Professional Documents

Culture Documents

Design Guide For Air Slide Conveyor PDF

Uploaded by

Hasan Barzegar AvvalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Guide For Air Slide Conveyor PDF

Uploaded by

Hasan Barzegar AvvalCopyright:

Available Formats

DESIGN GUIDE FOR AIR SLIDE CONVEYOR

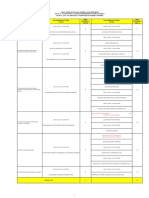

No Subject Requirement (Rule of thumb & Application)

0.66 multiply by bulk density 5 up to 200 lb/ft^3, For material has angle of repose 35 up to 40 deg is categorized as most free flowing material (Book) For bulk density 70PCF - 20inch WG in plenum chamber For bulk density > 70PCF - 27inch WG in plenum chamber

References and notes

DCL, if aerated bulk density is not known DCL

1 Aerated bulk material density 2 Applicated material density for air slide conveyor

3 Pressure required for close type conveyor

400 mmWG 40mBar 4 Permeability and pressure drop of Porous DIAPHRAM unknown Permeability 1.5 m^3/m^2.min, Pressure drop 100mmWG (10mBar)

DCL, 70PCF 1.24ton/m^3 20 inch WG 50 mBar 27 inch WG 67 mBar FLSmidth DCL FLSmidth For case P630, length 35m and diaphram area is 0.63*35 = 22.05 m^2, check fan capacity selected from graphical table 43m^3/min (40mBar) Air ow rate through Porous Membrane= 1.5m^3/m^2.min * 22.05m^2 = 33 m^3/min -------------------------------------------------------- Safety factor for air flow rate for fan according to porous membrane requirement is about 43/33 SF1.3 DCL , Most product suitable for air gravity conveying are handled on a conveyor sloped at between 6 and 12 degrees. The slope can be reduced to 1 or 2 degrees for product which have excellent fluidizing characteristics. FLSmidth, The areated material flows like a liquid at a suitable inclination of the conveyor (4o-15o) depending on the type of material conveyed

5 Minimum sugested conveyor angle

8 deg, but may be as low as 6 degrees depending on product material type.

7 deg, currently aplicated on Tonasa V project is 7 deg (not as minimum but applied conveyor angle)

6a The volume of free air required (Fan flow rate)

10 SCFM (Standard cubic feet per minute) per square foot Dimension of air slide conveyor of DCL A=24 inch (2 ft), length=35m (115 ft) Membrane area = 2 x 115 (ft^2) = 230 ft^2 -------------------------------------------------------Free air requirement = 10 SCFM/sqft * 230 sqft = 2300 SCFM (65 m^3/min) Fan flow rate = standard 65 m^3/min

6b

DCL The volume of free air required for most applications is approximately 10 SCFM per square foot of conveying media when handling a product like cement, fly ash, phosphate rock dust, and lime products. However the air requirements may vary for other materials from 4 to 15 SCFM (standard cubic feet per minute) per square foot. In conveying alumina and bauxite, the air requirement for fluidization can be as little as 4 SCFM. Please be aware that there is no definite formula for calculating the volume of free air required. In order to establish the proper air requirements for materials not previously handled, DCL offers testing at their facility Handbook of pneumatic conveying engineering Chapter 18. Fluidized motion conveying system Basic property of cement portland: 1. Bulk density : 1,070kg/m^3 67lbs/ft^3 2. Particle density : 3,060kg/m^3 191lbs/ft^3 3. Mean particle size : 14m -------------------------------------------------------------Taken from table that (approximation) Terminal velocity needed is 5ft/sec 0.025m/s Porous membrane area is 230ft^2 21.37m^2 Fan ow rate is 0.025m/s*21.37m^2 0.534 m^3/s 32m^3/min SF=1.3 (FLSmidth - previous result) -------------------------------------------------------------------------Fan flow rate requirement = 1.3 * 32m^3/min 42m^3/min Fan flow rate = standard 42m^3/min

6c

FLSmidth Fan flow rate based on P630 and conveying distance 35m is 43 standard m^3/min Fan flow rate = standard 43m^3/min

7 Air supply interval 8 Air pressure for open type conveyors installed in silos or hoppers are generally determined by the head of product over the conveyor

Up to 100 m Air pressure for all material: head product over conveyor, H< 2ft - 1PSI head product over conveyor, 2H<15ft - 2PSI head product over conveyo, H>15ft - 6PSI Except for alumina, pressure of 3 PSI is adequate regardless of head

