Professional Documents

Culture Documents

Service Manual Epson EMP 50 51 EMP 70 71

Uploaded by

Dennis Javier BujanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Manual Epson EMP 50 51 EMP 70 71

Uploaded by

Dennis Javier BujanCopyright:

Available Formats

Multi Media Projector

SERVICE MANUAL EMP-50/51(SVGA) EMP-70/71(XGA)

EMP-50/51(SVGA) , 70/71(XGA)

INTRODUCTION

This Service Manual describes of the hardware information which is necessary for thesmooth field service of the MULTE MEDIA PROJECTOR EMP-50/51(SVGA)/EMP-70/71(XGA) and the trouble shooting.As the primary technologies modification will be supplied with the service bulletin, you may update this manual. HOW TO USE THE SERVICE MANUAL Since the service manual describes the topics which may be required in the field maintenance, you may utilize this for repair or diagnosis of failures. The contents are as following. Before you start the maintenance service, read every safety precautions and observe safety precautions and observe safety rules. precautions: SAFETY,MAINTENANCE,PERSON chapter 1: GENERAL (PART NAME, SYSTEM FUNCTION, SPECIFICATION, etc...) chapter 2: THEORY OF OPERATION (HARDWARE,INTERNAL CONNECTION, FUNCTION OF UNITS, etc...) chapter 3: DISASSEMBLE & ASSEMBLE (ASSEMBLY PROCESS FOR MAIN FRAME) chapter 4: TROUBLE SHOOTING

VCCI RADIO FREQUENCY INTERFERENCE SELF RESTRICTION

This product is the type 1 information equipment and uses radio frequency energy and fully complies with the limits for the specifications in the computer information equipment radio interference regulation (VCCI rules). If not installed and used properly manufacturers instructions, may cause interference to radio and television reception.

TRADEMARK

EPSON is the trademark of SEIKO EPSON CORPORATION.

NOTICES

1. This document should not be reproduced in whole or in part without the written permission of SEIKO EPSON CORPORATION. 2. Any of description in this document is the subject to change without notice in future. 3. The information and specification in this document are the most up-to-date at the time of publication. However, we are unable to guarantee the accuracy of printed material after the date of publication. In case of any mistake or lack of description, please kindly notify us to correct. 4. Any influence by utilizing the document may be out of our responsibility regardless the item 3 above. 2001 SEIKO EPSON CORPORATION

SEIKO EPSON

0-2

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

Record of Revisions

History REV. A REV. B Issued Date 2000.11.10 2001.11.22 Alternation

ELP-51/71-model addition, a safe test addition

Memo Random

Free area to memorize any important technical information here.

SEIKO EPSON

0-3

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

<PRECAUTIONS>

1. MAINTAIN THE SAFETY OF OPERATORS

(1). PROTECTION FROM ELECTRIC SHOCK Whenever doing any repair work on the product, be sure to turn off the power switch and remove the power cable from the electrical outlet. Whenever inevitably turning the power on to the product opening the case or cover (repair process) be sure to take off any metallic materials such as a watch, cuffs, rings, and tie pins which may touch the metallic part of the product and dangerous of electric shock. (2). PROTECTION FROM ACCIDENTAL INJURY Be sure not to touch the lamp inner housing and its circumstances after the power is turned off, they may be heated up even after the cooling down process was completed. Also make sure not to touch the fan (inhale/exhaust/power supply unit A) and safety switch terminal during the operation of repair as turning the power on. Make sure to protect your hands by gloves from sharp edges during assembly and disassembly. Do not look into the light source or lens while the lights is on. Protect eyes from being damaged. (3). PROTECTION FROM ACCIDENTS Any operation should be done while the device placed on a flat and stable place to prevent the device or parts from being dropped. Be careful not to place tools and parts on the device or at your feet. Whenever doing any repair work on the product, be sure to away from a place for foreigner come across in order to prevent the product from being used in incomplete condition or accidental near miss. Be sure not to leave the product during any repair work. Be sure to use attached power cable and secure the earth line when you supply the power to the product.

2. SAFETY MAINTENANCE

(1). PROTECTION FROM ELECTROSTATIC DISCHARGE Whenever doing any repair work on the product, be sure to wear the wrist band and the electrostatic mat with grounding. When replacing any electric components (Boards and Optical engine), it is recommended to touch the electrostatic plastic bag of the component to the metallic part of the product once before take out the component from plastic bag. (2). LIMITATION OF PARTS Use only authorized or supplied parts from EPSON for the parts replacement including the lamp inner housing, and so on. Use only the power cable and the interface cables attached with the product. (3). SAFETY TESTING The following tests should be carried out on repair parts used in the LCP. (3-1).Test items Insulation resistance test Ground continuity check Illumination check

SEIKO EPSON

0-4

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

(3-2).Testing procedure Carry out testing in the order given below.

Repair Insulation resistance test Ground continuity check Illumination check End

Safety inspections

(3-3).Testing methods 1).Insulation resistance test Testing apparatus: Insulation ohmmeter (Rating: 500 V/100 M) Check item <Insulation resistance check> Inspection method Insulation ohmmeter Standard/Judgment level Insulation resistance should be 10 M or more

Insulation ohmmeter settings

Line terminal Ground terminal Display 1. Set the range selection switch to 500 V. 2. Connect the black lead wire to the ground terminal. 3. Connect the red lead wire to the line terminal. 4. Connect the black lead wire (crocodile clip) to c in order to measure the insulation resistance (1) (between a and c) in the diagram below. 5. Next, insert the probe of the red lead wire into a. 6. Set the measure switch to LOCK, and then measure the insulation resistance after 1 minute. 7. Check that the insulation resistance after 1 minute is 10 M or more. 8. Next, measure the insulation resistance at (2) (between b and c) in the diagram below in the same way as for (1). 9. Check that the insulation resistance at (2) after 1 minute is 10 M or more. Power supply lines Measure switch

Range selection switch

(1) (2)

Projector AC inlet

Caution: Because high voltages (500 V) are present, do not touch the probe during testing.

Exposed metal part of projector

Computer IN connector

SEIKO EPSON

0-5

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

2).Ground continuity check Testing apparatus: Multimeter (with sensitivity down to 0.1 ) Check item <Ground continuity check> Multimeter settings Inspection method Multimeter Standard/Judgment level Should be no resistance (0.5 or less)

Display 1. Turn on the power switch. 2. Set the range selection switch to . 3. Connect the black lead wire to the COM terminal. 4. Connect the red lead wire to the V//Hz terminal. 5. Check that the resistance at (1) in the diagram below is 0.5 or less.

AC inlet ground DC/AC, SW

Range selection switch

(1)

Projector AC inlet

Terminals

COM

V , , Hz

Computer IN connector Exposed metal part of projector

3).Illumination check Test conditions: Input a PC or video signal to the LCP and check the illumination for about 5 minutes. Judgment: Projector should operate normally with no smoke or fire.

SEIKO EPSON

0-6

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

(4). Others Visually check the distortion or dirt at the connectors of the power cable. If dirty, clean off, and if distorted, replace the cable in order to avoid firing by the flush over phenomenon. When plug the internal connector cables or the interface cables, be sure to fully plug into the connectors until it stack to the connector edge. Whenever doing removal of parts or repair work on the product, make sure that the work is done in a clean room, free of dust and dirt in order to keep the optical element away from dirt. When disconnecting the operation panels FPC cable from the CN501 connector on the MA board, be sure to release the connector lock first. The connector lock should be unlocked by pulling up the both end of connector lock simultaneously with tweezers. Explored view of CN501

Lock

CN501

Unlock

light valve FPC

Unlock the connector lock before disconnect the three FPC cables of the light valve and MA-IF cable. (Pull up the black area of the connector.)

Lock state connector lock FPC cable Unlock state (Pulling up the black area) connector lock FPC cable

3. REQUIREMENT FOR THE MAINTENANCE PERSON

Authorized person should have the following knowledge and skill for the maintenance of EMP50/51,EMP-70/71. Need to sufficiently understand the operation and the descriptions of Users manual. Need to have the basic knowledge of electricity (safety operation, circuit diagram, electrostatic, and else...)

