Professional Documents

Culture Documents

AGRICULTURE PROJECTS-Automatic Irrigation System GSM (SMS RECEIVED FARMER)

Uploaded by

R.ASHOKKUMAAROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AGRICULTURE PROJECTS-Automatic Irrigation System GSM (SMS RECEIVED FARMER)

Uploaded by

R.ASHOKKUMAARCopyright:

Available Formats

EMBEDDED SYSTEM BASED GSM COMMUNICATION FOR AUTOMATIC IRRIGATION CONTROL SYSTEM

IEEE Reference: Wireless sensor network based remote irrigation control system and Automation using DTMF code. Abstract: Agriculture is a source of livelihood of majority Indians and has great impact on the economy of the country. In dry areas or in case of inadequate rainfall, irrigation becomes difficult. So, it needs to be automated for proper yield and handled remotely for farmer safety. In this paper we suggest a Wireless sensor network and Embedded based technique to control water flow for sectored, sprinkler or drip section irrigation. This system will be very economical in terms of the hardware cost, power consumption and call charges. In places such as agriculture lands, there is a continuous need for monitoring the water level at particular places. In places such as drip irrigation for coconuts and bananas, the water is let out through pipes directly to each field. A person has to carefully monitor the water level at regular intervals. His job becomes tedious during night

times and for frequent power cuts. Sometimes there is wastage of water and electricity due to negligence and other times there is a hard job for the user. The project helps in automating this job. This is highly helpful in places such as drip irrigation system where there are many flow pipes but does not require any change in the agricultural fields. Further there is a wireless communication device consisting of very high frequency transceiver. It helps to coordinate any action between the controlling authority and the fields. So each field can be placed as a separate wireless node and these field transceivers act as a high speed wireless network. The project proposes a water level sensor at each place where the water has to be monitored. When the motor is switched on the sensors are activated and the fields are irrigated automatically. Once the water reaches a particular level which may even take hours, the system takes appropriate steps to regulate or even stop the water flow. The farmers job gets over immediately after switching the power supply. The circuit also monitors the water in the well/bore well so that if the water level goes

very low it switches off the main motor to prevent dry run and also to prevent damage to the motor. The project houses a high speed microcontroller and water sensors at different fields and inside the well. These sensors are attached to the microcontroller and are controlled accordingly using motor and water control circuits. The microcontroller used is a high Speed microcontroller for fault free operation. It has a variety of advantages over conventional old microcontrollers such as RISC architecture, larger memory word, fast operation and a host of inbuilt features such as ADC, communication protocols etc., The project also houses a GSM modem where the user can easily be notified by any fault in the system or if all fields are properly irrigated or if there is no sufficient water in the well. The same can be used to switch on the system and off by simply sending an SMS. This scheduling helps greatly because as agriculture power supplies are provided only at a particular time of day and not all hours. This is highly helpful in places if the user is out of his home for

any purpose or his home is far away from his agricultural land which is a common scenario. This helps in precious saving of water and electricity and eases the job of the person. The project can be used in large agricultural lands, coconut plantations and many other plantations and even in home environment or industries and colleges where there are large gardens to monitor and irri

gate them automatically.

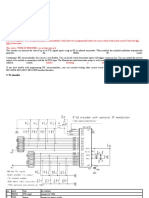

Block Diagram:

Humitity sensor

Signal conditioning ckt LCD DISPLAY FOR STATUS

Soil moisture Sensor

Interfacing Circuit

ADC

Relay Driver Relay Driver (2) Relay PIC MICROCONTROLLER PIC16F877

GSM interfacing Circuit WIPER Motor

Relay (2)

GSM

Valves (2)

+5V Power supply (to all components)

Hardware Components: 1. Embedded Microcontroller PIC 16F877 2. GSM module 3. Relays 4. Relay Drive 5. HUMITITY/TEMP 6. SOIL MOISTURE 7. WIPER MOTOR Software Tools: 1. Eagle for PCB design 3. OrCAD for Schematic Design 4. MPLAB IDE for controller programming Advantages: 1. This system will be very economical in terms of the hardware cost and power consumption. 2. This helps in precious saving of water and electricity and eases the job of the person. 3. It can be implemented in large agricultural areas. 4. By the use of GSM the user can control the motor from anywhere by just sending SMS.

