ESAL (Equivalent Standard Axle Loads) in design life, selected as 10 years. 5 classes of sub-grade strength and 7 ranges of design traffic. Warrants for providing bituminous surface treatment. Long term performance monitoring by systematic condition surveys at regular intervals.

Design Traffic parameter

It has been expressed in terms of cumulative 80kN (8.16 tonnes) ESAL (Equivalent Standard Axle Loads) applications during the design life (10 years). Seasonal variations by way of enhanced traffic during the harvesting seasons have also been considered. Traffic growth rate shall be assessed by conducting traffic survey at least for 3 days each during peak and non peak seasons. In the absence of details, a traffic growth rate of 6% may be taken.

Composition of rural traffic It is not only the traffic volume but also its composition that plays an important role in determining the pavement thickness and its composition. Heavy Commercial Vehicles (HCV) like full sized trucks and buses and the Medium-heavy commercial Vehicles (MCV) with a gross laden weight 3.0 tonnes and above shall be considered.

Procedure has also been suggested to evaluate and consider the effect of Solid Wheeled Vehicles (SWC/iron-rimmed) in computing the design traffic.

Equivalency Factors for different axle loads

Axle l Load tonnes 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0 13.0 14.0 15.0 kN 29.4 39.2 49.1 58.8 68.7 78.5 88.3 98.1 107.9 117.7 127.5 137.3 147.1 Equivalency factors 0.02 0.06 0.14 0.29 0.54 0.92 1.48 2.25 3.30 4.70 6.40 8.66 11.42

Axle equivalency factor = (W/Ws)4

W is single axle load in kN

Ws is Standard Axle Load of 80kN(8.16t)

Vehicle Damage Factor

1) Fully loaded Heavy Vehicle (HCV): Rear Axle=10.2t and Front axle=5.0t. VDF= 2.44+0.14=2.58 2) Un-laden/partially loaded HCV: Rear Axle=6.0t and Front axle=3.0t. VDF=0.29+0.02= 0.31 3) Overloaded (20%) HCV: Rear Axle=12.3t and Front axle=6.0t. VDF= 5.06+0.29= 5.35 4) Unladen/partially loaded MCV Rear Axle=3.0t and Front axle=1.5t. VDF=0.018+0.001= 0.019

Equivalent Standard Axle Load applications

+. N=T0365 L .

Where T0 = ESAL per day = number of commercial vehicles per day in the year of opening VDF = annual traffic growth rate(6%) L = lane Distribution Factor: L = 1 for single lane or intermediate lane L = 0.75 for two-lane roads n = design life in years(10 years)

Seasonal Variations in Rural Traffic

Average Annual Daily Traffic (AADT) in CVPD

100 150 200 300 400 500

Correction Factor for Solid-Wheeled (iron rimmed)Cart Traffic 1.70 1.25 1.20 1.15 1.10 1.07

In the Equivalent Standard Axle Load calculations, the above correction factor Is to be applied for Sold-Wheeled Carts if there Is significant volume of SWC(Iron Rimmed Vehicles). Damaging effect to the road surface by SWC is twice the damaging effect of a laden 6-8 t MCV.

Table 4 of SP:62 Guidelines for providing a Bituminous Surface Treatment

Type of Surfacing Annual Rain fall T1 ADT< 100

Traffic category

T2 T3 ADT= ADT= 100to150 150to200 T4 ADT> 200

Over 1500mm/ year

1000-1500mm/ year Less than 1000mm/ year

Gravel

Gravel Gravel

BT

Gravel Gravel

BT

BT Gravel

BT

BT BT

Sub Grade Strength

4-day soaked CBR values for new roads can be assessed by one of the following. 1) Based on Soil Classification and table 1 of SP:72 2) Using a Nomo graph (appendix C of SP:62) 3) using 2 sets of equations, based on classification test data, one for plastic soils and other for non plastic soils (appendix D of SP:62) 4) By conducting actual CBR tests in the laboratory.