4. OTHERS

Any questions on the EMP-50/51,EMP-70/71 maintenance including supply of the service parts or contents of the document would like to be contacted to the below address. Any technical information about amendments is occasionally available as the service bulletin. SEIKO EPSON CORPORATION ADDRESS: 4897 SHIMAUCHI, MATSUMOTO-SHI, NAGANO-KEN 390-8640 JAPAN TEL: 81-263-48-5437 FAX: 81-263-48-5680 ATTN: VD CS Group

SEIKO EPSON

0-7

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

Chapter 1 Product general

1.1. PRODUCT GENERAL ............................................................................ 1-2 1.2. PART NAME ........................................................................................... 1-3 1.2.1. Outside View of Main Frame ........................................................... 1-3 1.2.2. Inside View of Main Frame.............................................................. 1-5 1.2.3. Outside View of Remote Controller ................................................. 1-7 1.3. SPECIFICATIONS .................................................................................. 1-8 1.4. INTERFACE SPECIFICATION ............................................................. 1-10 1.4.1. Computer....................................................................................... 1-10 1.4.2. Audio-In ......................................................................................... 1-11 1.4.3. Audio Out ...................................................................................... 1-11 1.4.4. S-Video.......................................................................................... 1-11 1.4.5. Composite VideoVideo-Audio Interface ....................................... 1-12 1.4.6. Mouse/Com ................................................................................... 1-12 1.4.7. USB Mouse ................................................................................... 1-12

Chapter 2 Theory of operation

2.1. HARDWARE ........................................................................................... 2-2 2.1.1. Electrical System Connections........................................................ 2-3 2.1.2. Circuit block..................................................................................... 2-4 2.1.3. Process Outline ............................................................................... 2-5 2.2. Optical Engine......................................................................................... 2-6 2.3. POWER SUPPLY UNIT .......................................................................... 2-9 2.4. BALLAST UNIT ..................................................................................... 2-12 2.5. MA BOARD ........................................................................................... 2-13 2.6. OPERATION PANEL ............................................................................ 2-16 2.7. IF BOARD ............................................................................................. 2-17 2.8. RECEPTOR SENSOR .......................................................................... 2-19 2.9. SPEAKER ............................................................................................. 2-20 2.10. TEMPERATURE CONTROL .............................................................. 2-21 2.10.1. SENSOR/SWITCH ...................................................................... 2-21 2.10.2. Lamp Cover Detection Switch ..................................................... 2-21 2.10.3. SAFETY SWITCH ....................................................................... 2-22 2.10.4. THERMISTOR AND TEMPERATURE SENSOR OPERATION . 2-22 2.11. FAN OPERATION............................................................................... 2-24 2.12. LED INDICATOR ................................................................................ 2-26

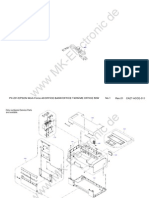

Chapter 3 Disassembly and assembly

3.1. DISASSEMBLY AND ASSEMBLY PROCEDURES ............................... 3-2 3.2. DISASSEMBLING THE MAIN UNIT ....................................................... 3-5 3.2.1. Removing the Lamp Inner Housing................................................. 3-6 3.2.2. Removing the Front Case Unit ........................................................ 3-7 3.2.3. Removing the Upper Case Unit....................................................... 3-8 3.2.4. Removing the Speaker.................................................................... 3-9 3.2.5. Removing the Safety switch .......................................................... 3-10 3.2.6. Removing the LAMP Thermistor ................................................... 3-10 3.2.7. Removing the Lamp Fan ............................................................... 3-11 3.2.8. Removing the MA Board Assy ...................................................... 3-11 3.2.9. Removing IF Board/IF Fixing Plate ............................................... 3-13

SEIKO EPSON

0-8

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

3.2.10. Removing the Shilde plate RE/Lampe fan duct........................... 3-13 3.2.11. Removing the Optical engine ...................................................... 3-14 3.2.12. Removing the Focus ring ............................................................ 3-16 3.2.13. Removing the Projection Lens .................................................... 3-16 3.2.14. Removing the PBS fan/Ballast duct Unit ..................................... 3-17 3.2.15. Removing the Intake (L/V) fan..................................................... 3-17 3.2.16. Removing the Ballast unit............................................................ 3-18 3.2.17. Removing the Exhaust fan .......................................................... 3-18 3.2.18. Removing the Lamp Cover Detection Switch.............................. 3-19 3.2.19. Removing the Power Supply Unit................................................ 3-19 3.2.20. Removing the Foot unit/Rear foot ............................................... 3-20

Chapter 4 Troubleshooting

4.1. BEFORE STARTING TROUBLESHOOTING PROCEDURES .............. 4-2 4.1.1. Tools and Accessories Required for Troubleshooting..................... 4-2 4.1.2. Field Replacement Parts ................................................................. 4-2 4.2. ENTRY .................................................................................................... 4-3 4.2.1. Outside view.................................................................................... 4-4 4.2.2. Internal cable connections............................................................... 4-5 4.2.3. Power ON/OFF................................................................................ 4-6 4.2.4. Display/Picture quality ..................................................................... 4-8 4.2.5. Audio output .................................................................................. 4-10 4.2.6. Operation panel............................................................................. 4-11 4.2.7. Remote controller .......................................................................... 4-12 4.2.8. Mouse/Com, USB Mouse.............................................................. 4-13 4.2.9. Others............................................................................................ 4-14

SEIKO EPSON

0-9

Revision:B

Chapter 1 Product general

EMP-50/51(SVGA) , 70/71(XGA)

1.1. PRODUCT GENERAL

EMP-50/51 EMP-70/71 MULTI MEDIA PROJECTOR designed as the new model of EPSON projector series is the portability device with SVGA (EMP-50/51)/XGA (EMP-70/71) resolution to project enhanced color images from the personal computers CRT and any one of video equipment such as video tape deck, video camcorders or digital camera. FEATURE OF EMP-50/51,EMP-70/71 Portable light weight, compact size The new type of power unit and circuit board and the simple structure enables to minimize the body in A4 file size [220(D)x300(W)x80(H)mm] with the weight of 3.1 kg. Bright and clear image A compact, high-luminance lamp inner housing (EMP-50/70 UHE-150W.EMP-51/71 UHE-160W) and an optical block produce images with a luminance of 1200lm (for the EMP-51)1000lm (for the EMP-50/71) or 700lm (for the EMP-70). The size of the projected image can be set within a range of 30300 inches (projection distance 1.011.0 m). High resolution full color (16770 thousands colors) EMP-50/51: 3 (R, G, and B) of TN liquid crystal panels of 480,000 pixel will supply SVGA resolution of 800 x 600 dots. EMP-70/71: 3 (R, G, and B) of TN liquid crystal panels of 786,432 pixel will supply XGA resolution of 1024 x768 dots. Standard attachment of remote controller The projector can be controlled using a handheld remote control unit, with menus being provided for Image source switching and Image adjustment. Connectivity with various computers The advanced data signal determination function enables EMP-50/51,EMP-70/71 to connect with various computers such as IBM-compatible PCs and laptops, Macintosh. It also determines video signal of NTSC, PAL or SECAM in composite video, S-Video format. Advanced Image Real-time Resizer The projector also features a new customized resinging processor (Advanced Image Real-time Resizer) chip for supporting of miscellaneous video signals. No matter what type of output is used, the result is full-size video image of outstanding clarity. Low noise Less than 42dB at operation. Automatic Video Tracking A totally new AVTSSTM (Automatic Video Tracking and Synchronization Sensing, patent pending) provides automatic setup of image from a computer with a touch of the AUTO button for quick and easy projection of beautiful images every time. Simple Maintenance The easy maintenance. Number of image adjustment process is not required.

SEIKO EPSON

1-2

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

1.2. PART NAME

1.2.1. Outside View of Main Frame

Projector Unit

Operation panel Tele Wide Speaker Operation display indicator Warning indicator

Receptor part Focus ring Projection lens Front foot Foot lever

<FRONT SIDE VIEW>

Air Intake vent Input/Output terminals Air Intake vent

<REAR SIDE VIEW>

Figure1-1

Operation panel

Power button ON/OFF of the switching power supply. Help button Explain the treatment method when the trouble is broke out in terms of the item. Keystone(<Select>) button Adjust the screen when it was distorted to the trapezoid. At Help menu, it works <Select> +/- key.

Source button Switches input source. Computer S-video Composite Video Computer. Not connecting S-Video, S-Video is not selected. At Help menu, it works enter key.

Figure1-2

SEIKO EPSON

1-3

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

Input Terminals

Computer/ Component Terminal Input the video signal from the computer, or the RGB video signal. Audio In Terminal Input the audio signal from the computer by the stereo mini jack. Mouse/Com Terminal Used when using the remote control as a wireless mouse.

USB Mouse Terminal Used when using the remote control as a wireless mouse.

Audio Out Terminal Out put the audio signal to the external speaker.

S-Video Terminal Input the S-video signal of the A/V devices.

R-Audio-L Terminals Input the audio signal from the A/V devices.

Video Terminal Input the video signal of the A/V devices.