5V Power supply (to all components)

RF interfacing Circuit

You might also like

- Solar Powered Automatic Irrigation SystemDocument31 pagesSolar Powered Automatic Irrigation SystemKhan Arshid Iqbal100% (8)

- Arduino Based Automatic Plant Irrigation System With Message AlertDocument26 pagesArduino Based Automatic Plant Irrigation System With Message AlertBelayneh Tadesse100% (4)

- Electonics Products & DesignDocument42 pagesElectonics Products & DesignMudboxNo ratings yet

- Iot Based Smart Irrigation SystemDocument5 pagesIot Based Smart Irrigation SystemReddy RNo ratings yet

- Automatic Irrigation SystemDocument28 pagesAutomatic Irrigation SystemAbhinavOrugantiNo ratings yet

- Smart Irrigation Using Low Cost Moisture Sensor and Cortex Arm m3Document7 pagesSmart Irrigation Using Low Cost Moisture Sensor and Cortex Arm m3meenachiNo ratings yet

- Automated Garden Watering SystemDocument14 pagesAutomated Garden Watering Systemvincent john chattoNo ratings yet

- Automatic Irrigation SystemDocument4 pagesAutomatic Irrigation SystemRajasekar PanneerselvamNo ratings yet

- Control Valve For Irrigation PurposeDocument38 pagesControl Valve For Irrigation PurposeAjit KalasaitNo ratings yet

- Automatic Irrigation System Using Micro Controller Main DocumentDocument16 pagesAutomatic Irrigation System Using Micro Controller Main DocumentSai Datta100% (2)

- GSM Water Tank MonitoringDocument5 pagesGSM Water Tank Monitoringss mNo ratings yet

- Phpapp01Document11 pagesPhpapp01Rakesh MaityNo ratings yet

- 3 Phase Irrigation Water Pump Controller Students3KDocument5 pages3 Phase Irrigation Water Pump Controller Students3KAmin AzadNo ratings yet

- Irjet V7i9293Document4 pagesIrjet V7i9293Carla FitzpatrickNo ratings yet

- GSM Based Motor Control System With Water Level MonitoringDocument8 pagesGSM Based Motor Control System With Water Level MonitoringIJRASETPublicationsNo ratings yet

- Final Designs of Online Active DAQDocument75 pagesFinal Designs of Online Active DAQAbdul RazzakNo ratings yet

- Water Theft DetectionDocument7 pagesWater Theft DetectionvijayarajeceNo ratings yet

- Smart Irrigation SystemDocument12 pagesSmart Irrigation SystemT.M. MEHRAB HASANNo ratings yet

- IOT Enabled Smart Farm Using Node Based ESP8266Document15 pagesIOT Enabled Smart Farm Using Node Based ESP8266dinadayanithiNo ratings yet

- Automatic Plant Irrigation System Literature ReviewDocument7 pagesAutomatic Plant Irrigation System Literature Reviewfvhj1y00No ratings yet

- Smart Irrigation FINAL ReviewDocument31 pagesSmart Irrigation FINAL ReviewKavya YelishettyNo ratings yet

- Review of Poly House Controll SystemDocument3 pagesReview of Poly House Controll SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Mookambika Technical Campus .: Automatic Irrigation SystemDocument25 pagesMookambika Technical Campus .: Automatic Irrigation SystemMadhuNo ratings yet

- 10.agriculture Field Motor Control System Using GSMDocument64 pages10.agriculture Field Motor Control System Using GSManil kumarNo ratings yet

- Smart Irrigation System Using GSM Module and ControllerDocument12 pagesSmart Irrigation System Using GSM Module and Controllersachin anjuuNo ratings yet

- Indoor Farming and Spray Water SystemDocument33 pagesIndoor Farming and Spray Water SystemDinesh KumarNo ratings yet

- 1.1 Increasing Usage of Technology in Other Sectors: 1.3 Problems in Irrigation in IndiaDocument6 pages1.1 Increasing Usage of Technology in Other Sectors: 1.3 Problems in Irrigation in IndiaCarl FischerNo ratings yet

- Proyecto Riego AutomaticoDocument4 pagesProyecto Riego AutomaticoAlexander Jara SandovalNo ratings yet

