Professional Documents

Culture Documents

Design and Behavior of Jib Cranes

Uploaded by

dicktracy11Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Behavior of Jib Cranes

Uploaded by

dicktracy11Copyright:

Available Formats

CIVL 510

Design of behavior of jib crane

Designandbehaviorofjibcrane

Zhen Sun, Abdul Wajid, Qijun Chang

Abstract

(Source:Google)

For: Dr.Stiemer

CIVL510

UniversityofBritishColumbia

By:

ZHENSUN(83204081)

ABDULWAJID(83210088)

QIJUNCHANG(83263087)

Date: April22,2010

Design of behavior of jib crane

Ajibcraneisatypeofcranewhereahorizontalmember(jiborboom),

supportingamoveablehoist,isfixedtoawallortoafloormounted

pillar.Jibcranesareusedinindustrialpremisesandonmilitaryvehicles.

Thejibmayswingthroughanarc,togiveadditionallateralmovement,

orbefixed.Similarcranes,oftenknownsimplyashoists,werefittedon

thetopfloorofwarehousebuildingstoenablegoodstobeliftedtoall

floors.

DesignofjibcraneforCanadianapplicationsisbasedonCMAA(Crane

ManufacturersAssociationofAmerica)specifications#74whichisfor

TopRunningandUnderRunningSingleGirderElectricOverhead

TravelingCranesUtilizingunderRunningTrolleyHoistisreviewed.Steel

structurecomponentsdesignofjibcraneshouldfollowCanadiansteel

structuredesigncodewhichisHandbookofSteelConstruction.

Designofjibcraneincludesstructuraldesign,mechanicaldesignand

electricalequipmentdesignpart.Inthiscase,itfocusedonstructural

designforjibcrane,suchassteelgirder,steelmast,baseplate,bolts

design.

Developmentofaformattedspreadsheetapplicationbasedon

spreadsheettemplatefortensionmember,compressionmemberand

boltsconnection.

4/28/2010

PAGE 1 OF 20

CIVL 510

Design of behavior of jib crane

Zhen Sun, Abdul Wajid, Qijun Chang

TableofContents

Designandbehaviorofjibcrane..............................................................1

Abstract................................................................................................1

TableofContents.................................................................................2

TableofFigures....................................................................................2

1.0Introduction...................................................................................3

2.0Background....................................................................................3

3.0Applicationsofjibcrane.................................................................5

4.0Canadiandesigncode....................................................................5

5.0Designexample..............................................................................8

6.0Spreadshhetapplications.............................................................13

7.0Conclusion....................................................................................13

8.0Bibliography.................................................................................14

AppendixA:SpreadsheetApplication................................................14

Spreadsheetapplicationscreenshot.............................................15

TableofFigures

Figure1:Freestandingjibcrane...........................................................3

Figure2:.Wallmountedjibcrane.............................................................3

Figure3:Wallbracketjibcrane................................................................5

Figure4:Maststylejibcrane...................................................................5

Figure5:Roundmastdesignforfreestandingjibcrane.........................9

Figure6:Ishapemastdesignforwallmountedjibcrane..................10

Figure7:Ishapemastdesignformaststylejibcrane...........................10

Figure8:Tierodspicture........................................................................13

Figure9:Wallbracketconnectionpicture.............................................13

Design of behavior of jib crane

4/28/2010

PAGE 2 OF 20

CIVL 510

Design of behavior of jib crane

Zhen Sun, Abdul Wajid, Qijun Chang

DESIGNANDBEHAVIOUROFJIBCRANES

1.0 Introduction

Acantileveredbeamwithhoistandtrolley.Theliftingdevicemay

pickuploadsinallorpartofacirclearoundthecolumntowhichit

isattachedandaremadeofrolledsteelIbeams.

Ajibcraneisatypeofcranewhereahorizontalmember(jibor

boom),supportingamoveablehoist,isfixedtoawallortoafloor

mountedpillar.Jibcranesareusedinindustrialpremisesandon

militaryvehicles.Thejibmayswingthroughanarc,togive

additionallateralmovement,orbefixed.Similarcranes,often

knownsimplyashoists,werefittedonthetopfloorofwarehouse

buildingstoenablegoodstobeliftedtoallfloors.

2.0Background

2.1HISTORYOFJIBCRANE

In1934,MrGibb,ofAberdeenaccompaniedbyMrMitchell,of

Inverness,inspectedtheharbour,andMrTelfordbeingconsulted,plans

weredrawnforitsreconstruction.Atthisworktravellingjibcranewas

used.FirstactualjibcranewasusedbyTheDavidRoundCompanyin

1869.

2.2 TYPESOFJIBCRANES

2.2.1 Freestandingjibcrane.

(Source:http://www.jherbertcorp.com/cranejib.htm)

FreestandingJibCranesisdirectlyfixedonthefloorwithoutany

supporttokeepitupright.Tomaintainitsstabilityandnottoppleover

ityoufixittoafoundationof3to5feetdeepandupto4to10feet

squarefoundationbase.Thefoundationdependsontheloadandreach.

Advantageofthistypeofcraneisitdoesntneedasupportwallor

structureandprovidesoptimalrangeofspanandcontrolcompareto

wallmountedcranesandothertypesofJibcranes.Thepicturehere

showsa2tonfreestandingjibcraneusedinayardenvironment.

