Professional Documents

Culture Documents

(Triveni) Rajashri Power 10 MW For ACC by

Uploaded by

nogeshwarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Triveni) Rajashri Power 10 MW For ACC by

Uploaded by

nogeshwarCopyright:

Available Formats

WEQP0903064/R0 21 March 2009 M/s RAJASHRI POWER & ISAPT LTD.

1ST Flr, Reena Apartment,Pachpedi Naka, Dhamtari Road, Raipur .C.G. 492001. Kind Attn: Mr. Azad Jain Executive Director Sub: Offer for your requirement of 10MW Condensing TG Set. Ref:- Your enquiry RPIL/TG/02 dt.14.03.09 Dear Sir, This has reference to your E mail enq. Dt. 14.03.2009 and subsequent discussions regarding the subject requirement. Based on the details confirmed we are pleased to give our offer for . 10 MW Condensing TG Set. Suitable for Air cooled condenser system. We hope it will be in line with your requirements. However in case of any queries or clarifications required, please feel free to contact the undersigned as per your convenience. Thanking you and assuring you of our best services always. Yours Faithfully For Triveni Engineering & Industries Limited

Prashant Dhanpawde Senior Manager Mketing & Sales M-9890165860 E mail-prashantdhanpawde@tbg.trivenigroup.com

Dear Customer, Triveni Turbine Business Group is an ISO 9001 certified company. As a commitment to environment we have laid out our environment policy which will be practiced during our operations, manufacturing and other areas of operation. We are enclosing a copy of the broad guidelines of our environment policy herewith as a part of our offer. All our products will confine to broad guidelines laid out by the above environment policy. If you wish to have a look into our environment policies, we will be glad to furnish the same.

For TRIVENI ENGG. & INDUSTRIES LTD.,

Authorized Signatory

ENVIRONMENTAL POLICY We, at Triveni Engineering & Industries Limited, manufacturing Steam Turbines, related products and accessories commit ourselves to: Comply will all applicable environmental legislation and regulations. Continually improve our Environmental Management System. Prevent pollution; reduce waste and consumption of resources, especially electrical energy and oil. Provide appropriate awareness / training to employees on the Environmental Management System and the importance of good operating practices. Create environmental awareness amongst our associates i.e., sub contractors, Suppliers, Transporters and customers. Make the policy available to interested parties on their request.

CHIEF EXECUTIVE OFFICER

M/s Rajashri Power & Ispat Ltd.

Page 2 of 32

INDEX SECTION I Chapter 1 Chapter 2 Chapter 3 Chapter 4 Chapter 5 Chapter 6 Chapter 7 Chapter 8 Chapter 9 Chapter 10 Chapter 11 TECHNICAL : : : : : : : : : : : Scope of Supply Technical Specifications Performance Parameters Utilities to be provided by Purchaser Limits of Tender and Exclusions List of Tools and Tackles List of sub-vendors Drawing & Documentation Schedule QAP Reference list Recommended Steam Purity chart

M/s Rajashri Power & Ispat Ltd.

Page 3 of 32

SECTION I CHAPTER 1 SCOPE OF SUPPLY PART-A MECHANICAL Steam Turbine Multistage, Nozzle governed, Horizontal spindle, two bearings, Impulse type Extraction Bleed cum condensing steam Turbine with: - Hydraulically operated Stop & Emergency Valve with integral steam strainer for inlet - Hydraulically operated Throttle/Governing valves for inlet steam flow control Safety devices - Over speed trip (Mechanical & Electrical) and alarm - Low lube oil pressure trip and alarm - Low control oil pressure trip and alarm - High thrust wear trip and alarm - High exhaust/condenser pressure trip and alarm - Manual trip (Hand trip) - Vibration high trip & alarm - Remote emergency trip (Solenoid trip) - DP across lube oil filters high alarm Gearbox - Double helical, single reduction Gearbox with hardened & ground gears. The design will be as per AGMA standards with a service factor of 1.3 Couplings - Non-lubricated, steel laminated, flexible type, high-speed coupling and low speed couplings with coupling guards. Governing System - Electronic governor (Woodward 505) complete with electro-hydraulic actuators and magnetic speed pick ups - A.C. motor driven Auxiliary Control Oil Pump (ACOP) - Hydraulic accumulator - Control oil filter - Interconnecting control oil piping Lubrication System Forced feed lubrication system, common for Turbine, Gearbox & Alternator comprising of: - Lube oil tank (combined with turbine base plate) provided with cleaning doors and air breather - Main Oil Pump (MOP) driven by gearbox low speed shaft - A.C. Motor driven auxiliary oil pump for flooding the bearings during start-up and wired through a pressure switch for automatic cut-in and cut-out in the event of main oil pump not supplying required quantity of oil. - D. C. Motor driven Emergency lube Oil Pump (EOP) with auto cut-in & cut-out facility - A. C. Motor driven Main Control Oil Pump (MCOP) - A. C. Motor driven Auxiliary Control Oil Pump (MCOP) - Suction strainers for MOP, AOP, EOP, MCOP and ACOP - Pressure relief valves for discharge of MOP, AOP, MCOP, ACOP and lube oil line - Oil coolers (1 working + 1 standby) with on-line changeover arrangement - Oil filters (1 working + 1 standby) with on-line change-over arrangement - AC motor driven oil vapour extractor mounted on oil tank M/s Rajashri Power & Ispat Ltd. Page 4 of 32

Pressure regulating valve to achieve desired lube oil pressure Set of complete lube oil piping within the limits of the turbine base frame and sufficient to meet the requirement of the ordered equipment. (The lube oil pipe will be SS downstream the filter)

Accessories Motorized barring gear arrangement Base plate for turbine and gearbox Insulation for Turbine hot parts (lagging & cladding) Set of foundation bolts. Vibration Monitoring System for high speed train only ( Shinkawa Make) Set of special tools & tackles for maintenance Mating flanges for all the equipment connections in our scope of supply Oil Centrifuge System NRV,ISV and FFRV for bleed system (loose supply) PART-B ELECTRICAL AC Generator AC Generator shall be complete with following: - Brush-less exciter - Air coolers - Twin bearings - Digital AVR cum Excitation panel - Anti-condensation heaters - Water leakage detector 1 per cooler - Lube oil flow regulator 1 per bearing Auxiliaries for Generator protection and control - Generator protection (Relay) Panel - Metering & synchronizing panel - Lightning arrestor, Surge capacitor and Potential transformer (LA, SC & PT) panel - Neutral grounding resistor (NGR) panel - Battery & - Battery charger cum DC distribution panel - TG MCC Panel PART-C CONTROL & INSTRUMENTATION The following field instruments will be provided on the equipments supplied by Triveni. Turbine - Dial type pressure gauges for: MOP, AOP & EOP discharge Gland steam header Gland steam return lines - Dial type Diff. pressure indicator with switch for monitoring DP across lube oil filters - Pressure switches for: Lube oil pressure very low trip & alarm Control oil pressure low alarm AOP auto cut-in & cut-out EOP auto cut-in & cut-out - Transparent level gauge for oil tank - Dial type temperature gauges for: M/s Rajashri Power & Ispat Ltd. Page 5 of 32

RTDs for:

Gearbox bearing oil Oil cooler inlet & outlet Turbine bearing oil Gearbox bearing oil

Generator - Dial type pressure gauge for lube oil - 1 per bearing Dial type temperature gauges for: Bearing oil 1 per bearing Hot air & cold air 1 each per cooler Temperature sensors for: Winding temperature (embedded RTDs) 4 per phase Bearing oil temperature (duplex RTD) 1 per bearing Hot air & cold air 1 each per cooler Temperature scanner to monitor Generator winding and bearing oil temperature.