<REAR SIDE VIEW>

Figure1-3

AC inlet

Air exhaust vent

<LEFT SIDE VIEW>

Figure1-4

SEIKO EPSON

1-4

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

1.2.2. Inside View of Main Frame

Power supply unit

MA board

Projection lens

Ballast unit

Exhaust fan

LAMP thermistor L/V thermistor

Safety switch

Lamp fan

IF board assembly

Figure1-5

Operation panel

Speaker

Figure1-6

SEIKO EPSON

1-5

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

RC photosensor

Foot lever R

Foot lever L

Foot unit

Rear foot

Foot unit

Figure1-7

Lamp fan

Figure1-8

Lamp inner housing

Figure1-9

SEIKO EPSON

1-6

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

1.2.3. Outside View of Remote Controller

Remote controller

POWER Button This button is used to turn the projector power on and off. Indicator Lights during signal output from remote control. Freeze Button This button is used to momentarily pause playback of moving pictures. If you press the button once more, or if you press the ESC key, normal playback will resume. A/V Mute Button This button is used to momentarily turn off the picture and sound. If you press the button once more, or if you press the Esc button or the Volume button, normal playback will resume. Effect Button This button is used to activate the assigned effect function. Enter Button Press this button to accept menu selections. If cascading screens are being displayed, the screen directly underneath the current screen will be displayed. When projecting images from a computer, this button operates in the same way as the left button on a two-button mouse. When the Enter button is pressed up or down or to the left or right, the remote control unit operates as a wireless mouse to move the pointer moves in the direction that the button was pressed. If a menu is being displayed, the currently-selected item can then be adjusted. When the Enter button is pressed up or down or to the left or right, the bar moves in the direction that the button was pressed. Menu Button This button is used to display and clear on-screen menus. Computer Button This button is used to switch to a picture which is being input from the computer terminal. S-Video Button This button is used to switch to a picture which is being input from the S-Video terminal. DOWN UP

Remote Control Light Part The remote control signals are output from here.

R/C ON OFF Switch This switch is used to turn the remote control units power supply on and off. E-zoom Button This button is used to activate the E-Zoom function in order to enlarge or reduce the size of the projected images. The function can be cancelled by pressing the Esc button. To enlarge To reduce Esc Button This button is used to cancel the function which is currently being used. If a menu or help screen is being displayed, the screen directly above the current screen will be displayed. When projecting images from a computer, this button operates in the same way as the right button on a two-button mouse. Help Button This button is used to provide explanations of the various projector functions and operations. You can use this feature if you are not sure what to do. Video Button This button is used to switch to a picture which is being input from the video terminal. Auto Button This button is used to optimise computer images. Volume Button This button is used to adjust the volume.

Figure1-10

SEIKO EPSON

1-7

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

1.3. SPECIFICATIONS

Table 1-1

OPTICAL FEATURES Display method Optical method Projection image size Projection distance Resolution Projection Lens Focus adjustment Zooming adjustment Lamp inner housing Lamp life (Lamp inner housing) EMP-50/70 EMP-51/71 Transparency type poly-silicon TFT color liquid crystal display (R/G/B three panels) Dichroic mirror separation and prism combine method Minimum 30 inch to maximum 300 inch 1.0 m to 11.0 m EMP-50: 800 x 600 dots EMP-51: 800 x 600 dots EMP-70: 1024 x768 dots EMP-71: 1024 x768 dots F1.5 (26.3 mm) Manual Digital(1:1.2) UHE discharge lamp 150W UHE discharge lamp 160W Life : 1500 hours (at 50% brightness or Life : 1500 hours (at 50% when survival rate is 50%) brightness or when survival rate Average illuminance: EMP-50:1000lm is 50%) EMP-70:700lm Average illuminance Average illuminance ratio:90% EMP-51:1200lm EMP-71:1000lm Dynamic speakers 8-1W (monaural) External speaker 3.5mm Stereo mini-jack Internal speaker output is stopped when mini-jack is plugged. Output signal:0 to 500mVrms load imperdance:600 (Adjustable with volume selection) Audio signal(monaural) from the video devices. Interface type: RCA jack (white: Stereo L or monaural/Red: Stereo R) Input signal:500mVrms/47k Host computer Audio input (monaural) Interface type:3.5mm Stereo mini-jack Input signal: 500mVrms/47K For controlling EMP-50/51,EMP-70/71 operating mode. Signal is detected with internal receptor board. Control range: Within 10 m and 30 degree for right and left, 15degree for up and down from receptor. Host computer RGB output Interface type: HD-15pin(DDC1/2B compatible) Input signal:0.7Vp-p,75. Interface type: Min-DIN 4pin Luminous:1.0Vp-p, Chrominous 0.284Vpp. Input signal: 1.0Vp-p,sync.negative 75. Interface type: RCA jack (yellow) TV signal type: NTSC 3.58MHz,NTSC4.43(4.43MHz) PAL 4.43MHz,NPAL(3.58MHz), MPAL ( 3 . 5 8 M H z ) , PAL60(4.43MHz) SECAM 4.43MHz Auto identification(Default) Auto identification (PS/2 Mouse or RS232C) Interface type: DIN 9pin

AUDIO FEATURES Output for internal speaker Audio out Interface (Audio-OUT)

Video Audio L/R interface (Audio L/R)

Audio In interface (Audio In) REMOTE CONTROL Wireless remote controller

VIDEO INPUT/OUTPUT Computer interface (PC-RGB) S-Video Interface Video interface (Composite video)

MOUSE/COM Serial Mouse or RS-232C PS ADB

SEIKO EPSON

1-8

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

Table 1-1

USB MOUSE USB Mouse POWER SUPPLY, etc. Input Voltage Power Consumption Dimensions Weight ENVIRONMENT Operational/storage temperature Operational/storage humidity Operational/storage Altitude USB Mouse Interface type: USB connector series B AC100-120V /220-240V10% (50/60Hz) Approx. 230 W (Standby mode:8.6W) 220 mm (D) x 300 mm (W) x 80 mm (H) Approx. 3.1 kg +5C~+35C / -10C~+60C (non condensing) 20%~80% / 10%~90% (non condensing) 2286/9144m

SEIKO EPSON

1-9

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

1.4. INTERFACE SPECIFICATION

Figure1-11

1.4.1. Computer/Component Video Interface

Computer video input D-Sub 15 (HD)

CN100 7513S-15G2

Pin No. 1 2 3 4 5 6 7 8

Pin name Computer Red video signal Green video signal Blue video signal Monitor bit ID bit 2 GND GND GND GND Component Cr / Pr Y Cb / Pb None None GND GND GND

Pin No. 9 (None) 10 11 12 13 14 15

Pin name Computer (No pin) Sync GND Monitor bit ID bit 0 SDA Horizontal sync/ composite sync Vertical sync SCL Component (No pin) None None None None None None

SEIKO EPSON

1-10

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

1.4.2. Audio-In (Computer audio input) Interface

Stereo mini jack with 2 circuits for detection pin (The detection pin which is not required for audio input, is equipped for audio out terminal.)

6

Pin No. 1 2 3 4 5 6 7 8 9

Signal name GND Computer audio input L Computer audio input R GND GND GND GND GND GND

J000 LGS6507-0800

1.4.3. Audio Out (audio output) Interface

Stereo mini jack with 2 circuits for detection pin

6

1 9

DGND

Pin No. 1 2 3 4 5 6 7 8 9

Signal name GND Audio output L Audio output R NC AJET GND GND GND GND

J001 LGS6507-0800

1.4.4. S-Video Interface

Mini DIN 4-pin with a detection pin

CN000

TSC7708-012021

8 7

DGND

Pin No. 1 2 3 4 5 6

Signal name GND GND Y signal input C signal input Input detect pin GND

4 2

3 1

SEIKO EPSON

1-11

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

1.4.5. Composite VideoVideo-Audio Interface

RCA pin jack x 3

CN001 JPJ4791-010234

CVBS(Yellow)

1

R(Red)

5 4

L(White)

Pin No 1 2 3 4 5 6 7 8

DGND DGND

Signal name GND CVBS GND NC VAINL GND VAINL VAINR

1.4.6. Mouse/Com Interface

Mini DIN 9-Pin

CN900

35128A-09G2T

Pin No 1 2 3 4 5 6 7 8 9

DGND

1 3 7 4 8

2 5 6 9

Signal name PCV CLK/ADB DATA TxD RxD DTR DSR IDO GND

1.4.7. USB Mouse Interface

USB connectorseries B

CN901

UC1112C-K1

2 3 1 4

Pin No 1 2 3 4 Signal name VCC DD+ GND

DGND

SEIKO EPSON

1-12

Revision:B

Chapter 2 Theory of operation

EMP-50/51(SVGA) , 70/71(XGA)

2.1. HARDWARE

The hardware of EMP-50/51,EMP-70/71 is distinguished in the optical system and the electrical system. Inside of the breaking line in the Figure2-1 is the optical engine(one maintenance part).