FLSmidth DCL, pressure up to 1PSI can be supplied by centrifugal blower and pressure greater than 1PSI should be supplied by positive displacement blower . A high pressure compressor plant is not recommended for use in supplying fluidization air as this source is considered dirty air meaning the presence of water and oil Fuller Airslide Conveying Technology, FLSmidth For example, Material Cement Portland (A36M/A16M) A36M: 1.27 up to 1.75 ton/m^3 A16M: 1.06 up to 1.32 ton/m^3 Angle of repose 30-44 deg For A=600 Nominal capacity > 1,500 m^3/h For A16M Cement portland, the capacity is > 1,500 ton/h

9a Standard dimension of conveying channel

9b

DCL 24 inch (600 mm) - 39,000 ft^3/h 1,100m^3/h For A16M Cement portland, the capacity is > 1,100 ton/h

9c

FLSmidth For example, For P630, capacity range is from 250 up to 1000 m^3/h For A16M Cement portland, the capacity up to 1,000 ton/h Conveying angle minimum 4 deg , apllied 7 deg For 35m conveyor length, Fan capacity 35m^3/min (based on 400mmWG air pressure)

9d

Conveyor box width (b) 0.65 (mass flow rate/particle density)^0.5 Mass flow rate = 800 ton/h Cement portland (non aerated) density = 72 ~ 99 lbs/ft^3 85lbs/^3 0.5 as aspect ratio (depth/width of flowing bed) --------------------------------------b 0.65 (800/85)^0.5 2ft 610mm

Handbook of pneumatic conveying engineering Chapter 18. Fluidized motion conveying system

You might also like

- Design Guide For Air Slide Conveyor PDFDocument4 pagesDesign Guide For Air Slide Conveyor PDFDaniel0010100% (2)

- Airslide CalculationDocument1 pageAirslide Calculationsunil_supeda33% (3)

- Airslide Calculation Form Project: Department: Equipment NoDocument3 pagesAirslide Calculation Form Project: Department: Equipment NoManoj Thakur0% (1)

- Field Operator Certification: Sturtevant Separator GuideDocument27 pagesField Operator Certification: Sturtevant Separator GuideRobson DE Freitas WerlingNo ratings yet

- Ball Mill Heat Balance ExplanationDocument4 pagesBall Mill Heat Balance ExplanationVisnu Sankar67% (3)

- Air Slide Conveyor Design RequirementsDocument1 pageAir Slide Conveyor Design RequirementsayaskantkNo ratings yet

- Bag Filter CalculationDocument2 pagesBag Filter Calculationjenifferrayen71% (7)

- Calculation and Design of Air-Slide Conveyor for Thermal Power PlantDocument7 pagesCalculation and Design of Air-Slide Conveyor for Thermal Power PlantHannan yusuf KhanNo ratings yet

- Rotary Valves Feeders and AirlocksDocument7 pagesRotary Valves Feeders and Airlocksmarvin17100% (1)

- Air Slide ConveyorDocument12 pagesAir Slide Conveyorluwky.kitut42No ratings yet

- 11.30 DR Stefan Seemann, KHD Humboldt Wedag GMBHDocument15 pages11.30 DR Stefan Seemann, KHD Humboldt Wedag GMBHMohd AliNo ratings yet

- Bucket Elevator Design and OperationDocument39 pagesBucket Elevator Design and OperationLarry Washington100% (1)

- Kiln Girth Gear Force CalculationDocument7 pagesKiln Girth Gear Force Calculationvikubhardwaj9224No ratings yet

- Krupp Industries India Ltd design calculation manualDocument24 pagesKrupp Industries India Ltd design calculation manualMohsen Ardestani100% (4)

- Spider Air Slide Design For Line-1Document8 pagesSpider Air Slide Design For Line-1Irfan AhmedNo ratings yet

- Bag House Filter DesignDocument5 pagesBag House Filter DesignShermal FernandoNo ratings yet

- Ashaka PulseJet PresentationDocument67 pagesAshaka PulseJet PresentationMega Purnama Zainal100% (2)

- 06 SeparatorDocument91 pages06 SeparatorVăn Vinh100% (2)

- Bag Filter: Technical Manual For Installation, Operation and MaintenanceDocument14 pagesBag Filter: Technical Manual For Installation, Operation and MaintenanceAnand Kesarkar100% (2)

- Air SlidesDocument6 pagesAir SlidesMehmet C33% (3)

- AIRSLIDESDocument4 pagesAIRSLIDESGonzalo VargasNo ratings yet

- All Cement Formulae PDFDocument163 pagesAll Cement Formulae PDFGanapathy SubramaniamNo ratings yet

- Apron Feeder Power Calculations PDFDocument4 pagesApron Feeder Power Calculations PDFtuba25% (4)

- Doc VRM Measurements BATDocument15 pagesDoc VRM Measurements BATsaji kumarNo ratings yet

- Dedusting SystemDocument54 pagesDedusting SystemIrfan Ahmed100% (1)

- 04 05 08Document55 pages04 05 08taghdirim100% (5)

