Professional Documents

Culture Documents

Biological Wastewater Treatment - Principles Modelling and Design

Uploaded by

Nguyen Phuc Pham78%(9)78% found this document useful (9 votes)

6K views103 pagesEbook for Environmental Engineer

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEbook for Environmental Engineer

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF or read online from Scribd

78%(9)78% found this document useful (9 votes)

6K views103 pagesBiological Wastewater Treatment - Principles Modelling and Design

Uploaded by

Nguyen Phuc PhamEbook for Environmental Engineer

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF or read online from Scribd

You are on page 1of 103

Brdjanovic

elttiit

a

a

S

uouswaoy: TWA Publishing.

{ncons 09s UK

Tetge(o)20 7593500

Fs 0) 20 0343055

Epbleatons@ieap. cok

FE nonnivapobengor

Stock We sine

Unde the UNCopyigt ess and Pret A (3998). me prt ubcatin nay be epratues, sore

trtansmed ay foimor yay mean ton neprorpemssonn wing ot the pubes, te

Caicet protagapmcreproducton nacarcace wth hte ot ances indy te Copy cae

‘esncynneUs, or hacenrarcewnnthe terms o Senses sane by fe apprepraterprocctn rts

rants ose the UX tngute corer evolu oul he er sales Rete shoudbe set

IW Pubisg at theaecress pried stove

Puousnngars swale ot be ced upon witout pandas cosaeaten ae loess ace. W=nd

Ia rblsng net cep response fran essa aang sere yy puson ago INNS

fremacing \pesaymatera omar nts ptleaton

rin bra Gatsopuinen oat Data

‘emulague enstor tebe hatte he brary Congest

one desig: Pater Sto

Sropnicdeee menses

san ssgzsto

IBN sretay3e83

AUTHORS Inset eae

res COEAD Ele olen Nona Canada

George ANA ‘Unrest Cape Tow ane Tee, Souther

Jat oonccancn NovtreUnvey, MrtenayNee>

Mogens inte Tec Uther Dena ay, Oa

Drtono rt MARTINS faussao Agar Fare, Pocus

Eoartard#NORGAOTH erty Instat Uaana champagne, USA

Digs ROSS Unter of ators ine, S.A

MhaelK STENSTAOM. Unters ef ora Losaneels USA

Ime taucs nurs fascite e. arboreugh, cata

Marke vantoosenscat —Gatnaeey a oehslegy Da Mo Nathartnts

Contents

Ooge t

Wastewater Treatment Development 1

Fie, RC vn sie a oe

22 tenet otmesbolngy

25 Stochonetn aa ners

1. _thsoigh ef wasenster

Tate

TO anc

Inport components

i geld enpeat

is teosrgsnee

Sper waters andintera pnt reece steams

states

2 Varators

Waster fle

FE HapgeslNeema

Sm Spsemcesgn opemtonand conte

Og 6

Innovative Nitragen Removal 139

62 htodicion

63. Irpacetsdesteamarocesses

63, Thentrogenaee

SL. edad Heemova

eh Menger

Cage

Phosphorus Removal 155,

FR oes Coen, Gh CHOKE e Le 0

2a_ptoaucion

Pre of erranced bogs phesproru roy (CBP)

55 WechanimefEEPF

Fp nd developer EPR systems

Ze _ Motel developmen for BFR

Fe Weeder stacy ate mote

35 esgnempe

[is Teton secs ie memde of Prem

SC pestfistona Noetrnatens

a eogen acuta

a = some

EE comamoacmum ——_‘atlogen enor =

.sS._Wastewater fingerprint Cece

=n eo

‘Organic Matter Removal 2 a Typesoertae pathogens

ao tote and uhng Pe

SS detpnesmpe

efector ote eculements

TA. Grponscesuronygencemne

4s. Dany dug production

‘ho, Sysemoesgrand conta

Gn) Steet ote age

Ong 5

Nitrogen Removal 87

Gi cama nd MC Head

52 popgealhnet

EE roceistines

Sk Taco tering nitteaton

EE urietregarenens ter scge pracicion

SE Davgneanideraions

TA Sn De

2 Aarauontesmotgy

$2, slower ster

Si Gmetingmantaces! data process condtons

SE Aeratonrequrenents

Cpe 0

Toxicity 2B

IMG rece

03. ‘Messre tox

403. liebe model ter xe estates

14, eaingwihoxcky

408. Corekcgremss

Oe

Bulking Slade ast

FRCL a bse Maas GA tana

3. Ratna bstvan-orphsogy ae cophysllagy

1. Curent general hens toesplan bub sage

Ha. Mamemstemoceting

Mh. Geruursbge

Mg. Concesons

oe

Final Settling 309

es id haa

2 Sating ant conigaaton practice

133, Mewuresaf gency

(24 Mar icergloretnatona sett nk eps

2g overview athe seals coy andotie ead for deg

eg 5

Process Control 33

6 oon

54 behing oroeand maine

{3 Thersaaf conta an atamston

Sa farwresen andor

Hoy tase onoreoeeste

122 aarp feetbck nwateyntr tester yt

133 Operaing coe evinge die toconal

‘Blo egotinand pant wide con!

‘it Coneucharemas

og

Anaerobic Wastewater Treatment 45

[rs Le Mad at eran

fea Weblog’ fsmenbecamelont

S63 Preitrg tech rst

Saar {24_tryas cf tenuis aecuonacepioe

125 Hodeingt scandy atten {5g Weahgeh eco

Ep esmecnaer {85 mmontaton nssge yabuaton

467 Anroberentor ayer

ge 188 Uptow marebe sage blnlet(LASS)rexor

oar) 333 e10 Anse Vestment of domestic and munkial se

Shae etm wy bbe berrert corer mnogo

11 Mentranecepantionpinles

Sicwetgistdeszn

a comma ncnbnetecenloges

33 ew cae stuns

age

‘Modalling Activated Sludge Processes om

FRC Ue aa, HE Hee DBpro a ON a

123 Wireline

13 Modeling bases

124 Stein derloment of okntimadt ASH

Thy Atrated suger! evelepent Noor

149° oncesons

Sage

‘Modeling Biotins 47

Nore

ra Mesatonforrodelngbitnsara tow to chee appopite

‘matt modeling ppeacies?

173. Modeling pox fr ebonmassumgzsnge itr

tubstateandsegicthgestemal mau arse resins

174 aampleothow hy = W)canbe ised pred! boflmreactor

perfomance

195. Uectrofecteral mass ranerresitance

15 combing peta decay wit detache!

579 Iglaont ney ong bare,

70 ow oes soho stwictre vence Dotimpeterance?

Writ Medelpuranctes

wit Modeling bo

one 8

Biofilm Reactors 49

ope

181 otineactors

182 eugnporanetrs

18). Rew a deteminemasimun deg fae or desig nding

104 Sterdetenconaentns

Copyrighted material

1

Wastewater Treatment Development

Mogens Henze, Mark C.M. van Loosdrecht, George A. Ekama and

Damir Brdjanovic

11 _GLOBAL DRIVERS FOR SANITATION

In 2007, the development of sanitation was voted to be important in this is to not only comeet people to

the greatest medical advance in the last 166 vears in & sanitation solutions, but o make this connection last in

contest run by the British Medical Journal (Festiman, a environmentally sustainable way. Sewer systems and

2007) THis confirms the utterly important role of proper wastewater treatment plants have proven to be very

saniution in achieving and maintaining goo! public efficient in conveying and removing pathogens, organic

health In many industrialized counties, wastewater is pollutants and mutients: However, they require proper

Uwansported safely away feom the housebokls, Proper operation an maintenance, and « good understanding of

sewage treaiment is however not always in place, in the prncesses invaived

Particular in many developing countries where

sanitation coverage ix, hy far. Tess in comparisce with

‘water supply. The need for proper sanitation was made

explicit in the Unitod Nations Millenium Development Wastewater treaiment development was the moat visible

Goals. Goal number 7 urges for the reduction by half of in the 20" century. Sewage has for a long time been

the population living without proper sunitation, Despite considered o potential heath risk and nuisonee in urban,

significant efforts, progress on sanvation targets is Very agglomerations, The feruliser value of human excreta

slow and till lacking behind Acknowledging the was already recognized in carly days. The Ansient

‘pact of sanitation on public heals. poverty reduction, Greeks (300 BC to 300 AD) used public latnines Which

12_HISTORY OF WASTEWATER TREATMENT

economic and sceial development and the environment drained into sewers conveying the sewage and

the General Assembly of the United Nations declared stormwater io a collection basin outside the city. From

2008 to be the International Yearof Sanitation The geal there, brick-lined conduits took the Wasiewater to