Table 1 of SP:62: Typical Presumptive Design CBR values

Description of sub grade soil

IS Soil Classification CH, MH

Typical Soaked CBR Values % 2 3*

Highly Plastic Clays and Silts

Silty clays and sandy clays Clayey sands and Silty sands

ML, MI

SC, SM

4-5

6 - 10

*Expansive soils like BC soil may have a soaked CBR of less than 2%. Free Swelling Index test as per IS:2720 part 40 should be conducted.

Quick Estimation of CBR (appendix D)

Plastic Soil CBR = 75/(1+0.728WPI) Where WPI = Weighted Plasticity Index = P075 PI PI = Plasticity Index of the soil in % P075 = % passing 0.075mm sieve in decimal. Non-Plastic soil CBR = 28.091(D60)0.3581 Where D60 = diameter in mm of the grain size corresponding to 60% finer.

Expansive Soil Sub Grade Expansive soil should be compacted to 95% Standard Compaction at a moisture content 1 to 2% higher than optimum. When the CBR of subgrade is less than 2%, the economic feasibility of replacing 300mm sub grade with suitable soil and CBR of improved sub grade shall be considered for design. Alternatively, a capping layer of thickness less than 100mm of modified soil with CBR not less than10% should be provided. CBR of 2% may be considered for design

IRC: SP 72 2007, Pavement Design Catalogue. CBR = 2%

Bituminous Surface treated WBM/CRMB Base of gravel, WBM, CRMB of CBR not less than 100% Gravel Base of CBR not less than 80% Granular Sub Base of CBR not less than 20% Modified soil or sub grade of CBR not less than 10%

Cumulative ESAL applications

10,000 to 30,000 30,000 to 60,000

Nil 75

nil nil

200 150

nil nil

100 100

60,000 to 1,00,000

1,00,000 to 2,00,000 2,00,000 to 3,00,000 3,00,000 to 6,00,000 6,00,000 to10,00,000

75

75 75 75 75

100

100 100 100 150

nil

nil nil nil nil

100

100 150 225 200

100

150 150 150 225

IRC:SP :72 2007, Pavement Design Catalogue.CBR = 3 to 4%

Bituminous Surface treated WBM/CRMB Base of gravel, WBM, CRMB of CBR not less than 100% Gravel Base of CBR not less than 80% Granular Sub Base of CBR not less than 20% Modified soil or sub grade of CBR not less than 10%

Cumulative ESAL applications

10,000 to 30,000 30,000 to 60,000

Nil nil

nil nil

200 275

nil nil

nil nil

60,000 to 1,00,000

1,00,000 to 2,00,000 2,00,000 to 3,00,000 3,00,000 to 6,00,000 6,00,000 to10,00,000

75

75 75 75 75

100

100 100 150 150

nil

nil nil nil nil

150

100 100 100 150

nil

100 150 150 150

IRC: SP 72 2007, Pavement Design Catalogue. CBR = 5 to 6%

Cumulative ESAL applications Bituminous Surface treated WBM/CRMB Base of gravel, WBM, CRMB of CBR not less than 100% Gravel Base of CBR not less than 80% Granular Sub Base of CBR not less than 20% Modified soil or sub grade of CBR not less than 10%

10,000 to 30,000 30,000 to 60,000

Nil nil

nil nil

175 250

nil nil

nil nil

60,000 to 1,00,000

1,00,000 to 2,00,000 2,00,000 to 3,00,000 3,00,000 to 6,00,000 6,00,000 to10,00,000

nil

75 75 75 75

nil

100 100 100 150

275

nil nil nil nil

nil

125 150 100 100

nil

nil nil 100 100

IRC: SP 72 2007, Pavement Design Catalogue. CBR = 7 to 9%

Bituminous Surface treated WBM/CRMB Base of gravel, WBM, CRMB of CBR not less than 100% Gravel Base of CBR not less than 80% Granular Sub Base of CBR not less than 20% Modified soil or sub grade of CBR not less than 10%

