Professional Documents

Culture Documents

Deep Drawing:: Metalworking

Uploaded by

Saurabh SharmaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Deep Drawing:: Metalworking

Uploaded by

Saurabh SharmaCopyright:

Available Formats

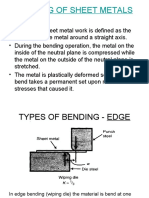

Drawing is a metalworking operation in which the diameter or thickness of a metal is reduced using tensile forces.

Drawing can be done on both cylindrical metals and sheet metals. In a cylindrical workpiece, drawing is used to reduce the diameter. In sheet metal, it is used to reduce thickness. In drawing, the metallic workpiece is pulled through a suitable hole in a die, either manually or automatically. This streches the metal by reducing its cross-sectional dimensions. The following are the common types of drawing: 1. Deep Drawing 2. Wire Drawing 3. Rod Drawing (or Bar Drawing) 4. Tube Drawing

1. Deep Drawing:

Deep drawing is a type of sheet metal drawing. In this process, a die with a cavity is used. The sheet metal is heated to a plastic state and is placed above the cavity in the die. A punch is used to force the sheet metal through the cavity and the metal is drawn.

2. Wire Drawing:

Wire drawing is used for reducing the diameter of a wire. Wire drawing can be done on wires whose diameter is less than 16mm. In this operation, a series of dies with decreasing hole size are used. Initially the wire is fed into the die with the largest hole and is drawn through it. It is then fed into the second die with a smaller hole and drawn again. This process is repeated using many dies. In each stage, the hole size of the die decreases. In the end, a fine wire with small diameter is obtained. This wire can be coiled using appropriate machines.

3. Rod Drawing (or Bar Drawing):

Rod drawing is an operation used to reduce the diameter of a rod. It is similar to wire drawing. Here, a rod is pulled through a suitably sized hole in a die. Due to tensile force on the rod, the diameter of the rod decreases. The image above illustrates rod drawing.

4. Tube Drawing:

In tube drawing, a hollow tube is pulled through a hole in a die. This reduces its cross-sectional dimensions. The following video illustrates aluminium tube drawing:

Tube Drawing Animation Video

Drawing (Metalworki

You might also like

- Drawing ProcessDocument47 pagesDrawing ProcessMetalAnand Chelliah75% (4)

- Mechanical Engineering Manufacturing-Process Machine-Drawing Notes PDFDocument10 pagesMechanical Engineering Manufacturing-Process Machine-Drawing Notes PDFahmed titoNo ratings yet

- 4 - Chapter 4 - Part 1Document66 pages4 - Chapter 4 - Part 1zhwan Anwar nooriNo ratings yet

- Unit - IV Drawing of Rods, Wires and TubesDocument13 pagesUnit - IV Drawing of Rods, Wires and TubesMaddipudi RamakrishnaNo ratings yet

- Unit IV 180208091907Document153 pagesUnit IV 180208091907tamilselvan nNo ratings yet

- 9 Different Types of Sheet Metal Operations With Diagrams Following Are The 9 Different Types of Sheet Metal OperationsDocument15 pages9 Different Types of Sheet Metal Operations With Diagrams Following Are The 9 Different Types of Sheet Metal OperationsAbdulbar kelilNo ratings yet

- Drawing (Manufacturing)Document3 pagesDrawing (Manufacturing)Carlos BustamanteNo ratings yet

- Workshop Project JUNE 2013 Sheet Metal Shop: Group 1Document13 pagesWorkshop Project JUNE 2013 Sheet Metal Shop: Group 1AdarshAgrawalaNo ratings yet

- Compiled By: Norliana Mohd Abbas: SourcesDocument25 pagesCompiled By: Norliana Mohd Abbas: SourcesafnanhananyNo ratings yet

- Assignment 1 SolutionDocument7 pagesAssignment 1 Solutiontoursena44No ratings yet

- Chapter 6 - NotesDocument7 pagesChapter 6 - NotesPraneethNo ratings yet

- Wire DrawingDocument7 pagesWire DrawingUtkarsh0% (1)

- Sheet Metal OperationsDocument7 pagesSheet Metal OperationsThabiso MmesoNo ratings yet

- Group (17) Wire Drawing PDFDocument14 pagesGroup (17) Wire Drawing PDFPeter Adel0% (1)

- Sheet Metal OperationsDocument7 pagesSheet Metal OperationsSuneth TharakaNo ratings yet

- Sheet Metal Proces DetailsDocument11 pagesSheet Metal Proces DetailsTito TitoNo ratings yet