Was to focus the worl’s attention on the need to stari agricultural fields which used the wastewater for

mplementing proper sanilation solutions for all

= 3781843391883. Publehedy [WA Pulsting, London, UK,

Loosdract, GA, Ekame and. drove

irsigation and to fertilise erops and orchards The sewers

Were periodically Nushed with wastewater,

The Romans took this system further: in about 800

RC, they constructed the Cloaca Maxine. Initially. this

central sewer system was used to drain the marsh upon

Which Rone was later built. By 100 AD, the syste was

almost complete and connections had been made to

some howtes Water wav supplied by an aqueduet

system which cared sewage fromt the publie baths and

latrines to the sewers beneals the city and finally into

the Tiber. The streets wore regularly washed with water

from the aqueduct system arid the waste washed into the

‘This system worked very well Hecause it could

count on an effective government and the protection oF

‘8 powserfl army to maintain the far-reaching aqueduct

When the Roms Empire collapsed, their sanitary

Approach céllapsed with it as well. The period between

430 aad 1750 AD is therefore known as the “Sunitary

Dark Ages” (Wolfe, 1999) During this period the main

form of wasie disposal was simply to dispose of i in the

streets, ofien by emptying buckets fem second-storey

windows, Around 1800, collection system appeared in

many cities, driven by the city dwellers who did nol

‘want fo put up vith the smell anymore. It was also

waleomed by the farmers around the city who found

good use for this “humane” In Amsterdam, a cart

drove through the streets in which the buckets could be

emptied. The eart was ironiealy named after a brand of

eat de cologne kaown at that time the Boldoot ext

However, spllimg during transportation and emptying of

the buckets was tmaveidable, ard the olfactory burden

on the citzens did not decrease much, BY then, plans

aroas for a general sewer system. Iligh investment costs

and uncertamty over flushing and maintenance of the

sewers pa the fast implementation on bok

Around 1900, Mi, Liemur eame up with a solution,

He developed a plan for separate collection of toilet

ater and oF grey and ston water Toilet water was to

be collected through a vacium sewer called the Liermt

‘stem GM. van Bemmelen, 1868). This system found

tus in several European towns (Figure 1.1),

‘The collecied sewnge did not undergo any treatment

Instead, it was spread out over land as a fenizer

However, waterlogging became « major problem, and

the continuous expansion of the cies made 11 more

ee ae

y % =

a

ATPase — pent

Fur 213 Overview of bacterial Woenergtis (adapted from

Comeau ete, 1986)

22.6 Nutritional requirements for microbial

srowth

In addition to energy, microorganisms require sourees

of carbon and inergame compounds to synlhesize

cellular components. Bacteria found in wastewater

treatment plants are typically composed of 75-80%

water and this, of 20-25% dry matter

“The dry mattcr content is determined from a Liquid

sample of known volume by retaining Biomass on a

lass fiber filer baving & nominal pore sizes of about

12 microm and evaporating the water to dryness in an

foven heated a 105°C. After cooling, the dried biomass

is weighed on an analytical balenee and the results

expressed a8 total suspended solids (PSS) in yin*

(img!) The dried glass fibve filter that retained the

biomass can then be combusted at 550°C in a mule

5

furnace to bur the erpanic matter (considered to be

ccamposed of C, H, © ant N). The ash remaining is

‘considered to represent the inorganic components and is

termed ash or fixed suspended solids (FSS). By

difference, the organic mater is ealeulated which is

termed volatile suspended solids (VSS)

The typical eomposition of the dey matter (188) of

bocteria is presented in Table 21

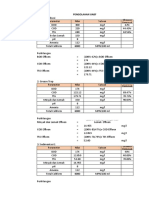

Tabla 2 Typical composition of baste (adapted from Matsa

cally 2003)

‘Gomsttuent or element Empirical mda

firealls CaT-ON

‘Major celulr eonsitueats

Protsin 550

Polysecherites 30

Lipit oa

DNA 31

RNA 20s

Other (sugars. amine 63

acids)

Inorvanis ions 10

{As ell elements says

Organic (VSS) 930

Carton 31.0

Oxygen 220

Nitrogen 120

Hdeozen 90

Inorganics SS) 10

Phosphorus 20

Sulfar 10

Potassun 10

Seam 10

Calcium os

Magnssiuon

Chlorine

ee

Other trace elements

‘The organic (VSS) and inorgenic content of bacteria

are thus about 93% and 7%, respoctivelv. Net only

should macro nutrients such as nitrogen and phosphors

need to be present for cell growth bul other elements are

also essential. These compounds are rarely missing in

municipal effluents but may be lscking in some

lnnlustral efMvents suet as fom sugar or pulp and paper

instres,

Empirical formulae proposed for cells (active

biomass) found in wastewater Leatment processes are

6

CHLON and Colfy-OyNyP which canbe

approximated (0 CsH-0;NP jp, These formulae give ery

ratler contents (TSS) for C,H, O,N and P that are in

relavely close agresment with the values presented in

Table 21. Other trice elements required include Zn,

Mn, Mo, Se, Co, Cu and Ni

2.2.7 Carbon and energy sources and microbial

diversity

Metabolism is the sum of all chemical processes that

take place in living cells (Pigure 2.14). It is divided into

two categories catabolism and anabolism. Catabolie

reactions are the ene‘gy supply of the esl. The catabolic

reaction is a redo reaction where the transport oF

elecivons fiom clecton don to electron acceptor is

enerating 2 proton motive fores which delivers ATP.

Anabolic reactions use this energy forthe syubesis oF

cellular components from carbon sources and other

rnutteas, Ifomganie carbon compounds ave the substrate

then they function as well in the eatabolie ss in the

anabolic reactions. The anabolic processes are more or

less the same in all bieteria, while the catabolic

processes can Vary widely between different microbial

isp

Energy production requires the presence of an

electron donor and an election acceptor A reduced

compound acts as the election donor (eg. organic

‘matter or ammonium) hile an exiized compound acts

a the electron acceptor (e.g. oxyaten or irate), The

‘minimum and maximum oxidaton states, swith an

esample of @ comesponding molecule, are shown in

Table 2.2 for signiticant elements in microbiolopy.

Carbon sources for biosvathesis are only of two

types, organi or inorganic. The energy sourees are of

tee types, organic, inorganic and from light, but the

Catabelism

fen Principles, Modelfng an Desi

veriety of combinations of electron donors and

acceplors results in # trea diversity of microorganisms

(lable 23).

‘The name of there groups come from Grosk roots

chemo: chemical; ropl- nourishment, organo: organic,

litho: inorganie; phovo: light; auto: self eter: other

Chemotrophs obtain energy from the oxidation of

electron donating molecules [rom their environment

‘These molecules can be organie (chemo-organotrophs

or —chemo-organoheterotrophs) or inorganic

(chemolithotrophs or chemolithoautoirophs). Chemo:

orgmotrophs ate notmallyhelerotrophs and

chensolithotrophs are normelly autotrophs with these

rhames being wsed interchangeably. Not every microbial

type is presented in this table, Other groups inclae

Achalorespirers whieh use some types of chlorinated

‘compounds as electron aseeptors

Examples of microbial growth reactions with their

Principal function in wastewater treatment are given

below. Neutral molecules are used for reactions even if

other ionie species may be dominant The Eq 21 to 26

are given fo illustraion of metabolism only an are no!

balanced

© Aerobic hoterctrophs

HO, +0, + NH, 4 ethor mutionts >

organic matter oxidation

ep

CHLON+C0, 41,0

© Denurifiers: nitrate removal

GH,O, +0, + HNO, + NH, + ether muvients >

ee (22)

CHON+C0,4H,04N,

2 Fermening orgerisms: conversion of larger ganic

‘compounds: glucose to acetic aid,

Arabolism

Honyrehete metals

Figure 2.14 Wetabclismasthe combination of eatabolim and anabolsm (acapted rm Todor, 2007)

CH 0, +0, + NH 4 eahor monrienss >

CHOWN +CHCOH +CO,

© erobie autotrophic bacteria (ammonta oxidizers)

removal of ammonia

23)

CO, + NHi,4.0, + other mutrionts >

aay

CHLO.N+HN0,+H,0 “

Table 22 signtfcat elements in mkrobiology

7

© ydrogenotrophic methanegemt: biogas production

HH, $010, + NU, + thor mutients >

CH.ON+CH,

‘+ Plans: O:production and greenhouse gas reduction

25)

00, + light + NH, other mrients >

CHON+0,

26

Relerence ordaton

Named symbol gata (0) and phase (2)

Tlesto-negatiniy Oxidation state

‘Oxidation sale

sand state of in ani state of mat x

Oye 0 Orig) 350

Niwgen No Nag) 307

Caton CCG) 250

Sif 8 SG) 2as

Hydoven Ho Hig) 210

uo Fe Fes) 164

Manginese_Mn__Mn(s) 160

“lL 10 °

am NI v

av CH v

au ns vl

o i, I

° Fe Mm

0 Ma wv

‘Oridtonsiatesshowareferece-min-tan phases stows we fa (@) an ws) Hlecto-negainil refer alms elena

elections (ea a high nxidtion ste these ebmcets (exept 1) we potent cleston apron fr este reacties (ed Fo

Hjem an proparaticn)

Table 23 Trophic closcation of miroorgavisis (edapted frm Altar apd McCorty, 200%; Metca¥ & Edy, 2003)

ee —

ergy source

Eleetzon donor

Caron soe

Elesron acceptor Typical product?

