Professional Documents

Culture Documents

Holman 1

Uploaded by

Kumar SamyanaikOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Holman 1

Uploaded by

Kumar SamyanaikCopyright:

Available Formats

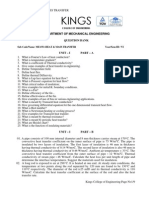

HOLMAN KUMAR 2-48 Derive an expression for the temperature distribution in a hollow cylinder with heat sources which

vary according to the linear relation q = a + br with qi the generation rate per unit volume at r = r i. The inside and outside temperatures are T = Ti at r = ri and T = T0 at r = r0. 2-49 The outside of a copper wire having a diameter of 2 mm is exposed to a convection environment with h=5000 W/m2K and T=1000C. What current must be passed through the wire to produce a center temperature of 150 0C? repeat for an aluminium wire of the same diameter. The resistivity of copper is 1.67 cm. A hollow tube having an inside diameter of 2.5 cm and a wall thickness of 0.4 mm is exposed to an environment at h = 100 W/m 2K and T = 400C. What heat-generation rate in the tube will produce a maximum tube temperature of 250 0C for k = 24 W/mK? Water flows on the inside of a steel pipe with an ID of 2.5 cm. The wall thickness is 2 mm, and the convection coefficient on the inside is 500 W/m 2K. The convection coefficient on the outside is 12 W/m 2K. Calculate the overall heat-transfer coefficient. What is the main determining factor for U? The pipe in problem 2-51 is covered with a layer of asbestos [k = 0.18 W/mK] while still surrounded by a convection environment with h = 12 W/m 2K. Calculate the critical insulation radius. Will the heat transfer be increased or decreased by adding an insulation thickness of (a) 0.5 mm, (b) 10 mm? Calculate the overall heat-transfer coefficient for problem. 2-4. Calculate the overall heat-transfer coefficient for problem. 2-5. Air flows at 1200C in a thin wall stainless steel tube with h = 65 W/m 2K. The inside diameter of the tube is 2.5 cm and the wall thickness is 0.4 mm. k = 18 W/mK for the steel. The tube is exposed to an environment with h = 6.5 W/m 2K and T = 150C. Calculate the overall heat-transfer coefficient and the heat loss per meter of length. What thickness of an insulation having k = 40 W/mK should be added to reduce the heat loss by 90 percent? An insulating glass window is constructed of two 5 mm glass plates separated by an air layer having a thickness of 4 mm. The air layer may be considered stagnant so that pure conduction is involved. The convection coefficients for the inner and outer surfaces are 12 and 50 W/m 2K, respectively. Calculate the overall heat-transfer coefficient for this arrangement, and the R value. Repeat the calculation for a single glass plate 5 mm thick. A wall consists of a 1 mm layer of copper, a 4 mm layer of 1 percent carbon steel, a 1 cm layer of asbestos sheet, and 10 cm of fiberglass blanket. Calculate the overall heat-transfer coefficient for this arrangement. If the two outside surfaces are at 10 and 1500C, calculate each of the interface temperatures. A thin rod of length L has its two ends connected to two walls which are maintained at temperatures T1 and T2, respectively. The rod loses heat to the environment at T by convection. Derive an expression (a) for the temperature distribution in the rod and (b) for the total heat lost by the rod. A rod of length L has one end maintained at temperature T 0 and is exposed to an environment of temperature T. An electrical heating element is placed in the rod so 1