- 2017im148, PTD Assignment 6 & 7Document8 pages2017im148, PTD Assignment 6 & 7rehmatali11121314No ratings yet

- Manufacturing Process 2 (Bending of Sheet Metals)Document27 pagesManufacturing Process 2 (Bending of Sheet Metals)bananaNo ratings yet

- 2017im148, PTD Assignment 6 & 7Document8 pages2017im148, PTD Assignment 6 & 7rehmatali11121314No ratings yet

- Wire DrawingDocument4 pagesWire DrawingVenkat KrishnaNo ratings yet

- Plastic DeformationDocument3 pagesPlastic DeformationCleng LaynesNo ratings yet

- Chapter 4 (Sheet Metal Fabrication) With VideoDocument71 pagesChapter 4 (Sheet Metal Fabrication) With VideoSamrat BhattaraiNo ratings yet

- Plastic Metal Forming of Metals and PowdersDocument20 pagesPlastic Metal Forming of Metals and Powdersيوسف عادل حسانينNo ratings yet

- Metal Forming 1Document11 pagesMetal Forming 1Atanga EmosNo ratings yet

- Drawing (Manufacturing)Document4 pagesDrawing (Manufacturing)zidaaanNo ratings yet

- Experiment 5 (Forging)Document3 pagesExperiment 5 (Forging)Er Keval PatelNo ratings yet

- Part I: Material Behavior, Press Selection: Die Science: 6 Questions To Answer To Achieve Successful Deep DrawingDocument11 pagesPart I: Material Behavior, Press Selection: Die Science: 6 Questions To Answer To Achieve Successful Deep DrawingsachinNo ratings yet

- Class Notes - Sheet MetalDocument6 pagesClass Notes - Sheet MetalVedurupaka Venkata SaiNo ratings yet

- ManufProc 5 SheetMetalFormingDocument65 pagesManufProc 5 SheetMetalFormingHannan yusuf KhanNo ratings yet

- Sheetmetal IntroDocument48 pagesSheetmetal IntroBharat M GajeraNo ratings yet

- Dies 3Document24 pagesDies 3Capiee OkeyNo ratings yet

- Wire and Tube DrawingDocument11 pagesWire and Tube DrawingNur Fatyn SyaqiraNo ratings yet

- Sheet Metal Processes BendingDocument11 pagesSheet Metal Processes BendingYashvir SinghNo ratings yet

- Metal Forming ProcessDocument13 pagesMetal Forming ProcessSabbir AhammedNo ratings yet

- Drawing Processes: by Hasanain Faleh Jassem (Roll (Roll No. 39) Under Guidance of Dr. Karim N. HusainDocument48 pagesDrawing Processes: by Hasanain Faleh Jassem (Roll (Roll No. 39) Under Guidance of Dr. Karim N. HusainalsltanyhasanNo ratings yet

- Different Types of Sheet Metal Operations Are:: 1. Shearing OperationDocument10 pagesDifferent Types of Sheet Metal Operations Are:: 1. Shearing OperationSai Asrith KonagallaNo ratings yet

- Bulk Deformation Process Wire Rod Tube Drawing Ch6Document51 pagesBulk Deformation Process Wire Rod Tube Drawing Ch6gereNo ratings yet

- Unit IV OrigionalDocument25 pagesUnit IV OrigionalPrakash SinghNo ratings yet

- GR GNT 00166580000000717Document25 pagesGR GNT 00166580000000717ashoku24007No ratings yet

- Press & Press WorkDocument7 pagesPress & Press Workapi-19822628No ratings yet

- Sheet Metal FormingDocument5 pagesSheet Metal FormingScribdd3r100% (2)

- Bending ProcessDocument32 pagesBending ProcessdfdsNo ratings yet

- Sheet Metal WorkingDocument26 pagesSheet Metal Workingvelavansu0% (1)

- Wire Drawing Shearing Processes FinalDocument19 pagesWire Drawing Shearing Processes FinalJairam AtluriNo ratings yet

- Sheet Metal FormingDocument34 pagesSheet Metal FormingAamir RafiqNo ratings yet

- 202004032250570818prashant Engg Manufacturing Sheet Metal 3Document14 pages202004032250570818prashant Engg Manufacturing Sheet Metal 3GURU SAMY ANo ratings yet

- Wire Tube DrawingDocument48 pagesWire Tube DrawingSarthak JadhavNo ratings yet

- Principle of Rod, Wire Drawing & Tube DrawingDocument2 pagesPrinciple of Rod, Wire Drawing & Tube DrawingvijayakumarNo ratings yet