Trophic group Microbial srow Type of € donor

‘Chemotroph

Organotioph Acrobicheterorophs Organic oO 0,10 Organic

Denititirs Organi NOs, N NCOs 1:0 Organic

Fermenting organisms Organic Organ Orme VEA® Organic

Iron reducers Oreanie Fell Fed) Onzanie

Sulfate reducers Acctute soe ns. Acctate

Methanogens (cctoclastc) Acetate acetate cH, Acetate

Lithouoph—-Niifers: AOR! NH o No; co;

Nitrfiers: NOR® Noy oO No; co:

‘Anammox’ bacteria NHS NO; N co;

Denititiers B Ns. HH co,

Denitaties s N2.SOP HO COs

Iron oxidizes Feat °, Feat co;

Sulphate reduests Hy soe 1S. 10, cos

Sulphate oxidizers TLS,848:07 Op 80; co:

Aerobic hyiogenotrophs Ms oO 10 co:

Methanegens i os cH, co;

Alrvdrogenotrophic)

Phooioph

Algae. plants 10 COs o co;

Photosyatheticbacteia 11S 05 SO} cos

Gabe sores organs fr beterctpis and erga (CO) Foralotopls misono can we bah." Typal prdost: CO, and TD ae

produc of catalog geactaton

> icoronpasine, "VTA elatile Fy aid pally acetate propia,

sy).

208; anmoniaondizngbactern, NOS: mints exszing bates “Ararumox: anos ammonia oxing baste

ren Principles, Modelfng nd Desi

Table 24 Onyen ane microorganisms (adapted from Madigan an Nartinko, 2006)

Gow Relationship oO» “Type of meabolian

Acrobss

Obligite Required 8 20%) ‘Aerobie respiration

Facultative Beiter ifpresen, ot esentil Aerobie or nia respiration, fermentation

Mieroaerophilie Requires lewlevels(eg 1%) ‘Aerobie respiration

Anacrobes

Acroteleant Not required, nat affected by its presence Fenmertaton or sulphate reduction

Ovlizate Os harmful or lethal Fermentation of anaerabiefenmertation

22.8 Environmental conditions (oxygen,

temperature, toxicity)

Environmental coniitons must be favourable for

microorganisms to grow. Major factors affecting growth

are oxygen and temperature but pH (ypisally 6 to 8)

and osmotic pressure (depends on the concentration of

salts) must also be appropriate

aad Oxygen

The noed, tolerance or sensitivity to molecular oxygen

(O») varies widely among micto-organisms (Table 2.4)

Aoroboa use oxygen and nay need it (cbiigat),

function in its absence (Facultative) or require (in low

levels (microacrophilic). Anaerobes do not use oxygen

but may tolerate it (aerotolerant) or not (oblate)

In aecobes. enzymes for oxygen reduction (t use O;

san elecion aeceplor) are slway’s induced. In contrast,

dlenitrifiers which are facultative serobes, also have

‘constitutive etizy mes for oxygen reduction but e1zymes

for nitrate (or nitrite) reduction need to he induced. 2

cendition that requires Ue absence of oxygen. All

enitrfying bactera can also use oxygen, their eslabolie

processes being relaively similar. Sulphate reducers on

the contrary cannot uss oxygen, their catabolic process

boeing very different irom aerobic respiration,

Table 25 Engneering.detiiton of some envirormerta

conditions

Cention acceplor

‘Absent

Asrobic OX

Anois AK

Anaerobic AN Ozsnd NO,

NO. rao tate (NO; pee NOD

While the absence of oxygen is referred to as anoxic

(without 2) oF anaerobic (without ait) by

microbiologists, engineers make a distinetion betwoon

UMese (Wo conitions. Thus, in the absence of oxygen,

the presence of absence of oxidized nitrogen (nitrate or

niuite) is referred io as anoxic and anaerebie conditions,

respectively (Table 25),

22.82 Temperature

‘Temperature has s significant effect on the growth rate

of microorganisms (Figure 2.15)

Geom rte

oo» 2 @ w wo w

Temgertre (C)

Figue 245 Efect of temperature on microbial growth rate

(edapted from Pittman and Mecary, 2901)

Those operating ct higher temperature range have «

higher maximum growth rate than those operating al ¢

lower range. The opiimal range of temperature for each

emup is relatively namow. With an increasing

temperature. a gradual mmerease in growth rate as

observed until on abrupt drop is observed due to the

denaturation of proteins at a higher temperature. ‘The

generally used toxms to deseribe these microorganisms

tre psvehrophile helow about 15°C. mesophile for 15:

40°C, henmophile at 40-70°C and hyperthermophile

whieh are active above 7°C up to around 11G°C.

23. STOICHIOMETRY AND ENERGETICS

23.1 Theoretical chemical oxygen demand

(thCO0) and electron equivalents

The chemical oxygen demand (COD) determination is

commonly condcted in laboratories and anvelves the

conidation of crganie compounds in tho presence of an

acidic dichromate selution heated at 150°C for 2 hours.

The mura

test is expressed as oxsizen equivalents in ¢Q3in’ (or

mga

1 of electrons donated by dichromate in the

‘The lection equivalents of exygen ean be

determined hy noting that | mole of O; weighs 32 g and

contains 4 electron equivalents (2 O molecales * 2 10

molec). Thus, 1 electron

corresponds to 8 gof COD Eq. 27)

equivalent (eeq)

Teey =8 COD 27)

Considering that orzamie matte i an electron donor

while O; is an electron acceptor, dissolved

considered to represent negative COD (Eg. 2.8)

1g0;=-1 COD 28)

The theoretical chemical oxygen demand (UhCOD) of

a substrate can be determined by ‘siting a balanced

equation in which Oy is added and the compound is

‘mineralised to end products with ammonia remaining in

its NH (11) osidation sate. The theoretical COD may

deviate fromm the measured COD when a compound is

nt reaeing inthe COD test

Bq 2.9 gives generalised equation for this purpose

The equation refers to the thCOD of aC. HN. O

contiining subsuate (adaplel from Rutunana and

MeCarty 2001)

CH ON ©

2n 10.50 I.Se-B)O; >

nco, +exHt +2 0

29)

and

ico neigh BA2OSE= 15M) 16

Tine sT6h= He

19

For exemple (Fa 2.16), the mineralisation of glucose

ives,

Gylt,.0q +005 +000, +0H,0 so

180g 192 °

This. 1g elteose represents 1067 thCOD

(192/180)

Considering that 8 g of Os corresponds to 1 ea. |

mol of glucose donates 24 veg. Thus, removing O, from

the above equabon, adding 24 elections as products of

the reaction, and as many protons ({I") for change

balance, and water for & balance gives the following

half reaction equation (Pg 2.11)

ea

CH Op + 6HD->6CO, + 34e 4 24H

For 1 629, Eq 2.11 becomes

Leu

a

22.149 400, +6 +

aca

A. Similar approach can be used for election

aceeptors. For oxygen this gives

02503 +11 +e -¥0511,0 13)

‘Summing the ebove to equations again gives the

ful reaction equation for glneose

Similaly forthe transformation of nitrate to nitrogen

20s (denitiication), the ewiation stale of nitrogen is

reduced froma +V 19 0.

HINO, 45H" +50 05N, +310

‘The COD equivalent of this rwaction is 5 eax/anol

gCODIeeq = 40 gCODImolHNO, = 286 ¢CODINO

N As electrons ate accepted and not dantled, the COD

‘cquivslent of | g of utrate-nitrogen i thus minus 286

COD (2.85 gCODZNOSNY = 401C14 gob,

\Wating equations with neutral or charged molecules

does not change the number of electron equivalents of «

reaction as the number of protons (H') will be adjusted.

20 Biclogkalwastewater Testrient Prncples, Modelling ad Desig

Table 26 Theretcal COD} various compounes by weicht

Compound ‘Weight

(vss)

Chemical formula = CHON. = Chvt Nit Phot thCOD. CODIVSS

«g/mol or ow (2) Gime) egy

Biomass

ALON 113 33 2 0 190 1a

CHONP i 1a 2 2 22 wo va

Co ON? 13 2 2 23 1960 146

Cu: O:38 aL 55 1 0 193 Lae

Cul hyON 393 58 4 0 560 1a

Cx anion 960 50 10 Bt 18a

cto, 6 56 o 0 us 167

Organic substances

Casein Coltg0.Ns 1s 2 15, o 256138

Averageormnies — CylhyON 393 35 4 0 360) 1a

Carbohydrates CHO. 22 a ° ° a0 13

Fats. als GOs iM n 0 0 22 203

Oils cleieacid ClO» 254 85 ° 0 88 36

Proteins CullsO.N: 320 3 9 0 34120

Givcose Cattn0s 180 40 ° o w2 107

Formaie Ch0: 46 % o 0 16 0x

‘Acetate cto: 0 «0 ° 0 ot 10

Propionste 0, 4 " ° 0 112 151

Batyrate Cato: 8 3 o 0 160 182

Methane oly 6 8 o 0 64 4.00

Hvdeozen i 2 : s - 16800

The theoretical COD of a number of compounds is et, Open sata Seany

presented Table 26. Various biomass equations ve trae

URCOD to dey weight ratios varying botween 1.37 and

1.48 gCODIgVSS, with 142 being considered typical

for municipal biolegieel wastewater keatment

For sulstates, however, the thCOD'VSS ratio varies

really according to the degree of reduction of the

substrate. Ratios range between 0.35 for fomate, &

highly oxiized substrate, to 409 gram COD per gram

substrate for methane, and to 8 gram COD per grat for

hydrogen An average municipal wasiewater would

have a wypival COD to volatile solids dilteed plas

particulate) of 1.2 pCODIeVS,

232 Cell growth

Cell growth in a bateh test is characterized by four

phaser during which the substrate and biomass

ceanceatation evolve (Figure 2.16)

ancertetion

Figure 216 Biomass growth in batch mode (adapted from

-Meteal& Ede, 2003)