Turbine Control Panel TC Panel shall house electronic governor, alarm annunciator for turbine faults, temperature scanner for turbine & gearbox bearing oil temperature monitoring, remote controls for all auxiliary motors of turbine (AOP, EOP and barring gear), condenser hotwell level controls, turbine safety interlocks & trip logic and turbine speed controls (push buttons). Turbine Gauge Panel TG Panel shall house the pressure and temperature gauges for various operating parameters, speed indicator and speed raise and lower push buttons for turbine. Impulse piping with fittings shall be supplied loose for interconnection between field tap-off points and gauge panel. Turbine Aux. MCC MCC Panel shall house: - DOL starters for: AOP motor CEP-1 & 2 motors Barring gear motor Vapour extractor motor DC motor (EOP) starter panel cum DCDB DC motor starter panel shall house feeder & control circuit for EOP motor. Local push button station Local control stations with on/off push buttons for: AOP 1 & 2 motors EOP motor Barring Gear motor Vapour extractor motor

M/s Rajashri Power & Ispat Ltd.

Page 6 of 32

PART A MECHANICAL STEAM TURBINE Design: Type Casing split Rotor type Shaft seal No. of governing valves Bearing support Rated speed Rated power

CHAPTER 2 TECHNICAL SPECIFICATIONS

SECTION - II

: : : : : : : :

Multistage, impulse, nozzle governed bleed cum condensing Horizontal Solidly forged & machined rotor with integral disks. Labyrinth Three (Inlet) Double pedestal 6827 RPM 10000 kW

Oil system: - Oil: Governing oil pressure Lube oil pressure Oil type Retention time Material of oil reservoir Material of oil piping from Pumps to filters Material of oil piping from Filters to bearings Material of oil piping from Bearings to reservoir Main oil pump: Type Operating speed Capacity Driver Material of body Material of end cover Material of drive gear Auxiliary oil pump : Type Operating speed Capacity Driver Material of body Material of end cover Material of drive gear

: : : : : : : : : : : : : : : : : : : : : :

14 kg/cm2g 1.5 Kg/Cm2g Servo prime ISO VG-46 / 57 / 68 5 minutes Carbon steel Carbon steel SS Carbon steel Gear (positive displacement)/Screw 1500 rpm 650 Liters/minute Gearbox low speed shaft CI CI EN 36 / EN 40 Gear (positive displacement)/Screw 1500 rpm 650 Liters/minute AC motor (22 kW, 415 V, 3 Phase) CI CI EN 36 / EN 40

Main & Auxiliary Control oil pump: Type : Gear/Screw (positive displacement) Operating speed : 1500 rpm Capacity : 68 Liters/minute Driver : A.C. Motor (2.5 kW, 415 V, 3 Phase) M/s Rajashri Power & Ispat Ltd.

Page 7 of 32

Material of body Material of end cover Material of drive gear Emergency oil pump: Type Operating speed Capacity Driver Material of body Material of end cover Material of drive gear Oil cooler : Design code Type Oil inlet temperature Oil outlet temperature Oil flow Capacity Mounting Lube oil filter: Element type Oil flow Capacity Oil filtration Capacity Mounting Oil Vapour Extractor: Type Capacity Driver Mounting

: : : : : : : : : : : : : : : : : : : : : : : :

CI CI EN 36 / EN 40 Gear (positive displacement) 1500 rpm 200 Liters/minute DC motor (5 kW, 110 V, DC) CI CI EN 36 / EN 40 HEI / TEMA Plate type 60 0C 46 0C 630 Liters/minute Saddle support Micro-felt 650 Liters/minute 10 15 microns Foot Centrifugal 400 m3/Hr AC Motor (0.375 KW, 415 V, 3 Phase) Flange

Bearings: - Journal Bearings Type Material Thrust Bearings Type Material

: : : :

Tilting pad White metal with steel Babbitt Tilting pad White metal with steel Babbitt

Governing System: - Governor: Type Inputs (critical) Control range Control accuracy Speed droop Power supply Accessories - Hydraulic Accumulator: M/s Rajashri Power & Ispat Ltd.

: : : : : : :

Electronic 2 speeds from MPU-1 & 2 80 to 110% of rated speed As per NEMA class D 3 to 6% (programmable) 110 V DC 2 Magnetic speed pick-ups (MPU) 1 electro-hydraulic actuator

Page 8 of 32

Type Working fluid Capacity - Governing oil filter: Element type Oil flow Capacity Oil filtration Capacity Safety devices: - Over speed trip: Type -

: : : : : :

Bladder Pre-charged Nitrogen 20 Liters Micro-felt 35 Liters/minute 10 15 microns

Eccentric spring loaded oil dump valve Spring loaded spool valve combined with LP trip Spring loaded spool valve combined with LP trip Through Vibration Monitoring system Through pressure switch and solenoid trip Block & dump valve in trip oil line Local hand lever Solenoid operated block & dump valve De-energise to open & trip

Low lube oil pressure trip: Type : Low control oil pressure trip: Type : High thrust wear trip: Type :

High exhaust pressure trip: Type : Hand trip: Type Operation Solenoid trip: Type Operation : : : :

GEARBOX Design: Type Input / Output speed Ratio S.F. Accessory COUPLINGS - High Speed Coupling Type Low Speed Coupling Type ACCESSORIES - Barring gear: Type Driver Turbine connections: For

: : : : :

Double helical, Single reduction 6827 / 1500 RPM 4.55 : 1 1.3 AGMA Air breather

: : : : Number

Flexible element with shear pins Flexible element Auto disengage AC motor (22.0 kW, 415 V, 3 Phase) Size Rating Orientation Page 9 of 32

M/s Rajashri Power & Ispat Ltd.

Inlet steam Exhaust steam Noise level PART B ELECTRICAL AC GENERATOR (TDPS make) Design: Rated output Rated voltage Rated current Rated frequency Combined variation of voltage & frequency Rated p.f. No. of phases No. of terminals Connection Rated speed / No. of pole Short circuit ratio Ambient temperature Excitation Rotor Cooling method Mounting Insulation Temperature rise Enclosure Duty Rotation Noise level Terminal box Reference standard Harmonic loading Bearings: Type Accessory Lube oil system: Type Source Air coolers: Cooling method Capacity Cooler tube material Mounting Anti condensation heaters: Type

One One :

8 NB

ANSI 900 # RF Special

Side Down

90 dB(A)

: : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : :

10000 kW 11 kV +/- 10% 50 Hz + / - 5% + / - 10% 0.8 (lag) 3 phase 3 for phase & 3 for neutral Star 1500 rpm / 4 pole More than 0.5 45 Deg.C Brush less Cylindrical CACW Horizontal Class F (both rotor and stator) Class B limits (both rotor and stator) IP-54 (Stator) & IP-23 (Exciter) Continuous and suitable for parallel operation To suit driver output 90 dB(A) To suit HT cables IS-4722 IEEE 519 Sleeve Temperature gauge Forced feed Turbine lube oil system CACW 2 x 60% Admiralty brass/stainless steel Top/Side Resistance heating Page 10 of 32

M/s Rajashri Power & Ispat Ltd.

Power supply Water leakage detector: Location Quantity AVR CUM EXCITATION PANEL Design: Control type Control modes Voltage adj. Range Regulation Dead time Features: -

: : :

230 V, Single phase Bottom of cooler 1 No. per cooler

: : : : :

Digital 1 auto + 1 manual +/- 10% +/- 0.5% Less than 30 mS

Compounding Remote voltage control Auto-Manual follow-up Under frequency protection Field flashing provision

AVR cum excitation panel shall be complete with generator voltmeter, field voltmeter, field ammeter, PF meter, null meter, Auto/Manual selector switch, AC supply & DC supply on /off control switches, indicating lamps and space heater with thermostat. GENERATOR RELAY PANEL Generator relay panel shall house the following: - Numeric Relay for generator protection: DESCRIPTION Under voltage protection relay Reverse active power protection relay Loss of excitation (Field failure) protection relay Auxiliary relays & timers for loss of excitation protection relay TAG NO. 27 32P 40G 40X 27/40G T1/40G T2/40G 46 51V 59 2-59 60A 60B 60C 64 80 81 87 86G 86T

Negative phase sequence protection relay Voltage controlled over current protection relay Over voltage protection relay Timer for over voltage protection relay PT fuse failure sensing relays

Stator earth fault protection relay DC supply supervision relay Under & over frequency protection relay Differential protection relay Generator master trip relay Turbine master trip relay

The panel shall be complete with AC supply & DC supply on /off control switches, indicating lamps and panel space heater with thermostat. M/s Rajashri Power & Ispat Ltd. Page 11 of 32

General: Type Dimensions in mm Weight

: : :

Simplex, dead front & free standing 1000 (L) x 1000 (D) x 2310 (H) 800 KG

GENERATOR CONTROL (METERING CUM SYNCHRONISING) PANEL Generator control panel shall house the following: Meters Type System Reference standard Ammeters Voltmeter KW meter KVA meter KVAR meter PF meter Frequency meter Trivector meter Synchronising equipment Double voltmeter Double frequency meter Synchroscope Check synchronizing Relay Aux. relays for Synchronising scheme Auto Synchroniser : : : : : : : : : : : : : : : : : Digital 3 phase, 4 wire, unbalanced load IS-1248 3 Nos. 1 No. with selector switch 1 No. 1 No. 1 No. 1 No. 1 No. 1 No. 1 No. 1 No. 1 No. 1 No. 1 Set 1no.