2.2.2 Wallmountedjibcrane

(Source:http://www.jherbertcorp.com/cranejib.htm)

Design of behavior of jib crane

4/28/2010

PAGE 3 OF 20

CIVL 510

Design of behavior of jib crane

Zhen Sun, Abdul Wajid, Qijun Chang

Wallmountedjibcrane.Likethenamesuggeststhiskindofjibcraneis

fittedontothewall.Itrequiresverylittleheadroom,soitcanbefitted

very close to the underside of roofs etc. to provide maximum lift for

your hoist. The coverage like other types of cranes is circular and

generally around 20 feet. But it requires a strong wall or column

structuretofititanddegreeofrotationislesserthanthatofMaststyle

and free standing jib cranes. This crane is very efficient way to move

materialwhenfloorspaceisnotavailableanddiggingafoundationfor

thecraneisnotfeasible.

2.2.3 Wallbracketjibcrane

(Source:http://www.jherbertcorp.com/cranejib.htm)

(Source:http://www.jherbertcorp.com/cranejib.htm)

Thiscraneissimilartowallmountedjibcranesbutwithabracket.Its

amosteconomicalmeansofprovidinghoistcoverageforindividualuse

inbays,alongwallsorcolumnsofplants.Theinstallationrequirements

andloadandrotationarelikethewallmountedcrane.Usealotfor

swingingaroundobstaclesandoverobstructions.

2.2.4 Maststylejibcrane

Design of behavior of jib crane

Thisissimilartofreestandingjibcranesbutdoesntneedaspecial

foundationmakingitmoreeconomical.Buttheydorequiremountingat

thetopandbottom.Theyalsoprovideafull360degreerotationjibs

dependingonthemanufacturerandmaximumamountofliftwithfull

useofavailableheadroomandallowsspecificplacementofboomto

clearobstructions.

2.2WORKINGOFJIBCRANE

Theunderlyinglayoutofajibcranesconsistsofasolidboomshackled

toafixedpivotpoint.Inturn,thispivotissecurelymountedontoawall

orontopofafreestandingcolumn.Thispivotmovesfreely,allowing

180or360degreerotation,andawidearcofoperation.Theliftingis

performedbyanincorporatedpulleyormotorizedchainhoist,which

canslidealongthebookandofferalargefootprintofoperation.Free

standingandmasttypejibcranesoffer360degreerotation.Wall

mountedtypesoffer200degreerotation.

4/28/2010

PAGE 4 OF 20

CIVL 510

Design of behavior of jib crane

3.0APPLICATIONSOFJIBCRANE

Jibcranesarearranged,forexample,inshipbuildingyardsforuse

intransportationofheavyburdens.

Ajibcraneisprovidedwhichcanpreventanunexpected

movementofaburdenandcansufficientlyensurethesafetyofa

burdenhandlingwork.

Themajorstrengthisitsstabilityandflexibilityofthedevice.

Itisidealforliftingaproducttoorfrommaterialhandlingsystem

toaworkstationormachine.

Jibcraneiscommonlyusedforworkstationandsimple

loading/unloadingoperationswhereitisnotnecessarytospota

loadprecisely.

Jibcranesmostoftenhandlelighterloadsatlowerdutycyclesthan

theirbridgeandgantrycranecounterparts.

4.0CanadianDesignCode

4.1CapacityforJibCrane

Themaximumweightoftheapplicationshouldmatchandnotexceed

designweight.Thecapacityratingisbasedonadesignloadwhich

includesthecapacityratingofthecraneplus15%ofthecapacityforthe

weightofthehoistandtrolley,25%ofthecapacityasanallowancefor

impact.Thedeflectionisbasedonadesignloadwhichincludescapacity

plus15%ofcapacityforthehoistandtrolley.

4.2LoadsonJibcrane:(CMAAPage13)

Trolleyload:theweightofthetrolleyandequipmentattachedtothe

trolley.

Deadload:theweightifalleffectivepartsofthebridgestructure,the

machinerypartsandthefixedequipmentsupportedbythestructure.

Liftedload:Theworkingloadandtheweightoftheliftingdevices

VerticalinertiaForces:DeadLoadFactor+HoistLoadFactor.

Design of behavior of jib crane

Zhen Sun, Abdul Wajid, Qijun Chang

AccordingtoCMAAPage14,Deadloadfactorequalsto1.2andHoist

loadfactorequalsto0.15.

Inertiaforcesfromdrives:theinertiaforcesoccurduringaccelerationor

decelerationorcranemotionsanddependonthedrivingandbraking

torques.IFDequalsto2.5%oftheverticalload.

Loadscalculationforjibcrane:

(Craneinregularuseunderprincipalloading)

DL(DLFB)+TL(DLFT)+LL(1+HLF)+IFD(InertiaForcesfromDrives)

TestLoadswillbe125percentofrelatedload.

4.3Girderdesign:BasedonHSCpage5157,beamdiagramsand

formulaeNo.32,simplebeamtwoequalconcentratedmovingloads,

seetheequationbelow:

Andthen,itiseasytogetthemaximumbendingmomentonthebeam

section.

Designcheck:

4/28/2010

PAGE 5 OF 20

CIVL 510

Design of behavior of jib crane

Zhen Sun, Abdul Wajid, Qijun Chang

Andclause13.8.3applies:AllclassesofsectionsexceptClass1andClass

2sectionsofIShapedMembers,whichrequireresistingbothbending

momentsandanaxialcompressiveforce,shouldfollow:

Usinginthefreestandingjibcranescolumndesign:

ValueofU1:

Valuesof1:

F

0.9 Z

M

12

ForsteelE=200000MPa

Andforbiaxialbending,themembershallmeetthefollowing

requirementwhichis

M

M

1.0

M

M

Thegirdersspreadsheetcanbeusedtocheckgirdersection.

4.4Columndesign:basedonHSCpage135,clause13.8.2applies:Class

1andClass2sectionsofIShapedMembersrequiretoresistboth

bendingmomentsandanaxialcompressiveforceshouldfollow:

Usinginthewallmountedjibcranescolumndesign:

Design of behavior of jib crane

Thecompressionmemberspreadsheetcanbeusedtocheckcolumn

design.