“The four phases are

(UL) The lag phase during whieh there is litle biomass

imereare and lite substrate consumed as the calle

‘acelimate to the new situation,

2) The exponential growth phase follows dung which

the biomass grows at 8 maximum rate consuming

much of the substrate which is readily availble

(G) The stationary phase is nest during which litle

extemal substate 18 available and the biomass

‘concentration remains relatively constant

(4 Finally, the dosoy phase is associaied with biomass

decay due tothe consumption ofthe intemal carbon

and onorgy

‘due o predation and vais

evens for ils mainlenanes needs, ad

‘hese growth conditions may be found in wastewater

trcatment plants at start-up (lag phese), in highly loaded

plants or the fiont part of plug flew process (exponential

srovth phase), inthe mid and end section of «plug ow

process (stationary phase) and ina facultative lagoon or

saobie sludge digester (decay phi).

233 Yield and energy

23.3.1 Energy rom catabolism

Microbial metabolism requires energy for cll synthesis

Depending on the elestton acceptor and donor couple

and the associated energy production, a sarying

proportion of the electrons available {fom the election

onor will be available for biomass synthesis. For

example, aecobie oxidation of glucose generates much

more energy than the transformation of ghicose into

methane explaining why the cell yield of the fis!

reaction is greater than tha! of the sevond, Divenergeties

provides a tool to quaniily the amount of enensy

available for various bologisal reactions which ean thea

be used to determine the biomass viel afa reaction

Energy product

oxidation and reduction of chemicals available to

tictoorganisms. In « given seeetion, the eloctron donor

GED) is ovidized while the electron acceptor (FA) is

reduced, The eestton donor is considered to be the high

energy substrate or "fac" of the reaction and a ange

variety of compounds

acceptor, conversely, is an oxidized form and # more

limited number is available for biological systems

(mainly oxygen, nitrate, nitrite, ron (1), sulfate, carbon

dioside,

on by ertabolism depends on the

Play this role, The electron

The change in Gibbs energy (AG) is a useful

property of a hick

chameterzes the maximum amount of enexgy (Work)

thermody namie reaction

obtwinahle for a given reaction. The supersript

innicates that the ccmpounds invelved are at standard

conditions (1 mole, 1 atmospher

biological processes often the standard Gibbs energy is

given for pl 7, which is thon denoted by adding s prime

() 10 the symbol for the Gibbs energy. Some half

reactions for biological systems and Gibbs energy

changes per electton equivalent (AG? kllesq) ate listed

in Table 27,

) ang 25°C. For

In combining electton donor and sleetton asceplor

reactions it should be noted that all reactions in ‘Table

2.7 are presented as clectron acceptors with the election

fon the left hard side. ‘Thus, for an electron donor

reaction, the reagents and products of the reaction

should be exehanged and the sign of the Gidbs enerzy

change should be chan

I the et sesction results in @ negative AO", this

‘means that energy em be released and the reaction ean

‘occur spontaneously, an energonie rexeion, Comversely

if the net reaction results in a positive AG°, energy

input would be needed forthe sexetion 10 take lace and

‘ill not cour spontaneously, an endergonie reaction

The energy available from the transformation of

sslucose (election done) by aerobic oxidation (with 0.

fas elsctron acceptor) and by methonogenssis (with

cerbon dioxide as electron acceptor) is ilusirated a

Table28.

These 190 osiatien reactions of glucose illustrate

Unt aerobie metabolism proves nearly 7 times mere

energy than angerobie methanozencsis, Consequently

the cell yield would be expected fo be much higher with

‘oxygen than with carbon dioxide es electron acesptors.

Other biological seactions ae illustated on Figuse 2.17

23.3.1 Synthesis fraction and biomass yield

A portion ofthe eleeron-dlonor substrate is used for ell

synthesis (f? trae synthesis faction) and

enerey production (true enerey fraction) (Figure

2.18) On an election equivaleat (ee) bass, dhe sum of

1 plus £? equals 1 The election balance, and ths the

is maintained,

ne ret foe

ayy

2 ological Wastewater Treatment Frincipls, Modsng ave Dei

Table 2.7 Haltcesctions fr biological systems (Mca & Eddy, 2003") (unt for Gis pe electron equveent’)

Parameter Thltrescion ae Ta,

Reaetions for Basel cell synthesis (Ra)

Ammonia smiragen Leo, eOse hay

Wee a egopsehu;o a1)

Nitrate ws sivozen Scope L Nop edb ee = LC yHOyNUL 0 45)

ents er let aces (B) :

Ninte NOR +50 40 EN 4340 328 G1)

Nitrate ING faite -4yrfo née 2.19)

Sulfite bso +$ur' +e sfilsr fis dno 360 02D)

Sulfate bso} +H +e pastas theo 127 2)

e ton oid (ete L050 4 =4en+4in0 wan em

Fermentation)

eats fer eesti dons (Ra

Organic donor (heterotophic reactions)

Domestic wastonater Zoos Lainy econ se —LeytyoweRno M80 228)

Proteins $024 Zirh oe = Le ystizOngruo 222 G2)

Formate LHCON+H! be = LHCOO +4430 4807 25)

Gimore C0, 61745 = Heath 06440 4196 220)

Cartonyarates Leo; +H se Lenortio 41m 2p

Methane feopet ae shoot thio 3731 a2

Pynvate 400; +4, HCO} +H +e =henwocoe+gHo 3578 G29)

Ehanot Ecos HT +e =kcnscnsonetio 3179 230)

Propionate HC0,-+ ROO; +H +0 = henencoosgi 3791 Gah)

Ace Yeo, L203 oar 46> = Jeni 00" hi1,0 2768232)

Inorganie donors autotrophic rections)

eter 74400 GM)

4x0; +1 oe 4015 235)

fu; ofa ais a3

$05 fir ee me ax)

pooh +48 was 38)

hoor 4e 2128 2.39)

Loh base also 4810 2130 G4)

preparer eh ar aan

whee ody sae 242)

$50} ar 40° as0f- +0 4 ee)

Taped iow Notary (97S) and Sanger oral (904) Reavans and prods a ma DUNE SER HE] TOA

Table 2.8 Energy avaiable rom the transformation af sucose

Kerabe pnichtion of glucose “Annerobie oxidtion of plucose(methanogenes)

ED: glucose o COs EA: 0: 01,0 SGT ED; glucose to COs: FA: CO, 19 CH, ao

8 dveeq) 8 die)

Lo 1 Ley «

Donor Lovo, 41,07 400,40 +e 4196 O;+i +e 81.96

BONO

1 1 1 lon at

Accepior: 40,447 +e 4 41,0 7814 Acceptor 400, +1 +e a Len+tno 2

a a eg

hd 40, -+400,1409 120.10 Nee Legit 0, ~ Len, +400, W78s

G9 FOG 2 ge

(On 1 mole basis for glucose the net equation ‘Ona I mole basis for glucese the net equation

‘wail hecome (+ 2) ‘aeag_ecomes + 2): 438

Cyl 0, 460, <6C0 4611.0 Cig = SCH + CO,

05° wureeny

os sit

° yheg

EEEES

a Eibe

Fiqure 2.7 Energy scale for redox couples wth glucose 2s electron donor (dapte¢ from Rittmann and McCarty, 2001)

24

The active bacterial cells generated by growth using

the imal election donor then undergo decay du wo

maintenance, predation and cell Iysis. Daring deesy’ ©

portion of the active bacterial cells become the electron

donor to generate more energy and more reaction end

products. “The global split of electron equivalents

between votive residual eetls (fe observed synthesis

faction) and reaction endl pmduets (observed ene

fractien) remains equal to 1

fafeel

‘The fraction f? ane f,c0n be expressed in mass units

rather than on sn eeq basis, and are then called tre

yield (or maximum thcorelial yield, Y) and observed

viold (Y..), respectively

The fraction f.” ean be used to estimate the te yield

Y

ya 46

5, °

whe

M, sam cells per empirical mo) of cells

8 number of gram thCOD por eog (eee hall

reaction Eq2.18 in Table 2.7)

a number of eeg per empirical mo} of cells

With CaL-O2N as the empirical formula for cells the

molecular Weight is 113 ginel. Wilh ammonia as dhe

nitrogen source for its synthesis, there are 20 eq per

empincal mole of cells (Table 27, reaction Bq 2.18)

and the above equation ean be simplified 10

ye

TR eConaols

40-706

aan

where the ratie of 142 gram COD per gram cells

\wasalio callated in Table 2.6

Similarly, f; can be used t estimate the observed

yield,

eg)

ray proauctien

te te a

f fe peat

+ Bastien

“ise

° skit

f 1a

resist

‘ale

Figure 218 Use of electron donor for energy Eroducton ane

call syathess, Note: action of electrons doaated : enerzy

‘synths (adapted from itt and McCarty 200%)