Cumulative ESAL applications

10,000 to 30,000 30,000 to 60,000

Nil nil

nil nil

150 175

nil nil

nil nil

60,000 to 1,00,000

1,00,000 to 2,00,000 2,00,000 to 3,00,000 3,00,000 to 6,00,000 6,00,000 to10,00,000

nil

75 75 75 75

nil

100 100 100 150

225

nil nil nil nil

nil

100 125 150 150

nil

nil nil nil nil

IRC: SP 72 2007, Pavement Design Catalogue. CBR = 10 to 15%

Bituminous Surface treated WBM/CRMB Base of gravel, WBM, CRMB of CBR not less than 100% Gravel Base of CBR not less than 80% Granular Sub Base of CBR not less than 20% Modified soil or sub grade of CBR not less than 10%

Cumulative ESAL applications

10,000 to 30,000 30,000 to 60,000

Nil nil

nil nil

125 150

nil nil

nil nil

60,000 to 1,00,000

1,00,000 to 2,00,000 2,00,000 to 3,00,000 3,00,000 to 6,00,000 6,00,000 to10,00,000

nil

75 75 75 75

nil

150 100 100 150

175

nil nil nil nil

nil

nil 100 125 125

nil

nil nil nil nil

You might also like

- Design of Concrete Pavements For Rural Roads As Per Irc:Sp 62-2013Document3 pagesDesign of Concrete Pavements For Rural Roads As Per Irc:Sp 62-2013bnkadia60% (5)

- MOST Specifications For Road & BridgesDocument654 pagesMOST Specifications For Road & Bridgespbalakrishnan90% (59)

- IRC Guidelines for Design of Plain Jointed Rigid PavementsDocument3 pagesIRC Guidelines for Design of Plain Jointed Rigid PavementsBilal Ahmed Barbhuiya72% (18)

- IRCSP13 - Design of SlabCulverts PDFDocument17 pagesIRCSP13 - Design of SlabCulverts PDFV Venkata Narayana83% (111)

- Ministrycirculars PDFDocument80 pagesMinistrycirculars PDFnaba1577100% (1)

- MoRD Specification For Rural Roads 2014Document626 pagesMoRD Specification For Rural Roads 2014Manoj81% (16)

- SAMIDocument14 pagesSAMIPURUSHOTTAM100% (3)

- Pipe Log, ExcelDocument5 pagesPipe Log, ExcelMasar Abdul RakmanNo ratings yet

- Pavement Design As Per Irc SP 72-2015Document29 pagesPavement Design As Per Irc SP 72-2015Madhavpokale75% (4)

- Pavement Design, Construction and Maintenance for Bituminous RoadsDocument62 pagesPavement Design, Construction and Maintenance for Bituminous RoadsMadhavpokaleNo ratings yet

- Annexure 4.7 - IIT PAVE OutputDocument22 pagesAnnexure 4.7 - IIT PAVE OutputTanmoy Das0% (2)

- WMM Density ExamplesDocument65 pagesWMM Density ExamplesV Venkata Narayana75% (8)

- Mix Design of Stone Matrix Asphalt With Othwad Quarry Aggregate and Bitumen VG 40Document109 pagesMix Design of Stone Matrix Asphalt With Othwad Quarry Aggregate and Bitumen VG 40ਸੁਖਬੀਰ ਸਿੰਘ ਮਾਂਗਟNo ratings yet

- SMART TITLEDocument47 pagesSMART TITLErajibchattarajNo ratings yet

- 7.FDT For Soil, GSB, WMM by Sand Replacement MethodDocument50 pages7.FDT For Soil, GSB, WMM by Sand Replacement MethodSoundar Pachiappan100% (9)

- MoRD Specifications and Manual - Rural Road Construction PDFDocument156 pagesMoRD Specifications and Manual - Rural Road Construction PDFswabright65% (34)

- PP1-Design of Flexible PavementDocument37 pagesPP1-Design of Flexible PavementSrinivas PNo ratings yet

- Design of Flexible Pavements According to IRC 37-2012Document86 pagesDesign of Flexible Pavements According to IRC 37-2012Rahul John Roy100% (5)

