Professional Documents

Culture Documents

LRPC Strand

Uploaded by

anon_655956777Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LRPC Strand

Uploaded by

anon_655956777Copyright:

Available Formats

Review and Comments

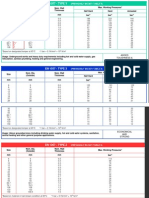

Ref: - SJEPL Submittal SJEPL/ASP/2-419 dated 2nd july2013 Reg: - Review of source LRPC strand Reference to above source details of LRPC strand has reviewed with following comments as tabulated bellow. General Details:The requirements for manufacture, supply and testing of uncoated, stress relieved low relaxation seven ply steel strands for prestressed concrete, the Low relaxation strand, when initially loaded to 70 percent of specified minimum breaking strength of the strand shall have relaxation losses of not more than 1.8 percent after 100 h and not more than 2.5 percent after 1 000 h when tested. The approval of source depends upon fulfillment of the all criteria in general:Source details M/s Usha Martin Ltd. Address Work office Ranchi, HOKolkata Company Profile Attached In-house test report Attached Witness of the test Third party test Remarks

Done by PMC and Conducted EPC representative Ok Done by PMC and EPC representative.

Dhar MP, M/s TATA Dattepara road Attached Steel Ltd. - Kolkata Test Details: - (Physical test witnessed) Source details For 15.2 mm dia M/s Usha Martin Ltd. M/s TATA Steel Ltd. Noted :- (*) Nominal dia. (mm) +0.66, -0.15 15.35 Nominal mass (kg/km) 1102

Attached

Conducted

Nominal area of strand (mm2) 140

0.2% proof load (KN) Min 234.6

Breaking strength (KN) 260.7

Elongation (%)

Remarks As per IS 14268 , class -II

Max. 5%

1136.1

144.6

243.88

270.7

4.3 Ok (*)

15.05

1140.2

Not tested

245.1

267.0

3.8

1) Some of the physical parameters have not been tested i.e. Lay length(mm), difference of outer wire w.r.t. core diameter of wire (%), Modulus of Elasticity E (kg/mm2) and Relaxation

In-house /Manufacturer Test Details:Physical and Chemical composition of material of both sources have been tested with full satisfaction of IS 14268-1995, hence it is considered to be in order. Criteria for Conformity:Any sample fail any of the tests, by agreement between the manufacturer and the purchaser, two additional test samples from the same end of the same coil shall be taken and subjected to the test or tests in which the original sample failed, both additional samples pass the test or tests, the coil from which they were taken shall be deemed to comply with the requirements of this standard. The coil should be securely strapped to prevent distortion of the coil in transit and unless otherwise Specified the coil shall be protected against damage in transit by wrapping with hessian. Water soluble oil may be applied on strands. Marking:Each pack carries a label giving the following details: a) Indication of the source of manufacture b) Coil number c) Nominal diameter of strand d) Class, where applicable. Strand should be supplied in reels or in reel less manufacturers or producers may be obtained from Packs having a minimum core diameter of 600 mm Conclusion /Comment:The sources of low relaxation prestressed concrete (LRPC) Strand M/s Usha Martin Ltd. and M/s TATA Steel Ltd should be considered in order subject to fulfillment of test witness for the following parameters which are not tested during selection of source by PMC representative and EPC representative i.e. Lay length (mm), difference of outer wire w.r.t. core diameter of wire (%), Modulus of Elasticity E (kg/mm2). Further the most important property of LRPC relaxation losses has no where attached with this report. Therefore it is suggested that concessionaire may ask to manufacturer to provide the relaxation of LRPC for the satisfaction of IS: 14268.

Sudhir Kumar SQME (IE)

You might also like

- Revised Phed BSR 2023Document90 pagesRevised Phed BSR 2023RJ JangidNo ratings yet

- Indus Way - 100069 PDFDocument2 pagesIndus Way - 100069 PDFAadeesh JainNo ratings yet

- Essar Chequered PlateDocument2 pagesEssar Chequered PlateSandeep NarayananNo ratings yet

- BS en 1057 - Copper Pipework TablesDocument2 pagesBS en 1057 - Copper Pipework TablespaulnwhiteNo ratings yet

- Amendment No. 6 June 2021 To Is 1239 (Part 1) : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - SpecificationDocument3 pagesAmendment No. 6 June 2021 To Is 1239 (Part 1) : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - SpecificationRaghav TiwaryNo ratings yet