- Preface: GreenbeeDocument26 pagesPreface: Greenbeevidhya_k2009No ratings yet

- Smart Irrigation Using Node-Mcu: Shaikh Awais Yusuf, Sayed Mojiz Abbas, Prof. Sonali SuryawanshiDocument5 pagesSmart Irrigation Using Node-Mcu: Shaikh Awais Yusuf, Sayed Mojiz Abbas, Prof. Sonali Suryawanshishital shermaleNo ratings yet

- Auto Indoor Hydro Phonic Fodder Grow ChamberDocument17 pagesAuto Indoor Hydro Phonic Fodder Grow Chamberchandra100% (1)

- Solar Tracking and MPPT AlgorithmsDocument4 pagesSolar Tracking and MPPT AlgorithmsbalabooksNo ratings yet

- Synopsis For Solar Based Automatic Irrigation SystemDocument7 pagesSynopsis For Solar Based Automatic Irrigation SystemKhan Arshid Iqbal100% (2)

- Solar Irrigation System Using Sensors and GSMDocument25 pagesSolar Irrigation System Using Sensors and GSMKomal EjazNo ratings yet

- GSM Controlled Automatic Irrigation System Using 8051 Microcontroller OriginalDocument13 pagesGSM Controlled Automatic Irrigation System Using 8051 Microcontroller Originalamism24No ratings yet

- Solar Powered Auto Irrigation System Using GSM ModuleDocument3 pagesSolar Powered Auto Irrigation System Using GSM ModuleGRD JournalsNo ratings yet

- Literature Review of Iot Based Plant Watering SystemDocument8 pagesLiterature Review of Iot Based Plant Watering SystemJulie RyneNo ratings yet

- GSM Based Water Management in Irrigation System Using ARM7: N.D. Pergad, Y.P. PatilDocument3 pagesGSM Based Water Management in Irrigation System Using ARM7: N.D. Pergad, Y.P. PatilmeenachiNo ratings yet

- Solar Powered Auto Irrigation SystemDocument13 pagesSolar Powered Auto Irrigation Systemlokesh_045No ratings yet

- Industry 5.0Document21 pagesIndustry 5.0Dinesh GaikotiNo ratings yet

- New Microsoft Office Word DocumentDocument23 pagesNew Microsoft Office Word Documentvenkatesh_0460No ratings yet

- GSM Based Transformer Fault Monitoring SystemDocument5 pagesGSM Based Transformer Fault Monitoring SystemEditor IJTSRDNo ratings yet

- IoT Based Smart Irrigation System With Humidity and Water Level Monitoring System SynopsisDocument6 pagesIoT Based Smart Irrigation System With Humidity and Water Level Monitoring System SynopsisatikpNo ratings yet

- Subha FinalDocument45 pagesSubha FinalbalaNo ratings yet

- Robotic and SensorDocument7 pagesRobotic and SensorD Palanivel RajanNo ratings yet

- Solar FenceDocument31 pagesSolar FenceSARIKANo ratings yet

- GSM modem interfacing with microcontroller 8051Document9 pagesGSM modem interfacing with microcontroller 8051amism24No ratings yet

- Arduino Project: Smart Irrigation SystemDocument13 pagesArduino Project: Smart Irrigation SystemAleeza AnjumNo ratings yet

- Microcontroller Based Dam Gate Control SystemDocument6 pagesMicrocontroller Based Dam Gate Control SystemVishal Subhash patilNo ratings yet

- Wireless Automatic Plant Irrigation System: Vinay Bakale, Siddesh TalokarDocument5 pagesWireless Automatic Plant Irrigation System: Vinay Bakale, Siddesh Talokarﹺ ﹺ ﹺ ﹺNo ratings yet

- Automated IrrigationDocument12 pagesAutomated IrrigationKarthik RaitaniNo ratings yet

- Tech Seminar 2022Document29 pagesTech Seminar 2022srilakshmi hNo ratings yet

- Power Theft Detection Using Arduino - AbstarctDocument6 pagesPower Theft Detection Using Arduino - AbstarctGeetuNo ratings yet

- Smart Irrigation System (Maheen)Document15 pagesSmart Irrigation System (Maheen)kiswah computersNo ratings yet

- ICNSCET19-International Conference On New Scientific Creations in Engineering and TechnologyDocument11 pagesICNSCET19-International Conference On New Scientific Creations in Engineering and TechnologyDeka MNo ratings yet