- Oil Analysis Report for VRM Hydraulic SystemDocument2 pagesOil Analysis Report for VRM Hydraulic SystemBhaskar Reddy100% (1)

- Bucket Elevator Vs AirliftDocument10 pagesBucket Elevator Vs AirliftSunil D Pujari100% (1)

- 16 High Efficiency Separator LG 2005-02-02 DGLDocument23 pages16 High Efficiency Separator LG 2005-02-02 DGLRobson DE Freitas WerlingNo ratings yet

- CoolersDocument297 pagesCoolersMUNNALURU UMAKANTHA RAONo ratings yet

- Bag Filter Himenviro - O&m - Cement MillDocument51 pagesBag Filter Himenviro - O&m - Cement Millsambhu0% (1)

- AUMUND Bucket Elevator PDFDocument16 pagesAUMUND Bucket Elevator PDFMadhusudhan Gajula100% (5)

- Weigh Feeders: Learner GuideDocument19 pagesWeigh Feeders: Learner GuideRobson DE Freitas WerlingNo ratings yet

- TS of Travelling TripperDocument10 pagesTS of Travelling TripperShashank HegdeNo ratings yet

- Rotary Airlock Feeder (Valve)Document6 pagesRotary Airlock Feeder (Valve)Ali Hüthüt100% (3)

- Rotary Kiln Motor Instruction ManualDocument15 pagesRotary Kiln Motor Instruction ManualMuhammad100% (3)

- Kiln Thruster LogicDocument3 pagesKiln Thruster LogicSameer kumar GOGOI0% (1)

- Multifuel Rotary Kiln Burner: Presented At: "1 Burner Day" 18 February 2004"Document38 pagesMultifuel Rotary Kiln Burner: Presented At: "1 Burner Day" 18 February 2004"mustafNo ratings yet

- Mini Plant Training Material: Air SlidesDocument28 pagesMini Plant Training Material: Air Slidesbulentbulut100% (2)

- Conveyor Pulley DesignDocument2 pagesConveyor Pulley DesignZoebair100% (1)

- Air in Standard and Normal ConditionDocument2 pagesAir in Standard and Normal ConditionJoko DewotoNo ratings yet

- Air Slide Working ManualDocument20 pagesAir Slide Working ManualKrishnadas Gopalakrishnan100% (3)

- Bucket Elevator Calculation: Yellow Cell To Be FilledDocument2 pagesBucket Elevator Calculation: Yellow Cell To Be Filledm_verma21100% (2)

- Loesche Classifiers Modification Report at MCLDocument42 pagesLoesche Classifiers Modification Report at MCLnsprasad88No ratings yet

- Basic Criteria For Selection of Bag FilterDocument33 pagesBasic Criteria For Selection of Bag FilterMuhammadShoaib100% (3)

- Rex High Performance Chain Bucket Elevator ManualDocument170 pagesRex High Performance Chain Bucket Elevator ManualJohnNo ratings yet

- Vertical Roller MillsDocument56 pagesVertical Roller MillsKob PuangthaisongNo ratings yet

- Chairpad ShimDocument2 pagesChairpad Shimsarat kumar mondal100% (1)

- Bucket Elevator Calculation for Quang Trach 1 Thermal Power PlantDocument8 pagesBucket Elevator Calculation for Quang Trach 1 Thermal Power PlanthbookNo ratings yet

- Kiln AlignmentDocument30 pagesKiln AlignmentKenny Ruiz100% (1)

- Digitally signed wet dust extraction system design reportDocument17 pagesDigitally signed wet dust extraction system design reportmathan_aeNo ratings yet

- Settling ChambersDocument2 pagesSettling ChambersAnonymous d3sWgsNo ratings yet

- Rules Thumb: Summary: P Z 90 TorrDocument9 pagesRules Thumb: Summary: P Z 90 TorrNdzalama RekotsoNo ratings yet

- Compressed Air Design - PSME Seminar 2016Document24 pagesCompressed Air Design - PSME Seminar 2016nathanielvillanueva093086No ratings yet

- HeuristicsDocument19 pagesHeuristicsJesús MorenoNo ratings yet

- Heuristic SDocument19 pagesHeuristic SSaraNo ratings yet

- Heuristic SDocument19 pagesHeuristic SSaraNo ratings yet

- Heuristic SDocument19 pagesHeuristic SSaraNo ratings yet

- AC Duct Design PDFDocument6 pagesAC Duct Design PDFkumar123rajuNo ratings yet

- Solid Mixing in Different Mixing BoxDocument11 pagesSolid Mixing in Different Mixing BoxHasan Barzegar AvvalNo ratings yet

- Solids Article A PDFDocument4 pagesSolids Article A PDFHasan Barzegar AvvalNo ratings yet