- Constructio and QC in Rigid Pavements As Per IRC 15 and 58 201Document192 pagesConstructio and QC in Rigid Pavements As Per IRC 15 and 58 201Vizag Roads100% (39)

- Rigid Pavement Construction As Per IRC SP 62 2004Document113 pagesRigid Pavement Construction As Per IRC SP 62 2004Vizag Roads98% (54)

- Mistake in Bitumen Content Assessment in OGPC and SC in APDocument14 pagesMistake in Bitumen Content Assessment in OGPC and SC in APPrakasam VemavarapuNo ratings yet

- Highway Materials Testing ExperimentsDocument168 pagesHighway Materials Testing ExperimentsVizag Roads89% (9)

- Pavement Design ReportDocument86 pagesPavement Design ReportAK100% (1)

- FIELD DATA SHEET FOR TRAFFIC CENSUS (BOTH DIRECTIONSDocument13 pagesFIELD DATA SHEET FOR TRAFFIC CENSUS (BOTH DIRECTIONSD Chinnam NaiduNo ratings yet

- Highways Department: Enable Macros To Use This ApplicationDocument14 pagesHighways Department: Enable Macros To Use This Applicationveevimal100% (1)

- Widening of existing road to 2 lane NH standards from Potin to Pangin on NH-13Document30 pagesWidening of existing road to 2 lane NH standards from Potin to Pangin on NH-13Navarun VashisthNo ratings yet

- Simple Way of Constructing Road BridgesDocument83 pagesSimple Way of Constructing Road BridgesV Venkata Narayana94% (18)

- IRC 37-2012 Venkats Presentation On FlexiblePavement Design SoftDocument99 pagesIRC 37-2012 Venkats Presentation On FlexiblePavement Design SoftV Venkata Narayana89% (18)

- IRC 37 2018 Guidelines For The Design of Flexible Pavements PDFDocument3 pagesIRC 37 2018 Guidelines For The Design of Flexible Pavements PDFKhairul HoqueNo ratings yet

- RD - W.B.M. ROAD CONSTRUCTIONDocument16 pagesRD - W.B.M. ROAD CONSTRUCTIONMuthusamy ArumugamNo ratings yet

- 1 - 827 - ORN - 40 Axle Load Surveys and Traffic Counts For Traffic LoadingDocument76 pages1 - 827 - ORN - 40 Axle Load Surveys and Traffic Counts For Traffic LoadingHendhira Astianto100% (2)

- Morth 2900 Pipe CulvertsDocument5 pagesMorth 2900 Pipe CulvertsRamesh100% (3)

- 4 Construction and QC in Flexible Pavements As Per MORTH 5th Revision ADocument236 pages4 Construction and QC in Flexible Pavements As Per MORTH 5th Revision AVallabhareddy Nageswara Rao60% (5)

- (PDF) IRC-58 2015 Excel SheetDocument3 pages(PDF) IRC-58 2015 Excel SheetPratik JoshiNo ratings yet

- Flexible Pavement Design PMGSY As Per IRC 72Document2 pagesFlexible Pavement Design PMGSY As Per IRC 72Mayuri ShahNo ratings yet

- Approach Slab Plans for Highway BridgesDocument9 pagesApproach Slab Plans for Highway BridgesV Venkata Narayana100% (1)

- Sieve Analysis of Wet Mix MacadamDocument2 pagesSieve Analysis of Wet Mix Macadamjitendra100% (1)

- Irc 15-2017 PDFDocument94 pagesIrc 15-2017 PDFRashmi Ranjan Samal67% (15)

- IRC 82 2015 Maintenance of Bitumen Surface PDFDocument82 pagesIRC 82 2015 Maintenance of Bitumen Surface PDFanant11235100% (7)

- What Is The Difference Between Codes IRC 37-2001 & 2012Document5 pagesWhat Is The Difference Between Codes IRC 37-2001 & 2012Bijay Krishna Das100% (1)

- 57 - MoRTH 5th RVN What Is Where and Where Is What - Venkata Narayana - PrintDocument4 pages57 - MoRTH 5th RVN What Is Where and Where Is What - Venkata Narayana - PrintV Venkata Narayana100% (2)