- EMBEDDED GREENHOUSE MONITORING SYSTEMDocument4 pagesEMBEDDED GREENHOUSE MONITORING SYSTEMBitch ass SalsshhNo ratings yet

- Sensor Based Automatic Drip Irrigation SystemDocument4 pagesSensor Based Automatic Drip Irrigation SystemJournal 4 ResearchNo ratings yet

- Final Report p5Document34 pagesFinal Report p5Thejas A VNo ratings yet

- Auto Irrigation System With GSM NotificationDocument14 pagesAuto Irrigation System With GSM NotificationRakesh Menon0% (1)

- IEEE PROJECTS ECE-ZigbeebasedHospitalAutomationWithOnline Graphand WAPDocument5 pagesIEEE PROJECTS ECE-ZigbeebasedHospitalAutomationWithOnline Graphand WAPR.ASHOKKUMAARNo ratings yet

- LAND MINE DETECTOR-Land Mine Detection and Indication Using GPS and GSMDocument7 pagesLAND MINE DETECTOR-Land Mine Detection and Indication Using GPS and GSMR.ASHOKKUMAARNo ratings yet

- Chennai Inplant Training (Ipt) Inplant Training in Chennai-MaastechDocument13 pagesChennai Inplant Training (Ipt) Inplant Training in Chennai-MaastechR.ASHOKKUMAARNo ratings yet

- Latest Ieee Project Titles For Ece/eee/e&i/biomedical-Latest Ieee Project TitlesDocument59 pagesLatest Ieee Project Titles For Ece/eee/e&i/biomedical-Latest Ieee Project TitlesR.ASHOKKUMAAR75% (4)

- IEEE PROJECT ABSTRACT:Infant Incubator Baby Parameter Sensing and Monitoring - IeeeDocument3 pagesIEEE PROJECT ABSTRACT:Infant Incubator Baby Parameter Sensing and Monitoring - IeeeR.ASHOKKUMAAR100% (2)

- IEEE ELECTRICAL PROJECTS ABSTRACT-Fuzzy Logic Based Differential Relay For Power Transformer Protection - IEEEDocument7 pagesIEEE ELECTRICAL PROJECTS ABSTRACT-Fuzzy Logic Based Differential Relay For Power Transformer Protection - IEEER.ASHOKKUMAARNo ratings yet

- ECE PROJECT ABSTRACT-Railway Track Pedestrain Crossing Without Using StaircaseDocument9 pagesECE PROJECT ABSTRACT-Railway Track Pedestrain Crossing Without Using StaircaseR.ASHOKKUMAAR100% (1)

- HYBRID POWER GENERATION-Wind-Solar Energy - Hybrid Power Generation System (WISE)Document6 pagesHYBRID POWER GENERATION-Wind-Solar Energy - Hybrid Power Generation System (WISE)R.ASHOKKUMAARNo ratings yet

- ELECTRICAL PROJECT TOPICS&Embedded PIC Microcontroller Based Motor Protection SystemDocument4 pagesELECTRICAL PROJECT TOPICS&Embedded PIC Microcontroller Based Motor Protection SystemR.ASHOKKUMAAR0% (1)

- Inplant Training For Engineering Students Chennai-Eee/ece/e&i/ice BiomedicalDocument14 pagesInplant Training For Engineering Students Chennai-Eee/ece/e&i/ice BiomedicalR.ASHOKKUMAARNo ratings yet

- GSM Based Advanced Home Industrial Automation Controller SystemDocument4 pagesGSM Based Advanced Home Industrial Automation Controller SystemR.ASHOKKUMAARNo ratings yet

- GSM Based Advanced Home Industrial Automation Controller SystemDocument4 pagesGSM Based Advanced Home Industrial Automation Controller SystemR.ASHOKKUMAARNo ratings yet

- Electric Power Generation Using Foot Step MethodDocument5 pagesElectric Power Generation Using Foot Step MethodMailvelan BalasubramaniamNo ratings yet

- MEDICAL ELECTRONICS PROJECTS ABSTRACT-Digital Pulmonary Function Test - SpirometryDocument4 pagesMEDICAL ELECTRONICS PROJECTS ABSTRACT-Digital Pulmonary Function Test - SpirometryR.ASHOKKUMAARNo ratings yet

- BIOMEDICAL ENGINEERING PROJECT TOPICS-Dspic Based Automated Peritoneal DialysisDocument6 pagesBIOMEDICAL ENGINEERING PROJECT TOPICS-Dspic Based Automated Peritoneal DialysisR.ASHOKKUMAARNo ratings yet