2333

If an empirically balanced stoichiomeitie equstion ean

be obtained for biomas! syethesis from a given

wastenaler, the biomass observed yield canbe

ealeulated. Using the protein casein to represent

‘wastewater in laboralory experimentation with activated

sladgs, Borges ef ul. (1956) propesod the following

equation

observed yleld from stoichiometry

Cl 0583 +30; >

CHAO. +NH, +5005 +10

bacterial cells

2.49)

seep » | om 7m iw

wiecain | 100 D6)

econ 12-100 | 139 ooo

cop 26s | wo

‘nts, consuming 184 g of casein requites 95 g of

oxygen and produces 113 g bacterial cells and other

reaction end prodults, Similar proportions Would be

expected for a full-scale wastewater treatment plant

Ureating this compound (which 38 of comparable

composition Io sypieal domestic wastewater), The

biomass true yield (Y) 1 thus, (61 g biomass per g

substrate consumed (= 113/18), Note that the mass of

products equals that of reactants (280 g/mol of ease

consumed)

On 2 COD has the THCOD of exsein being 1.36

gCODIgCasein (Table 2 5) gives 256 gcoD/melCasein,

find the UCOD of bacterial cells of composition

CHENO, being 142 gCOD/gVSS, gives 160

gCOL/molCells, The observed syrthens faction (fis

tus 0.62 gCODIgCOD (0.61x1 42/1 39).

The oxygen requirement is 96 g Os per mole of

caiein eonsumel, eorespording 10 052 gO./eCesein

(9/184), Thus, the energy production fraction (f,) 1s

0.38 g COD of Os per g COD of casein (052/139),

Note that oxygen has « negative COD (-.0 gCOD/20;)

and the COD balance is maintained.

Spt he =0.02 +038

oo 2.50)

The expenmentally reported observed (and not

‘rue") ayathesis fraction (f) of 0.62 i quite high in

comparison to ether values published in the literature

for wastewater treatment, This. the trie synthesis

faction (/") should orly be a litte higher and the cells

were probably close to their exponential growth passe, &

condition in which the faction of energy obtained trom

erogenous decay is minimal, Indeed, using the

methodology presented in the next setion, and the hal?

cote in

Table 27 fer protein, which has a very’ similer chemical

siveture to that of easeia, a tue svutbesis fraction (9)

ff 064 ean hecsloulated

reaction and fee energy change value pre

The nitrogen and phosphonis requirements for eel

towth can be evaluated by considering that they

constitute 12.0 and 2.0%, respectively, of the volatile

fraciion of the biomass progueed (the CHON traction)

fas con be estimated in the empirical equation

CAHNOWP), (Table 25), In the above example, for 113

fg of biomass produced (corresponding to 184 g of

ewsein dexraded), 13.4 g of nitrogen would need to be

added cither from organic (eg casein) of inorganic

sourees (e ammonia, Similarly, 2.26 gf phosphorus

‘Would need to be added por 113 g of biomass prodused

234

Bioenergetics can be used as an aemative to

conducting careful laboratory seale experimentation to

determine the uve (Or masimun) yield of a reaction

The approach presented belove is adapted from that of

Metcalf & Eildy (2003) which isa simplifiation of that

bf Rittmann ané McCarty @001) which vas recently

Updated by MeCarty (2007), An allemative approach

has heen developed by Heljnen et al Gn preparation)

True yield estimation from bioenergetics

Which mainly differs fom the above ones in its

25

ceimstion of anabolic energy need by an enersy

dissipation funetion instead of en efficiency factor.

These references provide additional details to those

presented below for the development of other halt

reictions and their free energy changes, complex

fermentation reactions, autotrophic reactions and now

standard conditions,

Te simplified procedure presented below is divided

ino 4 steps which consist n deterraining, (7 the enensy

provided fica catabolism knowing the electron donor,

the electron acceptor and the source of nitrogen for

growth, (i) the energy needed for cell synthesis

(anabolism). (i) the energy needed for the overall

sg1wth sesction (metabolism) end (é) the teue yield (Y})

coefficient

AA. Energy providing reaction (catabolism)

The methodology to develop the reaction and associated

Gibbs exergy production for the catabolic reaction oF

the electron donor (ED) and eleciton acceptor (EA) was

presented in section 2.33.1, The method of Ritimen &

MeCarty (2001) assumes that only a fraction (40 to

80%, typically 60%) of the energy availsble from an

osidationsreduction reaetion is used in the anabolism

‘while the est Jost as heat

Way =p

where

Gos Gibbs energy available for etabolism from 1

12eq oF ED (iceg)

K fraction of energy transfer captured (typically

060)

AGiy Gibbs energy released trom 1 eey of ED

ehsio09)

8. Energy needed jor call

14°C. Moreover, 2 sludge age of 3 day’ is around the

limit of validity for the steady’ state activated sludge

model because al sludge ages ower than this the

assumption that all the biodegradable organics are

utilized isnot valid. So there is hitle merit in developing

empirical methods for estimaung the peak oxygen

emaral for fully arabic systoms without nitefiation

49 DAILY SLUDGE PRODUCTION

‘The mass of sludge produced per day by the activated

sludge system is equal tothe mass of stulge wasted per

day from it via the waste flow and is called waste

activated sludge (WAS) of secondary sludge From the

definition of sludge age (ave Eq. 4.1), the mass of

sludge TSS produced per dav FX; 1s given by the mass

of sludge in the system MX; divided by the sludge age

FX, = MX, / SRP (mgt'ssia) 4.33)

Substituting Eqs 412 and 4.17 far MX; and

simplitving, Vields the sludge produced per dav per mg

COD load on the biologisal reastor, ie

A Sou" foun

(1 bg SRE 7

f

1+ Spb SRT

(mgT'SSid permgCOD 4) (4.34)

A plot ofthe daly total shidge mass (TSS) produced

per unit COD load on the biological reactor (Fg. 4.34)

versus shudge age is shown in Figare 46 for the

example raw and setled wastewaters It can be seen tha

the mass of sludge produced in the activated sludge

rent Principles, Modelfng a Desi

system (per unit COD lsd on the biological reactor)

ecteases as the sludge age incteases for both raw and

settled wastewater but the rate of decrease is negligible

at sludge ages longer than sbout 20 days, ‘Treating

sett wastewater results in lower secondary sludge

production pet unit COD load on the biological reactor

than treating raw wastewater. This is because the

Uunbodegradable partizulale COD fraction (fyyg) and

Inorganic content (XpyS\) in seitled wastewater ore

significant lower than that m raw wastewater

ude production

(WsT3S/aper COD‘)

stage age)

Figure 46 Daly sludge production in kgVSSI¢ ard kaTSS/ per

rgcO0 lend per diy on the bilagjcal peattr fer the example

raw and sted weatowater t

Temperature effects on secondary sludge production

are stnall = sludge production at 14°C is about 5%

greater than at 22'C, a difference which is completely

masked by the uncertainty in the estimaies of the

‘wastewater characteristic fy and the VSS/TSS ratio (f)

tof the shadge if the influcat ISS concenteation (Xia) is

not measured

Although the secondary sludge production treating

settled wastewater is lower than that weating 1346

wastewster, the total sludge mass treating settled

uasienater is higher because the total slulge production

Includes both the primary and secondary sludges, at

plants treating raw wastewater, only secondary sludge is

procuced

In the system sreating raw wastewater, the primary

sludge 18 in effect treated in the setvated sludge reactor

iteolt, From the COD balance, the moze oxygen that is

utilized inthe system, the lower the sludge production

tnd the lower the aetive faction of the sludge (Figure

43B,C). Therefore, because the carbonaceous ox gen

76

sludge age Also, the settling tank sueace ate,

underflow reeyele ratio and aeration capacity must be

accurstely sized for the particular wastewater and

sludge age ofthe system. I these aspects are catered for

adequately, then with hydraulic control of the sludge

age, plant contol is simplined and, on small se

plants, may even do away with the requirements for

solids and SVI tes except st long intervals, Hydraulic

conttl of shulge age makes parameters like LF and

F/M redundant and introduces an entirely different

attade to system control, It is eminently practical and

establishes the desred sludge age to ensure all year

roured niification When nitrification is « requirement,

sludge age control becomes a requirement. and then

hydraulic control of shidge age is the easiest and most

practical way to do this Moreaver, with hydraulie

contol of sludge age the mode of faze of the plant is

completely different than with solids mass control. With

Use solids mass contuol the plat fails due te nitiication

stopping and 4 high eiMent ammonia concentration,

rnon-visible dissolved constituent which sls is dificult

to remove by other means. With sludge age contol, the

plant fails more obviously - studge aver the secondary

setting tank eiflnent weirs At plants an

levels of technical capaeity, this is more likely wo

prompt remedial action

ped with lowe

4st SELECTION OF SLUDGE AGE

Selection ofthe sludge cge te tbe mort frndamertal end

Important decision inthe design of an activated studge

“ostem, The sludge se selected for a plant depends on

‘many factors. some of which are listed in Table 45 such

as sability of the system, sludge sctleability, whether

or not the waste sludge should be suitable for direct

discharge to drying beds, end most important of al, the

quality of eMuent required 1 is COD removal only

aeceplable, must the effluent be nitrifed, is nitrogen and

phosphorus removal required Several of the factors

have alieady been discussed earlier and will net be

repeated hee Only a few clarifying and aeitional

ccennmetis on Table 4.3 will be made below

att Short sludge ages (1 to days)

4att1 Conventional plants

These plants are operated in the conventional

configuration Le. @ sem plag flow configuration, but

‘modified systems sich as contact stabilization, step

acration, slop feed and others are also implemented.