- 09 - VV - Pavement Design IRC37-2018 - 29jan2020 - Admin KHRI PDFDocument24 pages09 - VV - Pavement Design IRC37-2018 - 29jan2020 - Admin KHRI PDFAmit Rajendra Phadatare100% (1)

- IRC 58 ExcelDocument21 pagesIRC 58 ExcelMadhavpokale100% (4)

- Pavement Design Report 07-03-2020Document18 pagesPavement Design Report 07-03-2020Chandan Kumar Das50% (2)

- List of IRCDocument31 pagesList of IRCPrapulla RameshNo ratings yet

- RE Wall ConstructionDocument80 pagesRE Wall ConstructionV Venkata Narayana88% (8)

- Cust Design by IIT Pave Software - 08-05-2020Document117 pagesCust Design by IIT Pave Software - 08-05-2020ARTI PALEKAR75% (8)

- Annexure 5.14 Mix DesignDocument10 pagesAnnexure 5.14 Mix Designmiesty50% (2)

- Unit 7 (CONSTRUCTION OF RIGID/CONCRETE PAVEMENT)Document29 pagesUnit 7 (CONSTRUCTION OF RIGID/CONCRETE PAVEMENT)Zara Nabilah76% (33)

- Pavement Design CalculationDocument4 pagesPavement Design Calculationparkashmishra50% (2)

- Flexible Pavement Design SK RaoDocument62 pagesFlexible Pavement Design SK Raokrishnarao krishnarao329100% (3)

- Venkats Interpretation On Configuration of MORTHDocument29 pagesVenkats Interpretation On Configuration of MORTHV Venkata Narayana100% (3)

- Pavement Design Method NewDocument61 pagesPavement Design Method NewPrakash BhandariNo ratings yet

- Mechanistic Pavement Design Using IRC & AI MethodsDocument39 pagesMechanistic Pavement Design Using IRC & AI MethodsAmit Ruchi Yadav100% (1)

- Flexible Pavement DesignDocument127 pagesFlexible Pavement Designer_kenedy100% (5)

- Final PPT On Life Cycle Cost AnalysisDocument33 pagesFinal PPT On Life Cycle Cost AnalysisBharath Kumar M100% (1)

- History of Flexible Pavement Design in IRC 37 GuidelinesDocument41 pagesHistory of Flexible Pavement Design in IRC 37 GuidelinesUday KumarNo ratings yet

- Design of Flexible Pavements For Low Volume Rural Roads - FinalDocument31 pagesDesign of Flexible Pavements For Low Volume Rural Roads - FinalAsit MohantyNo ratings yet

- Flexible Pavement Design MethodsDocument9 pagesFlexible Pavement Design Methodsmuneerpmh100% (1)

- Flexible Pavement Design IRC37 2001 1Document5 pagesFlexible Pavement Design IRC37 2001 1Chatnoir NoirNo ratings yet

- SCHEDULE OF RATES 2013-14 - Government of Andhra Pradesh.Document174 pagesSCHEDULE OF RATES 2013-14 - Government of Andhra Pradesh.Vizag Roads100% (5)

- Highway Materials Testing ExperimentsDocument168 pagesHighway Materials Testing ExperimentsVizag Roads89% (9)

- Buildings SoR 2012 13Document411 pagesBuildings SoR 2012 13Madhu SayariNo ratings yet

- PD Inspecting MPCS in E G DT On 13-09-2012Document15 pagesPD Inspecting MPCS in E G DT On 13-09-2012Vizag RoadsNo ratings yet

- Emulsion Price List Wef 01-04-2011Document6 pagesEmulsion Price List Wef 01-04-2011Vizag RoadsNo ratings yet

- NCRMP TPQA Inspection Visakhapatnam DistrictDocument25 pagesNCRMP TPQA Inspection Visakhapatnam DistrictVizag RoadsNo ratings yet

- Modified BitumenDocument26 pagesModified BitumenVizag Roads100% (2)

- Common SoR 2012-13Document455 pagesCommon SoR 2012-13gsgoud1975100% (1)