2-50

2-51

2-52

2-53 2-54 2-55

2-56

2-57

2-58

2-59

HOLMAN KUMAR that heat is generated uniformly along the length at a rate q. Derive an expression (a) for the temperature distribution in the rod and (b) for the total heat transferred to the environment. Obtain an expression for the value of q which will make the heat transfer zero at the end which is maintained at T 0. 2-60 One end of a copper rod 30 cm long is firmly connected to a wall which is maintained at 2000C. The other end is firmly connected to a wall which is maintained at 93 0C. Air is blown across the rod so that a heat-transfer coefficient of 17 W/m 2K is maintained. The diameter of the rod is 12.5 mm. The temperature of the air is 38 0C. What is the net heat lost to the air in watts? Verify the temperature distribution for case 2 in sec. 2-9, i.e. that T-T/T0- T =coshm(L-x)+(h/mk)sinhm(L-x)/coshmL+(h/mk)sinhmL Subsequently show that the heat transfer is q = hPkA(T0-T)sinhmL+(h/mk)coshmL/coshmL+(h/mk)sinhmL 2-62 An aluminium rod 2.5 cm in diameter and 15 cm long protrudes from a wall which is maintained at 2600C. The rod is exposed to an environment at 16 0C. The convection heat-transfer coefficient is 15 W/m2K. Calculate the heat lost by the rod. Derive Eq. (2-35) by integrating the convection heat loss from the rod of case 1 in Sec. 2-9. Derive Eq. (2-36) by integrating the convection heat loss from the rod of case 3 in Sec. 2-9. A long, thin copper rod 6.4 mm in diameter is exposed to an environment at 20 0C. The base temperature of the rod is 1500C. The heat-transfer coefficient between the rod and the environment is 24 W/m2K. Calculate the heat given up by the rod. A very long copper rod [k = 372 W/mK] 2.5 cm in diameter has one end maintained at 900C. The rod is exposed to a fluid whose temperature is 400C. The heat-transfer coefficient is 3.5 W/m2K. How much heat is lost by the rod? An aluminium fin 1.6 mm thick is placed on a circular tube with 2.5 cm OD. The fin is 6.4 mm long. The tube wall is maintained at 150 0C, the environment temperature is 150C, and the convection heat-transfer coefficient is 23 W/m 2K. Calculate the heat lost by the fin. The total efficiency for a finned surface may be defined as the ratio of the total heat transfer of the combined area of the surface and fins to the heat which would be transferred if this total area were maintained at the base temperature T 0. Show that this efficiency can be calculated from t = 1-Af/A (1- f) where t = total efficiency Af = surface area of all fins A = total heat-transfer area, including fins and exposed tube or other surface f = fin efficiency 2-69 A triangular fin of stainless steel (18% Cr, 8% Ni) is attached to a plane wall maintained at 4600C. The fin thickness is 6.4 mm, and the length is 2.5 cm. The 2