- MEDICAL ELECTRONICS PROJECTS ABSTRACT-Digital Pulmonary Function Test - SpirometryDocument4 pagesMEDICAL ELECTRONICS PROJECTS ABSTRACT-Digital Pulmonary Function Test - SpirometryR.ASHOKKUMAARNo ratings yet

- Final Year Embedded System Project Titles/list For Ece/eee/e&i/biomedicalDocument51 pagesFinal Year Embedded System Project Titles/list For Ece/eee/e&i/biomedicalR.ASHOKKUMAARNo ratings yet

- Electrica Project Topics-Scada For Substation Monitoring&controlthrough Computer (PC)Document4 pagesElectrica Project Topics-Scada For Substation Monitoring&controlthrough Computer (PC)R.ASHOKKUMAARNo ratings yet

- RFID PROJECT ABSTRACT-Automatic Door Locking System Using RFIDDocument6 pagesRFID PROJECT ABSTRACT-Automatic Door Locking System Using RFIDR.ASHOKKUMAAR100% (3)

- FINGER PRINT PROJECT ABSTRACT-Biometric Fingerprint Identification With PIC Based LockerSecurity SystemDocument7 pagesFINGER PRINT PROJECT ABSTRACT-Biometric Fingerprint Identification With PIC Based LockerSecurity SystemR.ASHOKKUMAAR100% (1)

- Inplant Training For Engineering Students Chennai-Eee/ece/e&i/ice BiomedicalDocument14 pagesInplant Training For Engineering Students Chennai-Eee/ece/e&i/ice BiomedicalR.ASHOKKUMAARNo ratings yet

- ELECTRONIC PROJECT ABSTRACT-Airport Baggage Conveyour Using Ivrs&Embedded SystemsDocument8 pagesELECTRONIC PROJECT ABSTRACT-Airport Baggage Conveyour Using Ivrs&Embedded SystemsR.ASHOKKUMAARNo ratings yet

- TSUNAMI WARNING SYSTEM PROJECTS:Seismic Alerts Trhough GSM NetworkDocument2 pagesTSUNAMI WARNING SYSTEM PROJECTS:Seismic Alerts Trhough GSM NetworkR.ASHOKKUMAARNo ratings yet

- Door Open Alarm-Burglar Alarm System With Sms&call Alert Police&house OwnerDocument8 pagesDoor Open Alarm-Burglar Alarm System With Sms&call Alert Police&house OwnerR.ASHOKKUMAARNo ratings yet

- Automatic Beam Changer For Car Headlight in City Areas-Multiple Target Tracking For Intelligent Headlights ControlDocument2 pagesAutomatic Beam Changer For Car Headlight in City Areas-Multiple Target Tracking For Intelligent Headlights ControlR.ASHOKKUMAARNo ratings yet

- NEW ELECTRONICS PROJECT ABSTRACT-Assisting Blind Person Using Dijkstra's Shortest Path AlgorithmDocument4 pagesNEW ELECTRONICS PROJECT ABSTRACT-Assisting Blind Person Using Dijkstra's Shortest Path AlgorithmR.ASHOKKUMAARNo ratings yet

- Automatic Anesthesia Controller Using Heart Beat Sensor-MEDICAL ELECTRONICS PROJECTSDocument6 pagesAutomatic Anesthesia Controller Using Heart Beat Sensor-MEDICAL ELECTRONICS PROJECTSR.ASHOKKUMAAR100% (2)

- LAND MINE DETECTOR-Land Mine Detection and Indication Using GPS and GSMDocument7 pagesLAND MINE DETECTOR-Land Mine Detection and Indication Using GPS and GSMR.ASHOKKUMAARNo ratings yet

- IEEE PROJECTS ECE-ZigbeebasedHospitalAutomationWithOnline Graphand WAPDocument5 pagesIEEE PROJECTS ECE-ZigbeebasedHospitalAutomationWithOnline Graphand WAPR.ASHOKKUMAARNo ratings yet

- Electronic code lock using PIC microcontrollerDocument11 pagesElectronic code lock using PIC microcontrollerTeo JavaNo ratings yet