Short shudge age plans have been extensively used in

Europe and North America before N (and P) removal

beceme requiremen's. Their main objective is COD

removal only, for Which sludge ages of | 40 3 days are

sufficient. BOD, or COD radvetions range from 75 to

‘90%, The removal achieved depenils on the wastewater

characteristics, the opsrition of the plant in particular

the management of the transfer of the sludge between

the reactor and SSTs and the efficiency of the STs

Because predatory activity of protozoan organisms on

the free swimming boeteria is limited at short sfudge

ages, the non-sellling compenent (or dispersion) ot the

activated sludge floes is high which causes turbidity and

high eflluent COD (Chao and Keunath, 1979: Packer e

al, 1971),

Ii is accepted in Table 43 that short shalge age

plants would not normally nity. For temperate and

high latitude regions, ssheve wastewater temperatures

are generally below 20°C, this would be the case

However, in wopiced and low titude regions, where

wastewater lemperatares can exceed 25 te 30°C. short

sla

ize systems Would norway aitily. in fat, t would

be dificul to atop

fs best to accept milrfication as inevitable and design the

advaniageous (0 inelule 4 small primary anoxic. zone

(-15.20% anoxic mass fraction, sse Chapter 5) in the

system 10 denitily a consideruble propartion of the

nirate generated even if N removal is not required - this

increases the minimum sludge age for mitnficaien

ree

the risk of sludge Hlotation end high eitluent COD due

tification on the SST bottom,

mn doing so For these sitnations, it

sovordingly, Furthermore, it would be

‘onygen demand, recovers alkalinity and reduces

iological P removal is possible ot short stulge ages

of 3 to 5 days - the phosphate accamulaing organisms

(PAO®) are relatively fast growing heterotrophs. In the

absence of nitrification, an unaerated zone Would be

anaerobic (i. no nittte or ony'gen present or catering

it) and provided the readily biodegradable (RI) COD

ard short chain Faty acids (SCFAS) are avaiable from

the influent. biological excess P removal will take place

The eriginal Phoredox system developed ty. Bamard

U6) is

vases on such af reactor sngerobie-serohie

The minigun sludge age for EBPR is

temperature dependent, inctetsing ax temperature

decreases and 38 around 5 w 5 days at 14 tw 20

(Mamsis er al, 1992) At these temperatures, the

‘minimum siudge age for nitnhiestion is signitieanity

longer than that for EEPR, s0 that nitifeation generally

‘would not ke place with the result tit te adverse

cffeet of trl on the ERPR would be abieat

However, in warner climates the minimum sludge age

(2°) sluge treatment. These plants therefore treat raw

Wastewater and the sludge age is chosen so that the

active fraction (or residusl biodegradable onganics) of

the waste sludge is sufficiently low to allow ats direct

discharge to shulge drying beds, The siudge age

required to produce sludge suficinlly stale s0 as not

to generate odour problems is uncertain and will depend

oon the temperature and climatic conditions, 'e. whether

for not the sludge can be dried sufficiently. quiekly

before it starts smelling. probably exceeding 30 days.

Interestingly, from a auvey of the residual

biodegradable organics in wastewaier suudges treated by

different sludge stabilization systems, Samson and

Hkama (2000) found that aerobically digested waste

activated studge contained the lomest residual

biodegradable orparies (10%) compared with wel air

oxicized (Zimpro) and amerobically digested primary

sludges (25-60%, Figure 410),

5 ‘le

§ >

do

Figure 440 % residual biodegradable organics remaining it

sublised wasteweter sugges ested with diferent

Stablizaton stem types. 00 Primary sledge; VFA: vlaile

fatty aids; WAS: waste activated shidge) Legend: G) Rise

tunettiod wartawater, (3) Zinpro hurmus + 40 hg eluble

(C00, (3) Ancerobically digested 0 + WAS = high VFA, (3)

AAraerebialy dgestad 10 only high VFA (5) Anaeroticalls

digested 1, ss tape - low VFA (3) Zimpro umes + 10 Ie

‘able C00, (2) Anseroblcly digested to, and stage. low VEAL

(6) DAF thickened WAS, (9) Aneerobcal digested 0 » WAS,

Single stage-low VFA and, (0) Aerobcally dgestea was

4.132. Anoxic-aerobic plants

(Once the sludge age exczeds 20 10 25 days, nitrification

fs inevitable and i advisable for reasons cited above

to incorporate denitrification in the system, which at

these long sludge ages would not atfet the stability of

nivilicaion, Furthermore, ifrequired, EBPR also can be

incladed for litle ext cost. Infact, biological N and P

removal are significantly greater with raw wastewater

than the settled wastewater due to the higher organic

load To include N (and P) removal, the reactor is

rent Principles, Modelfng a Desi

subdivided into unaerated (anoxic snd amerobic) and

farated zones na variety of configurations

Denitrification takes place in the unsersted but mised

zones receiving nitrified mixed liquor via recycles from

the aerated zones to give the so-called rirification

denitrification (ND) systems. The ND systems include 4

stage ardenpho, which ancorporates primary and

secondary anoxic reactors, Modified Lutzack Ettinger

(MLE), which incorposaies only a primory anoxic

reactor, Orbal, Carousel and oxidation ditch systems in

which the anonic zones created are olong differen!

lengths of the same long channel reactor, of an

Iermittently decanted extended aoration (DEA)

systems. While incorporation of demtnfication imposes

some additional censtraints on the design at long sludge

age, these are minor provided the aeration eapacity of

te plant is sufficient to ensure efficient nitifieation

under ll expected conditions (see Charter 5)

4.153, Anaerobicanoxic-aerobie plants

‘When the EBPR is required, an inital anterobie reactor

fs inclided inthe configuration that receives the influent

wastewater but minimal oxygen and aikae via the

sludge reeyeles. For FRPR, assurance of 1 ze10 nitrate

discharge to the anaerobic zone is critical for achieving

good P removal and is an additional constraint on the

design when including EBPR in extended aation

systems. The extent of EBPR achieved will depend on ¢

number of factors, mainly the amfluent readily

biodegradable (RB) COD concentration, the TP/COD

ratio anf the degree to which nitrate can be excluded

from the anaorobie reactor, which depends on the

influent TKN/COD rato.

‘The waste sludge from extended aeration systems

including EBPR bias the potential to release high P

concentrations, This can be dealt with in specially

designed dewateringlckying beds with sand filler under

drains and weir overflows, which allow the drving bed

faho 10 operate as a dewatering system. While

discharging waste sludge directly tothe drving bed, the

under drain and overflow are monitored for P

concentration and when this gets to say $ mgPA, sludge

wasiage t the drying bed and the return oF supernatant

to the head ofthe works is stopped. The relatively small

volume of high P iguor that drains from the drying bed

thereafter is ether chemically treated or irrigated at the

plant site. The dewatering capability of the drying bed

Allows significantly more sludge to be discharged to it

tina drying beds without these dewatering features,

86

ological Wastewater Treatment Frinclpls, Modsng ae Desi

‘ibrevaton _Descigtion

ADWE ‘Average dry weather low

AS Activated slge

wo ‘Biologia! oy gen demand

BNR. Biological nutrest removal

cop Chemial exygen demand

Dsvi Dilued sludge volume index

Do Dissolved oxygen

EBPR Enhanced biological phosphorus removal

Ess. Event suspended solids

EM od to microorganisms ratio

HRT Hydraulic retention time

FSA Free and sine ammonia

IDEA Iniemmittertly decanted extended aeration

Iss Inorgaate component oF he vetleable solids nays

Ur Load factor

MLSS ‘Maxed liquor suspended solids

MLvss. Mixed liquor volatile suspend solids

Ons Onlinary heteretrophi organisons

ND [Nitnifieationstentifieation

PAOs Phosphorus accumulating o

PE Person equivalent

Pst Primary setling tank

Pwwr Penk wet weather flaw

RBCOD ‘Readily bodegracable COD

SRI Sludge retention time (hudge cee)

ss Suspended solids

ss Sewendatysetling nk

sv Sludge volume index

sv Settled volume

SSVI Stired sludge volume index

TKN Total Kjell nitrogen

rss otal suspended solids

VEAe Vote fty acids

vss Volatile suspended solids

was Waste aetivaed sludge

=e oe

Ou, “Aribenivs temperature ccelficient for the endogenous respiration ate ofOHO: —~

2 Secondary soting tank diameter m

90

takes place, it will he nearly complete (provided all

ner requirements are met - see below) but the

smmenia concentration is nol readily reduced to 2er9

523

tis generally aecepted that all organisms undergo some

form of biomass loss due to maintenenes or endogenous

energy requiten

biosnass fase

iis VSS decreases and it continues to utlize oxygen

swith This process is called endogencus

respiration. Different organisms have different

cendogsnovs respiration rates Por the OWOs, it is quite

high (buss = 0.24 Md), whereas for the ANOS it is low

(by = 0.04 /4). ‘The endogenous respiration process

for the ANOs is modelled in exaetly the same Way as

tat fer the Os, i.