- Assignment01 PPT57Document15 pagesAssignment01 PPT57Usman AhmedNo ratings yet

- Drawing of MetalsDocument10 pagesDrawing of MetalsWazing WaNo ratings yet

- SPiningDocument45 pagesSPiningnvemanNo ratings yet

- Extrusion & Drawing Sheet MetalDocument63 pagesExtrusion & Drawing Sheet MetalMADHAVNo ratings yet

- Sheet Metal FormingDocument25 pagesSheet Metal Formingankushkapoor2003No ratings yet

- Module 6 Drawing-Lecture 1 PDFDocument8 pagesModule 6 Drawing-Lecture 1 PDFDevlina GaharwarNo ratings yet

- Unit IIIDocument114 pagesUnit IIIManoj Kumar SNo ratings yet

- Chapter-2 BendingDocument16 pagesChapter-2 BendingNikhil PrasannaNo ratings yet

- 43-Sheet Metal Punching MachineDocument25 pages43-Sheet Metal Punching MachinesathishNo ratings yet

- Sheet Metal OperationDocument17 pagesSheet Metal Operationsekar_scribd60% (5)

- Exceptional Communication and Networking Skills Successful Workingbb The Ability To Work Under Pressure and Multi-Task The Ability To Follow Instructions and Deliver Quality ResultsDocument1 pageExceptional Communication and Networking Skills Successful Workingbb The Ability To Work Under Pressure and Multi-Task The Ability To Follow Instructions and Deliver Quality ResultsJesus Rosas MontalvoNo ratings yet

- Intro Physics 1Document516 pagesIntro Physics 1Lucas De Paula FerreiraNo ratings yet

- College GPA CalculatorDocument1 pageCollege GPA CalculatorSaurabh SharmaNo ratings yet

- 02 Teaching Sustainable PDFDocument42 pages02 Teaching Sustainable PDFSaurabh SharmaNo ratings yet

- CSWA Exam Practice QuestionsDocument26 pagesCSWA Exam Practice QuestionsManuel Norberto Montoya Quezada100% (1)

- Prtoblem J BDocument24 pagesPrtoblem J BjhpandiNo ratings yet

- Python For Data Science PDFDocument15 pagesPython For Data Science PDFMuhammad Wahyu Dwimulyo100% (3)

- The Ultimate Sap User Guide The Essential Rehan ZaidiDocument1,119 pagesThe Ultimate Sap User Guide The Essential Rehan ZaidiShashi WableNo ratings yet

- Central Topic PDFDocument1 pageCentral Topic PDFSaurabh SharmaNo ratings yet

- SOLIDWORKS Shortcut Keys DocumentDocument2 pagesSOLIDWORKS Shortcut Keys DocumentTerminatorX75100% (1)

- Daily Indian GM Diet Plan 7 Days PDFDocument5 pagesDaily Indian GM Diet Plan 7 Days PDFZaara BarriosNo ratings yet

- SOLIDWORKS Shortcut Keys DocumentDocument2 pagesSOLIDWORKS Shortcut Keys DocumentTerminatorX75100% (1)

- 2 Months Target CAT - 21 Sept Batch: Cetking Advance WorkshopsDocument1 page2 Months Target CAT - 21 Sept Batch: Cetking Advance WorkshopsjoNo ratings yet

- Applelogo NCDocument24 pagesApplelogo NCSaurabh SharmaNo ratings yet

- Manual ProteusDocument477 pagesManual ProteusJose Negley Torres OcarizNo ratings yet

- Apple LogoDocument14 pagesApple LogoSaurabh SharmaNo ratings yet

- Unit 1Document82 pagesUnit 1zubbbuNo ratings yet

- Preparation of Papers in Two-Column Format For The IEEE SSC 2006/ Dublin, Ireland Proceedings CD-ROMDocument3 pagesPreparation of Papers in Two-Column Format For The IEEE SSC 2006/ Dublin, Ireland Proceedings CD-ROMSaurabh SharmaNo ratings yet

- Me202 L2Document27 pagesMe202 L2Saurabh SharmaNo ratings yet

- Apple LogoDocument14 pagesApple LogoSaurabh SharmaNo ratings yet

- Thermo MECH AERO NotesDocument290 pagesThermo MECH AERO NotesHasan128No ratings yet

- Feasibility Study Solar System - 2Document1 pageFeasibility Study Solar System - 2Saurabh SharmaNo ratings yet

- Manit Choudhary Aptitude FormulaDocument5 pagesManit Choudhary Aptitude Formulawimaxaaabgl100% (1)

- Me202 L7Document37 pagesMe202 L7Saurabh SharmaNo ratings yet

- AllBallsBallbearingsizechart PDFDocument4 pagesAllBallsBallbearingsizechart PDFSaurabh SharmaNo ratings yet