2-61

2-63 2-64 2-65

2-66

2-67

2-68

HOLMAN KUMAR environment is at 930C, and the convection heat-transfer coefficient is 28 W/m 2K. Calculate the heat lost from the fin. 2-70 A 2.5 cm diameter tube has circumferential fins of rectangular profile spaced at 9.5 mm increments along its length. The fins are constructed of aluminium and are 0.8 mm thick and 12.5 mm long. The tube wall temperature is maintained at 200 0C, and the environment temperature is 93 0C. The heat-transfer coefficient is 110 W/m 2K. Calculate the heat loss from the tube per meter of length. A circumferential fin of rectangular profile surrounds a 2.5 cm diameter tube. The length of the fin is 6.4 mm, and the thickness is 3.2 mm. The fin is constructed of mild steel. If air blows over the fin so that a heat-transfer coefficient of 28 W/m 2K is experienced and the temperatures of the base and air are 260 and 93 0C, respectively, calculate the heat transfer from the fin. A straight rectangular fin 2.0 cm thick and 14 cm long is constructed of steel and placed on the outside of a wall maintained at 200 0C. The environment temperature is 150C, and the heat-transfer coefficient for convection is 20 W/m 2K. Calculate the heat lost from the fin per unit depth. an aluminium fin 1.6 mm thick surrounds a tube 2.5 cm in diameter. The length of the fin is 12.5 mm. The tube-wall temperature is 200 0C, and the environment temperature is 200C. The heat-transfer coefficient is 60 W/m 2K. What is the heat lost by the fin? Obtain an expression for the optimum thickness of a straight rectangular fin for a given profile area. Use the simplified insulated-tip solution. Derive a differential equation (do not solve) for the temperature distribution in a straight triangular fin. For convenience take the coordinate axis as shown and assume one-dimensional heat flow. <FIG. P2-75> 2-76 A long stainless steel rod [k=16W/mK] has a square cross section 12.5 by 12.5 mm and has one end maintained at 2500C. the heat-transfer coefficient is 40W/m 2K, and the environment temperature is 900C. Calculate the heat lost by the rod. A straight fin of rectangular profile is constructed of duralumin (94% Al, 3% Cu) with a thickness of 2.4 mm. The fin is 19 mm long, and it is subjected to a convection environment with h=85 W/m2K. if the base temperature is 90 0C and the environment is at 250C, calculate the heat transfer per unit length of fin. A certain internal-combustion engine is air cooled and has a cylinder constructed of cast iron [k=62W/mK]. The fins on the cylinder have a length of 1.5 cm and thickness of 0.3 cm. The convection coefficient is 68 W/m 2K. The cylinder diameter is 10 cm. Calculate the heat loss per fin for a base temperature of 230 0C and environment temperature of 350C. A 1.6 mm diameter stainless steel rod [k=22W/mK] protrudes from a wall maintained at 490C. The rod is 12.5 mm long, and the convection coefficient is 570 W/m 2K. The environment temperature is 250C. Calculate the temperature of the tip of the rod. Repeat the calculation for h=200 and 1200 W/m2K. A 2 cm diameter glass rod 6 cm long [k=0.8 W/mK] has a base temperature of 100 0C and is exposed to an air convection environment at 20 0C. The temperature at the tip of the rod is measured as 350C. What is the convection heat-transfer coefficient? How much heat is lost by the rod? 3

2-71

2-72

2-73

2.74 2-75

2-77

2-78

2-79

2-80

HOLMAN KUMAR 2-81 A straight rectangular fin has a length of 2.0 cm and a thickness of 1.5 mm. The thermal conductivity is 55 W/mK, and it is exposed to a convection environment at 200C and h=500 W/m2K. Calculate the maximum possible heat loss for a base temperature of 2000C. What is the actual heat loss? 2-82 A straight rectangular fin has a length of 3.5 cm and a thickness of 1.4 mm. The thermal conductivity is 55 W/mK. The fin is exposed to a convection environment at 200C and h=500 W/m2K. Calculate the maximum possible heat loss for a base temperature of 1500C. What is the actual heat loss for this base temperature? A circumferential fin of rectangular profile is constructed of 1 percent carbon steel and attached to a circular tube maintained at 150 0C. The diameter of the tube is 5 cm, and the length is also 5 cm, with a thickness of 2 mm. The surrounding air is maintained at 200C and the convection heat-transfer coefficient may be taken as 100 W/m2K. Calculate the heat lost from the fin. A circumferential fin of rectangular profile is constructed of aluminium and surrounds a 3 cm diameter tube. The fin is 2 cm long and 1 mm thick. The tube wall temperature is 2000C, and the fin is exposed to a fluid at 20 0C with a convection heat-transfer coefficient of 80 W/m2K. Calculate the heat loss from the fin. A 1.0 cm diameter steel rod (k=20 W/m 2k) is 20 cm long. It has one end maintained at 500C and the other at 1000C. it is exposed to a convection environment at 20 0C with h=85 W/m2K. Calculate the temperature at the center of the rod. A straight rectangular fin of steel (1% C) is 2.6 cm thick and 17 cm long. It is placed on the outside of a wall which is maintained at 230 0C. The surrounding air temperature is 250C, and the convection heat-transfer coefficient is 23 W/m 2K. Calculate the heat lost from the fin per unit depth and the fin efficiency. A stainless steel rod has a square c/s measuring 1 by 1 cm. The rod length is 8 cm and k=18 W/mK. The base temperature of the rod is 300 0C. The rod is exposed to a convection environment at 500C with h=45W/m2K. Calculate the heat lost by the rod.