- Common SoR 2012-13Document455 pagesCommon SoR 2012-13gsgoud1975100% (1)

- PD, NCRMP Phase II Bridge Sites Inspection On 13-09-2012Document20 pagesPD, NCRMP Phase II Bridge Sites Inspection On 13-09-2012Vizag RoadsNo ratings yet

- Sites For D Type MPCS in E.G.districtsDocument11 pagesSites For D Type MPCS in E.G.districtsVizag RoadsNo ratings yet

- Pothole Repair Technology During Monsoon - by Prof. Prithvi Singh Kandhal, Jaipur, RajasthanDocument3 pagesPothole Repair Technology During Monsoon - by Prof. Prithvi Singh Kandhal, Jaipur, RajasthanVizag Roads100% (1)

- Rigid Pavement Construction As Per IRC SP 62 2004Document113 pagesRigid Pavement Construction As Per IRC SP 62 2004Vizag Roads98% (54)

- Bitumen Prices For The Year 2011Document28 pagesBitumen Prices For The Year 2011Vizag Roads100% (1)

- Bridge Hand BookDocument51 pagesBridge Hand BookPranjal AgrawalNo ratings yet

- A Study On Soil Stabilization Through Innovative Material For Construction of Rural RoadsDocument15 pagesA Study On Soil Stabilization Through Innovative Material For Construction of Rural RoadsVizag Roads100% (3)

- Hindustan Petroleum Corporation Limited: Price ListDocument10 pagesHindustan Petroleum Corporation Limited: Price ListVizag Roads33% (3)

- Hot Mix Recycling of Asphalt Pavements It's Long Overdue in India!Document5 pagesHot Mix Recycling of Asphalt Pavements It's Long Overdue in India!Vizag RoadsNo ratings yet

- Classification of Roads in IndiaDocument30 pagesClassification of Roads in IndiaVizag Roads95% (38)

- Hindustan Petroleum Corporation Limited: Price ListDocument10 pagesHindustan Petroleum Corporation Limited: Price ListVizag Roads33% (3)

- Construction of Tiered Reinforced Soil Retaining Wall at VijayawadaDocument54 pagesConstruction of Tiered Reinforced Soil Retaining Wall at VijayawadaVizag Roads100% (1)

- Bitumen Price List April 2011 To 1st August 2011Document17 pagesBitumen Price List April 2011 To 1st August 2011Vizag RoadsNo ratings yet

- Materials Rates Govt of AP Year 2011Document12 pagesMaterials Rates Govt of AP Year 2011Vizag Roads100% (1)

- Building SSR 2011-12Document403 pagesBuilding SSR 2011-12Guru Prasad0% (1)

- Bitumen Price List April 2011 To 1st August 2011Document17 pagesBitumen Price List April 2011 To 1st August 2011Vizag RoadsNo ratings yet

- Hindustan Petroleum Corporation Limited: Price ListDocument10 pagesHindustan Petroleum Corporation Limited: Price ListVizag Roads33% (3)

- Bitumen Price List April 2011 To 1st August 2011Document17 pagesBitumen Price List April 2011 To 1st August 2011Vizag RoadsNo ratings yet

- Bitumen Price List April 2011 To 1st August 2011Document17 pagesBitumen Price List April 2011 To 1st August 2011Vizag RoadsNo ratings yet

- A Simplified Pavement Condition Index Regression Model For Pavement EvaluationDocument11 pagesA Simplified Pavement Condition Index Regression Model For Pavement Evaluationnelson alfredo grau valenzuelaNo ratings yet

- 21KH0040 Revised PlanDocument24 pages21KH0040 Revised PlanHARRIS DOMINIC DE CHAVEZNo ratings yet

- Australean Guidelines For Road Network Condition Monitoring Part 3 - Pavement StrengthDocument86 pagesAustralean Guidelines For Road Network Condition Monitoring Part 3 - Pavement Strengthaskarah100% (2)