Temperature scanner for monitoring generator winding and bearing temperature Alarm annunciator for generator fault monitoring

The panel shall be complete with synchronising selector switches, breaker control (T/N/C) switches, push buttons, AC supply & DC supply on /off control switches, indicating lamps and panel space heater with thermostat. General : Type Dimensions in mm Weight LA, SC & PT PANEL LA, SC & PT panel shall house the following : Lightning arrestor 10 kA 3 Nos. (1 per phase) Page 12 of 32 : : : Desk & free standing 1200 (L) x 1100 (D) x 2310 (H) 750 KG

Discharge current : Quantity : M/s Rajashri Power & Ispat Ltd.

Surge capacitor Capacitance per phase Quantity : : 0.25 F 3 Nos. (1 per phase)

Potential transformers For Protection Metering Excitation Quantity 3 Nos. 3 Nos. 1 No. Secondary output 110 V 110 V 415 / 240 V Class 3P 1 3

The panel shall be complete with AC supply on /off control switch, illuminating lamp with limit switch for each PT compartment, indicating lamps and space heater with thermostat. General : Type Terminal box Material of busbars Dimensions in mm Weight : : : : : Simplex, modular & free standing To suit HT Cables Aluminium 1800 (L) x 1650 (D) x 2350 (H) 1,000 KG

NEUTRAL GROUNDING RESISTOR PANEL NGR panel shall house the following: Resistor Type Rated current Duty rating Resistor grid type Temperature rise Mounting & fixing of Resistor units : : : : : : : : : : : Naturally air cooled 100 A 10 seconds Punched steel 3750 C over ambient (max.) Mounted on grid rods; fixed and assembled in tiers separated by porcelain insulators Manual. One 2 Nos. (for on / off positions) Porcelain insulated 12 mm terminal studs Two Nos. Secondary output 1A 1A 1A 1A Class 5 P 10 PS 5 P 10 0.5 Page 13 of 32

- Neutral isolator Operation No. of poles Limit switches Earth connection Type Quantity

Current transformers For Quantity Generator 3 Nos. protection Differential 3 Nos. protection Earth fault 1 No. protection Metering 3 Nos.

M/s Rajashri Power & Ispat Ltd.

Compounding

1 No.

1A

The panel shall be complete with AC supply & DC supply on /off control switch, illuminating lamp with limit switch for each PT compartment, indicating lamps and space heater with thermostat. General: Type Terminal box Material of busbars Dimensions in mm Weight BATTERY Type Capacity Rating Volt per cell No. of cells : : : : : : : : : : Simplex, dead front & free standing To suit HT Cables Aluminium 1500 (L) x 1000 (D) x 1400 (H) 1,000 KG Maintenance Free 400 AH 110 V, DC 2 V, DC 55

BATTERY CHARGER CUM DC DISTRIBUTION PANEL Battery charger cum DC distribution panel shall house the following: - Battery charger Quantity : One float & one float cum boost charger Input : 240 V, 1 phase, 50 Hz, AC supply Output : 75 A, 110 V DC (Float charger) 80 A, 110 V DC (Float cum boost charger) Voltage regulation : +/- 1% from no-load to full load Operation mode : Auto / Manual Charger panel shall be provided with alarm for following faults : Float charger failed Float cum boost charger failed DC voltage high DC voltage low AC supply failed Batter earth fault Charger panel shall house following meters : AC Voltmeter DC Voltmeter with selector for load/charger/battery DC Ammeter for load DC Ammeter for charger DC Ammeter for battery DC distribution system Panel shall be provided with feeders for: DC motor starter panel HT Breaker panel Relay panel Generator control panel AVR cum excitation panel M/s Rajashri Power & Ispat Ltd. : : : : : 1 No. 1 No. 1 No. 1 No. 1 No. Page 14 of 32

Turbine control panel Spare General : Type Dimensions in mm Weight AC MOTORS Type Winding connection Duty Enclosure Cooling Insulation Power supply Speed / No. of poles DC MOTOR Type Duty Enclosure Cooling Insulation Power supply Speed

: :

1 No. 2Nos. : : : Simplex, dead front & free standing 1200 (L) x 1000 (D) x 1800 (H) 300 KG

: : : : : : : : : : : : : : :

Induction Delta Continuous IP-55 TEFC Class F 415 V, 3 Phase, 50 Hz To suit driven equipment Shunt field Continuous IP-55 TEFC Class F 110 V 1440 RPM

TURBINE CONTROL PANEL Turbine control panel shall house the following: - Electronic governor with keyed-in operating program - Condenser hotwell level indicator cum controller - Relay based hard wired turbine safety interlocks and trip logic - Remote controls comprising of selector switches, ammeters, push buttons & indicating lamps for: AOP motor EOP motor Barring gear motor Vapour extractor motor - Push buttons for turbine speed raise and lower - Turbine remote trip/reset push buttons - Temperature scanner for Monitoring turbine and gearbox bearing temperature - Alarm annunciator for Turbine fault monitoring The panel shall be complete with AC supply & Dc supply on /off control switches, indicating lamps and space heater. TURBINE GAUGE PANEL Turbine gauge panel shall house the following gauges: - Pressure gauges for: Inlet steam HP Wheel case Bleed Steam Exhaust steam M/s Rajashri Power & Ispat Ltd. Page 15 of 32

Lube oil Control oil Temperature gauges for: Inlet steam Bleed steams Exhaust steam

TURBINE AUXILIARY MCC MCC panel shall house the following: Incoming feeder complete with switch-fuse unit, voltmeter, CT operated ammeter, indicating lamps & bus bars DOL starter complete with switch-fuse unit, contactor, overload relay, CT operated ammeter, indicating lamps & pushbuttons for : AOP motor Barring gear motor Vapour extractor motor

Turbine speed indicator and speed raise / lower push buttons

DC MOTOR (EOP) STARTER PANEL DC motor starter panel shall house the following: Incoming feeder complete with switch-fuse unit, voltmeter, ammeter and indicating lamps 2 step resistance starter for EOP motor complete with switch-fuse unit, contactor, overload relay, ammeter, indicating lamps & pushbuttons.

M/s Rajashri Power & Ispat Ltd.