Power supply unit AC input Generate DC bias Generate ballast bias

MA board Initial setting of the cirduit and interface control. (Senser, Fan, Speaker, Remotecontrol etc.) Produce R/G/B video signal

IF board

Audio-Out Audio L/R S-Video Video Mouse/Com USB Mouse

Ballast unit Generate lamp power

Operation panel Computer PBS fan Lamp fan Light valve R/G/B Exhaust fan *2 Prism Composit R/G/B Projection lens unit (Focus) Intake fan *1 Receptor sensor

150W(EMP-50/70) 160W(EMP-51/71) Lamp inner housing

Light guide unit Divide the optical souce into three (R/G/B) with lens, filter and mirror *1:Intake fan cools light valve R/G/B (Liquid crystal panel) *2:Exhaust fan discharges the heat of lamp inner unit mainly. *3:Please treat (Includes MA board) area as one part on the repair.

Figure2-1

(Projection process outline) 1. Analog signal (S-Video or Video signal) is provided to the MA Board through IF board. (Analog signal should be once changed into digital signal by the IF Board.) 2. The display signal (digital) is stored temporarily in the video memory of the MA board, after which it is output as the signal to drive the R/G/B light valves. 3. The light valves R/G/B are individual panels each others. They work to shut or transmit the lights from the light guide unit. 4. The lights transmitted through the light valves will be combined with the prism and projected through the projection lens unit.

SEIKO EPSON

2-2

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

2.1.1. Electrical System Connections

Electrical units are physically connected mainly to the MA Board as shown below.

S P

Operation panel CN800 SP

Exhaust fan

Power supply unit Lamp Cover Detection switch Ballast unit PBS fan

Lamp thermistor

CN1005 EX Fan

PJ080 MA board

CN501 SW Panel CN1000 L/V Fan

CN1100 Power supply unit CN500 ON/OFF CN1800 XGA-R CN1102 SCI CN1801 SVGA-R CN1001 PBS Fan

CN1601 SVGA-B CN1600 XGA-B

CN1003 L/V TH

L/V thermistor

Intake fan

Lamp fan

CN1002 Lamp Fan

CN1004 Lamp TH CN1701 SVGA-G CN1700 XGA-G CN901 USB CN300 input terminal

Circuit board connector

CN100 PC input terminal CN900 COM input terminal

CN101

J000 Audio-IN terminal J001 Audio-OUT terminal CN001 CVBS VideoAudio terminal CN000 S-Video terminal

Figure2-2

Basically, EMP-50/51 and EMP-70/71 circuit are same except number of compornents, etc.

SEIKO EPSON

2-3

Revision:B

The control circuit consists of components which are based around the MA board as shown in the diagram below.

PC In DDC Sync control block RGB Sync. D-sub 15 RGB(16bit) HS/VS/clock Vport Resizing Processor Main CPU OSD PW164D (Pixelworks) Bus Excahnge Swich Sync. correct circuit Gport 3ch Video Amp. 3ch ADC PLL Sync.Sep. THC7116 (Thine) RGBx2(48bit) HS/VS/clock RGB(24bit) HS/VS/clock

DCC block DDC EEPROM 24LCS21A (Microchip) Resizing and control block AD conversion block

LV screen block Driver ASIC (GAUGE2) EV9812R (TOSHIBA) ET7040 (TFT)

DEC Driver DEC Driver Level Shifter

L/V CN

Video In Video decoder block Chroma Processor SAA7114 (Philips) Select CVBS (RCA) Y/C (DIN 4) 4 Wire Serial

DEC Driver DEC Driver

L/V CN AMP. NRS

EMP-50/51(SVGA) , 70/71(XGA)

DEC Driver DEC Driver I 2C Bus 3 Wire Serial

CPU BUS

Serial DAC M62367GP (Mitsubishi)

AMP.

LCCOM

Video Audio in (RCAx2 Stereo) Audio block Audio Controller TDA7430 (ST) Clock Generate Circuit Memory Clock = 122.950Mhz (System Clock = 40.983Mhz) Display Clock = 49.152Mhz(SVGA),73.728Mhz(XGA) PSCI Clock = 49.152Mhz (THC7116 Clock = 12.288)

I 2C Bus

Serial ADC AD7417 (Analog Devices) Flash 8Mbit MBM29DL800BD (Fujitsu) SRAM 1Mbit IDT71V016S15PH (IDT)

PC Audio in (Stereo mini)

Temperature control block

Audio out (Stereo mini) Power Amp. TDA7056AT (Philips) Mute

THERMISTOR Drive Circuit

FAN Drive Circuit

Power supply block Power Save Control IC (PSCI) PowerSaveControl IR Decode,UART KeyScan,LED Control MouseDriver I/F EV9816C (SANYO) Speaker Main Power on/off Ballast Cntl Power Supply Circuit 3.3V_T,5V_T 2.5V_D,3.0V_A,3.3V_D,3.3V_A 5V_D,8V_A,15V_A

THERMISTOR THERMISTOR

USB (mouse)

FAN FAN FAN FAN

Com PORT ADB PS/2

2.1.2. Circuit block

PC I/F block Mouse Driver MC68HC08KL8 (Motorola,SMK) RS-Driver HIN202CA (Harris)

RS-232C (DIN 9)

SW (Tele Wide)

5V_T,3.3V,8V,19V Power Supply

Ballast

AC IN

IR SW Board LED LED

SEIKO EPSON

Lamp

2-4

Clock block

Figure2-3

Revision:B

L/V CN

EMP-50/51(SVGA) , 70/71(XGA)

2.1.3. Process Outline

1. The video input signal is sent from the "Computer" interface (analog RGB) or from the IF board (analog) to the MA board. (Video signals are converted to digital signals at the IF board.) 2. Display video signal (digital) is once stored in the video memory (SRAM) on the MA board then the DR board generates signals to drive the light valves R/G/B. 3. The light valves R/G/B are individual panels each others. They work to shut or transmit the lights from the light guide unit. 4. The lights transmitted through the light valves will be combined with prism and projected through the projection lens unit. 5. The audio signal is provided from IF board interface and out put to the built in speaker or external speaker (Audio Out) via a audio controller. Circuit process block

MA board RGB (analog) signal Video (analog) signal Audio signal (Computer/ Video) Audio-Out Speaker Video amplifier ADC croma processor Audio contoroler Amplifirer Power save controller Display control Display correction

Resizing processor (Main CPU)

LCD driver

R G B Light valve R/G/B

Figure2-4

SEIKO EPSON

2-5

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

2.2. Optical Engine

The optical engine consists of 4 blocks (Lamp inner unit,Light guide unit, Light valve RGB/ Prism unit, and Projection lens unit) as shown below. These units are combined as a set into a single service unit for carrying out adjustments. Optical engine is different with EMP-50/51, EMP-70/71 and there are no compatibility.

Projection lens

Prism unit Lamp inner unit Light valve (R) Light valve (B)

Light valve (G)

Light guide unit

Figure2-5

! Caution: Take care not to cause any shock or mechanical stress to the optical system and also not to disassemble the light guide unit. Otherwise, the pixel divergence may occur. The alignment adjustment for each other is applied in the factory, and also electrical correction is applied with MA board according to the each optical system. Therefor do not exchange each unit to the other optical engine. The data that was adjusted in accordance with the characteristic of L/V has been written to the MA board. Absolutely it makes the optical engine and the MA board the set and ask the repair

Table 2-1 Unit function

UNIT NAME Lamp inner unit Light guide unit FUNCTION & REMARKS Include one Discharge Lamp as a light source. Disperse the light from the light source and uniform by the lens array A/B. (Ultraviolet ray also eliminated.) Disperse the light in three (R/G/B) factors with condenser lens and mirror. Consist of three light valves, polarization plate and prism unit. Each light valve controls shutter of pixels. Prism unit composes R/G/B optical signals and transfers to the projection lens unit. A focus is adjusted and it projection on a screen.

Light valves/Prism unit

Projection lens unit

SEIKO EPSON

2-6

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

(1).LAMP INNER UNIT

This unit consists of the lamp inner housing and the ballast power supply connector. The lamp fixed on the base of the lower case is user replaceable item you can purchase it at EPSON service center. The average brightness of the lamp is reduced corresponding to its running hours. When the lamp is new, its brightness is maximum. After running about 1400 hours, the lamp reduces its brightness to almost half of a new one. The power connector is applied to receive the AC voltage from the ballast unit, so its lead wire is connected to the lamp.

Power connectors

Figure2-6

1. The lamp inner unit The brightness of the light source lamp reduces in proportion to its running hours as mentioned above. In this device the standard lamp life is 1400 hours. If you notice the lamp brightness reduces, we recommend you to replace the lamp inner unit even before 1400 hours. The total running hour of the lamp inner unit is written in IC109 (EEPROM) on the MA Board. If the lamp is reaching or has reached the end of its life, IC502 (power save controller) outputs some signals to control the following. (1)When the cumulative running time reaches 1,400 hours (1,400 hours or more), the prob lem/warning indicator flashes red at 1-second intervals. The controller (IC502) on the MA board monitors the cumulative running time and writes the data to IC109. The lamp will only continue to operate for 100 hours after the problem/warning indicator starts to flash, so you should replace the lamp as soon as possible at this time. (2)When the cumulative running time reaches 1500 hours The normal operating life of the lamp inner unit is 1500 hours. Please perform "Reset Lamp Timer" with an "About Menu" after exchanging lamps.