4.5Boltsconnectiondesign

Boltsconnectionisrecommendedtouseforlargerspansandcapacities

becauseofshippingconsiderations.Stiffenersareweldedtothemastat

thepointwherewallbracketsareconnectedtostiffentheweboftheI

beam.

4/28/2010

PAGE 6 OF 20

CIVL 510

Design of behavior of jib crane

Bearinginboltedconnections:

B

3 tdnF ,

Boltsinshear:Vr=0.6bnmAbFu,

BoltsinTension:Tr=0.75bnAbFu,

Boltsincombinedshearandtension:(Vf/Vr)2+(Tf/Tr)2 1,

Boltsinslipcriticalconnections:V

0.53c k mnA F ,

V

T

Connectionsincombinedshearandtension:

1.9

V

A F

Zhen Sun, Abdul Wajid, Qijun Chang

4.7Anchorrodsforthebaseplate

1. Thefactoredtensileresistanceofananchorrodshallbetakenas

A F

T

Where:

0.67

A =thetensileareaoftherods

= d 0.938P formetricrods

1.0.

Therefore,boltconnectionspreadsheetcanbeusedtocheckboltgrade

fortheconnection.

4.6Tensionmembersdesign:(shearlagdesign)

forimperialrods

= d

Where:P=thepitchofthread,mm

n=numberofthreadsperinch

2. Anchorrodsinbearing

Thefactoredbearingresistanceofananchorrodshallbetakenas

B

1.4 Af ,

3. Anchorrodsinshear

Thefactoredshearresistanceofananchorrodshallbetakenas

0.60 A F

V

Whentherodsthreadsareinterceptedbytheshearplane,thefactored

shearresistanceshallbetakenas0.70V .

4. Anchorrodscheckinshearandtension:

V

T

1.

V

Anchorrodsarenotrequiredatbaseplateforconcentricallyloaded

columnscarryinggravityloadsonlysinceneitherendmomentsnor

horizontalforcesarepresent.

Anchorrodholesinbaseplateswhichwillreceiveanchorrodsthatare

groutedmaybeflamecut.

Anchorrodholesizeswillvarywithindividualfabricatorsdependingon

shopandfieldpractices.

4.8 Baseplatedesign:

Thetensionmemberspreadsheetcanbeusedtocheck.

Design of behavior of jib crane

4.8.1Theloadedbaseplatestherequiredbearingareaislessthanor

aboutequaltotheareaboundedbythecolumndimensionsbandd.

Platethickness:

4/28/2010

PAGE 7 OF 20

CIVL 510

Design of behavior of jib crane

tp=0.43b

B

F

Where:Br=o.85cf

f =specified28daystrengthofconcrete(MPa)

= 0.75

=2d/b

b=columnwidth(mm)

d=columndepth(mm)

Tominimizedeflectionofthebaseplate,thethicknessshouldbe

generallynotlessthanabout1/5ortheoverhang,morn.

4.8.2 Theloadedbaseplatestherequiredbearingareaexceedthe

areaboundedbythecolumndimensionsbandd.

C

BC F

Ort

C

BC F

whicheverisgreater.

Where:Br=o.85cf ,

C =totalfactoredcolumnload(KN)

A=B*C=areaofplate(mm2)

f =specified28daystrengthofconcrete(MPa)

=0.90forsteel

Tominimizedeflectionofthebaseplate,thethicknessshouldbe

generallynotlessthanabout1/5ortheoverhang,morn.

4.9Tierodsdesign

Atierodthreadedatends,afabricatedbeambracket,andtwowall

brackets;oneforthetierodandonefortheboom.Tierodsareusedto

supportwallbracketjibcrane.Tierodsbelongtotensionmember,

whichissimilartosteelcomponent,barpart.Tierodsdesignshould

followtensionmemberdesignrequirements.

Design of behavior of jib crane

5.0Designexample

Thejibcranedesignexampleislightserviceusingintheindustryarea.

SosomevaluesofjibcranecomefromManufactoryCompany.

JibcranedesigntargetassumptionandsomevaluesofJibcranefrom

ManufactoryCompany:(freestandingjibcrane)

1. Capacityofjibcrane:5tonnes=5000kg

2. Spanlength:6.096m

3. Overallheight:4.572m

4. Heightunderboom:3.658m

5.Mast:D=406.4mm

6.Trolleymodel:311D1423,weight:374.21kg(For5tonnesJibcrane)

7.Wheelbase:232mm=0.232m

5.1Loadscalculation:trystandardIbeamshape:W920*238

(W36*160)

,

Platethickness:

t

Zhen Sun, Abdul Wajid, Qijun Chang

Liftedload=

49.05 KN

DuetotheHLF=0.5*49.05=24.53KN,ImpactingonLL

=0.25*49.05=12.26KN.

Therefore,totalLL=49.05+24.53+12.26=85.84KN

.

Trolleyload=

3.67 KN

TLduetoDLF,whichequalsto3.67*1.2=4.4KN

FortheW920*238,themassis 238kg/m,whichequalsto2.34KN/m.

Therefore,thesectionmassis2.53KN/m,whichincluderailand

conductors.

Deadloadcanbecomputedas2.53KN/m*6.096m=15.42KN

DeadloadduetoDLF,whichequalsto15.42*1.2=18.5KN

FortheIFD,IFD=2.5%*Verticalload,Verticalload=TL+LL+DL=

4.4+85.84+18.5=108.74KN.Accordingly,IFD=2.5%*108.74=2.72KN

Therefore,totalload=108.74+2.72=111.46KN

Andtestloadis125%*111.46=139.3KN

5.2Determinesidetrustforjibcrane:

4/28/2010

PAGE 8 OF 20

CIVL 510

Design of behavior of jib crane

Zhen Sun, Abdul Wajid, Qijun Chang

5.4Columndesign

Cf=139.3KN

Mfx=139.3*2.99=417KN*m

1. For the free standing jib crane, try the column HS406*13, mass is

.

