Professional Documents

Culture Documents

Vessel Weld Efficiency

Uploaded by

Alvin SmithOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vessel Weld Efficiency

Uploaded by

Alvin SmithCopyright:

Available Formats

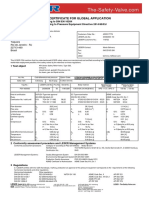

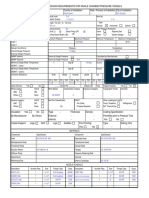

Pressure Vessel Engineering Ltd.

ASME VIII-1 Section UW-11 & UG-116(e) ASME Sample L-1.6.3 Project Left Head: [Category A] - long seam weld in head, not head to shell weld Flat Left head UW12 Column for this weld a Seamless Left head weld type UW12 Column for joining circ weld a Seamless Left head weld radiography Weld type number 0

UW-11(a) is met UW-11(a)(5)(b) is met Isolated long seam efficiency 1.00 Allowed UW12 column a Allowed head longitudinal efficiency 1.00

Vessel Weld Efficiency ver 2.10

Left Circ Weld: [Category A, B, C or D] head to shell weld Corner Left head to body circ-weld type None Left head to body circ-weld radiography Body Long Seam: [Category A] Smls or ERW Body long weld type Seamless Body long-weld radiography

UW-11(a) is met UW-11(a)(5)(b) is NOT met left circ efficiency 1 right circ efficiency 0.55 Allowed circ efficiency 0.55

UW12 column for this weld a Circ seam type number 7 Left circ weld efficiency 1.00

UW12 column for the body long seam a UW12 column for left circ weld a UW12 column for right circ weld c Long seam type number 0 Isolated long seam efficiency 1.00 Allowed UW12 column b Allowed long seam efficiency 0.85

Right Circ Weld: [Category A, B, C or D] head to shell weld Double_Fillet Right head to body circ-weld type None Right head to body circ-weld radiography

UW12 column c Circ seam type number 4 Right circ weld efficiency 0.55

Right Head: [Category A] - long seam weld in head, not head to shell weld Semi-Elliptical Right head UW12 column for this weld Seamless Right head weld type UW12 Column for joining circ weld Seamless Right head weld radiography Weld type number

UW-11(a) is met UW-11(a)(5)(b) is NOT met

a c 0

Isolated long seam efficiency 1.00 Allowed UW12 column b Allowed head longitudinal efficiency 0.85

Notes: RT1

Sketch:

Body efficiency is reduced by head to body welds Right head efficiency is reduced by right head to body weld

Comments:

This sheet is for educational use only. Only ASME can make code interpretations. UW-11(a) and UW-11(a)(5)(b) Complience is optional. ERW Pipe - start calculations with stress values from IID that INCLUDE the 0.85 long seam efficiency, then run the code calculations with the additional long and circ seam efficiency shown here - refer to UW-12(e).

Pressure Vessel Engineering Ltd. 120 Randall Drive, Suite B Waterloo, Ontario, Canada, N2V 1C6 www.pveng.com (519) 880-9808

You might also like

- Weld Profile B16.25 - B 16.9Document2 pagesWeld Profile B16.25 - B 16.9f_riseNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design Toolnaveen_86No ratings yet

- Nozzle DesignDocument391 pagesNozzle Designantonio gutierrezNo ratings yet

- Torque Tables For Spiral Wound Gaskets, ASME B16.5: Class 150Document2 pagesTorque Tables For Spiral Wound Gaskets, ASME B16.5: Class 150akalp1005No ratings yet

- Copiar de Nozzle - Design - ToolDocument2 pagesCopiar de Nozzle - Design - ToollavascudoNo ratings yet

- Hemispherical Head Design ToolDocument1 pageHemispherical Head Design Toolnaveen_86No ratings yet

- Cálculo de Flare Api 560Document9 pagesCálculo de Flare Api 560Lerida SalazarNo ratings yet

- Tank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeDocument1 pageTank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeABIDEEN BAMNENo ratings yet