- Amendment No. 4 July 2019 TO Is 1786: 2008 High Strength Deformed Steel Bars and Wires For Concrete Reinforcement - SpecificationDocument2 pagesAmendment No. 4 July 2019 TO Is 1786: 2008 High Strength Deformed Steel Bars and Wires For Concrete Reinforcement - SpecificationOMEGA CONSULTANT SERVICESNo ratings yet

- Reaffirmed 1998Document11 pagesReaffirmed 1998Jagan NathanNo ratings yet

- C1Ctup Rrannexwb Konkan Railway Corporation Limited: Speed PostDocument5 pagesC1Ctup Rrannexwb Konkan Railway Corporation Limited: Speed PostDurgesh NandanaNo ratings yet

- Is 6006Document19 pagesIs 6006Sathish KumarNo ratings yet

- Is 9523 (2000) - Ductile Iron Fittings For Pressure Pipes For Water, Gas and SewageDocument38 pagesIs 9523 (2000) - Ductile Iron Fittings For Pressure Pipes For Water, Gas and SewageSainaveen Thota100% (2)

- S235JR SteelDocument1 pageS235JR SteelNguyễn Thanh CườngNo ratings yet

- 4711Document10 pages4711Gaurav AgarwalNo ratings yet

- L&T Vadodara Mumbai Expressway PDFDocument3 pagesL&T Vadodara Mumbai Expressway PDFAnonymous hKVtzkmh6zNo ratings yet

- How To Read STD IS 2062 (2011)Document17 pagesHow To Read STD IS 2062 (2011)AkshayNo ratings yet

- 01 - 07 - 2017 List of Approved Vendors PDFDocument132 pages01 - 07 - 2017 List of Approved Vendors PDFPratik GuptaNo ratings yet

- Astm 143Document3 pagesAstm 143JH_ProjectNo ratings yet

- Is 6158 - 1984 Recommended Practice For Safeguarding Against Embrittlement of Hot-Dip Galvanized Iron and Steel ProductsDocument10 pagesIs 6158 - 1984 Recommended Practice For Safeguarding Against Embrittlement of Hot-Dip Galvanized Iron and Steel ProductsNadeem KhanNo ratings yet

- Is - Iso.16163.2005 (Sheet Thickness Tolerence) PDFDocument12 pagesIs - Iso.16163.2005 (Sheet Thickness Tolerence) PDFtarun panwarNo ratings yet

- Is - 2062Document10 pagesIs - 2062Jagjeet SinghNo ratings yet

- Asean Standards (Brunei) - ElectricalDocument5 pagesAsean Standards (Brunei) - ElectricalsulaimanNo ratings yet

- MOE Simplex - 24.06.2016 PDFDocument4 pagesMOE Simplex - 24.06.2016 PDFSabyasachi BangalNo ratings yet

- 2721 Chain LinkDocument8 pages2721 Chain LinkPankaj GargNo ratings yet

- Fastener Manufacturers in IndiaDocument8 pagesFastener Manufacturers in IndiaKaloti IndiaNo ratings yet

- Iso 6934Document1 pageIso 6934Muresan VirgilNo ratings yet

- Is 16651-2017Document18 pagesIs 16651-2017Assistant Coordinator Business DevelopmentNo ratings yet

- DPR - Z Morh - 06 07 2017Document24 pagesDPR - Z Morh - 06 07 2017Harish Kumar MahavarNo ratings yet

- Amendment No. 3 December 2021 TO Is 6911: 2017 Stainless Steel Plate, Sheet and Strip - SpecificationDocument4 pagesAmendment No. 3 December 2021 TO Is 6911: 2017 Stainless Steel Plate, Sheet and Strip - SpecificationshamrajjNo ratings yet

- Steel Tubes For Structural Purposes Conforming To IS 1161 - 1998Document2 pagesSteel Tubes For Structural Purposes Conforming To IS 1161 - 1998Ayush TariyalNo ratings yet

- JSS 52300-1992 PDFDocument68 pagesJSS 52300-1992 PDFNaga Prasad100% (2)

- Irc Gov in 015 2017Document96 pagesIrc Gov in 015 2017MAULIK RAVALNo ratings yet

- ck-105 Rev.1 of July'2014 Amdt - Slipno.1Document12 pagesck-105 Rev.1 of July'2014 Amdt - Slipno.1Sriram SubramanianNo ratings yet

- MKC Infrastructure LTD 21285Document1 pageMKC Infrastructure LTD 21285mkcil purchaseNo ratings yet

- Draft Indian Standard: Bureau of Indian StandardsDocument9 pagesDraft Indian Standard: Bureau of Indian StandardsPavan KumarNo ratings yet