- IMU Wk8Document30 pagesIMU Wk8Anh Là BiNo ratings yet

- Modeling First and Second Order SystemsDocument6 pagesModeling First and Second Order SystemsAKHameedNo ratings yet

- Me202 L1Document17 pagesMe202 L1Saurabh SharmaNo ratings yet

- AllBallsBallbearingsizechart PDFDocument4 pagesAllBallsBallbearingsizechart PDFSaurabh SharmaNo ratings yet

- The Brain Fingerprinting Technology DR - Lawrence A. Farwell The Brain Fingerprinting Technology DR - Lawrence A. FarwellDocument24 pagesThe Brain Fingerprinting Technology DR - Lawrence A. Farwell The Brain Fingerprinting Technology DR - Lawrence A. FarwellSaurabh SharmaNo ratings yet

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsFrom EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsRating: 4.5 out of 5 stars4.5/5 (2)

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (10)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastFrom EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastRating: 5 out of 5 stars5/5 (1)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiFrom EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiRating: 4 out of 5 stars4/5 (3)

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeFrom EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeRating: 5 out of 5 stars5/5 (1)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- House Rules: How to Decorate for Every Home, Style, and BudgetFrom EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNo ratings yet

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- Crochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestFrom EverandCrochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestRating: 5 out of 5 stars5/5 (2)

- Friends: The One with the Crochet: The Official Crochet Pattern BookFrom EverandFriends: The One with the Crochet: The Official Crochet Pattern BookRating: 5 out of 5 stars5/5 (1)

- Celtic Line Drawing - Simplified InstructionsFrom EverandCeltic Line Drawing - Simplified InstructionsRating: 5 out of 5 stars5/5 (4)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)From EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)No ratings yet

- Modern Granny Stitch Crochet: Make clothes and accessories using the granny stitchFrom EverandModern Granny Stitch Crochet: Make clothes and accessories using the granny stitchRating: 5 out of 5 stars5/5 (1)

- Too Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreFrom EverandToo Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreRating: 5 out of 5 stars5/5 (2)

- Dream Sewing Spaces: Design & Organization for Spaces Large & SmallFrom EverandDream Sewing Spaces: Design & Organization for Spaces Large & SmallRating: 4 out of 5 stars4/5 (24)

- Kawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreFrom EverandKawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreRating: 5 out of 5 stars5/5 (5)

- Crochet Collage Garden: 100 patterns for crochet flowers, plants and petalsFrom EverandCrochet Collage Garden: 100 patterns for crochet flowers, plants and petalsRating: 5 out of 5 stars5/5 (1)

- The Book Of Boro: Techniques and patterns inspired by traditional Japanese textilesFrom EverandThe Book Of Boro: Techniques and patterns inspired by traditional Japanese textilesRating: 5 out of 5 stars5/5 (1)

- Crochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysFrom EverandCrochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysRating: 4.5 out of 5 stars4.5/5 (7)

- Colorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsFrom EverandColorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsNo ratings yet

- Radical Sewing: Pattern-Free, Sustainable Fashions for All BodiesFrom EverandRadical Sewing: Pattern-Free, Sustainable Fashions for All BodiesNo ratings yet

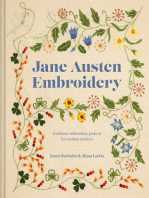

- Jane Austen Embroidery: Authentic embroidery projects for modern stitchersFrom EverandJane Austen Embroidery: Authentic embroidery projects for modern stitchersRating: 4 out of 5 stars4/5 (3)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsFrom EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsRating: 4.5 out of 5 stars4.5/5 (10)

- Crochet Lace: Techniques, Patterns, and ProjectsFrom EverandCrochet Lace: Techniques, Patterns, and ProjectsRating: 3.5 out of 5 stars3.5/5 (3)

- Tunisian Crochet for Beginners: Step-by-step Instructions, plus 5 Patterns!From EverandTunisian Crochet for Beginners: Step-by-step Instructions, plus 5 Patterns!Rating: 5 out of 5 stars5/5 (3)

- Knit Soxx for Everyone: 25 Colorful Sock Patterns for the Whole FamilyFrom EverandKnit Soxx for Everyone: 25 Colorful Sock Patterns for the Whole FamilyRating: 4.5 out of 5 stars4.5/5 (2)

- Creative Watercolor: A Step-by-Step Guide for BeginnersFrom EverandCreative Watercolor: A Step-by-Step Guide for BeginnersRating: 4 out of 5 stars4/5 (8)