- Weight Reduction TechnologyDocument6 pagesWeight Reduction Technologyapi-3775258No ratings yet

- Heating and Cooling CostsDocument7 pagesHeating and Cooling CostsHasan Barzegar AvvalNo ratings yet

- Magneto Caloric Properties of Ni2Mn1-xCuxGaDocument5 pagesMagneto Caloric Properties of Ni2Mn1-xCuxGaHasan Barzegar AvvalNo ratings yet

- Conveyor Belt Joining GuideDocument2 pagesConveyor Belt Joining GuideDaniel GarcíaNo ratings yet

- Design, Development and Analysis of Slat Conveyor For Bagasse Handling in Sugar IndustryDocument15 pagesDesign, Development and Analysis of Slat Conveyor For Bagasse Handling in Sugar Industry60606060No ratings yet

- Bulk Material Handling Belt-Conveyor-CatalogDocument21 pagesBulk Material Handling Belt-Conveyor-CatalogjayNo ratings yet

- Muenstermann Conveying CompleteDocument12 pagesMuenstermann Conveying CompleteRafaelNo ratings yet

- Rex Conveyor IdlersDocument139 pagesRex Conveyor IdlersRodrigo MachadoNo ratings yet

- M - Stainless Steel Take Up FramesDocument4 pagesM - Stainless Steel Take Up FramesKyriakos MichalakiNo ratings yet

- Feeder Loads and Power RequirementsDocument5 pagesFeeder Loads and Power RequirementsarsanioseNo ratings yet

- MODERN PIPE CONVEYORS FOR COAL AND ASH TRANSPORTDocument12 pagesMODERN PIPE CONVEYORS FOR COAL AND ASH TRANSPORTIgor San Martín Peñaloza0% (1)

- English Solid Woven Brochure 2013 PDFDocument16 pagesEnglish Solid Woven Brochure 2013 PDFAnil RoutNo ratings yet

- WO 2053 - Handling - Sec 3 - Electric DiagramDocument96 pagesWO 2053 - Handling - Sec 3 - Electric DiagramMinh TrầnNo ratings yet

- 7957 Item - 405371URSCHELSprint2DicerPartsList 0Document1 page7957 Item - 405371URSCHELSprint2DicerPartsList 0Murathan AydoğanNo ratings yet

- Application Manual-CementDocument4 pagesApplication Manual-CementC Enrique RodriguezNo ratings yet

- Automation and RoboticsDocument23 pagesAutomation and RoboticsvvipmembersNo ratings yet

- Formula calculates conveyor belt transition distanceDocument8 pagesFormula calculates conveyor belt transition distanceRajaram JayaramanNo ratings yet

- Richards Bay Minerals: General RBM ProcedureDocument7 pagesRichards Bay Minerals: General RBM ProcedureHuzaifa KtkNo ratings yet

- Striker SQR2062 20x6 Mobile Scalping ScreenDocument2 pagesStriker SQR2062 20x6 Mobile Scalping ScreenBenjamin MurphyNo ratings yet

- Trimech CatalogueDocument8 pagesTrimech Cataloguecaprolactamcl4571No ratings yet

- Coal Handling Plant: Key Processes and EquipmentDocument38 pagesCoal Handling Plant: Key Processes and Equipmentcp6355100% (3)

- Conveyor Design SummaryDocument37 pagesConveyor Design SummaryJoe GrosirNo ratings yet

- Design of Belt Conveyors Part 1Document32 pagesDesign of Belt Conveyors Part 1anirban687No ratings yet

- Build It SampleDocument7 pagesBuild It SampleMindWorks ResourcesNo ratings yet

- OKULEN Blade.Document10 pagesOKULEN Blade.Dung HoàngNo ratings yet

- Bersemuka LDocument7 pagesBersemuka LPK K0% (1)

- Centrifugation DefinitionDocument32 pagesCentrifugation DefinitionJai Balaji BakerNo ratings yet

- 7600 Series CE End Drive Conveyors: Installation, Maintenance and Parts ManualDocument48 pages7600 Series CE End Drive Conveyors: Installation, Maintenance and Parts ManualAlfred TsuiNo ratings yet

- ContiFlex EPDocument6 pagesContiFlex EPleomar61No ratings yet

- Sincronicas Con Cover Actualizado 2023 JasonDocument58 pagesSincronicas Con Cover Actualizado 2023 JasonSebastian QuintanaNo ratings yet

- Présentation de La Norme CEMA ConvoyeursDocument36 pagesPrésentation de La Norme CEMA ConvoyeursahmedNo ratings yet

- Tender Notice Konar OCPDocument171 pagesTender Notice Konar OCPAmit PalkarNo ratings yet

- Marbett Catalog 2014 PDFDocument394 pagesMarbett Catalog 2014 PDFEdgardo GambandeNo ratings yet