SEIKO EPSON

2-7

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

2. Light guide unit The light guide unit consists of three output filters (R, G and B). It filters out harmful ultraviolet radiation from the light which is output from the lamp inner unit, and also disperses the light so that even luminance is obtained. Inside the light guide unit are lenses for dispersing the light from the light source, and mirrors for separating the light into its spectral components. The diagram below shows internal views of the light guide unit Optical Process block

Light Valve R Lamp inner housing (Light Source)

Projection Lens

Light Valve G

Light Valve B Prism (R/G/B synthesize) Ballast Unit MA Board

Figure2-7

! Caution: A light guide unit, an optical head / prism unit, and a projection lens unit are collectively dealt with by the name "optical engine." he figure 2-25 shows the control circuit.

MA block LED indicator

IC502 (PSCI)

IC109 EE-PROM

LPSTC/LMPON Power ON/OFF control Power down detection Ballast output control CN1100

Ballast output ON/OFF

Lamp off detection

Lamp inner housing

Ballast unit

Power supply unit

SEIKO EPSON

2-8

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

2.3. POWER SUPPLY UNIT

The Power supply unit is consist from AC inlet, filter circuit and fuse.

AC Inlet

Filter Circuit assy

Figure2-8

(1). Circuit block

AC INLET AC input Safety switch EMI Filter

Ballast unit To CP1 connection

Smooth output

Primary power supply Smoothing/control block

DC output MA board CN1100(PS) To connector connection

Secondary power supply

Figure2-9

Fuse EMI filter circuit

: Overcurrent protection with malfanction of power supply unit or etc. It blows the fuse with overcurrent condition. : Noise reduction for AC input.

SEIKO EPSON

2-9

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

(2). Outline of function The power supply units output cable is connected to the CN1100 (P/S) connector on the MA board, and is used to connect the following voltages and signals. PWDS signal for the power down detection, DC output (+2.5V/+3.3V/+5V/+9V/+14V/+19V/-7V), Fan control signal (FANCL)...The control signal of the fan in the power supply unit. Power on/off signal (PWON), Trickle power (+3.3V/+5V). ! Caution: If the AC power cable is still connected after the power is shut off, +3.3V and +5V trickle background voltage are supplied to the MA board via CN1100(P/S) connector. The trickle voltage is subsequently supplied to the power on/off circuit. The EMI filter and primary regulator circuit work to neglect noise on the AC line and generate DC voltage for the regulator. Two of the regulator generates the various level of DC voltage as shown in the next table in the switching regulator. (The inside of () shows "EMP-51/71")The regulator detects the voltage output level at the +5V line and feed back to the switching circuit to maintain the constant output level regardless the load variation. Each output voltage level is not adjustable.

Table 2-2

Output Voltage Accuracy Ripple Ripple/ Spike Min

0.03A 1.0A 0.3A 0.1A -

Output current Typ.

0.15A (0.12A) 1.3A (0.9A) 0.6A 1.5A (0.7A) 0.5A 360V (190W)

Protection circuit Peak

1x10ms 6x10ms 5x20ms 4x20ms 10A

mV p-p mV p-p

+5T +3.3 +8 +19 Ballast +5V +3.3V +8V +19V 5% 5% 10% 10% 240390VDC 100 100 200 400 20000 (25000) 200 200 300 400 30000 (25000)

Max

0.5A 4.0A 3.0A 2.0A 0.6A

Over voltage

+7V +4.6V +12V +26V 410V

Over current

Intercepti on Intercepti on -

Load capacity (Reference) F

47 (100) 220 (100) 220 (100) 47x2

The fan is built for exhausting the heat generated in the power supply unit. The heat exhausted by the fan will be exhausted outside by the exhaust fan which is connected to the CN1001 on the MA board.

SEIKO EPSON

2-10

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

(3). Connector/Pin assignment

14 8

CN1100

Figure2-10

Power supply connector (MA board connector CN1100) pin assignment

Pin No. 1 2,3 4,5 6,7 8 9~14 Voltage +5V +3.3V +8V +19V SIGNAL GND Signal name 5.0V 3.3V 8.0V 19.0V PWON GND Remarks trickle

Power supply ON/OFF signal

SEIKO EPSON

2-11

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

2.4. BALLAST UNIT

It is the unit that regulates again the DC power supply (DC300-400V/0.4A) for the ballast that is supplied from the power supply unit to generates the AC power supply (AC45-120V) for the UHE lamp.

Ballast output connector (connect to the lamp inner unit) CN500 (Connect to the MA board)

CP1 (Connect to the power supply unit)

Lamp Cover Detection Switch

Figure2-11

Circuit Block

CP1 (connected to Power Supply Unit) Sub power supply +15/+20V regulator circuit DC input 240~390v Switching circuit Detection circuit CP501 (connected to MA Board CN1102) HV Ballast output LV AC45~120V

BACTA LGND LPSTC

Feedback

Figure2-12

(1). Process outline The sub power supply : The control circuit voltage (+15V/+20V) for the ballast unit is generated. : Perform the switch actuation for the regulation again according Switching circuit to the output signal (BACTA) of the MA board unit. (The BACTA signal control the ON/OFF of the ballast output.) Modify the switching duty according to the feedback signal from the detection circuit. : The voltage for the lamp of AC45~120V is generated. Regulator circuit : Monitoring the regulator circuit and generates the feedback Detection circuit signal of the output voltage in order to stabilize the voltage and detects the output current. When the lamp inner unit becomes consume (That the load current of ballast output disappears), the LPSTC signal is transmitted to the MA board unit.

SEIKO EPSON

2-12

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

2.5. MA BOARD

The MA Board controls the main circuit operation of the product. It consists of resizing processor (main CPU) Power I/O controller, digitizer (ADC, video amp. etc.), RAM, EEPROM, etc.The MA board controls everything except to generate the display signal and audio/video interface. The MA board is available as a unit for the service parts. The photographs below show the MA board for the EMP-50. (TOP SIDE)

Figure2-13

(BOTTOM SIDE)

Figure2-14

*MA boards are different according to the model and there are no compatibility.

SEIKO EPSON

2-13

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

MA board circuit block

IC102 R/G/B RGB Input CN100 SDA/SCL IC101 DDC(E2PROM) HSNC/VSYNC IC101/104/103 SYNC.CORRECT IC350, 351 3ch Video Amp. 3ch ADC PLL Sync. Separator

OSC 24.576MHz

IC400 Resizing Processor (Main CPU)

Graphic port

PDA0~23

GRO0~23 SCL/SDA

RD0~7

IC1200

Display port

GD0~7 BD0~7

Micro Processor Interface

Misc. Peripheral Interface (RESET)

D T R / D S R / T X D / R X D S C L / S D A

Video port

SNC.

P W D 0 1 5

P W A 0 1 9

W R R D C O N T R O L

LED0~5, KIN/OUT

P O W E R C O N T R O L L

SEIKO EPSON

IC602 Flash ROM (8Mbit)

CN352 CN353

IC502 Power Save Controller IC601 S-RAM (1Mbit) (Power, Serial I/F, etc.) Serial I/F signals MDB0~7 SMUTE/AJDET/etc. SCL/SDA CN300 Connect to CN101 on the IF Board

CN800 CPU Connector

IC501 Reset

IC505 EE-PROM

Figure2-15

2-14

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

(2). Outline of function Circuit function is almost same with EMP-50/51, EMP-70/71 MA board except video control, thus this paragraph explains EMP-50 MA board functions. IC502(Power save controller) and related circuits are backed up with +3.3V and +5V which provided from power supply as trickle power. (If the AC cable is connected to the AC source, power supply provides the +3.3V and +5V for back-up bias even if the power is turned off condition.) When the power is turned on with power button on the switch panel or remote to controller, IC502 on the MA board generate the reset signal and initialize the circuit, and the CPU reads the program from mask ROM and write it into SRAM. Then the CPU initialize the circuit functions according to the program and indicates the initial image. Two thermistors (L/V thermistor/LAMP thermistor) detects temperature. If the temperature exceeds certain degrees, the thermistors signal generates interrupt signal to the IC502 and change the fan operation or shut off the power supply regulation. These display data are write into the video memory (SRAM) then read out again with resizing processor. Video input (S-Video/Video In) signal are provided via IF board. These input signal are converted to digital with A/D chroma processor and stored into the SRAM. The EEPROM and timer circuit provided the operating time control of the lamp inner unit. Its operation is described below. Total running hours are stored to the IC109 (EE-PROM) and increment until new lamp innerhousing detection.