2-83

2-84

2-85

2.86

2-93

You might also like

- Heattransfer1 HW1 PDFDocument2 pagesHeattransfer1 HW1 PDFharrysalmonNo ratings yet

- HMT16 MarksDocument12 pagesHMT16 MarkstagoreboopathyNo ratings yet

- TutorialDocument3 pagesTutorialPaartiban PaneerselvamNo ratings yet

- Heat Transfer Equations and Critical Insulation RadiusDocument18 pagesHeat Transfer Equations and Critical Insulation RadiusPon ShanmugakumarNo ratings yet

- HT Notes For ESEDocument25 pagesHT Notes For ESEM BhurleNo ratings yet

- Unsolved Numericals of HTDocument4 pagesUnsolved Numericals of HTShailendra WaniNo ratings yet

- HT ProblemsDocument2 pagesHT ProblemsNipun SharmaNo ratings yet

- HMT Unit 1Document4 pagesHMT Unit 1Thulasi RamNo ratings yet

- HT Important Questions For End ExamDocument10 pagesHT Important Questions For End ExamSandeepKattaNo ratings yet

- Department of Chemical Engineering, NITK Assignment - 1: Heat Transfer (CH250)Document6 pagesDepartment of Chemical Engineering, NITK Assignment - 1: Heat Transfer (CH250)UdayNo ratings yet

- Heat Transfer Calculations SheetDocument3 pagesHeat Transfer Calculations SheetRafi Mahmoud SulaimanNo ratings yet

- Tutorial - Conduction Heat TransferDocument3 pagesTutorial - Conduction Heat TransferDayanidiNo ratings yet

- Sheet Three ConductionDocument3 pagesSheet Three ConductionMichael EmadNo ratings yet

- 9A03505 Heat TransferDocument4 pages9A03505 Heat TransfersivabharathamurthyNo ratings yet

- Heat & Mass Transfer Tutorial ProblemsDocument2 pagesHeat & Mass Transfer Tutorial ProblemsSaifullah AhmadNo ratings yet

- MIN-305 Heat & Mass Transfer Tutorial - 2Document2 pagesMIN-305 Heat & Mass Transfer Tutorial - 2Ashutosh SinghNo ratings yet

- T-MEET312 PS SurnameDocument9 pagesT-MEET312 PS Surnamekimbenedictaguilar19No ratings yet

- Problems 2Document4 pagesProblems 2Ebenezer EffisahNo ratings yet

- Heat and Mass TransfgerDocument15 pagesHeat and Mass TransfgerPeeyushiRaghavNo ratings yet

- HMT 113401 Anna UnivDocument4 pagesHMT 113401 Anna Univsathiya_ramNo ratings yet

- HMT5Document9 pagesHMT5SriniNo ratings yet

- 1,2,3 ProblemsDocument25 pages1,2,3 ProblemsWild BotNo ratings yet

- Assignment 2Document3 pagesAssignment 2Arjun AgarwalNo ratings yet

- Process Heat Transfer Question BankDocument10 pagesProcess Heat Transfer Question BankMadhuNo ratings yet

- Sheet 4Document3 pagesSheet 4Yasmin RedaNo ratings yet

- ConductionDocument159 pagesConductionNugi100% (1)

- Heat & MassQuestion BankDocument9 pagesHeat & MassQuestion Banksiva_marimuthu_2No ratings yet

- Format For Declaration by InternsDocument4 pagesFormat For Declaration by InternsNavya IshaNo ratings yet

- Unit 11problemsheetDocument6 pagesUnit 11problemsheetKelmy Thomas Maria100% (1)

- Assignment 3Document2 pagesAssignment 3Mukul ParasharNo ratings yet

- Heat Transfer - 012110043920 - 1Document8 pagesHeat Transfer - 012110043920 - 1shweta_770587No ratings yet