123kg/m,D=406.4mm, t=12.7mm,r=139mm.Deadload:

1.206KN/m.Columnheight=3.658m

Use20%ofthesumoftheliftedloadandtrolley(seeTable2.1of

CMAApage4),equallydistributedtoeachside.

Sidethrust=20%ofcombinedweightofliftedloadand

trolley=0.2*(4.4+85.84)=18.05KN=4.51KN/wheel.

Ratioofsidethrusttomaximumwheelload=4.51/110=0.041

SpecifiedmomentMHduetosidethrust:MH=0.041*322.65=13.2KN*m

Factoredmomentduetosidethrust:MHF=1.5*13.2=19.9KN*m

5.3Girderdesign

Forthefreestandingjibcrane,makeassumptionforthebeamdesign,

spanlengthis20inch(6.096m).Usingthegirderdesignformulation,

accordingtoCISCpage4,makeassumptionthatmaximumwheelload

ofperwheelisP=110KNwhichincludeimpact.

(Source:http://www.jherbertcorp.com/cranejib.htm)

TryaHS406*13column

Thepointofmaximumbendingmomentisat0.5 6096

2990mm,

Basedoncranewheelbasea=232mm<(22)*6096=3570mm,

P

SotheM

1

=

6.096

322.64 KN

.

V

P 2

110 2

216KN,

R

MLL 322.65 KN m.AndMduetoimpacting=322.65*0.25=80.66

KN*m

.

MDL 2.53 6.096

11.75KN*m

Therefore,factoredmomentM

1.25 11.75 1.5 322.64

80.66

619.64KN*m

DesigncheckW920*238,afterusingthespreadsheettocheck,itisOK.

Design of behavior of jib crane

1) Crosssectionalstrength

FromTableofFactoredAxialCompressiveResistance,Page458,Cr=Cro=

621KN.

FromTable46,page418,

1.0

KL

1.0

26.3,

C

Fromtable47,page419, A 2810MPa(byinterpolation),whichis

Eulerbucklingload.

Ce=2810*15700mm2=44117KN,

C

.

0.003,fromTable48,page420,

C

C

C

Accordingly,

4/28/2010

1.003,therefore,U1x=1.003

.

.

0.028

0.675

0.703

1.0,

PAGE 9 OF 20

CIVL 510

Design of behavior of jib crane

ItisOK.

2) Overallmemberstrength

KL

1.0

26.3,fromTable44,page413,C A

298,for

Fy=345MPa,

Cr=Crx=298*15700=4679KN(foruniaxialstrongaxisbending),U1x=

1.003

.

.

Therefore,

0.03 0.675 0.705 1.0,

ItisOK.

3) Lateraltorsionalbucklingstrength

Cr=Cry=4679KN,Mr=621KN*m,U1x=1.0

.

.

Accordingly,

0.03 0.671 0.701 1.0,

ItisOK.

2. Forthewallmountedjibcrane,trytheIshapecolumnW310*118,

columnheightis2900mm,r=136mm,A=15000mm2.

C

C

Zhen Sun, Abdul Wajid, Qijun Chang

0.002,fromTable48,page420,

1.002,therefore,U1x=1.002

.

.

0.03

Accordingly,

ItisOK.

2) Overallmemberstrength

KL

1.0

0.6

0.63

1.0,

21.3,fromTable44,page413,C A

303,for

Fy=345MPa,

Cr=Crx=303*15000=4545KN(foruniaxialstrongaxisbending),U1x=

1.002

.

.

.

Therefore,

0.031 0.6 0.631 1.0,

ItisOK.

3) Lateraltorsionalbucklingstrength

Cr=Cry=CrL=3850KN,(byinterpolation,tableonHSCpage437)

L=2900mm L

4920mm,Mrx=606KN*m,U1x=1.0

.

.

.

Accordingly,

0.036 0.585 0.621 1.0,

ItisOK.

3. For the mast style jib crane, try the Ishape column W310*118,

column height is 4267mm, r=136mm, A=15000mm2.

(Source:http://www.jherbertcorp.com/cranejib.htm)

1) Crosssectionalstrength

FromTableofFactoredAxialCompressiveResistance,Page437,Cr=Cro=

606KN.

FromTable46,page418,

1.0

KL

1.0

21.3,

C

Fromtable47,page419, A 4350MPa(byinterpolation),whichis

Eulerbucklingload.

Ce=4350*15000mm2=65250KN,

Design of behavior of jib crane

(Source:http://www.jherbertcorp.com/cranejib.htm)

1) Crosssectionalstrength

4/28/2010

PAGE 10 OF 20

CIVL 510

Design of behavior of jib crane

FromTableofFactoredAxialCompressiveResistance,Page437,Cr=Cro=

606KN.

FromTable46,page418,

1.0

KL

1.0

31.4,

Fromtable47,page419, A 2000MPa(byinterpolation),whichis

Eulerbucklingload.

Ce=2000*15000mm2=30000KN,

C

.

0.005,fromTable48,page420,

C

C

C

1.005,therefore,U1x=1.005

.

.

Accordingly,

ItisOK.

2) Overallmemberstrength

KL

1.0

0.03

0.59

0.62

31.4,fromTable44,page413,C A

1.0,

=0.0102

0.75

0.65

=2d/b=2,b=d=D=406.4mm

F

350 MP

=0.9forsteel

f =specified28daystrengthofconcrete(MP )=20 MP

A=B*C=Areaofplate(mm2)

DeterminetherequiredareaA=Cf/Br,totalfactoredcolumnloadCf=

5.3+139.3=144.6KN.DetermineBandCsothatthedimensionsmand

nareequal.