Table 2-3

lamp inner unit status When the operating time of the lamp inner unit exceeds 1400 hours. Problem/warning indicator state When the power is turned on, the problem/warning indicator flashes red at 1-second intervals.

If the above phenomenon is observed, it is necessary to replace the lamp inner unit. After replacing the lamp inner unit, you must reset the lamp timer manually.

SEIKO EPSON

2-15

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

2.6. OPERATION PANEL

This panel includes the 4 switches, and is connected to the CN501 on the MA Board. (Refer to the paragraph 1.2.1 for detail function)

Power Help Keystone

Source

Figure2-16

SEIKO EPSON

2-16

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

2.7. IF BOARD

AV board includes an audio control and chroma processor circuit and an interface connectors for audio and video signals from a host computer or external devices such as a video device. The interface connectors are shown below. PC Audio In Audio Out S-Video Video Audio L Audio R (External audio input) (Audio output for external speaker) (Super impose video input: Y/C signal) (Video device image data input: CVBS signal) (Video device audio L input) (Video device audio R input)

S-Video

Audio In

Audio R Audio Out

Audio L

Video

Figure2-17

SEIKO EPSON

2-17

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

The figure2-18 shows the IF board circuit block. IF board circuit block

Y/C

S Video

CN000

Video Audio L/R Audio-OUT (External speaker) Audio-In

CVBS CN001 Audio L/R J001 CN002 (IF board)

Connect to CN300 on the MA Board. (Cable connection)

J000

Figure2-18

The interface signal lines for S-Video and Video have chroma processor and convert the input signal to the digital then output signals to the MA Board through the connector CN002. Audio input signals from computer or from a video device (via Audio L/R) are first input to the controller and controlled the volume, tone, etc., then are output to the Audio Out interface or the built-in speaker via power amp. again. The audio controller performs the audio-signal output control based on the SCL/SDA (serial data/clock) signals provided from the MA Board. (ex. The sound volume control performs the audio volume control with 21 levels (mute ~ max.) based on the signals from the MA Board.)

SEIKO EPSON

2-18

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

2.8. RECEPTOR SENSOR

This is the board with the infrared signal detection component. The receptor sensor equipped in the front face.

Receptor element (Infrared ray detector)

Figure2-19

The output signal (serial data) which is received by the photosensor is input to the power save controller (IC502) on the MA board. 1. The MA board turns the power on and off and controls the menu displays based on the serial data which is received from the remote control unit (from the button switches of the remote control unit). 2. The serial signal send to the AV board via the MA Board performs the mute, tone control and audio volume control. The figure2-20 shows remote control circuit block.

Infrared ray Remote controller

MA Board IC504 IC502 PSCI

Figure2-20

SEIKO EPSON

2-19

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

2.9. SPEAKER

Two speaker units (8-1W) are equipped inside the upper case, faced upward. The audio input signal from a host computer or AV devices connected to this can be output in Monaural through the units. If an external speaker is connected (with the help of an accessory audio cable) to the AudioOut terminal, the built-in speakers are disabled.

Speaker

Figure2-21

IF Board

MA Board Resizing processor(CPU)

Video-In (Audio L/R)

CN001

IC800 Audio Controller

PC Audio

J000

CN002

CN300

Driver

Selector IC502 PSCI

LINE-OUT (External speaker)

J001

Power Amp.

CN800 Internal speaker

Receptor sensor

CN501 Switch panel

Remote controller

Figure2-22

The audio input from the computer or video component is amplified by the control circuits (audio controller and power amplifier) in the AV block, after which it is output from the built-in speakers which are connected to CN800. Detecting the connection to an external speaker (Audio Out), the MA Board only determines the use of the built-in speaker or the external speaker.

SEIKO EPSON

2-20

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

2.10. TEMPERATURE CONTROL

2.10.1. Sensors and switches

For users safety and safety operation of this projector (for prevention from malfunction), the following devices listed the table are installed in it.

Table 2-4 Sensor/switch

Name Lamp Cover Detection Switch Safety switch LAMP Thermistor L/V thermistor Location/Type Ballast unit Thermal switch on the light guide unit On the exhaust fan (Thermistor) On the prism duct (Thermistor) Function/Use Power off, in opening the lamp cover. (Power on is disabled.) Overheat protection for lamp inner unit area. Power is shut, temperature exceeds limitation. Overheat protection for lamp inner unit area. The lamp will turn off if the temperature exceeds the set limit. Overheat protection for light bulb. The lamp will turn off if the temperature exceeds the set limit.

2.10.2. Lamp Cover Detection Switch

This switch is installed on the side of the power supply unit and interlocks with the tab of the lamp cover. If you can turn on the projector with the lamp cover open, the (lamp inner unit) runs and generates the high heat. For replacing the lamp inner unit you open the cover. For this reason, the switch is installed to protect you from burn.

Lamp Cover Detection Switch

The Lamp Cover Detection Switch is installed on the AC input line of the power supply unit. Consequently, if the lamp cover is open, the AC power source is shut off and you can not turn on the power.

SEIKO EPSON

2-21

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

2.10.3. SAFETY SWITCH

This is the thermal switch for overheat protection installed on the light guide unit (lamp inner unit area). If overheat condition is caused by the contamination of the exhaust fan, normally the LAMP thermistor temporarily shuts off the lamp inner unit to protect it from overheat. The safety switch is installed, considering the LAMP thermistor trouble in overheat condition.

Safety switch

Figure2-23

A cable with fasteners connects the safety switch and the lamp cover sensor switch. If the temperature rises above a certain level, the AC power supply is isolated and all regulating operations are stopped. (AC power is shut off and this switch runs once, you can not start up the power, before the temperature decrease to certain degrees.) In this case, you must also consider the thermistor trouble or the MA Board trouble.

2.10.4. THERMISTOR AND TEMPERATURE SENSOR OPERATION

IC700 on the MA Board unit detects the temperature (resistance) with two thermistors in each 100ms. Two of thermistors are placed in the main body and mainly detect the temperature of optical block area. IC700 judge the following state according to the measurement result then change the fan operation or shut down the power.

SEIKO EPSON

2-22

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

Temperature detection result are notified to the operation with warning indicator.

Table 2-5 Temperature sensor

Condition Normal temperature Warning temperature Abnormal temperature Warning indicator Off flashing in orange Light in red flashing in red (2 second intervals) Meaning Operating in the normal condition Projection will stop if the temperature increase more. Over heat condition (stop the display) Malfunction with fan, thermistor, temperature detection circuit and etc.

Result of condition affect to the fan operations. Refer to the paragraph 2.11 for details. Refer to the paragraph 2.12 for detail of warning indicator. (1). LAMP thermistor LAMP thermistor is mounted with screw with the exhaust fan and detect the temperature of lamp area. To prevent the damage with over heat of lamp inner unit, Power save controller on the MA board notify the warning with temperature indicator or turns off the ballast power (lamp power) when the temperature exceed predefined level. (2). L/V thermistor Thermistor A is mounted on the prism. When the cooling function is not enough because of dirt condition with air filter frame consumption and user exchange possibility, Power save controller on the MA board on the MA Board it output the warning indication with temperature indicator or turns off ballast power (lamp power) in order to protect the damage of light valves (LCD panel).

LAMP thermistor L/V thermistor

Exhaust fan

Figure2-24 Thermistor A/LAMP thermistor

SEIKO EPSON

2-23

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

2.11. FAN OPERATION

Four of fan are placed in side of main frame. These fan are used for over-heat protection by exhausting heated air in order to secure the circuit operation and prevent the defect. (Mainly lamp inner unit, power supply unit B and ballast unit are produce the heat)

Lamp fan

Figure2-25

Exhaust fan Intake (L/V) fan

Figure2-26

PBS fan

Figure2-27

SEIKO EPSON

2-24

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

(1). Control block diagram of fan

Synchronous serial bus

PW

PW164 DACLD DACDI DACCLK

DAC

M62367 LD DI SK

AO1

LVFAN DRIVER FANON FRSLV LMPFAN DRIVER FANON FRSLMP PBSFAN DRIVER FANON FRSPBS EXFAN DRIVER FANON FRSEX

AO2 AO8

EV9716C

FANDET FANON

Figure2-28

(2). Out Line of function The four fans are connected by three lead wires. One of these is the signal line which sends feedback on whether the fans are detected to be running or not. The two thermistor (L/V thermistor/LAMP thermistor) are connected to the MA board. The driver CPU controls two fan (Intake fan/Exhaust fan) according the detected temperature of the thermistor. IC700 (Driver CPU) on the MA Board always observe the fan operations by monitoring feed back signals. If the feed back signal condition is different from expected, Controller judge as fan abnormal condition then turns on temperature indicator in red and turn off lamp with ballast power off. Fan feed back signal is used for monitering the fan operation is correct or not with CPU. If the feed back signal is not expected, CPU judge as fan trouble and turn on the temperature indicator in red. Power supply fan operate with slow or fast according to the FANCL signal which generate from IC502 (PSCI) on the MA board. (3). Fan operation Stand by: Turn on the fan regulator then drive the intake fan and exhaust fan with slow mode when the thermistor detect the over temperature of Slow turn level. Stop the intake fan and Exhaust fan then shut down the fan regulator when the thermistor detect the below temperature of Slow turn level. Lamp on: Before 0.5 second, start up the intake fan and exhaust fan for lamp on. After the lamp on, both fan operation are controlled high speed or low speed according to the detection of the thermistor. Cool down The fan continues to operate for 2 minutes after the lamp is turned off.