- Heat and Mass Transfer Practice Questions 1Document2 pagesHeat and Mass Transfer Practice Questions 1Lucky 230503No ratings yet

- HMT Imp QuesDocument4 pagesHMT Imp QuesEmily BarrettNo ratings yet

- HMT University QuestionsDocument12 pagesHMT University QuestionsDharshan KofiNo ratings yet

- HEAT AND MASS TRANSFER SOLUTIONSDocument11 pagesHEAT AND MASS TRANSFER SOLUTIONSanithayesurajNo ratings yet

- Heat & Mass Transfer UNIT-1 Question BankDocument4 pagesHeat & Mass Transfer UNIT-1 Question Banksaraa009No ratings yet

- Sem 4 QBDocument31 pagesSem 4 QBArvind ThankappanNo ratings yet

- Practice Set 1 (Basic Questions) (1 Copy)Document3 pagesPractice Set 1 (Basic Questions) (1 Copy)TutuNo ratings yet

- Heat Transfer Assignment 1Document3 pagesHeat Transfer Assignment 1Yehia Raef0% (1)

- Heat and Mass Transfer (MCC 15102) Assignmnet - 1: A F B C D EDocument4 pagesHeat and Mass Transfer (MCC 15102) Assignmnet - 1: A F B C D ERotten AppleNo ratings yet

- Tutorial 2-1Document4 pagesTutorial 2-1chandan rajNo ratings yet

- EjerciciosDocument24 pagesEjerciciosMarjorieNo ratings yet

- Updated ProblemsDocument3 pagesUpdated Problemsmahmoud koriemNo ratings yet

- HMTDocument4 pagesHMTsumeetsharma270% (1)

- HMT QBDocument14 pagesHMT QBsandeepsai369No ratings yet

- Ch3 HeatTransfer 2Document27 pagesCh3 HeatTransfer 2abubackersiddieq0% (1)

- Assignment-IDocument6 pagesAssignment-IPrerna JainNo ratings yet

- Department of Mechanical Engineering Question Bank Subject Name: HEAT & MASS TRANSFER Year/Sem: III / V Unit - I Conduction Part - ADocument20 pagesDepartment of Mechanical Engineering Question Bank Subject Name: HEAT & MASS TRANSFER Year/Sem: III / V Unit - I Conduction Part - AjoeannieNo ratings yet

- 34 Tutorial 1 HT1Document2 pages34 Tutorial 1 HT1jameeloNo ratings yet

- Assignment No. 1Document2 pagesAssignment No. 1venkybagalNo ratings yet

- Assignment 2Document1 pageAssignment 2Saptarshi MajiNo ratings yet

- Heat Transfer Problems and SolutionsDocument2 pagesHeat Transfer Problems and SolutionsChinnadurai LakshmananNo ratings yet

- Test-IV (Spring, 2015) ME 308 (Heat and Mass Transfer) : o o o o o 2 oDocument2 pagesTest-IV (Spring, 2015) ME 308 (Heat and Mass Transfer) : o o o o o 2 oKrishnaJaiswal0% (1)

- Solutions Manual to accompany Engineering Materials ScienceFrom EverandSolutions Manual to accompany Engineering Materials ScienceRating: 4 out of 5 stars4/5 (1)

- Product Catalogue (4753)Document48 pagesProduct Catalogue (4753)jebem tiNo ratings yet

- Physics HWDocument16 pagesPhysics HWbeltramini.gaiaNo ratings yet

- High Performance Thermal Insulation Systems Vacuum Insulated Products (VIP)Document124 pagesHigh Performance Thermal Insulation Systems Vacuum Insulated Products (VIP)Zakaria AketouaneNo ratings yet

- Calculation of Time Required To Fill Tanks With Compressed GasDocument4 pagesCalculation of Time Required To Fill Tanks With Compressed Gas1940LaSalleNo ratings yet