Page 16 of 32

GENERAL SPECIFICATIONS OF INSTRUMENTS Pressure and Temperature Gauges Dial : 150 mm circular Scale : 270 Deg. arc with black pointer Type : Bourdon (pressure gauge) Mercury in steel (temperature gauge) Accuracy : +/- 1 % Over range protection : 125 % Accessories : Shatter proof safety glass Pressure Switch Sensor type Material of case Material of bellows Pressure Transmitter Type Input Output Material for process connection internals : : : : : : : Bellows Die cast aluminium SS-316 2 wire, capacitance & electronic Direct 4 20 mA SS-316

Resistance Temperature Detectors: Element type : PT-100, 3 wire Solenoid Valve Power supply Operation Type : : : 110 V DC De-energise to open 2 way, universal ports Air at 1.5 Kg/cm2g 4 20 mA 0.2 to 1.0 Kg/cm2g (air) Die-cast aluminium alloy body Pressure gauges for supply & output 230 V, AC, Single phase PT-100, 3 wire RTD Channel No. & bearing / winding temperature Auto / Manual Programmable +/- 1 Deg.C Modular, plug-in cards, interchangeable Optical isolation provided through opto couplers Milky white (pre-trip alarm) Red (Trip alarm) 110 V DC Page 17 of 32

Current to Pneumatic Converter Supply : Input : Output : Enclosure : Accessory : Temperature Scanner Power supply Input Display Display mode Scan rate Accuracy : : : : : : : : :

Alarm Annunciator Type Input protection Colour of window

Power supply : M/s Rajashri Power & Ispat Ltd.

Fault initiation Accessories Air Filter Regulator Filter element Element material Body material

: :

Make to alarm Electronic hooter and Acknowledge & Reset 5 microns Sintered bronze Cast aluminium ***

Push

buttons

for

Test,

: : :

M/s Rajashri Power & Ispat Ltd.

Page 18 of 32

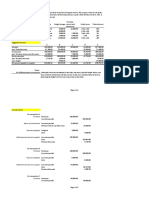

CHAPTER 3 PERFORMANCE DATA Turbine Gear box output speed Inlet steam pressure Inlet steam temperature Inlet flow Bleed for deaearator Bleed flow Exhaust pressure Exhaust flow Power Generation TG Rating Note: 1. : : : : : : : : : : : Multistage Impulse extraction cum condensing 1500 rpm 64 kg/cm2A 490 C 41.9 TPH 4.81 ata 4.80 TPH 0.17ata 37.10 TPH 10.0 MW 10.0 MW

SECTION - I

The above consumption data apply at steady state conditions, with the control valve fully open, deposit free blading and clean surface of cooling equipment in accordance with the Triveni performance Test Procedure which is based on the ASME - PTC 6 code. This consumption does not include the power and steam requirements of the condensing plant and auxiliary equipments. Instrumentation tolerance of +or- 3.0% is allowed as per the international testing practices. The data furnished are based on nominal main steam parameters at turbine inlet flange. The following are not included in the auxiliary power consumption furnished in Auxiliary power guarantee. a) All standby equipments. b) All electrical actuators and motorized valves c) Other intermittent equipments The steam consumption for and auxiliary equipments such as ejector motive steam, glandsealing steam etc. is not included in the steam consumption figure for turbine performance. Auxiliary power consumption indicated is at motor input terminals.

2.

3. 4.

5. 6.

M/s Rajashri Power & Ispat Ltd.

Page 19 of 32

SECTION I

CHAPTER 4 UTILITIES TO BE PROVIDED BY THE PURCHASER INTERMITTENT DEMAND 300kg/Hr (during start-up) 400 kg/Hr (during start-up) CONTINUOUS DEMAND N/A 350 Kg/Hr

A.

STEAM (SATURATED) CONSUMER / PURPOSE Turbine gland sealing system at 10 Kg/cm2 Ejector system at 10 Kg/cm2

B.

COOLING WATER (FRESH) Inlet pressure Inlet temperature Temperature rise (T) : : : 2.5 Kg/cm2g 32 Deg. C 8 Deg. C CONTINUOUS DEMAND NA 80 M3/hr 80 M3/hr 50 M3/hr

CONSUMER / PURPOSE Steam surface condenser Turbine oil cooler Generator air cooler Gland Vent Condenser C. INSTRUMENTATION AIR 1. D. For control purpose :

5 SCFM at 7.0 Kg/cm2

AC POWER Power supply CONSUMER AOP Motor CEP Motor Air Blower Motor Vapour Extr. Motor Barring Gear Motor ACOP Motor MCOP Motor : 415 V, 50 Hz, TP & N CONTINUOUS DEMAND N/A NA 1.5 kW 0.75 kW N/A N/A 2.5 kW

INTERMITTENT DEMAND 15 kW (During start-up & shut-down) N/A N/A N/A 22 kW (During shut-down) 2.5 kW N/A

Note :

All utility figures mentioned above are indicative only. The actual requirement shall be furnished during detailed engineering.

M/s Rajashri Power & Ispat Ltd.

Page 20 of 32

CHAPTER 5 LIMITS OF TENDER & EXCLUSIONS

SECTION - I

LIMITS OF TENDER: The offer is complete within the following limits beyond which Purchaser shall arrange any and all equipments: 1. 2. 3. 4. 5. 6. 7. 8. Inlet flange of Stop and emergency valve of the turbine. Bleed and exhaust flange of the turbine. Inlet and outlet flanges of the cooling water connections of oil cooler, and generator air cooler. At the inlet of gland sealing for auxiliary steam. Turbine drains with drain cocks terminated at nearest drain point. Instruments, air connections within the battery limit of not more than 5 meters from the turbine. Utility / Auxiliary power at the control panel terminals. Incoming terminals of alternator.

EXCLUSIONS: The following items are not included in sellers scope of supply and shall be arranged by purchaser: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. Steam and cooling water piping. Any piping and valves outside the above limits. Air cooled condenser system with expansion bellow Steam flow meters. Platforms, ladders of floor/platforms, foundation or civil work of any nature including their design. Routing design for piping and supports. Utility/Auxiliary & emergency power and air supply. Inlet isolation valve and PRDS for auxiliary steam supply. All HT cables, LT cables, control and signal cables along with cable termination,glands,cable trays,ducts etc. Electrical distribution system, outdoor switch yard & associated equipments. De-aerator, Cooling Tower, related instruments and piping. VCB panel. UPS. Oil Centrifuge. PLC/SCADA. Emergency overhead lube oil tank. Fire detection, alarm and protection system. Crane gantry. Complete earthing and earth pits First fill of oil and Flushing oil All/any statutory approvals. Any other item not specifically mentioned in Scope of Supply.

M/s Rajashri Power & Ispat Ltd.

Page 21 of 32

CHAPTER 6 LIST OF TOOLS AND TACKLES EQUIPMENT DESCRIPTION TURBINE Rotor lifting arrangement Overspeed trip cap removal bolt Fixture for putting oil seals with cover Allen keys 1/16 to Circlip plier (internal & external) 6 Double end spanner x 5/16 Double end spanner 3/8 x 7/16 Double end spanner x 9/16 Double end spanner 5/8 x Double end spanner 7/8 x 1 Double end spanner 24/27 mm & 30/32 mm Double end spanner 1 x 1-1/8 Single end spanner 1- Ring spanner 1 x 1-1/8 Ring spanner 1 x 1 Ring spanner 24/27 mm & 30/32 mm Open end spanner 1- & 1- Screw driver 6 & 12 Adjustable spanner 6 *** QUANTITY

SECTION - I

1 Set 1 No. 1 No. 1 Set 1 No. each 1 No. 1 No. 1 No. 1 No. 1 No. 1 No. each 1 No. 1 No. 1 No. 1 No. 1 No. each 1 No. each 1 No. each 1 No.

M/s Rajashri Power & Ispat Ltd.

Page 22 of 32

SECTION -I CHAPTER - 7 List of sub-vendors Please refer the attached separate list

M/s Rajashri Power & Ispat Ltd.