D

Consequently,A=144.6KN/0.0102=14177mm2

3.14

.

291,forFy=

345MPa,

Cr=Crx=291*15000=4365KN(foruniaxialstrongaxisbending),U1x=

1.005

.

.

.

0.032 0.59 0.622 1.0,

Therefore,

ItisOK.

3) Lateraltorsionalbucklingstrength

Cr=Cry=CrL=3575KN,(byinterpolation,tableonHSCpage437)

L=4267mm L

4920mm,Mrx=606KN*m,U1x=1.0

.

.

.

Accordingly,

0.036 0.585 0.621 1.0,

ItisOK.

5.5Baseplatedesign

5.5.1Forthefreestandingjibcrane,thecolumnisHS406*13,deadload

forthecolumnis1.206*3.658=4.41KN.DeadloadduetoDLF,which

equalsto4.41*1.2=5.3KN

Design of behavior of jib crane

B

F

Where:Br=o.85cf =0.85 0.6

= 0.75

tp=0.43b

Zhen Sun, Abdul Wajid, Qijun Chang

129651mm2.

Therefore,tp=

0.43b

B

F

0.43 406.4 0.65

.

.

26.9

mm.

TryplateB=C=500mm

Andm=n=500406.4+12.7=53.15mm

.

Therefore,

10.6 t

26.9 mm

SoitisOK.UsePL27*500*500mmforthebaseplate.

5.5.2 Forthemaststylejibcrane,thecolumnisW310*118,deadload

forthecolumnis1.15*4.267=4.9KN.DeadloadduetoDLF,

whichequalsto4.9*1.2=5.9KN. C

5.9 139.3 145.2KN.

4/28/2010

PAGE 11 OF 20

CIVL 510

Design of behavior of jib crane

ForW310*118,b=307mm,d=314mm.

.

AreaofplaterequiredA

14235mm ,whichisless

thanheareaboundedbythecolumndimensionsbandd.

Accordingly,

tp=0.43b

B

F

0.43 406.4 0.66

.

.

27mm.

= 0.75

0.75

0.66

=2d/b=2*314/307=2.05,b=307mm,d=314mm.

F

350 MP .

TryplateB=C=500mm,

m=(5000.95*314)/2=101mm,

n=(5000.8*307)/2=127mm.

Therefore,n/5=127/5=25.4mm<tp=27mm.

ItisOK.Inthiscase,usePL27*500*500mmforthebaseplate.

5.6Boltsconnectiondesignandanchorrods

Fortheboltsconnectiononwallmountedjibcrane,

(Source:

Vfissupportedbysidethrust,whichequalsto18.05KN.Tfisthetotal

tensionfromtheloads,whichis139.3KN.

Therefore,sheartensionratioisX=18.05/139.3=0.13.

TryA325bolts,boltsdiameterd=3/4inch=19.05mm.

Design of behavior of jib crane

Zhen Sun, Abdul Wajid, Qijun Chang

FromHSC313(Table38),permittedVf=14KNandpermittedTf=140

perbolt.

Therefore,numberofboltsrequired=18.05/14 2.

Afterusingboltsconnectionspreadsheettocheckdesign,four3/4inch

A325boltsarerequired.

AndthenitisOK.

Anchorrodssizeisdecidedas20mmforroddiameterandhole

diameteris26mm.Four20mmanchorrodswillbeusedtoconnecttoa

prescribedreinforcedconcretefoundation.Therecommended

foundationsarebasedonasoilpressureof2,500lbs.persq.ft.

Anchorrodscheck:

WhenASTMA325MM20usesforanchorrods

Thefactoredtensileresistanceofananchorrodshallbetakenas

T

A F =0.67*

20 0.938 36 *830=82.7KN

Anchorrodsinshear:

Thefactoredshearresistanceofananchorrodshallbetakenas

0.60 A F =0.6*0.67* 20 *398=50.2KN

V

Anchorrodscheckinshearandtension:

V

T

1.

V

Vf=18.05/4=4.5KN,

Tf=139.3/4=34.8KN.

.

.

Therefore,

0.008 0.177 0.185 1

.

.

ItisOK.Consequently,fourA325MM20boltscanbeusedforanchor

rods.

5.7Tierodsdesign

Use2inchdiametertierodtoconnectafabricatedbeambracket,and

twowallbrackets.Showthepicturesbelow:

4/28/2010

PAGE 12 OF 20

CIVL 510

Design of behavior of jib crane

(Source:http://www.wallacecranes.com/jibwall.htm)

SpanlengthA=6096mm

BracketcentersB=2133mm

Supportbeambrackettobeamend=1066mm

SupporttopivotD=152.4mm

5.8Wallbracketconnection

Topandbottomwallbracketsutilizeaformedsteelchannel,withtwo

bronzebushings,bronzethrustwashers,andformedtierodclevises.

Showthepicturesbelow:

(Source:http://www.jherbertcorp.com/cranejib.htm)

6.0Spreadsheetapplications(checkdesigncomponents).

Jibcranehasmast,girder,andbaseplatethreemajorparts,different

typesofjibcranemayusedifferentshapeofsteelparts.Freestanding

jibcranewilluseroundshapemast,wallmountedjibcranewilluseI

shapecolumn.Forthissituation,wedevelopfourdifferent

spreadsheetsforeachconnectionandstresscheck.CAN/CSAS16.1

LimitStatesDesignofSteelStructureswasusedasthesourceforthe

Design of behavior of jib crane

Zhen Sun, Abdul Wajid, Qijun Chang

equationsandinputvalues.Aprintedcopyofthisspreadsheetis

providedinAppendixAofthisreport.