Endogenous respiration

nis. This behaviour manifests when &

pletely utilized its extemal substeate

Mba (mgANOVSSA) (59)

bee specific endogenous mass loss rate for nitri-

fers at I'C, (mgANOVSS/mgANOYSS d)

53 PROCESS KINETICS

The basie activated sludge system modelled for

nitrification is the single cempletely. mixed reactor

system wilh hydraulic contol of sludge age (see Figure

42) This systom unler steady state conditions provides

the information necessary for desig

The principal steady’ state solution required for this

Us eMuent ammonia coneentration (N,.). This solution

forms the basis for the analysis of the ritsfieation

process behaviour and provides the information for the

design of an activated sludge syslem including this

process. This information is sutfiient to

understand the modelling of the nitnfisation process in

activated sludge simulation models like ASML

53.1 Effluent ammonia concentration

‘A mass halance on the change in ntrfier mass MAX),

over the completely mixed system at steady state

(Figure 45) is given by

MAW gg —Py AN =

=A Mindy Pee N al A ~ LagOor tt

Kas *¥a ’

(mgANOVSS)

where

Vp reactor volume (I)

Qe waste Sudge How rate from the reactor (le)

Dividing ty VAI yields

Mg Meare bpp SEA 10)

or 7

At is zero and from 4, 4.1, Ow/V,=

Substituting these and solving for the reactor

‘ammonia concentration (Nand therelore also fora the

definition of completely mixed conditions, the elfluent

rnmonia concentration (Ni), yields,

Ky (bgp + VSRE)

Fans = bap #U SRE)

(oop) (5.11)

From 1g 5.11 on QS) in

the reactor and eMThent (N,.) are independent of the

specific yield coefficient CY.) an the influent atmimonie

concentration (N} Using pyoo = 0.33 J and Ko

mgQ/ at 20°C, aud taking bay = 0.04 /0 (Table 5.1), &

plotof Pq $11 withN,, verse sndge age SRT is given

in Figure 3.2. At long Sludge ages Ny 8 very low and

remains so until the sludge age is lowered ta about 4 d

Below 4 d, Ny ineresses repilly and in temns of 1g

5.11 ean eseeed the influent FSA ecnsenteation, Ny

This leary isnot possible so the limit of vakidity of Eq

the ammonia concent

Table 5 Kinetic constants and ther temperature seritity for autotrophic nirler organisms (AND) accepted in mest activated

shelgemodels

Gate constant Saal Ta Aa a

‘Yield coeticieat Ye meVSNinaFSA 010 100

[Bndogenous expiration rate ba a oot 1029

Hult saturation coetvient K, mgFSAl 10 Lis

Masimmum specific gowth rate ia a vanes Lis.

94

sensitive 10 flue Unless a sufficiently Ine serohie

sludge mess fraction (Infuy) 18 provided, nitification

will not take place and censequenlly nitrogen removal

by denitrification is not possible. Infact, the selection of

the mascimum unaerated sludge mass fraction to achieve

rear complete nitrification and 2 required degree of N

removal is the single most important decision that is

made in the design of the BNR aetvated sludge system

because it defines the system sludge oge and, for «

selected reactor MLSS cencentration, also the reactor

volume

om

oe | pense wc

i

sg | sont te

4 os

yon %

i me

2

Figure 53 Maximum unaerated sludge mass traction reqivee

to-ensureritsifcation versus sludge age fr masimum speci

growth rates of ries an OF 0.25 10 0.50}8 aC 14° Fr y=

135

From Eq. 5.15 and 5.19, it can be shown that for

constant flow and ammonia loa (Le steady state

contions)

Nag = Bt 8p-D) (ment) 620)

From Fq 520, Sci selected at say 125 or greater

at the minimum wastewater semperatie, the eMuent

ammonia concentration (N) will be lower than 2

InFSALNA at 14°C for Kao 10 mgNA, Although Ky

is higher at higher temperature, N, wil decrease with

increase in temperature bevause a constant. sludge age

Se inerenses wth increase i har Consequently, for

design the lower expected tempersture shouldbe

selosted to determine the sludge age and the aerobic

mass fraction, If this s done, using say 8/= 125, then i

con be accopted from Kg. $20 that tho effluent

ammonia concestration is below 2 mg/L a the fowest

temperature and around 1 mgNiT at 20°C, In this way

eoplcly calculating N, with Eq 5.15 1s n0t necessary

beceute provision for nose comple nitfisation bas

rent Principles, Modeling a Desi

been made by selection of 8 Cleany selection of the

Hayao and Sp Values has mujor consequences om the

effluent FSA. concentration and econcmies of the ND

activated sludge system,

‘Maaimum allowable unaerated mass

Iraction

543

The equaviens shove allow the (0 most important

‘cisions inthe design of an NDAS system to be made,

the maximum unsersted sludge mass fraetion and

sludae age to ensure near complete nitrification

Evidently from Figure 5.3, for fans > 080° the

lutaersted mass traction at 14°C can be as high as 0.7 at

1 sludge age of 40 days. Such a high unserated mess

faction is apparently also aeceptable at SRT = 10 days

or longer at 20°C

However, there are adiitional considerations that

constrain the unserated mass faction - cudge age

selection:

1) Experience with laboratory seale ND (andl NDEBPR)

‘stems have shown that at unaerated mass fractions

greater then 0.40, the Dlamentous bulking can

become « problem, in particular ot low temperakmes

(16°C). Systems with low unaerated mass fractions

of <0,30 show greater tendency for good setting

siulges (Musvot ef ai, 1994; Ekama ef af,1999,

Tesi otal, 2003),

2) In design of BNR plants for high N and P removal

the unaerated sludge mass fraction fyp usually needs

to be high (40%). Ifthe tayo valve 1s low (< 0.40

AA, which vill be the wausl case in design where

insufficient information on the tga 1 evatlable) the

necessary high fy, magaitades will be cbtained only

al long sludge ages (Figue 53). For example,

anos = 0.35 (A, thea with S13 al Tyg = 14°C, an

fuq= 045 (Eg. 519) gives a sludge age of 25 day's

and for fyy = 9.55 a sludge age of 37 days, Long

Siulge ages require large reactor volumes

increasing SRT froin 25 to 37 days increases the

reactor volume by 40% wheress Fy increased only

22%. Also, fo: the same P content in the sludge

‘mass. the P removal is reduced as the sludge age

increases because the mass of slude wasted daily

eereases as the sludge age inereases. Consequenty,

{or Jow ftqqz9 Values, the increase in N and P removal

that can be oblsined by increasing the mscrated

Sige mass fraction above 0.50 0 0.60 might not be

‘economical dae tothe large reactor volumes this will

require, and might even be counter productive

insofar ae affects P removal. A sludge age of 30

98

highest and remains approximately constant in the pH

range for 7.2 < pH < 80 bul decreases us the pH

decreases below 7.2 (Downing ef el. 1964; Loveless

and Painter 1968; Sotemann ef ef, 2005) modelled the

Ha =H dependency as (for S 8.0 have been observed

and it hos been nosed that nitrification effectively censes

ata pH of about 9.5 (Malan and Gouws, 1966; Wild et

‘al, 1971; Antoniou er al. 1990), Accordingly, for pH1>

72, Sotemann ef al. (2003) proposed Eq. 5.220 10

‘model the decline inthe py ftom pH > 7.2 to 95 ae 4

function of j.ayr3 Using fahibiton kinetics es foltaws:

Kos ~ pit

ine Ky pel

Hanpit = Ham 2K (6220)

where

K, 13

Ke 93

Ky #03

‘The overall effect of pl on jun is modelled by

eombining Eqs. 5224 and 5.22b. which is given by Ba,

5.22c and shown in Figure 5 7,11 ean be seen that in the

range pH = 7.2 10 8 3 the change i ug 8 smal, with

Hage ars 09.

bent = Ba 9238187214, — Kms PH 05.976

Hanoi = Ham Ee

where

2330

ie eet = | forpll> 7.2,

Kna=pil

Ky men PH sop pth c72

Kee tk, =a 12

and,

Haggss— OforpH > 9.5

Experimental data from the lierature are also shown

sure 57 to peovide some quantitative support for

Fg. 52% At low pl (<72) data fiom Wild ef al

(1971) and Anioniow ef ai, (1990) fit the equation

reasonably well Very few data are available for

pIP-BS, but the few points from Antoniou er a. (1990)

rent Principles, Modelfng a Desi

show reasomible agreement with Eq, $22

Accordingly, Eq, $12¢ was accepted to calculate

4g it the pH range 5.5 to 9.5. From Eq. 522c, the

‘minimum sludge age for mirification (SRT,) at

different pH and temperature (7) and unaerated muss

fraction (fy) is givon by

Sy

MA ggts San )~bat D

ia) (6.23)

2

Faction wangi/ban?2

ie easzib

eqs

Figure 57 Maximum specific rom rote of riifer a ¢

traction of te vate at pH 7.2, versus pH oF te mixed quo

“Model prediction is given by solid tne Data from aan and

‘cous (1965) Downing el (954); Wideta. (197), Antoniou

etal (1950)

The problem with nitrification in low alkalinity

wastewater is that the plT oblained is ait known,

because it is imieractively established between the

egiee of nitrification, Joss of alkalinity. pL and wayy.