Page 23 of 32

CHAPTER 8

SECTION - I

DRAWING AND DOCUMENTATION SCHEDULE DRAWING / DOCUMENTATION DESCRIPTION P&I diagrams with Bill of materials for : Steam, condensate & ejector system Governing & lube oil system Cooling water system Foundation Block Plan Power House Lay-out Electrical Single line diagram GA Drawing of Turbine GA Drawing of Condenser GA Drawing of Ejector GA Drawing of CE pumps GA Drawing of Alternator GA & Schematics of AVR Panel GA & Schematics of LAPT & NGR Panels GA & Schematics of Relay Panel GA & Schematics of MCS Panel GA & Schematics of TCP & TGP GA & Schematics of TG Aux. MCC GA & Schematics of DC Motor starter GA & Schematics of Battery charger Performance curve Electronic governor program chart Relay setting chart Cable Schedule Maintenance manuals NOTE : 1. Drawings shall be submitted for information / approval within 8 to 12 weeks from date of receipt of technically & commercially clear purchase order/LOI. You shall approve all drawings submitted for approval within a period of 15 days of submission failing which our delivery will get affected. 2. Final drawings and documents shall be submitted along with supply of equipment. INFORMATION (I) / APPROVAL (A) 2 sets (A) FINAL

4 sets

2 sets (A) 2 sets (A) 2 sets (A) 2 sets (I) 2 sets (I) 2 sets (I) 2 sets (I) 2 sets (I) 2 sets (I) 2 sets (I) 2 sets (I) 2 sets (I) 2 sets (I) 2 sets (I) 2 sets (I) 2 sets (I) ------

4 sets 4 sets 4 sets 4 sets 4 sets 4 sets 4 sets 4 sets 4 sets 4 sets 4 sets 4 sets 4 sets 4 sets 4 sets 4 sets 4 sets 4 sets 4 sets 4 sets 4 sets

M/s Rajashri Power & Ispat Ltd.

Page 24 of 32

CHAPTER 9 Q A PLAN EQUIPMENT DESCRIPTION Complete assembled turbine 1. 2. 3. 4. 5. Condenser Ejector CE Pumps Complete assembled generator 1. 2. 1. 2. 1. 2. 1. 2. 3. 4. 5. 6. 7. 8. 1. 2. 3. 4. 1. 2. 1. 2. 3. TESTS

SECTION - I

LAPT panel / NGR panel /AVR panel / Relay panel / Met. cum synch. panel / TCP / Battery charger panel / Aux. MCC Turbine Gauge Panel Instruments

Visual & dimensional checks No-load run test & functional check on safety devices Vibration check Noise level check Open inspection & dynamic rotor balancing (after no-load run test) Visual & dimensional checks Hydrostatic test Visual & dimensional checks Operational & functional tests Visual & dimensional checks Operational & functional tests Visual & dimensional checks OCC & SCC test Over speed test Vibration check Noise level check HV test Measurement of winding resistance and insulation resistance Measurement of shaft voltage Visual & dimensional checks Operational & functional tests HV test Measurement of insulation resistances Visual & dimensional checks Range calibration Visual & dimensional checks Operational & functional tests Range calibration

NOTE :

1. Material test certificates from manufacturers shall be submitted for major components of turbine and other bought-out items along with supply. 2. We have not envisaged any customer hold point in QAP and delivery & price quoted are on the same basis.

M/s Rajashri Power & Ispat Ltd.

Page 25 of 32

CHAPTER 10 REFERENCE LIST

SECTION-I

Refer attached reference list

M/s Rajashri Power & Ispat Ltd.

Page 26 of 32

SECTION I CHAPTER 11 RECOMMENDED STEAM PURITY Technically pure steam is of such quality, that it does not cause deposits in the steam pre-heaters, in the fittings, heaters as well as in the turbine, which might require the intentional shut-down of the boiler or some part of the equipment, for their cleaning, outside of the normal equipment maintenance program. The recommended or limit values of the purity of steam are stated in the following table. The values are given in the maximal allowable day average concentrations. The concentration of the chlorine ions may be max. 3 g.l-1. IDENTIFIER Unit Recommended values 0.3 Specific electrical conductivity at 25oC 1) S.cm-1 -1 Silicon dioxide (SiO2) 20 g.l + + -1 Sodium and potassium (Na + K ) 10 g.l -1 Total Fe contents (Fe) 20 g.l Ammonia (NH3) mg.l-1 1 Copper-total Cu 3 g/kg 1) Measured after the flow through strong acidic H-katex. NOTE: Limit values 1 35

The measurement of the electrical conductivity at 250 C (S/cm-1) must be done without the presence of operational chemical agents, e.g. ammonia or hydrazine, which tends to increase the conductivity. This is why the measurement of specific electrical conductivity has to be done after the flow of the sample through the strong acidic H-katex, which is the filter that keeps all cations of the chemical compounds. By the filtration chemically pure water can be obtained.

RECOMMENDED STEAM PURITY - LIMITS Continuous Conductivity Micro-Ohms/cm at 25 0c Drum Once through SiO. ppb, max. Fe. ppb, max. Cu. ppb, max. Na + K, ppb, max. Upto 800 PSIG 801 to 1450 PSIG 1451 to 2400 PSIG Over 2400 PSIG NOTE : Start UP

0.3 0.2 20 20 3

1.0 0.5 50 50 10

20 10 5 3

20 10 5 3

THE ABOVE DATA IS ADAPTED FROM NEMA STANDARD PUBLICATION NO. SM23 (1985) PAGE 40 SECTION 10.7

Page 27 of 32

M/s Rajashri Power & Ispat Ltd.

CHAPTER 1

SECTION-II

SPECIAL COMMERCIAL TERMS & CONDITIONS OF SALE THIS OFFER IS SUBJECT TO THE CONDITIONS MENTIONED HEREUNDER: PRICE: For Supply of 10MW TG set. Rs. 595.00Lacs,[Rs. Five Hundred and ninty five lacs only] Ex-works, inclusive of packing & forwarding but exclusive of all taxes, duties and transit insurance and freight. This above price is based on scope of supply described in Chapter-1 of Section-I of our quotation and will be confined to the limits defined in the "Limits of Tender" and will also be subject to the Exclusions as per Chapter-5 of Section-I of this offer attached hereto. For Erection and Commissioning of 10MW TG set. Rs. 20.00 lacs (Rs. Twenty Lacs only) for Erection and Commissioning of equipments in our scope of supply. DELIVERY 11 months ex works basis from the date of receipt of your technically and commercially clear order and advance amount. This delivery is subject to the Force Majeure clause as given in our General Commercial Terms & Conditions of Sale. In case of any delay on your part in giving technical and / or commercial clearance and / or payment of advance, the delivery shall stand postponed automatically. Further in the event of your delay / non-payment of our bills for supplies already made, we shall be entitled to hold further supplies till we receive your payment. E & C- 2 months TERMS OF PAYMENT 1. 2. 3. 4. 20% of the total order value along with your LOI / Purchase Order. 10% of the total order value as against submission of major contractual drawings. 10% of the total order value against proof of placement of orders for major bought outs. Balance 60% of the total order value along with all taxes and duties against proforma invoice on pro-rata basis before dispatch.

TAXES AND DUTIES The price quoted is ex-works/our sub-contractors works. Taxes & duties shall be charged extra at actuals at the rates effective at the time of despatch. PRICE VARIATION The price quoted above is firm for the duration of the contract except for statutory variations. If delivery is delayed due to reasons attributable to you, the price escalation shall be mutually discussed and agreed upon. In case of any imported equipment, where we may have declared the quantum of imports in Indian Rupees, this amount would be subject to Foreign Exchange & Import duty variation.

M/s Rajashri Power & Ispat Ltd.

Page 28 of 32

WARRANTY The equipment supplied by us is guaranteed for a period of twelve calendar months from the date of commissioning of the equipment or eighteen calendar months from the date of despatch whichever occurs earlier. Our liability is limited to making good any defects in design, material or workmanship developing in goods of our own manufacture under proper use and arising solely from faulty design, materials or workmanship provided always that such defective parts are promptly returned free to our works unless otherwise arranged. The repaired or new parts will be delivered free of charge F.O.R. station of despatch. At the termination of such period all liability on our part ceases. While all reasonable precautions are taken in the design of our machinery to resist normal operational hazards, we would respectfully point out that our guarantee does not cover damage due to carry over water or solid particles or corrosive and fouling effects of contaminated feed waters and / or omissions / commissions attributable to you. GENERAL COMMERCIAL TERMS AND CONDITIONS OF SALE : This tender and any contract which may result there from is subject to our General Commercial Terms & Conditions of Sale (enclosed herewith), except as may otherwise be agreed to in writing, or as may be modified in the main body of this tender. In case of any conflict between the Special Terms and Conditions of Sale & the General Terms and Conditions of Sale, the former will prevail. VALIDITY This quotation stands valid for 30 days from the date of this proposal, after which it is subject to revision/confirmation in writing by us.