Theinputparametersarelimitedtoaspecificselection,suchasthebolt

gradesanddiameters.Datavalidationisusedonnumericalinputsto

ensurethattheuserhasenteredvaliddata.

ThespreadsheetsarebuiltonaformattedsheetprovidedbyDr.

Stiemerandareavailablefordownloadat

www.sigi.ca/engineering/steel_design.html.

Thisspreadsheetallowstheusertodefinevariablesandwritethe

formulasintextformat.TheFormatSheetmacroisusedtoparsethe

formulasandwritetheexcelformulainanadjacentcell.

ForthedescriptionsintheFormatSheetweuseGooglesketchupto

builda3Dmodelandsnaptheperspective.Someofthedescriptions

looksimilarwiththeFormatSheetthenwedonotcreateourown

model.

Fourtypesofspreadsheetareusedtochecksteelcomponentsdesign:

1. Girderdesigncheck

2. Mastdesigncheck

3. Boltconnectioncheck

4. Tensionmembercheck

7.0Conclusion

Jibcranedesignprocessesshouldbeidentifiedbyeachsteelcomponent

design.Andthenchecktheconditionforeachcomponent,jibcrane

designwillbedone.Usingthesameprinciple,thedifferentcapacitiesof

jibcranescanbedesigned.Followingthedesignprocesses,the

installationwouldbeeasybyManufactoryCompany.

4/28/2010

PAGE 13 OF 20

CIVL 510

Design of behavior of jib crane

8.0Bibliography

CISC.HandbookofSteelConstruction.Toronto,Ontario:Quadratone

GraphicsLtd,2007.

CMAA.CraneManufacturersAssociationofAmerica.

Guideforthedesignofcranesupportingsteelstructures.NiagaraFalls,

Ontario:HATCHLtd.

http://www.jherbertcorp.com/cranejib.htm

http://www.dearborncrane.com/crane_buyers_guide/jib_cranes.htm

Zhen Sun, Abdul Wajid, Qijun Chang

AppendixA:SpreadsheetApplication

http://www.faqs.org/patents/app/20100072157

http://hubpages.com/hub/GuidetoBridgeCranesandJib

CranesTheBackboneofLogistics

http://lims.mech.northwestern.edu/projects/jibcrane/

http://dcmreality.blogspot.com/2007/11/cranes.html

http://www.bestjibcranes.com/4populartypesofjibcranes/

www.sigi.ca/engineering/steel_design.html

Design of behavior of jib crane

4/28/2010

PAGE 14 OF 20

CIVL 510

Design of behavior of jib crane

Zhen Sun, Abdul Wajid, Qijun Chang

Spreadsheetapplicationscreenshot

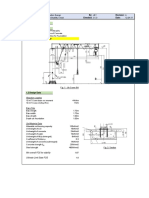

Girderdesigncheck

Design of behavior of jib crane

4/28/2010

PAGE 15 OF 20

CIVL 510

Design of behavior of jib crane

Zhen Sun, Abdul Wajid, Qijun Chang

Mastdesigncheck

Ishapemastdesigncheck:

Design of behavior of jib crane

4/28/2010

PAGE 16 OF 20

CIVL 510

Design of behavior of jib crane

Zhen Sun, Abdul Wajid, Qijun Chang

Roundmastdesigncheck:

Design of behavior of jib crane

4/28/2010

PAGE 17 OF 20

CIVL 510

Design of behavior of jib crane

Zhen Sun, Abdul Wajid, Qijun Chang

Boltsconnectiondesigncheck:

Design of behavior of jib crane

4/28/2010

PAGE 18 OF 20

CIVL 510

Design of behavior of jib crane

Zhen Sun, Abdul Wajid, Qijun Chang

Design of behavior of jib crane

4/28/2010

PAGE 19 OF 20

CIVL 510

Design of behavior of jib crane

Zhen Sun, Abdul Wajid, Qijun Chang

Design of behavior of jib crane

4/28/2010

PAGE 20 OF 20

You might also like

- Design Analysis-Jib CraneDocument22 pagesDesign Analysis-Jib Cranesainal100% (3)

- Design Concept For Jib CraneDocument12 pagesDesign Concept For Jib Cranevish5610100% (3)

- Power Jib Crane DesignDocument64 pagesPower Jib Crane Designhalder.kalyan100% (4)

- Jib Crane Design SellDocument13 pagesJib Crane Design Selljafary100% (3)

- Jib CraneDocument42 pagesJib Cranethiru_jsr67% (6)

- Crane DesignDocument18 pagesCrane DesignSina Enteshari100% (4)

- Jib CranesDocument32 pagesJib CranesmaheshbandhamNo ratings yet

- Crane Design TompsonDocument255 pagesCrane Design TompsonAhmed100% (4)

- Jib CraneDocument16 pagesJib Cranesuperman3k100% (2)

- Jib Crane CalculationDocument2 pagesJib Crane Calculationpaiyyapan78% (9)

- Gantry Crane Design Calculations - Google SearchDocument2 pagesGantry Crane Design Calculations - Google SearchJebin Abraham100% (1)

- Crane Girder DesignDocument6 pagesCrane Girder DesignAya Montes100% (3)

- Jib Crane HandbookDocument10 pagesJib Crane Handbookprp_a100% (3)

- Crane Girder Design ProcedureDocument18 pagesCrane Girder Design ProcedureBhadresh Shah0% (1)

- Design Concepts For Jib Cranes PDFDocument12 pagesDesign Concepts For Jib Cranes PDFanthony cordovaNo ratings yet