- Rigid Pavement Design For: Any Airport Anywhere, USA Engineer's Are Us 3-XX-XXX-XXDocument15 pagesRigid Pavement Design For: Any Airport Anywhere, USA Engineer's Are Us 3-XX-XXX-XXKaterineNo ratings yet

- 2019 Dec. CE467-C - Ktu QbankDocument2 pages2019 Dec. CE467-C - Ktu QbankAthira RaghavanNo ratings yet

- Flexible Pavement Evolution A Case StudyDocument11 pagesFlexible Pavement Evolution A Case Studydeep khirsariyaNo ratings yet

- Input DataDocument1 pageInput DataForood Torabian IsfahaniNo ratings yet

- Highway & Traffic Engineering Lecture-1Document174 pagesHighway & Traffic Engineering Lecture-1alpeshcivilNo ratings yet

- Precast Rigid PavementDocument53 pagesPrecast Rigid Pavementvsballa75% (8)

- 1388 PDFDocument218 pages1388 PDFHengchhorn PhaiNo ratings yet

- Final Design Report-TANROADSDocument94 pagesFinal Design Report-TANROADSJOSHUA KWIMBANo ratings yet

- Asphalt Manual 35 (Sabita) 0418 PDFDocument92 pagesAsphalt Manual 35 (Sabita) 0418 PDFBradley HariramNo ratings yet

- Optimum Asphalt Pavement Design Using Life Cycle Cost AnalysisDocument11 pagesOptimum Asphalt Pavement Design Using Life Cycle Cost AnalysisPeteris SkelsNo ratings yet

- Concrete Road Design and Construction - Update (2007-2009)Document48 pagesConcrete Road Design and Construction - Update (2007-2009)William HarrowNo ratings yet

- Activities Tranning - NCCER PDFDocument49 pagesActivities Tranning - NCCER PDFAbdiel RiveraNo ratings yet

- Team Leader/Highway Engineer: ORM ECHDocument8 pagesTeam Leader/Highway Engineer: ORM ECHMd. Juwel MondolNo ratings yet

- PH: 9326863164,9823080325, 8275289096, 9404417042, 9595542887 Pune, Amravati, Akola, Badnera, Mumbai, NagpurDocument6 pagesPH: 9326863164,9823080325, 8275289096, 9404417042, 9595542887 Pune, Amravati, Akola, Badnera, Mumbai, NagpurPushpak MahakalkarNo ratings yet

- Index to PE Civil Reference ManualDocument77 pagesIndex to PE Civil Reference Manualfarid nNo ratings yet

- Tanroads Regional Manager's Office - IringaDocument9 pagesTanroads Regional Manager's Office - IringaElisha WankogereNo ratings yet

- ASTM D5340 by NinaadDocument32 pagesASTM D5340 by NinaadajazrajNo ratings yet

- Bituminous Macadam SpecificationsDocument4 pagesBituminous Macadam SpecificationsPremalata NaiduNo ratings yet

- 0 6386 3 PDFDocument302 pages0 6386 3 PDFMD Meftahul AlamNo ratings yet

- HPD Mod 3Document58 pagesHPD Mod 3Swathy MohanNo ratings yet

- Builders: Property LineDocument1 pageBuilders: Property LineJames Nathaniel EscaroNo ratings yet

- R18 3rd Year Civil Engineering Course StructureDocument39 pagesR18 3rd Year Civil Engineering Course StructurebittuchintuNo ratings yet

- Astm D2172-17 (Me4) PDFDocument10 pagesAstm D2172-17 (Me4) PDFJosé Manuel MejíaNo ratings yet

- Materials Testing Technology: Prepared byDocument115 pagesMaterials Testing Technology: Prepared byPaolo NabosNo ratings yet

- Colonel. P Nallathambi. ME (Structural Engg), MBA, FIE, FIV, Structural ConsultantDocument7 pagesColonel. P Nallathambi. ME (Structural Engg), MBA, FIE, FIV, Structural ConsultantAhmad AnasNo ratings yet

- NZTA P11E N Draft v4 30 Sep 21Document6 pagesNZTA P11E N Draft v4 30 Sep 21Ramy HusseinNo ratings yet