- Disclosure To Promote The Right To InformationDocument27 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- IRS-T-12 - 2009 With A & C 1, 2 & 3 - Specifications For Flat Bottom Rails PDFDocument64 pagesIRS-T-12 - 2009 With A & C 1, 2 & 3 - Specifications For Flat Bottom Rails PDFKumar AbhishekNo ratings yet

- Is 2708 1993Document10 pagesIs 2708 1993ghosh_ranjoyNo ratings yet

- CM PF 307 Brand NameDocument1 pageCM PF 307 Brand NameJagannath Majhi100% (3)

- Steel Pipe Is 1161Document5 pagesSteel Pipe Is 1161Shuvro ChakravortyNo ratings yet

- Whoiswho 87Document141 pagesWhoiswho 87kaladhar reddyNo ratings yet

- Reasoned Document IRS M-39-2020Document42 pagesReasoned Document IRS M-39-2020Metal deptNo ratings yet

- BS en 10130-2006Document16 pagesBS en 10130-2006mossamorrisNo ratings yet

- All Unified PL On SR RequestDocument87 pagesAll Unified PL On SR RequestRohit Kumar SinghNo ratings yet

- BS 1044-1Document70 pagesBS 1044-1JudithLorenaMendezSandoval100% (1)

- (First Revision) : Specification FOR Crane Rail SectionsDocument19 pages(First Revision) : Specification FOR Crane Rail SectionsNeo NaveenNo ratings yet

- Disclosure To Promote The Right To InformationDocument34 pagesDisclosure To Promote The Right To InformationSainath AmudaNo ratings yet

- SherardizingDocument2 pagesSherardizingRichard HockleyNo ratings yet

- Gantrex Mk20 Pad Data Sheet MetricDocument2 pagesGantrex Mk20 Pad Data Sheet Metricjhon jairo arangoNo ratings yet

- 01 Tuojh 2021 Ls 30 Twu 2021 RD : (01 January 2021 To 30 June 2021.)Document268 pages01 Tuojh 2021 Ls 30 Twu 2021 RD : (01 January 2021 To 30 June 2021.)ManojNo ratings yet

- 2 Cable Trunking and DuctsDocument8 pages2 Cable Trunking and Ductsaanouar77No ratings yet

- Is 12818-2010 PDFDocument22 pagesIs 12818-2010 PDFINFOHEPL RCLNo ratings yet

- GB 1499.1-2008 Steel For The Reinforcement of Concrete-Part 1 Hot Rolled Plain BarsDocument13 pagesGB 1499.1-2008 Steel For The Reinforcement of Concrete-Part 1 Hot Rolled Plain BarsH. Camer E.No ratings yet

- New BS EN CodesDocument2 pagesNew BS EN Codessivaraju1No ratings yet

- Amendment No. 3 March 2017 TO Is 1786: 2008 High Strength Deformed Bars and Wires For Concrete Reinforcement - SpecificationDocument3 pagesAmendment No. 3 March 2017 TO Is 1786: 2008 High Strength Deformed Bars and Wires For Concrete Reinforcement - Specificationraviteja036No ratings yet

- Technical Data SheetDocument10 pagesTechnical Data SheetaqazamNo ratings yet

- L1 Che Spe 001Document8 pagesL1 Che Spe 0014493464No ratings yet

- 2 B 02 Al59 Cond Equiv Zebra MooseDocument28 pages2 B 02 Al59 Cond Equiv Zebra MoosevgovaNo ratings yet

- QAP For ACSR Conductor PDFDocument10 pagesQAP For ACSR Conductor PDFprithvirajd20100% (1)

- Tubing and CasingDocument10 pagesTubing and CasingEnd LabNo ratings yet

- Technical Specification of Dog ConductorDocument6 pagesTechnical Specification of Dog ConductorSupriyo Podder75% (4)

- Technical Specification For Acsr Conductors: WbsedclDocument9 pagesTechnical Specification For Acsr Conductors: Wbsedclraja kumarNo ratings yet

- Type Test LetterDocument10 pagesType Test LetterNeeraj TyagiNo ratings yet

- Network Diagram: Engineering Field Office - 445 CDDocument7 pagesNetwork Diagram: Engineering Field Office - 445 CDJeffrey DioquinoNo ratings yet

- Design Criteria For Sewage SystemsDocument400 pagesDesign Criteria For Sewage SystemselcusiNo ratings yet