- Shell Thickness Calculation: C WP F D WP TDocument16 pagesShell Thickness Calculation: C WP F D WP Tpatiltushar79No ratings yet

- Heat Ex Changers EstimationDocument46 pagesHeat Ex Changers Estimationshankarbt83No ratings yet

- Hemispherical Head Design ToolDocument1 pageHemispherical Head Design ToolBanamali NaskarNo ratings yet

- Title: ASME Electronic Stress Tables, 2004 Metric Edition Table: Table 1A - Maximum Allowable Stress Values S For Ferrous MaterialsDocument5 pagesTitle: ASME Electronic Stress Tables, 2004 Metric Edition Table: Table 1A - Maximum Allowable Stress Values S For Ferrous MaterialsAdhar ChawlaNo ratings yet

- Pressure & Temperature ClassificationDocument1 pagePressure & Temperature Classificationkeo85100% (1)

- Toriconical Head Ver 1.1Document4 pagesToriconical Head Ver 1.1Iqbal AhmadsNo ratings yet

- WEP Standard For Reference OnlyDocument37 pagesWEP Standard For Reference OnlyKiran NikateNo ratings yet

- PSV 430066 PDFDocument41 pagesPSV 430066 PDFErikikoNo ratings yet

- Neck Flanges Pressure Nominal (PN) 63 - According To DIN en 1092-1Document2 pagesNeck Flanges Pressure Nominal (PN) 63 - According To DIN en 1092-1Zoran Tanja JarakovićNo ratings yet

- ASME B31.3 CalculatorDocument144 pagesASME B31.3 CalculatorLeoNo ratings yet

- Welder Performance Qualification (WPQ)Document2 pagesWelder Performance Qualification (WPQ)alokbdasNo ratings yet

- UG-22 LoadingsDocument1 pageUG-22 LoadingsRavi YadavNo ratings yet

- MD PV ASME v0.1Document35 pagesMD PV ASME v0.1rizalramaNo ratings yet

- PV Elite Vessel Analysis Program HorizontalDocument55 pagesPV Elite Vessel Analysis Program HorizontalMarizta Perdani PutriNo ratings yet

- Pressure Test in Accordance With The Standard Din en 13445: Inspecta GroupDocument14 pagesPressure Test in Accordance With The Standard Din en 13445: Inspecta GroupNanang PhNo ratings yet

- Pressure Vessel Design 2018 VER BDocument61 pagesPressure Vessel Design 2018 VER BBob FitcherNo ratings yet

- Engineering Design Calculation - Dennis Kirk Centrifugal Fan Performance CharacteristicsDocument1 pageEngineering Design Calculation - Dennis Kirk Centrifugal Fan Performance CharacteristicsAnonymous EarAM2100% (1)

- AD 2000 Head Under Intenal PressureDocument3 pagesAD 2000 Head Under Intenal Pressuremechengg01No ratings yet

- Cálculo Flange ASME VIII 1 Apendice 2Document10 pagesCálculo Flange ASME VIII 1 Apendice 2jowarNo ratings yet

- Asme - HeaderDocument3 pagesAsme - HeaderReadersmoNo ratings yet

- Dish Volume CalcDocument48 pagesDish Volume Calclakumas15No ratings yet

- Pipe Thickness Calculation Data SheetDocument1 pagePipe Thickness Calculation Data SheetAnonymous 6ZWS6IG2J9No ratings yet

- Pipes. Pressure and Wall Thickness Equations and Data For A Straight Pipe. ASME B31.1 and B31.3.odsDocument100 pagesPipes. Pressure and Wall Thickness Equations and Data For A Straight Pipe. ASME B31.1 and B31.3.odsNaufal FirmansyahNo ratings yet

- Piping Calculation Program For ASME B31 1 CodeDocument3 pagesPiping Calculation Program For ASME B31 1 CodeAMIT100% (2)

- Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsDocument3 pagesForm U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsssNo ratings yet

- Mill Test Certificate: 121 1233.400 Tons.: 11.899Document6 pagesMill Test Certificate: 121 1233.400 Tons.: 11.899CarlosEduardoRodriguezNo ratings yet