SEIKO EPSON

2-25

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

2.12. LED INDICATOR

Two of indicators are mounted on the MA Board unit and indicate the machine operation status. You can see these indication at slit on the upper case unit.

Operation Warning indicator display indicator Operation Warning indicator display indicator

Figure2-29flashing

Table 2-6 LED indicator

Condition During warm-up During lamp on (normal) During cool down Warning (overheat) During power save Lamp malfunction Circuit malfunction, Fan malfunction, Sensor malfunction Overheat Sleep ode Operation display indicator Green flashing *1 Green Orange flashing *1 Green Orange OFF OFF OFF Green flashing *2 Warning indicator OFF OFF OFF Orange flashing *1 OFF Red flashing *1 Red flashing *2 Red OFF

*1: Flash 1: The indicator is on for 0.5 sec and off for 0.5 sec. *2: Flash 2: The indicator is on for 1 sec and off for 1 sec.

SEIKO EPSON

2-26

Revision:B

Chapter 3 Disassembly and assembly

EMP-50/51(SVGA) , 70/71(XGA)

3.1. DISASSEMBLY AND ASSEMBLY PROCEDURES

This section explains how to disassemble the EMP-50/51, EMP-70/71. The reassembly procedure is the exact reverse of the disassembly procedure. 1. Preparations (1). Remove any ring, wrist watch, cuff buttons, or other metal accessories that are likely to get in contact with the equipment. (2). Wear gloves. (3). Wear a wrist band and ground it. Place a ground mat. (4). Turn off the main unit and the host computer. (5). Unplug the power cord from the main unit and service outlet. (Even if the power is off condition, back-up bias is regulated and supplied to the circuit board when the power code is connected to the service outlet.) (6). Disconnect the interface cable from the main unit. (7). Clean the air filter, interface and case cover with a vacuum cleaner. 2. Required tools and accessories Prepare the tools and accessories listed in the table below.

Table 3-1

Name (+)Phillips screwdriver 2 Allen key Hex wrench (5mm) Tweezers Radio pliers Brush Vacuum cleaner Paper wiper Air blower Glove Wrist band, Ground map Q.t.y 1 1 1 1 1 1 1 Some 1 1 1 Supply Market Market Market Market Market Market Market Market Market Market Market Use Disassemble the case and interiors Disassemble the case and interiors Removal of computer interface Unlock the FPC connector on D.R board Remove L/V thermistor Brush off the dust around fan Clean the fan and filter Clean the projection lens Clean the fan and filter. Avoid finger injury Avoid electro static influence

3. Limitation of disassembly (Optical engine handling) The disassembly of the mechanical section is detailed in paragraph 3.2. The optical engine is one replaceable part. When you order the maintenance parts or request our repair service, perform works by the units listed in the table. The optical components listed in the table are required the mechanical alignment or electrical correction in the control circuit. (writing the image adjustment data)

Table 3-2

1 2 3 Optical head unit Prism unit Light guide unit These units are specified as Optical engine. (Treat as one replaceable part in the field maintenance.)

* Do not disassemble the Optical engine. * Do not exchange any unit on the optical engine to the others. * The optical engine and the MA board should be handle as a single set.

SEIKO EPSON

3-2

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

3-1.Mechanical adjustments for optical engine. (1). Optical Head Unit The alignment (height/left and right/concurrent) of the polarization plates (include R/G/B light valves) is applied in the factory. If the alignment is modified, clear color image will not be made, because of the color divergence. ! Caution: Do not apply any mechanical stress to the polarization plate, and also not loosen the screws. (2). Prism Unit To synthesize the light output from each polarization plate (include R/G/B light valves), the alignment (concurrent to the polarization plate) of the prism unit is applied in our factory. If the alignment is modified, clear image will not be made, because of the pixel divergence to R/G/B synthesizing and projection lens unit, being out of focus and color uniformity. ! Caution: Do not loosen the prism unit fixing screws. (3). Light guide unit The alignment of the light guide unit on the optical head unit is applied (gap and concurrent to the polarization plate) in our factory. If the alignment is modified, clear image will not be made, because of being out of the brightness uniformity on the display screen (brightness or chroma is not uniform on the screen.) In consideration of the alignment of the lens array and the mirrors, and also their combinations, the factory setting is applied to the light guide unit to support the best display performance. (If the alignment is modified or the location is changed, there comes distortion on the display screen, therefore clear image will not be made.) ! Caution: Do not disassemble the light guide unit. If you remove the upper guide cover from the unit, the alignment of lenses or mirrors may be unintentionally changed and also dust may stick to the unit. Since EMP-50/50.EMP-70/71 requires very precise adjustment, it can not be adjusted in the field. (4). Electrical corrections (MA Board Assy) The optical mechanism contains mechanical parts which require adjustment as described above. There are also some individual differences for the control circuit (MA board) with items such as the output driver for the display signal, and some individual differences in the optical mechanism (such as the light valves) itself. In order to obtain the optimum display, these electrical and mechanical differences need to be eliminated, rather than making mechanical adjustments, and so a variety of correction values are written into the ROM at the time of shipment from the factory. Accordingly, the optical mechanism (consisting of the optical head, light guide unit, prism unit and projection lens unit) is designed as a single set (the optical engine).

SEIKO EPSON

3-3

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

At the factory shipment, following correction data are stored in the Flash ROM on the MA Board Assy according to the specified optical engine. Gamma adjustment data Flicker adjustment data Ghost contrast adjustment data Sub contrast adjustment data Color unevenness correction data *For the writing correction values, an expensive, special device and also skillful engineer are necessary, therefore it can not adjust in the field. 3-2.Caution for field maintenance Observe the following procedure, when you repair. Otherwise, display quality is not guaranteed, and also EPSON repair service is not available. 1. Do not disassemble the block. (Do not loosen any screws.) 2. If any of the optical engine components are defective, replace the whole optical engine as a single unit. And when you send back them to us for repair, send back them in set (by optical engine). 3. The optical engine components are treated as a single unit, and thus the individual components which make up this unit should never be installed as single components. (For example, the prism unit must never be used by itself as a replacement for another prism unit.) 4. Precautions Precautions given to the individual assembly and disassembly procedures. Read them carefully before starting the assembly or disassembly procedure. A set of general precautions are given below. As you disassemble the main unit, dust that is sticked to the internal fans and air filters is likely to migrate and contaminate the light valves R, G, and B which are the heart of the display mechanism, thus deteriorating the display quality. Accordingly, before reassembling, check the dust inside of the main unit and, if necessary, clean them with a vacuum cleaner. The light valves R, G, and B and circuit board assemblies are highly sensitive to static electricity. When you remove a optical engine or circuit board, place it in an antistatic bag immediately. When you perform the assembly or disassembly operations listed below, check the pertinent unit and its surfaces for any dirt before reinstalling them. If the unit is found dirty, clean it. 1. Removing the optical engine. 2. Removing the lamp inner housing. The speaker unit incorporates a permanent magnet. Keep it away from electromagnetic media such as floppy disks and magnetic cards. Handle the optical engine (projection lens and light guide units) with care as they are highly susceptible to vibration and shock. Do not try to disassemble any part (ex.power supply unit) that is not covered in this manual.

SEIKO EPSON

3-4

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

3.2. DISASSEMBLING THE MAIN UNIT

The flowchart for disassembling the main unit is shown below.You can take same disassembling procedure for EMP-50/51, 70/71. Since you can reassemble the dismantled parts in the reverse order of disassembly, unless specifically specified, this manual not contains reassembly procedure. Detailed descriptions of the disassembly procedures are given in Subsections

Do not disassemble the optical engine.