- Manual Crane CalculationDocument98 pagesManual Crane CalculationLarry Bea67% (15)

- Crane Beam Design: AISC Design Guide 7 Example 18.1.2 LRFD Aisc CSD 3/25/2005Document38 pagesCrane Beam Design: AISC Design Guide 7 Example 18.1.2 LRFD Aisc CSD 3/25/2005yercNo ratings yet

- Crane Girder DesignDocument6 pagesCrane Girder Designarzu50% (2)

- Jib Foundation Preliminary DesignDocument4 pagesJib Foundation Preliminary DesignChiedu Okondu50% (2)

- Donati Jib Crane Zwenkkranen - Low - ResDocument32 pagesDonati Jib Crane Zwenkkranen - Low - Resvuong100% (1)

- Crane BeamDocument8 pagesCrane BeamastorNo ratings yet

- Design of Gantry Girders 1Document10 pagesDesign of Gantry Girders 1Abhishek Agarwal100% (2)

- Slew Jib Crane StandardsDocument23 pagesSlew Jib Crane StandardsMichael Miotk100% (2)

- Steel Crane Girder Design ExampleDocument4 pagesSteel Crane Girder Design Examplesaman2580100% (1)

- GB 3811-83 Design Rules For Cranes PDFDocument238 pagesGB 3811-83 Design Rules For Cranes PDFmudithaNo ratings yet

- Jib Cranr CalculationDocument2 pagesJib Cranr CalculationShishupal Choudhary50% (6)

- Gantry GirderDocument5 pagesGantry GirderDas TadankiNo ratings yet

- ProgressiveCrane E Book OverheadCranesToptoBottomDocument57 pagesProgressiveCrane E Book OverheadCranesToptoBottomsamdol619100% (1)

- Calculate Design Beam Jib CraneDocument25 pagesCalculate Design Beam Jib Cranejafary100% (14)

- Design of Crane Runway Beam With ChannelDocument9 pagesDesign of Crane Runway Beam With Channellatyrniang100% (3)

- Double Girder Box Type Eot Crane Design v2.0Document64 pagesDouble Girder Box Type Eot Crane Design v2.0deua2004100% (1)

- Gantry Crane Beam Design CalculationDocument2 pagesGantry Crane Beam Design CalculationReda Elawady67% (6)

- Double Girder Gantry CraneDocument12 pagesDouble Girder Gantry CranePhanHatham100% (1)

- Design and Fabrication of Portable Gib CraneDocument36 pagesDesign and Fabrication of Portable Gib CraneAbdul Rasheed100% (7)

- Design and Fabrication of Movable Jib Crane 2020-21Document15 pagesDesign and Fabrication of Movable Jib Crane 2020-21Chandan S RNo ratings yet

- MH CranesDocument9 pagesMH Cranesfika nashirotul millahNo ratings yet

- Design Validations of 450 T Eot Crane With Fea ApproachDocument73 pagesDesign Validations of 450 T Eot Crane With Fea ApproachPartth VachhaniNo ratings yet

- Overview of Eclectric Overhead Traveling Cranes PDFDocument121 pagesOverview of Eclectric Overhead Traveling Cranes PDFSamik Mukherjee100% (1)

- Heavy DutyDocument23 pagesHeavy DutyEmran MuftiNo ratings yet

- TowercranDocument32 pagesTowercrandaveNo ratings yet

- Crane Lifting MCD ProjectDocument43 pagesCrane Lifting MCD ProjectMahes WarNo ratings yet

- Designand Analysisof Wall Mounted Jib CraneDocument11 pagesDesignand Analysisof Wall Mounted Jib CraneDerrick ApongNo ratings yet

- Types of CraneDocument7 pagesTypes of CraneAltayeb YassinNo ratings yet

- Design and Fabrication of Hydraulic FlooDocument35 pagesDesign and Fabrication of Hydraulic FlooEric RogersNo ratings yet

- Chapter-1: Design & Fabrication of Hydraulic Floor Crane 2014Document35 pagesChapter-1: Design & Fabrication of Hydraulic Floor Crane 2014Habtamu GeremewNo ratings yet

- Addis Ababa Bole Internationa Airport InterpriseDocument21 pagesAddis Ababa Bole Internationa Airport Interprisegari100% (1)

- Chapter-1: Design & Fabrication of Hydraulic Floor Crane 2014Document35 pagesChapter-1: Design & Fabrication of Hydraulic Floor Crane 2014Habtamu GeremewNo ratings yet

- Design Algorithm For Tower Crane FoundationsDocument5 pagesDesign Algorithm For Tower Crane Foundationsdraxtter100% (1)

- Report On Gantry Crane and Overhead CraneDocument23 pagesReport On Gantry Crane and Overhead CraneAbhay UpadhyayNo ratings yet

- Crane Hook's Design and Stress Values CalculationDocument26 pagesCrane Hook's Design and Stress Values CalculationbolarinwadeNo ratings yet

- Heavy Lift ProjectsDocument7 pagesHeavy Lift Projectssajjad_naghdi241No ratings yet

- Electric Overhead Traveling Nav GNFCDocument7 pagesElectric Overhead Traveling Nav GNFCkeyur1109No ratings yet

- Lifting and Handling EquipmentsDocument54 pagesLifting and Handling Equipmentsalvin100% (1)

- Design Guide For Overhead CranesDocument3 pagesDesign Guide For Overhead CranesralluinNo ratings yet

- VA Crane Design ProjectsDocument17 pagesVA Crane Design Projectsdsn_sarmaNo ratings yet

- 3 Way Dumping TruckDocument15 pages3 Way Dumping TruckSIVAKUMARNo ratings yet

- Steel CstructionDocument18 pagesSteel CstructionChen QingNo ratings yet

- Dinesh (2015) - Analysis of Crane Hook Using ANSYS Simulation ToolDocument5 pagesDinesh (2015) - Analysis of Crane Hook Using ANSYS Simulation ToolGogyNo ratings yet