- Siphon CalcDocument2 pagesSiphon CalcfaridhassaniNo ratings yet

- B Jack Nos For Cs Ss MaterialDocument12 pagesB Jack Nos For Cs Ss MaterialfahadfiazNo ratings yet

- Bopp & Reuther CatalogueDocument60 pagesBopp & Reuther CatalogueIrfan BagwanNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document5 pagesCalculation of Pipe Reinforcement ASME B31 3Umar Aslam0% (1)

- DSHG 06 3C4 YukenDocument16 pagesDSHG 06 3C4 YukenJindal HydraulicsNo ratings yet

- Dimensions of Restriction Orifice Plates For ASME b16Document5 pagesDimensions of Restriction Orifice Plates For ASME b16Mohamed Salah SolimanNo ratings yet

- WRC-107 Lifting Lugs - Vert. Vessel Vertical LiftDocument5 pagesWRC-107 Lifting Lugs - Vert. Vessel Vertical LiftManoj MulikNo ratings yet

- F&D Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageF&D Head Design Tool: Pressure Vessel Engineering LTDMauricio KookcNo ratings yet

- Carbon Steel ASME B36.10M Stainless Steel ASME B36.19M Cu-Ni Brass Bronze Thermoplastic ThermosettingDocument9 pagesCarbon Steel ASME B36.10M Stainless Steel ASME B36.19M Cu-Ni Brass Bronze Thermoplastic ThermosettingkaviramanNo ratings yet

- Design of Obround Flange For Pressure Vessel Application by Analytical Method and FEA To Comply With ASME CodeDocument11 pagesDesign of Obround Flange For Pressure Vessel Application by Analytical Method and FEA To Comply With ASME CodeFelip PrietoNo ratings yet

- ASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelDocument16 pagesASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelPanya Purahong100% (1)

- Vessel Weld Efficiency: Pressure Vessel Engineering LTDDocument1 pageVessel Weld Efficiency: Pressure Vessel Engineering LTDgdwvcdNo ratings yet

- Copiar de Vessel - Weld - EfficiencyDocument4 pagesCopiar de Vessel - Weld - EfficiencylavascudoNo ratings yet

- Comment: Only ASME Can Make Interpretations On The ASME VIII-1 Code Weld Efficiencies For ASME VIII-1 Vessels - Section UW-11 (A) (5) (B)Document11 pagesComment: Only ASME Can Make Interpretations On The ASME VIII-1 Code Weld Efficiencies For ASME VIII-1 Vessels - Section UW-11 (A) (5) (B)MechanicalNo ratings yet

- Vessel Weld Efficiency: Pressure Vessel Engineering LTDDocument6 pagesVessel Weld Efficiency: Pressure Vessel Engineering LTDMechanicalNo ratings yet

- Allowed Head Efficiency Ver2.11Document7 pagesAllowed Head Efficiency Ver2.11olekNo ratings yet

- American Welding Society StandardsDocument2 pagesAmerican Welding Society StandardsGeorge Nicolaides100% (1)

- ASME Pressure Vessel JointDocument8 pagesASME Pressure Vessel Jointf4CHNo ratings yet

- Hubbell Catalog PDFDocument52 pagesHubbell Catalog PDFpaulsiancasnNo ratings yet

- ASME Code News (Questions and Answers)Document4 pagesASME Code News (Questions and Answers)dj22500No ratings yet

- Joint Efficiency RuleDocument4 pagesJoint Efficiency RulesubhaNo ratings yet

- American Welding SocietyDocument3 pagesAmerican Welding SocietyRamsey RasmeyNo ratings yet

- 1 - CBT Welding NDT 26 02 2020 - Ans and ExplanetionDocument27 pages1 - CBT Welding NDT 26 02 2020 - Ans and ExplanetionAMALENDU PAULNo ratings yet

- ASME Pressure Vessel Joint EfficienciesDocument5 pagesASME Pressure Vessel Joint EfficienciesalokbdasNo ratings yet

- ASME VIII Div. 1 - 2 Joint EfficiencyDocument28 pagesASME VIII Div. 1 - 2 Joint EfficiencyYoucef ChorfaNo ratings yet