Lamp inner housing (3.2.1)

Front case unit (3.2.2) Upper case unit (3.2.3) Safety switch (3.2.5) LAMP thermistor (3.2.6) Lamp fan (3.2.7) MA board assy (3.2.8)

Speaker (3.2.4)

IF board assy (3.2.9)

IF fixing plate (3.2.9) IF board (3.2.9)

Lamp fan fixing plate (3.2.10)

Lamp fan duct (3.2.10)

Optical engine (3.2.11)

Focus ring (3.2.12) Projection lens (3.2.13)

Intake (L/V) fan duct (3.2.15) Intake (L/V) fan (3.2.15)

PBS fan (3.2.14)

Ballast duct unit (3.2.14)

Ballast unit (3.2.16)

Exhaust fan (3.2.17)

Power supply unit (3.2.19)

Lamp Cover Detection Switch (3.2.18)

Foot unit (3.2.20)

Rear foot (3.2.20)

Lower case (3.2.20)

Figure3-1

SEIKO EPSON

3-5

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

3.2.1. Removing the Lamp Inner Housing

Warning:The lamp unit is very hot immediately after it is in use and may cause injury with heat if you handle it carelessly. Before removing the lamp unit, make sure the temperature of the lamp inner housing unit has cooled down. 1. Move the two tabs on the lamp cover in the direction of the arrow, and then remove the lamp cover. 2. Loosen two lamp inner housing fixing screws. 3. Take out the lamp inner housing.

Tab Tab

Lamp cover

Figure3-2

Screws

Lamp inner housing

Figure3-3

! Caution: The lamp inner unit is very hot immediately after lamp is used, therefore pay attention to unit. Take care not to touch with a hand and make dirty the lamps clear glass surface.

SEIKO EPSON

3-6

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

3.2.2. Removing the Front Case Unit

1. Remove the lens cover from the projection lens. (Leave the strap attached to the front case unit.) 2. Remove the six screws(C.B.A SCREW3x5-4/H.F SCREW3x8-2) which are securing the front case unit, and then remove the front case unit. (Use a 2 mm Allen key to remove the special screws at the front.) 3. Hold both sides of the front case unit and pull it forward to remove it from the projector.

Front case unit

Lens cover

Figure3-4

When installing the front case, take the following order. 1) Clean off any dust which is adhering to the RC receptor window and the photosensor on the front case unit. 2) Secure the front case unit with the two special screws and the four other screws.

RC photosensor

RC receptor window

Figure3-5

SEIKO EPSON

3-7

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

3.2.3. Removing the Upper Case Unit

1. Remove six screws(C.B.A SCREW3x5-4/C.B.A SCREW 3x8-1/C.P SCREW 3x6-1).

Upper case unit

Figure3-6

2. Pull up the upper case unit about 5cm, and remove it.(Make sure two cables are connected to the upper case.)

ZoomKey-top Cable Upper case unit

Cable

Figure3-7

! Caution: Keep in mind that it is easy to lose a zoom key-top.

SEIKO EPSON

3-8

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

3. Unlock the CN501 connector on the MA board, and then take out the operation panel cable. 4. Pull out the speaker cable from the CN800 on the MA board assy.

CN800 CN501

Explored view of CN501

Lock

Speaker cable

Operation panel cable

Unlock

Figure3-8

3.2.4. Removing the Speaker

1. Remove the two screws(C.C.P-tite.SCREW.3x5) which are securing the speaker, and then remove the speaker.

Speaker

Figure3-9

! Caution: The speaker unit incorporates a permanent magnet. Keep it away from electromagnetic media such as floppy disks and magnetic cards.

SEIKO EPSON

3-9

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

3.2.5. Removing the Safety switch

1. Disconnect two of the fast-on tab terminal cables from the safety switch. 2. Remove a fixing screws(C.B.P-tite.SCREW.3x8) from the safety switch and detach the safety switch.

Fast-on tab cables

Safety switch

Figure3-10

3.2.6. Removing the LAMP Thermistor

1. Disconnect the LAMP thermistor cable from the CN1004 on the MA board assy. 2. Remove the nylon rivet (which is securing the exhaust fan), and then take out the lamp thermistor.

LAMP thermistor

Nylon rivet

Exhaust fan

Figure3-11

SEIKO EPSON

3-10

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

3.2.7. Removing the Lamp Fan

1. Disconnect the cable from the CN1005 connector on the MA board. 2. Remove the two screws(C.B.SCREW.3x15) which are securing the lamp fan, and then remove the lamp fan.

CN1005

Lamp fan

Figure3-12

Figure3-13

! Caution: When installing the lamp fan, remove the dust sticking to the fan.

3.2.8. Removing the MA Board Assy

1. Unlock the following light valve R/G/B cable connector.

Connector Lock

Connector Lock

Connector Lock

Figure3-14

Lock state connector lock FPC cable FPC cable Unlock state (Pulling up the black area) connector lock

SEIKO EPSON

3-11

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

2. Remove three light valve cables and the other cable connectors on the MA Board Assy (6 connectors). 3. Remove the two screws(H.H(O).SCREW.4-40) which are securing the computer video input connector. (Use a 5 mm hexagonal nut.) 4. Disconnect the DC power cable from the CN1100 connector on the MA board. 5. Remove the six screws(C.P.(O).SCREW.3x5) which are securing the MA board, and then remove the MA board. (These screws are also securing the earth plate.)

Screws

CN1101 CN1000 CN500 CN1102 CN1002 MA board assy

CN300 (FPC cable)

Screws

Figure3-15

Computer video input connector

CN1100 DC power supply cable connector Screws

Figure3-16

SEIKO EPSON

3-12

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

3.2.9. Removing the IF Board Assembly/IF Fixing Plate

1. Remove the three screws(C.P.(O).SCREW.3x5), and then remove the IF board assembly. 2. Remove the four screws(C.P.(O).SCREW.3x5-2/C.B.P-tite.SCREW.3x8-2) which are securing the IF board. 3. Separate the IF board assembly and the IF fixing plate.

IF board assembly

IF fixing plate

Figure3-17

3.2.10. Removing the Shield plate RE/Lamp fan duct

1. Remove the tow screws(C.P.(O).SCREW.3x5), and then remove the Shield plate RE and Conductive spring Low-Up. 2. Lamp fan duct is extracted from the Shield plate RE.

Lamp fan dukt

Shield plate RE

Figure3-18

SEIKO EPSON

3-13

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

3.2.11. Removing the Optical engine

1. Remove the two screw(C.C.P-tite.SCREW 3x8) which are securing the ballast power supply connector, and then remove the connector. 2. Remove the four screws(C.P.SCREW.3x8) which are securing the optical engine. 3. Lift the optical engine straight up to remove it.

Ballast power supply connector

Figure3-19

Screw

Screw

Screw Screw Optical engine

Figure3-20

SEIKO EPSON

3-14

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

! Caution: When installing the Ballast power connector, Refer to Figure3-21 and confirm to set correctly.

Bottom side view Ballast power supply connctor

Inside (Side of Optical engine)

Outside (Side of Ballat unit)

Figure3-21

SEIKO EPSON

3-15

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

3.2.12. Removing the Focus ring

1. Remove the three screws(C.P.B-tite.SCREW.2x5) fixing the Focus ring, then remove the Focus ring.

Focus ring

Figure3-22

3.2.13. Removing the Projection Lens

1. Remove the three screws(C.P.SCREW.3x8) which are securing the projection lens unit, and then remove the projection lens from the optical engine.

Projection lens

Optical engine

Figure3-23

SEIKO EPSON

3-16

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

3.2.14. Removing the PBS fan/Ballast duct unit

1. Remove the two screws, and then remove the PBS fan and Ballast duct unit from the optical engine. 2. Disconnect the lead wire which is attached to the optical engine with tape.

Ballast duct duct PBS fan

Tape

Figure3-24

3.2.15. Removing the Intake (L/V) fan

1. Remove the two screws(C.B.A.SCREW.3x5), and then remove the Intake (L/V) fan duct. 2. Remove the two screws(C.P.(S-P1)SCREW.3x28), and then remove the Intake (L/V) fan.

Intake (L/V) fan duct

Intake (L/V) fan

Figure3-25

SEIKO EPSON

3-17

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

3.2.16. Removing the Ballast unit

1. Disconnect the power supply unit cable from the CP1 connector. 2. Remove the two screws(C.P.(O).SCREW.3x5) which are securing the ballast unit.

Ballast unit Power supply unit

Ballast unit Power supply unit cable CP1

Figure3-26

3.2.17. Removing the Exhasut fan

1. Remove the two screws(C.C.SCREW.3x8) and then remove the exhaust fan.

Ballast unit Exhaust fan

Fan guard

Figure3-27

SEIKO EPSON

3-18

Revision:B

EMP-50/51(SVGA) , 70/71(XGA)

3.2.18. Removing the Lamp Cover Detection Switch

1. Remove the screw(C.P.(S-P1)SCREW2.3x10), and then remove the Lamp Cover Detection Switch.

Ballast umit

Lamp cover detection switch

Figure3-28

3.2.19. Removing the Power Supply Unit

1. Remove the screw(C.P.(O)SCREW.3x5), and then remove the power supply unit.