Prashant Dhanpawde Sr. Mgr.Mktg.

M/s Rajashri Power & Ispat Ltd.

Page 29 of 32

CHAPTER 2

SECTION II GENERAL COMMERCIAL TERMS & CONDITIONS OF SALE THE ACCEPTANCE OF THIS TENDER / QUOTATION INCLUDES THE ACCEPTANCE OF THE FOLLOWING TERMS AND CONDITIONS EXCEPT AS VARIED BY AGREEMENT/ PURCHASE ORDER ACCEPTED IN WRITING BY BOTH PARTIES.

1.

PRICES: Are net Ex-works prices inclusive of Packing & Forwarding charges. Are exclusive of all taxes, Duties, Octroi or any other statuary levies. Are based on materials to be procured from our standard sources subject to our standard Inspection & testing procedure. Are subject to timely finalisation of all technical details, approvals and availability of all clearances to enable us to proceed with the work uninterruptedly. Any increase or reduction in the cost of performance of the contract, if so by reason of making, passing of promulgation of any law or any order, regulation having the force of law, shall be added to or deducted from the contract Price, as the case may be. Concessional rate of Sales tax wherever applicable will be charged against valid declaration forms. In the absence of declaration forms, you will have to pay sales tax at prevailing non-concessional rate.

2. DELIVERY We shall deliver the equipment within the period specified in this offer. The commencement and completion of deliveries, however, are subject to the following: You will place technically and commercially clear order along with the advance as stipulated in this offer, so as to enable us to take work in hand and proceed uninterruptedly. You will make available, at mutually agreed dates, all other technical details / approvals which are required during the course of execution of the contract. You will honour the payment commitments as per the binding document during the course of execution Force Majeure conditions. The deliveries specified in this offer will automatically be extended by the period lost due to any of above accounts. 3. DESPATCH / STORAGE You shall issue final despatch instructions as per the Order. However, if you fail / delay to issue the despatch instruction within 14 days after notification that goods are ready for despatch, we shall move the goods for storage. In such an event you shall pay Storage charges @ 2 % per month or part thereof of the contract Price. 4. DRAWINGS, ETC. All descriptive literature, shipping specifications, drawings and particulars of weight and dimensions submitted with the tender offer are approximate only and the description and illustrations contained in the catalogues, and other advertisement matter are intended merely to present a general idea of the equipment described herein and none of these shall form part of the contract. We will submit within a reasonable time after acceptance of order, such drawings (as per our engineering practice) as are necessary to demonstrate fully that all parts of the equipment shall be supplied will conform to the provisions and intent of the contract. All drawings submitted to you for approval shall be approved / returned with comments, to us within 15 days failing which they will be deemed to have been approved. We shall have the right to improve / modify the design of equipment for better efficiencies during the tenure of contract without affecting your basic requirements 5. TESTS Our products are carefully inspected and subjected to all relevant tests in accordance to the relevant standards and will be despatched only after our best satisfaction. You or your representative can attend these tests provided that you notify in writing to us to that effect when the order is placed. In the event of any delay on your part in attending such tests after seven days notice from our side, your absence shall constitute a Waiver and the tests will proceed in your absence. All such tests will be deemed to have been approved by you. Any repetition of these inspections or tests shall be charged extra

M/s Rajashri Power & Ispat Ltd.

Page 30 of 32

to the contract price. The certificates given by us/our sub-Contractors of any such special tests shall be conclusive evidence of such tests. 6. SUSPENSION OF WORK: o If you fail to make any payment when due or perform on time any of your other obligations under the contract, we shall be entitled to suspend performance of the contract until the failure is remedied. The time for performance of the contract by us shall be extended accordingly and any cost (including financial costs, storage and demurrage or any other charges) thereby incurred by us shall be paid by you. o If performance of the contract is for any reason suspended by you and such suspension continues for more than 3 months, we shall be entitled at any time during that continued suspension by not less than 30 days' written notice to terminate the contract forthwith, in which event the provisions of the Termination Clause shall apply. In all cases where delay of failure in performance of this contract is directly or indirectly caused by or due to an act of God, war, mobilisation, demobilisation, requisition by / or interference from Government or Local Authorities, lockout, labour disturbance, trade disputes, fires, riots, strikes and / or civil commotion, malicious damages or any events or circumstances whatsoever beyond our control, then in such case, we shall be entitled to an extension of time for performance of this contract for a period corresponding to the period of delay by or in consequence of the operation (in whole or in part). 7. TERMINATION OF CONTRACT In case of termination of the contract at any point of time before its completion, you will be required to pay us cancellation charges as follows: 10% of the order value for termination before 25% of the delivery period. 25% of the order value for termination above 25 % but before 50% of the delivery period.40% of the order value for termination above 50% but before 75% of the delivery period. 60% of the order value for termination above 75% of the delivery period but before start of despatch. In the event of the any cancellation under the provisions of this clause, you shall have no claim over the designs, drawings and materials lying ready with us and will remain our property. 8. TITLE OF GOODS Title of the goods will automatically get transferred to you as soon as the goods leave our works / our sub-vendors works and the documents evidencing the title and the despatch are transferred in your favour. However our obligations will cease only on the commissioning of the equipment. The components will get despatched ex-works in convenient despatchable units as manufactured, depending upon the sequence, size, transportation facilities etc., and each such component shall be treated as contracted goods and payment for the goods made pro-rata.

9. INSURANCE Purchaser shall arrange comprehensive insurance covering supply, transit, storage at site cum erection and commissioning. For purpose of transit insurance, we shall furnish despatch particulars of equipment to enable you to arrange for transit insurance. Further all goods will be despatched on FREIGHT TO PAY basis to the Station specified by you at your risk. We shall accept no liability for damages or shortages in transit. . 10. FORCE MAJEURE In all cases where delay of failure in performance of this contract is directly or indirectly caused by or due to an act of God, war, mobilisation, demobilisation, requisition by / or interference from Government or Local Authorities, lockout, labour disturbance, trade disputes, fires, riots, strikes and / or civil commotion, malicious damages or any events or circumstances whatsoever beyond our control, then in such case, we shall be entitled to an extension of time for performance of this contract for a period corresponding to the period of delay by or in consequence of the operation (in whole or in part). 11. PATENTS In the event of any claim being made or action being brought against you in respect of infringement of patents by us for goods supplied to you hereunder, you shall notify us immediately. We shall be at liberty, with your assistance, if required, but at our own expense, to conduct all negotiations for the settlement of the same or any litigation that may arise therefrom. We shall indemnify you in respect of

M/s Rajashri Power & Ispat Ltd.

Page 31 of 32

any such claim. This is subject to such notification and provision that no such goods, or any part thereof, shall be used for any purpose other than that for which we supply them. 12. ARBITRATION All disputes, or difference whatsoever arising between us and yourselves, in connection with the contract, which cannot be settled through mutual negotiations in good faith, either of us may give the other notice in writing of the existence of such question, dispute or difference. The same shall be settled in accordance with the provisions of Indian Arbitration Act. The arbitrator shall be a person qualified to be appointed as an arbitrator, under the provision. The award of the arbitrator shall be final and binding on the parties and the persons claiming under them. Work under the contract shall continue, so far, as may be reasonably practical, during the arbitration proceedings, and no payments which may or shall become due shall be withheld on account of such proceedings. The venue for arbitration shall be Bangalore. 13. LEGAL CONSTRUCTION The contract shall in all respects be construed and be deemed to be governed by the provisions of the Indian Contract Act and Sale of Goods Act as may be in force at the time of execution of the contract. The contract shall be taken to have been made in our office and all proceedings, which either party to the contract might be entitled to make against the other under the contract shall be instituted in a court at Bangalore 14. PERFORMANCE TEST The Performance test will have to be carried out within 30 days of the commissioning. If performance test is not been able to conduct within 90 days due to reasons not attributable to Triveni Engg & Industries ltd, then it shall be deemed to have been carried out . 15. STORAGE AT SITE / OFFICE AT SITE Purchaser shall provide LOCKED Storage space at site to store critical equipments. He shall also arrange for make shift office and provide all facility like telephone, fax etc. for the suppliers supervisors.