- AISC - 358-10 - Prequalified - Connections-1-80Document80 pagesAISC - 358-10 - Prequalified - Connections-1-80Evelyn QuimíNo ratings yet

- Effect of Fuel Temperature On Mixing Characteristics of A Kerosene Jet Injected Into A Cavity-Based Supersonic CombustorDocument17 pagesEffect of Fuel Temperature On Mixing Characteristics of A Kerosene Jet Injected Into A Cavity-Based Supersonic CombustorCristianNo ratings yet

- DC PT Contractors Role Responsibilities PTIA IEAust NewcastleDocument30 pagesDC PT Contractors Role Responsibilities PTIA IEAust NewcastleSree NivasNo ratings yet

- Howe Truss Computation Analysis2Document11 pagesHowe Truss Computation Analysis2Wingartz Vendiola PosedioNo ratings yet

- Factors Influencing Hydrogen Induced CrackingDocument3 pagesFactors Influencing Hydrogen Induced CrackingNapoleon DasNo ratings yet

- Pipe & Tube SpecificationsDocument3 pagesPipe & Tube SpecificationsIbrahim Ali100% (1)

- Dereje Fufa: Integrated Design 2Document2 pagesDereje Fufa: Integrated Design 2Michael GezahegnNo ratings yet

- Viscometer-Group 7Document25 pagesViscometer-Group 7Camille Millondaga100% (1)

- 03.801 Design and Drawing of Reinforced Concrete Structures 2-0-2-4Document7 pages03.801 Design and Drawing of Reinforced Concrete Structures 2-0-2-4wisdomlover4uNo ratings yet

- Construction and Building Materials: H.Y. Leung, J. Kim, A. Nadeem, Jayaprakash Jaganathan, M.P. AnwarDocument7 pagesConstruction and Building Materials: H.Y. Leung, J. Kim, A. Nadeem, Jayaprakash Jaganathan, M.P. AnwarshanmugapriyasudhaswNo ratings yet

- Design For NSF by Harry PoulosDocument7 pagesDesign For NSF by Harry PoulosSantosoNo ratings yet

- Shell Momentum BalancesDocument48 pagesShell Momentum BalancesDianah NajeebNo ratings yet

- CE 162 MidtermsDocument2 pagesCE 162 MidtermsRoEm'z Suarez PaIlagoNo ratings yet

- Parala Maharaja Engineering College, Berhampur: 1. List Out The Advantages of Model AnalysisDocument10 pagesParala Maharaja Engineering College, Berhampur: 1. List Out The Advantages of Model AnalysisRohan KumarNo ratings yet

- Check Valve Flowserve RK76 - En-EsDocument24 pagesCheck Valve Flowserve RK76 - En-EsJavierNo ratings yet

- Steel Structures-Lecture 5 PDFDocument23 pagesSteel Structures-Lecture 5 PDFAli FarooqNo ratings yet

- Comparative Study On Design and Analysis of Multistoreyed Building (G+10) by Staad - Pro and Etabs Software'sDocument6 pagesComparative Study On Design and Analysis of Multistoreyed Building (G+10) by Staad - Pro and Etabs Software'sNaveen JatavNo ratings yet

- Structural Analysis NotesDocument166 pagesStructural Analysis NotesdunyNo ratings yet

- Compound Wall Toilet Revised (4) - ModelDocument1 pageCompound Wall Toilet Revised (4) - ModelInfra SupportNo ratings yet

- 2008 05 DD 41 Manhole FlotationDocument15 pages2008 05 DD 41 Manhole FlotationPedrin Cha Olivos100% (1)

- 003 - LICO Light Weight Column FormworkDocument8 pages003 - LICO Light Weight Column FormworksmaliscribdNo ratings yet

- Final Checklist-Site SupervisionDocument8 pagesFinal Checklist-Site SupervisionGsUpretiNo ratings yet

- A Discussion On Some of The Factors Affecting Well Spacing : F. M. D. CDocument10 pagesA Discussion On Some of The Factors Affecting Well Spacing : F. M. D. CHichem FakhfekhNo ratings yet

- Friction Coefficient in PipesDocument16 pagesFriction Coefficient in PipesVanessa AyalaNo ratings yet

- Ventiloconvectoare CITIZEN 2011Document6 pagesVentiloconvectoare CITIZEN 2011office8200No ratings yet

- Engenharia Hidraulica - InglesDocument8 pagesEngenharia Hidraulica - InglesPekirNo ratings yet

- University of ZimbabweDocument6 pagesUniversity of ZimbabweTynash NyakatsapaNo ratings yet