- Plastic Sheeting: Its Use For Emergency Shelter and Other PurposesDocument44 pagesPlastic Sheeting: Its Use For Emergency Shelter and Other PurposesOxfamNo ratings yet

- Tica SpecDocument29 pagesTica SpecCong ThanhNo ratings yet

- Catalog Daikin VRFDocument29 pagesCatalog Daikin VRFAlexandru PlesnicuteNo ratings yet

- Insulation PDS & MSDS PDFDocument11 pagesInsulation PDS & MSDS PDFsmartayaz1987No ratings yet

- Armacell Armaflex Sheet Roll Data SheetDocument4 pagesArmacell Armaflex Sheet Roll Data SheetDoniNo ratings yet

- IATA-Live Animal RegulationsDocument23 pagesIATA-Live Animal Regulationsfranky100% (1)

- Gea Plate Heat ExchangersSystemsDocument11 pagesGea Plate Heat ExchangersSystemsBrian May100% (1)

- SYSVRF AIR EVO C HP Q Installation ManualDocument18 pagesSYSVRF AIR EVO C HP Q Installation ManualTomás ArrebolaNo ratings yet

- Chilling: CHILLING - Cristina S. Nebres - MSU at NaawanDocument50 pagesChilling: CHILLING - Cristina S. Nebres - MSU at NaawanLaila UbandoNo ratings yet

- Chapter 3 SolutionsDocument6 pagesChapter 3 SolutionsAnonymous GjWVoVAnWYNo ratings yet

- 160kva Spec SheetDocument3 pages160kva Spec SheetGodfrey James MachotaNo ratings yet

- GEA Ecobraze Plate Heat ExchangersDocument6 pagesGEA Ecobraze Plate Heat ExchangersJean Edouard LalanneNo ratings yet

- NATRAJ INSULATION DATA SHEET REMOVABLE INSULATION JACKETSDocument1 pageNATRAJ INSULATION DATA SHEET REMOVABLE INSULATION JACKETSAmbadnya Hemangini PanditNo ratings yet

- Methods For Determining Time of Death - Maeda B - For Sci Med Pathol 2016Document35 pagesMethods For Determining Time of Death - Maeda B - For Sci Med Pathol 2016Txemari100% (1)

- Effect of Moisture On The Thermal Conductivity of Cellulose and Aramid Paper Impregnated With Various Dielectric LiquidsDocument17 pagesEffect of Moisture On The Thermal Conductivity of Cellulose and Aramid Paper Impregnated With Various Dielectric Liquidsnamsaigon316No ratings yet

- Aspen Aerogels Pyrogel XT PDFDocument4 pagesAspen Aerogels Pyrogel XT PDFBTconcordNo ratings yet

- Vapor Barrier InsulationDocument2 pagesVapor Barrier InsulationSam ChoiNo ratings yet

- K L K L K L: Moisture Barrier (MB) Shell (S) Thermal Liner (TL) 1 MM 1 MMDocument1 pageK L K L K L: Moisture Barrier (MB) Shell (S) Thermal Liner (TL) 1 MM 1 MMCarlos Gonzalez ValarezoNo ratings yet

- Insulator Prorox Ma 520 AluDocument1 pageInsulator Prorox Ma 520 AluNadia DaokajaiNo ratings yet

- Cat Enclosure IngDocument40 pagesCat Enclosure IngJuan Pablo GonzálezNo ratings yet

- Mec551 PDFDocument10 pagesMec551 PDFShah GrungeNo ratings yet

- Dalal Insulation BrochureDocument7 pagesDalal Insulation BrochureConsar natrayanNo ratings yet

- Final hmt-1 PDFDocument211 pagesFinal hmt-1 PDFPoyyamozhi Nadesan RanjithNo ratings yet

- Flexible Jumper Design PremiseDocument12 pagesFlexible Jumper Design PremiseAgus BudionoNo ratings yet