M/s Rajashri Power & Ispat Ltd.

Page 32 of 32

You might also like

- Boiler Turbine Generator: Unit Trip Report-Draft STPP, 2X600 MWDocument5 pagesBoiler Turbine Generator: Unit Trip Report-Draft STPP, 2X600 MWVishal Kumar Laddha100% (1)

- Jindal Hydrogen Gas DryerDocument2 pagesJindal Hydrogen Gas DryerLakshmi Narayan100% (2)

- NTPC PMI OFF AshHandlingSystemDocument24 pagesNTPC PMI OFF AshHandlingSystemAshish UppuNo ratings yet

- TG PG Test Procedure PDFDocument129 pagesTG PG Test Procedure PDFHari Prasad100% (2)

- Generator Protection (Steag) PDFDocument67 pagesGenerator Protection (Steag) PDFHari PrasadNo ratings yet

- Chapter 14 Governing SystemDocument7 pagesChapter 14 Governing Systemsambhu100% (1)

- 600MW Final Scheme Tracing Book - by JIPT PDFDocument123 pages600MW Final Scheme Tracing Book - by JIPT PDFAnudeep ReddyNo ratings yet

- 660MW Turbo Generator & Its AuxiliariesDocument88 pages660MW Turbo Generator & Its AuxiliariesAshvani ShuklaNo ratings yet

- 20mw Operation ManualDocument54 pages20mw Operation Manualrenjithkvpgdca27494% (18)

- CESC Dhariwal 300 MW - ChandrapurDocument10 pagesCESC Dhariwal 300 MW - Chandrapurramnadh803181No ratings yet

- Gen. Seal Oil System Emergency DPR Valve Not Operating-May09Document4 pagesGen. Seal Oil System Emergency DPR Valve Not Operating-May09Adnan Habib Khan100% (2)

- ESP Line Up & ChargingDocument10 pagesESP Line Up & Chargingsambhu100% (1)

- Procedure of Deaerator Charging in Power Plant - ASKPOWERPLANTDocument16 pagesProcedure of Deaerator Charging in Power Plant - ASKPOWERPLANTOtuagaNo ratings yet

- DehDocument34 pagesDehAnand Swami100% (1)

- ALSTOM Different-Types-of-Mills PDFDocument39 pagesALSTOM Different-Types-of-Mills PDFvivek1312100% (1)

- BHEL 600 MW Soot BlowerDocument279 pagesBHEL 600 MW Soot BlowerAmit Biswas75% (8)

- Turbine Emergency - Thermal Power Plant A-ZDocument5 pagesTurbine Emergency - Thermal Power Plant A-ZSiva Kulanji100% (1)

- 210 MW Seal Oil SystemDocument6 pages210 MW Seal Oil Systemmag_ktps20021520No ratings yet

- Presentation For Supercritical TechnologyDocument113 pagesPresentation For Supercritical TechnologyVIVEK100% (1)

- Adani MundraDocument139 pagesAdani MundraAbhishekNo ratings yet

- STEAG Energy Services India - Profile References-Rev 5 10 15Document43 pagesSTEAG Energy Services India - Profile References-Rev 5 10 15Prasad Rajendra100% (1)

- An Overview of CFBC Boiler: By-Mukesh JhaDocument88 pagesAn Overview of CFBC Boiler: By-Mukesh Jhabalaji krishnan100% (2)

- Generator Construction 210 MWDocument33 pagesGenerator Construction 210 MWPradeep_Vashist100% (1)

- Extraction Condensing Steam Turbine PDFDocument2 pagesExtraction Condensing Steam Turbine PDFAaronNo ratings yet

- Report On Unit-5 Clinker FormationDocument18 pagesReport On Unit-5 Clinker Formationsai_mss16No ratings yet

- 3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDocument15 pages3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDSGNo ratings yet

- SESI-TSPL-OPN-SOP-BTG-017 (Charging Auxiliary Steam Header)Document11 pagesSESI-TSPL-OPN-SOP-BTG-017 (Charging Auxiliary Steam Header)sourav mahapatraNo ratings yet

- 500 MW Generator, Salient FeaturesDocument10 pages500 MW Generator, Salient FeaturesSandeep MishraNo ratings yet

- 660 MW Sipat BoilerDocument88 pages660 MW Sipat BoilerNavneet SinghNo ratings yet

- PocketDiary SantaldihDocument198 pagesPocketDiary SantaldihJoydev GangulyNo ratings yet

- 2.3 Principle of Turbine Governing CompressedDocument54 pages2.3 Principle of Turbine Governing Compressedabhaymehta67100% (1)

- Sop of TG & AuxilliariesDocument29 pagesSop of TG & Auxilliarieschcrr67% (3)

- Bhatia Gummidipoondi WHRSG O&m Manual FinalDocument224 pagesBhatia Gummidipoondi WHRSG O&m Manual Finalt_syamprasadNo ratings yet

- Fans NptiDocument15 pagesFans NptigvprambabuNo ratings yet

- Slop Fired Boiler: Development of An EfficientDocument36 pagesSlop Fired Boiler: Development of An EfficientSantosh Kumar JaiswalNo ratings yet

- BCP Installation & CommissioningDocument18 pagesBCP Installation & CommissioningKrishnan SanthanarajNo ratings yet

- Gdtest of EspDocument13 pagesGdtest of Espsrigirisetty208No ratings yet

- BHEL Turbine ManualDocument58 pagesBHEL Turbine Manualnivasssv75% (4)

- Turbine Gate Valve Gearing (Turning Gear)Document5 pagesTurbine Gate Valve Gearing (Turning Gear)Sai Swaroop50% (2)

- Ball and Race MillDocument76 pagesBall and Race Millsandeep19861986100% (2)

- 5 Buffer Hopper D-PumpDocument4 pages5 Buffer Hopper D-PumpMithun Singh RajputNo ratings yet

- PRDSDocument21 pagesPRDSAshok RasekarNo ratings yet

- Esp Charging SopDocument3 pagesEsp Charging SopvikramshounNo ratings yet

- Bhel PPTDocument34 pagesBhel PPTMayur TapadiaNo ratings yet

- CFBC DCPP at A Glance.Document20 pagesCFBC DCPP at A Glance.Sumit SuryavanshiNo ratings yet

- Condenser Flood TestDocument14 pagesCondenser Flood Testsrigirisetty208100% (1)

- O & M ManualDocument131 pagesO & M Manualt_syamprasadNo ratings yet

- ESP ManualDocument158 pagesESP ManualSinter PlanningNo ratings yet

- DM Water Cost Chemical Name Unit Consumption Rate AmountDocument3 pagesDM Water Cost Chemical Name Unit Consumption Rate AmountRamdas TaloleNo ratings yet

- SPM Make Portable Vib 15 PDFDocument2 pagesSPM Make Portable Vib 15 PDFSSAC PVT.LTD.100% (1)

- Stator Water System Monitoring For Large Turbo-Generator-A User'S PerspectiveDocument12 pagesStator Water System Monitoring For Large Turbo-Generator-A User'S PerspectiveUmesh HadiyaNo ratings yet

- ResumeDocument7 pagesResumeponthirumaranNo ratings yet

- Seal Oil System (Presentation)Document16 pagesSeal Oil System (Presentation)ToniMelo100% (2)

- Gen-Seal&cool-New - 500 MWDocument98 pagesGen-Seal&cool-New - 500 MWharisankar100% (2)

- Turbogenerators Gyanendra Sharma NPTI DelhiDocument36 pagesTurbogenerators Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- TDBFP Writeup KorbaDocument15 pagesTDBFP Writeup Korbamkgchem100% (2)

- CFBC Boiler SOPDocument18 pagesCFBC Boiler SOPgangatharanNo ratings yet

- Triveni Offer - 17.1 MWDocument52 pagesTriveni Offer - 17.1 MWPrasanna kumar subudhi100% (1)