To investigate this interaction, the biological kinetic

ASMI iodel for carbon (C) and nittagen (N) reinoval

‘was integrated by Sotemann ef ai. (2005) with a two

phase (aqueousges) mised wesk acidfease chemistry

kinetic model to extend application of ASMI to

situations where an estimate for pEI in the biological

reictor is important This integration, which inchided

(CO; (and N;) gas generation by the biological processes

and thar stripping by eration, made a number of

‘additions to ASM), ine als the above etfeet of pH os

the autotrophic nitfiers (ANOs), From simulation of &

long sludge age NDAS syem with inerementally

eoreasing influent H,CO, alkalinity, when the effluent

H,CO, alkalinity fell below about $0 mgil as CaCO,

the asrobic reactor pH dropped below 6.3, which

severely retarded aithfication and caused the minumum

sludge age for nitrification (SRT) to inerease up to the

operating sludge age of the system. The simulation

where

Naw influent soluble unbiodsgratable organic

nitrogen, mgOrgN-NI| = Eg Ny Wbere Fee

{s the soluble unbiodegradable organic

faction ofthe infers TEN QM,

The two non-zero effluent TKN concentrations

PSA, Nge and OFgN, Nous) are soluble and so escape

withthe eluent and waste flow), The sluble (filtered)

TKN sm the effluent (N.)1 given by their sum,

Nie Nae + News (tered TKN) (5.33)

IE the effluent sample is aot filtered, the offen

TKN will be higher by the concentration of TKN in the

ffluent VSS, Le

Nie Naw + Nowe + FX ve

(onfiltered TKN)

where

Xn elMluent VSS concentration (mgVSSI)

f WN content of VSS~0.1

(agO1gN-N/ng VSS)

5.5.2 Nitrification capacity

roms a TKN mass balance over the AS system and SRT

> SRT. the concentration of mrate generated in the

stem (N,.) with respect (0 the influent flow is given

by the influent TKN (Ns) minus tie soluble etTuent

TKN (M,) aad the consentration of influoat TKN

incorporated in the sludge wasted daily from the AS

system (N). ie

N (5.35)

‘The N, concentration is determined from tae mass of

N inoorperated in the VSS mass harvested from the

reactor pet day (Hq. 527). The mass of VSS in the

reactor (MX,) does rot have to include the VSS mass of

nrfiers because this mass. as mentioned elie, is

negligible (< 2-49,

In Bg, 5.35, N, defines the nitifieation capacity of

the AS system. The nitrification capacity (N.) is the

mass of niuale prodused by nitiieation per unit

avenge influent flow, is, mgNOnN/. In Eq, 5.27, the

eMuent TKIN concentration @N.) depends on the

efficiency of nitnifi

maximum unaeraied sludge miss freetion (fy) at &

selected sludge age, if the factor of safety (S)) wat

selected 1.25 1.33 al the lowest expected

tion. In the caleulation for the

emperature (Ty), the efficiency of nitrification te high

(© 99%) and Ny generally will be Rss than 110 2

mgN/, Algo, with $)>1 28 at Thy, Ny il be vitvally

independent of both the system configuration and the

subdivision of the sludge mast into aerated and

lunaersted mass factons Consequently, for design

with $,> 1.28, Ny will by around 3 to 4 mgNM provided

that thete 48 reasonable assurance that the a&tUal .ae00

value will not be Test than the value aezepted for design

and that there 1s sificient aeration capacity so that

nivification is nol inhibited by an insuflisient oxygen

supply. Accepting the calculsted fy, and selected sludge

tage (SRT) at the lower temperature, then ot higher

temperatures the nitrification efliciency and the factor

of safety (8) both will increase so that at summer

temperatures (Tad).Ne Will be lower, approximately 2~

3 mg

Dividing Eq 535 by the tolal inllvent COD

cconeentration (S,) yields the nitrification espacity per

‘mgCOD applied tothe biological reactor, NS, iz

(536)

where

NJSy_nitiieation capacity per mgCOD apie’ we

the AS system (mgNimgOD}

Sq influent TKN/COD eoneentation

niuogen sequized for sludge production per

mgCOD applied (from Eq $27)

wo of te

N/Sa

The iti infu

fon capacity te cop

ceancentration ratio (N/S\) of @ system can be estunated

approsimetely by evaluating each of the terms in

3.365 follows:

NVS, This ratio 1s a wastewater characteristic and

obtained from the measured influent TKN

and COD eateenirations - i ean range from

0.07 to 0.10 for raw municipal westewater

and 010 100 14 for selted wastewater

Provided the efficient

nitrification is satisfied at the lowest

temperature (Ty). the efluent TKN at Try

(N,) will be Tow at 2-3 med

influent COD concentrations (34) ranging

from 1.000 1 500, Ny/S, will range from

0.095 1 GOI, AL Tyago Ny I=2 mgNM

raking lower the N/S, ratio

Given by Fg.5.27

Nuss

constant for

ie for

ammonia) available. For anosie conditions, the problem

Is the opposite, Here the problem is to calculate the

mass of electton donors (COD) that are required to

denitrify a known mass of electron acceptors nitrate. I

sufficient eleeron donors (COD) are not available thon

complete denitification cannet be achieved The

ealeulition of the nitrogen removal is essentially

reconeiliation of electron acceptors (nitrate) and donors

(COD) taking dve account of {7 the biological kinetics

of denitnfication and (2) the system operating

parameters (suck os resyele ratios, anoxie reactor sizes)

lunder which the deninfication is constrained to take

phic.

Euere Ton

Nin garotove Lui onase

Nin suoge

Sold phase

Figure 5.2 Ext routes for ntrogen in single sudge nitrification

ddenircation aciates stg systems

‘The electron donors (or COD or eneigy) for

denitrification ean come from two sources, (1) internal

for (H) extemal to the activated sludge system. The

former are those present in the system iself, ie. those in

the incoming wastewaler or generated within the

biological reactor by the activated udge itself; the

later are orgmnics imported to the activated sludge

system and specifically dosed into the anoxic zones) to

promote denitrification, eg. methanol, acetate,

‘molastes, ote, (Monteith eal, 1980). Here the focus is

fon inlemal COD sources for deninitication, tut the

prinsiples and procedures are suTicisntly general to be

adaptable to melude external COD (energy) sourves

also

5.8.4 Denitrification kinetics

There are three iniemal organics sources, vo from the

wastewater and one fiom the activated sludge mess

itsell The two in the wastewater are the two main forms

fof organics, ie, rewily biodegradable omganics

rent Principles, Modeling a Desi

(RBCOD) and slowly biodegraable —onganies

(SBCOD). The third is slowly diodsgralable organics

generated by the biomas itself through death and lysis

of organism mass (also known as endogenous mass loss!

rospiration). This self generated SBCOD is utilized in

the same way as te wastewater SECOD, but is

recognized separately because of its diferent source and

rate of supply to that of the influent The RBCOD and

SBCOD (influent or self generated) ere degraded via

ilferent mechanisms by the DHOs

‘he different RBCOD and SECOD degradation

‘mochanisms lead to different COD wiilization rates. The

RBCOD comprises swall simple dissolved organic

‘compounds that ean pass divectly through the cell wall

into the organism, e'@ sugars, short chain fatty acids

‘Aceondingly, the RBCOD van be used at a high rate

‘which does not change significantly whether nitrate or

oxygen serve as terminal electron acceptor (Ekama et

‘a1,1996) Simulation medels use the Monod equation to

‘model the uliization of RBCOD by OHOs under both

aerobic and anasic conditions, The SRCOD comprises

large particulate or colloidal orgeme compounds, tbo

Tare to poss into the organism directly, These organies

must be troken down (hydrolysed) in the slime layer

surrounding the organism to smaller components, which

then can be transferred inio the organism and wilized

‘The extracellular SBCOD hydrolysis rate is slow and

forms the limiting rate in the utilization of SBCOD.

This hydrolysis rate is much slower under anoxic

ceenditions than under aerobie eorsitions - only about

Wed (Stern and Marais, 1974, ven Haandel ef of

1981). This mtoduses a reduction factor (n) an the

SBCOD hydrolysis rate equation for anexic coniitons

(Eq. 5.45 below, Research has indicated that the

Utilization of RBCOD is simultaneous with the

hydrolvsis of SBCOD. Also the rate of RBCOD

Utiization is considerably faster (7 to 10 times) than the

rate of SBCOD hydrolysis so the denitrification rate