- Epemag 2000-05Document90 pagesEpemag 2000-05Martin ChipilukNo ratings yet

- Literature Review Traffic Light SystemDocument4 pagesLiterature Review Traffic Light Systemafmzslnxmqrjom100% (1)

- DTU EMBEDDED LAB REPORT ON BLINKING LED USING PIC MICROCONTROLLERDocument6 pagesDTU EMBEDDED LAB REPORT ON BLINKING LED USING PIC MICROCONTROLLER2K19/EC/192 SWASTIK SHARMANo ratings yet

- PIC Architecture OverviewDocument17 pagesPIC Architecture Overviewan1088No ratings yet

- PIC Tutorial ParanzDocument66 pagesPIC Tutorial ParanzEl Pandesal Domingo100% (3)

- Introduction Byte Oriented Instructions Bit Oriented Instructions Literal Oriented Instructions Questions SummeryDocument4 pagesIntroduction Byte Oriented Instructions Bit Oriented Instructions Literal Oriented Instructions Questions SummeryClare TeerakNo ratings yet

- Advanced View Pic Microcontroller Projects List - PIC MicrocontrollerDocument233 pagesAdvanced View Pic Microcontroller Projects List - PIC MicrocontrollerBilal AfzalNo ratings yet

- Getting Started With The Simulink Blockset For PIC Microcontrollers v3Document3 pagesGetting Started With The Simulink Blockset For PIC Microcontrollers v3Alex SisuNo ratings yet

- Microchip PIC32MX5XX/6XX/7XX Family Data SheetDocument254 pagesMicrochip PIC32MX5XX/6XX/7XX Family Data SheetmizishNo ratings yet

- Development of Electricity Theft Detection Using Smart MeterDocument9 pagesDevelopment of Electricity Theft Detection Using Smart Meter1382aceNo ratings yet

- Dynamic Traffic Light Control Using Microcontroller: Industrial and Control EngineeringDocument49 pagesDynamic Traffic Light Control Using Microcontroller: Industrial and Control EngineeringTalemaNo ratings yet

- Siliconchip Softwave ListDocument246 pagesSiliconchip Softwave ListLong Nguyen KimNo ratings yet

- PWM DC Motor ControllerDocument11 pagesPWM DC Motor ControllerSanthosh Kumar100% (1)

- Microcontrollers and Microprocessor Technology TutorialDocument4 pagesMicrocontrollers and Microprocessor Technology TutorialRene EBUNLE AKUPANNo ratings yet

- 06 - InterruptsDocument23 pages06 - InterruptsKhloud MousadNo ratings yet

- PIC Microcontroller in Practice: Educational Engineering TeamDocument74 pagesPIC Microcontroller in Practice: Educational Engineering TeamDominique Komey100% (1)

- PIC 16f877a Data SheetDocument234 pagesPIC 16f877a Data Sheetanon-26401438% (8)

- Encoder Based On PICDocument7 pagesEncoder Based On PICAntonnio Savio LeiteNo ratings yet

- City". We Implemented Using PIC Microcontroller and RF ModuleDocument56 pagesCity". We Implemented Using PIC Microcontroller and RF ModuleSai RakeshNo ratings yet

- Datasheet Search Site PDFDocument192 pagesDatasheet Search Site PDFALEXSAHDRNo ratings yet

- Cse Iot Btech III Yr V Sem Scheme SyllabusDocument28 pagesCse Iot Btech III Yr V Sem Scheme SyllabusVed Kumar GuptaNo ratings yet

- VSM TutorialDocument52 pagesVSM TutorialAnish BennyNo ratings yet

- Naslovna StranaDocument2 pagesNaslovna StranabokimirNo ratings yet

- CI-JBTAUX-2G Quick ManualDocument5 pagesCI-JBTAUX-2G Quick ManualhebrNo ratings yet

- Xc8 v2.41 Full Install Release Notes PICDocument105 pagesXc8 v2.41 Full Install Release Notes PICJose PereiraNo ratings yet

- M I C R o C o N T R o L A D o R e S P I CDocument3 pagesM I C R o C o N T R o L A D o R e S P I C4gen_7100% (1)

- 7 PIC18 InstructionSet Assembly Machine PDFDocument15 pages7 PIC18 InstructionSet Assembly Machine PDFbaseer khanNo ratings yet

- Bus Safety ReportDocument54 pagesBus Safety ReportS RAVINo ratings yet