- MTU 1085 HPDocument18 pagesMTU 1085 HPmajdirossross100% (2)

- Turbine RAS - Back Pressure Turbine 4Document33 pagesTurbine RAS - Back Pressure Turbine 4hemant visheNo ratings yet

- SADocument31 pagesSAnogeshwarNo ratings yet

- High Voltage Surge Arresters: Buyer S GuideDocument51 pagesHigh Voltage Surge Arresters: Buyer S Guidetaiptc4No ratings yet

- Tariff Schedule Final16 17Document30 pagesTariff Schedule Final16 17nogeshwarNo ratings yet

- Lightning ArrestersDocument12 pagesLightning Arrestersvbgiri100% (1)

- Atlas Copco Ga 37 Manual PDFDocument9 pagesAtlas Copco Ga 37 Manual PDFjeff0% (2)

- Heat RecoveryDocument14 pagesHeat RecoverynogeshwarNo ratings yet

- OpacityDocument3 pagesOpacitynogeshwarNo ratings yet

- Turbine AreaDocument4 pagesTurbine AreanogeshwarNo ratings yet

- Elite MeterDocument20 pagesElite Metercyber4india100% (5)

- Design InterfaceDocument57 pagesDesign InterfacenogeshwarNo ratings yet

- EconomizerDocument14 pagesEconomizersvanwonderenNo ratings yet

- CommissioningDocument7 pagesCommissioningnogeshwarNo ratings yet

- Steam Turbine Q & ADocument47 pagesSteam Turbine Q & Asrikanth9555100% (1)

- TPP Motorised ValveDocument1 pageTPP Motorised ValvenogeshwarNo ratings yet

- RTDTheoryDocument4 pagesRTDTheoryfarhan131No ratings yet

- Cooling Water Pump (CW) - 1Document4 pagesCooling Water Pump (CW) - 1nogeshwarNo ratings yet

- Coal Handling Plant MotorDocument3 pagesCoal Handling Plant MotornogeshwarNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Primary Air Fan (Pa Fan) - 1: Make: SiemensDocument9 pagesPrimary Air Fan (Pa Fan) - 1: Make: SiemensnogeshwarNo ratings yet

- Steam Turbine Q & ADocument47 pagesSteam Turbine Q & Asrikanth9555100% (1)

- Current Transformers How To Specify Them PDFDocument36 pagesCurrent Transformers How To Specify Them PDFargari19No ratings yet

- Power Plant EquipmentDocument2 pagesPower Plant EquipmentnogeshwarNo ratings yet

- Mo-0368-Ing R0 - Temon 4Document14 pagesMo-0368-Ing R0 - Temon 4nogeshwarNo ratings yet

- 106DADocument2 pages106DAHenna KadyanNo ratings yet

- DA PrinciplesDocument5 pagesDA Principlesveer_sNo ratings yet

- Gate2014 Brochure PDFDocument81 pagesGate2014 Brochure PDFsurabhidivyaNo ratings yet

- Gate2014 Brochure PDFDocument81 pagesGate2014 Brochure PDFsurabhidivyaNo ratings yet

- CPC ManualDocument96 pagesCPC ManualnogeshwarNo ratings yet

- Internal Corrosion of BoilersDocument5 pagesInternal Corrosion of BoilersnogeshwarNo ratings yet

- Deaer EtorDocument6 pagesDeaer EtornogeshwarNo ratings yet

- Navigation - Star FinderDocument31 pagesNavigation - Star FinderPrasadtNo ratings yet

- Register A Custom Table in Apps SchemaDocument5 pagesRegister A Custom Table in Apps SchemaIapps ErpSolutionsNo ratings yet

- 1.4 BG00381946 - ADocument1 page1.4 BG00381946 - AAnand KesarkarNo ratings yet

- Clay and Shale, Robert L VirtaDocument24 pagesClay and Shale, Robert L VirtaRifqi Brilyant AriefNo ratings yet

- Former Rajya Sabha MP Ajay Sancheti Appeals Finance Minister To Create New Laws To Regulate Cryptocurrency MarketDocument3 pagesFormer Rajya Sabha MP Ajay Sancheti Appeals Finance Minister To Create New Laws To Regulate Cryptocurrency MarketNation NextNo ratings yet

- ABS CBN CorporationDocument16 pagesABS CBN CorporationAlyssa BeatriceNo ratings yet

- 3.6 A 40Nm Cmos Highly Linear 0.4-To-6Ghz Receiver Resilient To 0Dbm Out-Of-Band BlockersDocument3 pages3.6 A 40Nm Cmos Highly Linear 0.4-To-6Ghz Receiver Resilient To 0Dbm Out-Of-Band Blockershaoyue huangNo ratings yet

- Handout No. 03 - Purchase TransactionsDocument4 pagesHandout No. 03 - Purchase TransactionsApril SasamNo ratings yet

- Obat Keras N0vember 2021Document137 pagesObat Keras N0vember 2021antonNo ratings yet

- Jerehy's ReportDocument65 pagesJerehy's Reportkupetroleum3No ratings yet

- B2 UNIT 6 Test StandardDocument6 pagesB2 UNIT 6 Test StandardКоваленко КатяNo ratings yet

- IGCSE Religious Studies (Edexcel - 2009 - Be Careful Not To Choose The New' IGCSE)Document8 pagesIGCSE Religious Studies (Edexcel - 2009 - Be Careful Not To Choose The New' IGCSE)Robbie TurnerNo ratings yet

- Concept MapDocument1 pageConcept Mapapi-402935758No ratings yet

- Nail Malformation Grade 8Document30 pagesNail Malformation Grade 8marbong coytopNo ratings yet

- Artikel 8 - (CURRICULUM EVALUATION)Document12 pagesArtikel 8 - (CURRICULUM EVALUATION)Kikit8No ratings yet

- Technical EnglishDocument7 pagesTechnical EnglishGul HaiderNo ratings yet

- 160 78-m1Document70 pages160 78-m1George100% (7)

- Examples Week1 CompressDocument6 pagesExamples Week1 CompressAngel HuitradoNo ratings yet

- Final Project Report by Himanshu Yadav Student of Fostiima Business SchoolDocument55 pagesFinal Project Report by Himanshu Yadav Student of Fostiima Business Schoolak88901No ratings yet

- VisualizationDocument2 pagesVisualizationKIRAN H SNo ratings yet

- Recovering The Snorra Edda On Playing Gods, Loki, and The Importance of HistoryDocument17 pagesRecovering The Snorra Edda On Playing Gods, Loki, and The Importance of HistoryM SNo ratings yet

- Business Communication MCQ PDFDocument54 pagesBusiness Communication MCQ PDFHimanshu ShahNo ratings yet

- 实用多元统计分析Document611 pages实用多元统计分析foo-hoat LimNo ratings yet

- Pengaruh Pemberian Dosis Pupuk Urea Terhadap Pertumbuhan Tanaman Bayam Cabut Putih (AmaranthusDocument10 pagesPengaruh Pemberian Dosis Pupuk Urea Terhadap Pertumbuhan Tanaman Bayam Cabut Putih (AmaranthusMartha YhunickeNo ratings yet

- MGMT 4Document26 pagesMGMT 4Said GunayNo ratings yet

- Kentucky Economic Development Guide 2010Document130 pagesKentucky Economic Development Guide 2010Journal CommunicationsNo ratings yet

- Position Trading Maximizing Probability of Winning TradesDocument91 pagesPosition Trading Maximizing Probability of Winning Tradescarlo bakaakoNo ratings yet

- Q4L6 Properties of KiteDocument8 pagesQ4L6 Properties of KiteAltheus Miguel Dela CruzNo ratings yet

- A Person On A Position of Air Traffic ControllerDocument7 pagesA Person On A Position of Air Traffic ControllerMUHAMMAD RAMZANNo ratings yet

- Russian Sec 2023-24Document2 pagesRussian Sec 2023-24Shivank PandeyNo ratings yet