- ASME VIII Div. 1 - 2 Joint EfficiencyDocument28 pagesASME VIII Div. 1 - 2 Joint Efficiencyعصمت ضيف الله89% (9)

- Wall Thickness Calculation of Offshore PipelinesDocument1 pageWall Thickness Calculation of Offshore PipelinesAlvin SmithNo ratings yet

- WRC Check List CriteriaDocument1 pageWRC Check List CriteriaAlvin Smith100% (1)

- 09 Job Procedure For Fire ProofingDocument4 pages09 Job Procedure For Fire ProofingAlvin Smith100% (2)

- Anurudh - Hazira FWNDocument2 pagesAnurudh - Hazira FWNAlvin SmithNo ratings yet

- Pressure Instruments: Engineers India LimitedDocument2 pagesPressure Instruments: Engineers India LimitedAlvin SmithNo ratings yet

- Wall Thickness Calculation of Offshore PipelinesDocument1 pageWall Thickness Calculation of Offshore PipelinesAlvin SmithNo ratings yet

- Specification For Painting-Piping & EquipmentDocument21 pagesSpecification For Painting-Piping & EquipmentAlvin Smith100% (2)

- Orifice Sizing CalculationDocument24 pagesOrifice Sizing Calculationjamestpp67% (3)

- Datasheet of Deluge ValveDocument2 pagesDatasheet of Deluge ValveAlvin SmithNo ratings yet

- Painting SpecDocument54 pagesPainting Specashim_scribd100% (4)

- 3-1643-0402 - Rev - 2 Index of IBR DocumentsDocument1 page3-1643-0402 - Rev - 2 Index of IBR DocumentsAlvin SmithNo ratings yet

- Comments On GAD Ball ValveDocument2 pagesComments On GAD Ball ValveAlvin SmithNo ratings yet

- Comments On GAD Ball ValveDocument2 pagesComments On GAD Ball ValveAlvin SmithNo ratings yet

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedAlvin Smith77% (26)

- Tutorial of WRC 107 For Lifting LugsDocument20 pagesTutorial of WRC 107 For Lifting LugsAlvin Smith100% (1)

- Engineers India Limited: Specification REV Plant: 003 Ongc, MehsanaDocument1 pageEngineers India Limited: Specification REV Plant: 003 Ongc, MehsanaAlvin SmithNo ratings yet

- Tutorial of WRC 107 For TrunnionDocument9 pagesTutorial of WRC 107 For TrunnionAlvin SmithNo ratings yet

- 3-1643-0406 Rev 1 Isometrics Line Index IBRDocument1 page3-1643-0406 Rev 1 Isometrics Line Index IBRAlvin SmithNo ratings yet

- WRC 107 For Vertical Internal ClipDocument22 pagesWRC 107 For Vertical Internal ClipAlvin SmithNo ratings yet

- 3-1643-0408 - Rev - 1 Support Legend IBRDocument1 page3-1643-0408 - Rev - 1 Support Legend IBRAlvin SmithNo ratings yet

- (Lt'Ldla) : Offshore Hook - Uf Construction ServisesDocument1 page(Lt'Ldla) : Offshore Hook - Uf Construction ServisesAlvin SmithNo ratings yet

- Pressure Safety Valve Sizing Calculation Rev.01 APUDocument10 pagesPressure Safety Valve Sizing Calculation Rev.01 APUAlvin SmithNo ratings yet

- Concession Request FormDocument2 pagesConcession Request FormAlvin Smith88% (8)

- Relay Settings Tables - 12mar12Document5 pagesRelay Settings Tables - 12mar12Alvin SmithNo ratings yet

- Tutorial of WRC 107 For TrunnionDocument9 pagesTutorial of WRC 107 For TrunnionAlvin SmithNo ratings yet

- Spec For Process Strainer 7Document4 pagesSpec For Process Strainer 7Alvin SmithNo ratings yet

- Motor Detail Specification PDFDocument6 pagesMotor Detail Specification PDFAlvin SmithNo ratings yet