- Ajme 5 2 2 PDFDocument10 pagesAjme 5 2 2 PDFDanielNo ratings yet

- PD CEN-TR 15728 2008 Inserts For Lifting and Handling Precast ElementsDocument54 pagesPD CEN-TR 15728 2008 Inserts For Lifting and Handling Precast Elementsdicktracy11100% (1)

- Soil Loads On PipelinesDocument10 pagesSoil Loads On Pipelinesdicktracy11No ratings yet

- Steel StacksDocument2 pagesSteel Stacksdicktracy11No ratings yet

- Concrete Beam Design Flow ChartDocument16 pagesConcrete Beam Design Flow Chartdicktracy11No ratings yet

- Bracket DesignDocument18 pagesBracket Designdicktracy11100% (2)

- 13 Songs You Wish You FoundDocument1 page13 Songs You Wish You Founddicktracy11No ratings yet

- Lifting Lug CalculationDocument5 pagesLifting Lug CalculationEm Mar100% (2)

- Cob Beam DesignDocument7 pagesCob Beam DesignAvinash PathaniaNo ratings yet

- Lewis Constructional Covering Floors PDFDocument2 pagesLewis Constructional Covering Floors PDFVengatesh NJNo ratings yet

- Amendment No. 2 November 2020 TO Is 13920: 2016 Ductile Design and Detailing of Reinforced Concrete Structures Subjected To Seismic Forces - Code of PracticeDocument3 pagesAmendment No. 2 November 2020 TO Is 13920: 2016 Ductile Design and Detailing of Reinforced Concrete Structures Subjected To Seismic Forces - Code of PracticeParchuri PraveenNo ratings yet

- Bracing Connections Green BookDocument29 pagesBracing Connections Green BookLesego MatojaneNo ratings yet

- Beam Design (SSB)Document7 pagesBeam Design (SSB)SaiSowmithGoudNaramalaNo ratings yet

- Ecv 3 UnitDocument8 pagesEcv 3 UnitshakirNo ratings yet

- Ijrdet 0115 02Document6 pagesIjrdet 0115 02Khurram ShehzadNo ratings yet

- Theory Questions Part 2 DCS1Document5 pagesTheory Questions Part 2 DCS1KEN ADAMSNo ratings yet

- Seismic Behaviour and Design of Composite Steel-Concrete StructuresDocument198 pagesSeismic Behaviour and Design of Composite Steel-Concrete Structuresuhu_plus6482No ratings yet

- Ponding of Two-Way Roof Systems: Everal Papers HaveDocument8 pagesPonding of Two-Way Roof Systems: Everal Papers HaveHarish RamachandranNo ratings yet

- Final Exam Open Book, Closed Notes, Do Not Write On This Sheet, Show All WorkDocument5 pagesFinal Exam Open Book, Closed Notes, Do Not Write On This Sheet, Show All Workandi suntoroNo ratings yet

- Presentaion SampleDocument39 pagesPresentaion SampleHamza ZejnilagićNo ratings yet

- Unitised Facade With AcpDocument3 pagesUnitised Facade With AcpVISHAL - CONQUÉRANTNo ratings yet

- Steel To Concrete Joints Design-Manual II enDocument292 pagesSteel To Concrete Joints Design-Manual II enSujeevan Tharmakulasingam100% (2)

- Design of Singly Reinforced Beam: Kaustubh G Wath (Civil Engineering) Itm College of EngineeringDocument27 pagesDesign of Singly Reinforced Beam: Kaustubh G Wath (Civil Engineering) Itm College of EngineeringSalam AbdulNo ratings yet

- Successful Designs For Curtain Wall Attachment PDFDocument4 pagesSuccessful Designs For Curtain Wall Attachment PDFTony ZapantaNo ratings yet

- #Report Altoontash 2004Document246 pages#Report Altoontash 2004Qurrain MirNo ratings yet

- Mechanics of Materials: Pure BendingDocument42 pagesMechanics of Materials: Pure BendingmaycollNo ratings yet

- Assessment Problems - Part IIDocument6 pagesAssessment Problems - Part IIShubham TribhuvanNo ratings yet

- WRD 12 (653) IS 5620 Recommendation For Structural Design Criteria For Low Head Slide Gates (Third Revision)Document32 pagesWRD 12 (653) IS 5620 Recommendation For Structural Design Criteria For Low Head Slide Gates (Third Revision)Anup MitraNo ratings yet

- 4281 - 03 Stiffened Shear WebDocument26 pages4281 - 03 Stiffened Shear WebAndrew GilbrideNo ratings yet

- JSSC Je Syllabus PDF 58Document15 pagesJSSC Je Syllabus PDF 58Apurb KumarNo ratings yet

- QS 2Document65 pagesQS 2Imani AsalankiNo ratings yet

- Typ. Section of Beam: Kalana DesignsDocument4 pagesTyp. Section of Beam: Kalana DesignsParth K PatelNo ratings yet

- Design Water TankDocument83 pagesDesign Water TankHemant Sonawadekar100% (2)

- High Rise Building 2Document168 pagesHigh Rise Building 2Pavithra.G100% (1)

- ETABS PresentationDocument66 pagesETABS Presentationbatistathegame0% (2)

- SAFIR 2011 ManualDocument58 pagesSAFIR 2011 ManualCZengenhariaNo ratings yet

- Adapt PT PDFDocument1 pageAdapt PT PDFOsama RaghibNo ratings yet

- DL 5022-1993Document134 pagesDL 5022-1993ecsuperal100% (1)