Professional Documents

Culture Documents

Job Safety Analysis Form Hydrotest

Uploaded by

yayongjcs100%(4)100% found this document useful (4 votes)

7K views3 pagesCopyright

© Attribution Non-Commercial (BY-NC)

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

100%(4)100% found this document useful (4 votes)

7K views3 pagesJob Safety Analysis Form Hydrotest

Uploaded by

yayongjcsCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 3

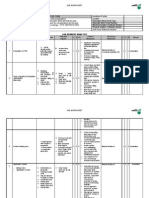

JOB SAFETY ANALYSIS FORM

SEQUENCE OF BASIC ACTIVITY

STEPS/ PRESSURE LEAKAGE TEST POTENTIAL HAZARD HAZARDS CONTROL RESPONSIBLE PARTY

1) Check pipe length Trip hazard Watch your steps Site supervisor

2) Check mech. joints & pipe joints Trip hazard Proper handling of tools Site supervisor

Follow safety procedure for small tools

3) Check manual pump Parts defect/ Malfunction requirement inspection Site supervisor

4) Inject water pressure w/ manual pump Bursting of rubber hose Pump gradually/ constant observation Site supervisor

5)Water pressure established, repeat #2 Bursting of main pipes body and

procedure its joints Initial backfill of trench Site supervisor

6) Check end caps Detachment where installed Secure support/ tightly installed Site supervisor

7) Release of water pressure Hit by pressurized water Complete PPE suits and stand clear Site supervisor

REVISION:

Concrete Batching Plant Requirements

Description unit Qty

1) Design Mix 20N/mm2 or 3000 psi ( 28 days ) ea 1

2) Design Mix 28N/mm2 or 3500 psi ( 28 days ) ea 1

3) Test Certificate

a. Cement ea 1

b. Sand ea 1

c. Gravel stone ea 1

d. Water ea 1

e. Admixture ea 1

4) Batching plant calibration certificate ea 1

5) Testing equipment calibration certificate ea 1

6) Concrete cylinder sample

a. 3000 psi ( 28 days ) ea 3

b. 3500 psi ( 28 days ) ea 3

Note: All of the above, need to be submitted today to CTJV

MANHOLES TABULATED DATA Width x 2 Width x 2

SURVEY ORDINATES Top wall Bottom slab Wall & slab Height ( outside-mtrs ( inside

Description Northing Easting finished elev finished elev. Thickness ( meters ) ) -mtrs )

Manholes # 1

Manholes # 2

Manholes # 3

Manholes # 4

Manholes # 5

Manholes # 6

Manholes # 7

Manholes # 8

Manholes # 9

Manholes # 10

Manholes # 11

You might also like

- Housekeeping Hazards Tool Box TalkDocument1 pageHousekeeping Hazards Tool Box TalkAli Alqaisy100% (1)

- Job Safety Analysis: How To Use This FormDocument4 pagesJob Safety Analysis: How To Use This Formjithin shankar100% (1)

- JSA For New EmployeesDocument20 pagesJSA For New EmployeesNilayNo ratings yet

- Jsa Ground Grid MocksvilleDocument2 pagesJsa Ground Grid MocksvilleChristopher NewbyNo ratings yet

- Lathe Machine Safety OperatingDocument4 pagesLathe Machine Safety Operatingebad100% (1)

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubNo ratings yet

- Loading and Unloading Pile Pipes SafelyDocument4 pagesLoading and Unloading Pile Pipes SafelyOsiobe Ewomazino100% (1)

- JSA PRE-TEST UploadDocument2 pagesJSA PRE-TEST UploadDenny Kurniawan PrawiraNo ratings yet

- Concrete Mixer Safety ChecklistDocument1 pageConcrete Mixer Safety ChecklistSafety Man Shop100% (1)

- JHA For Installation 2 Inch Nozzle..Document6 pagesJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- Risk Assessment Rib Erection & FabricationDocument2 pagesRisk Assessment Rib Erection & FabricationAkash SharmaNo ratings yet

- 28.1.1 Mobile Equipment Inspection ChecklistDocument1 page28.1.1 Mobile Equipment Inspection Checklistmohamed abdelmoniemNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Document4 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNo ratings yet

- Appendix A-Job Safety Analysis FormDocument3 pagesAppendix A-Job Safety Analysis Formjiks_i4uNo ratings yet

- NASDA WIND POWER SUB-STATION EXCAVATION SAFETYDocument2 pagesNASDA WIND POWER SUB-STATION EXCAVATION SAFETYRaza Muhammad SoomroNo ratings yet

- JSA For Installation of Out Door UnitsDocument4 pagesJSA For Installation of Out Door UnitsMohammed MinhajNo ratings yet

- SW JSA Piping 5 JSA Liquid Penetrate Test LPTDocument5 pagesSW JSA Piping 5 JSA Liquid Penetrate Test LPTAnwar Ali100% (1)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocument6 pagesRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- Work at Height Safety AnalysisDocument2 pagesWork at Height Safety AnalysiszebmechNo ratings yet

- JSA Working in Live AreasDocument1 pageJSA Working in Live Areasyc safetyNo ratings yet

- Safe Work Procedure (Air Compressor)Document2 pagesSafe Work Procedure (Air Compressor)SURJIT SINGH100% (1)

- 2020 06 17 JSA For Installation of The AC Unit in The Server RoomDocument11 pages2020 06 17 JSA For Installation of The AC Unit in The Server RoomDarren OscarNo ratings yet

- Jsa Welding Diesel PipelineDocument3 pagesJsa Welding Diesel PipelineHow Chin Engineering Sdn BhdNo ratings yet

- Scissor Lift Daily Inspection FormDocument1 pageScissor Lift Daily Inspection Formshamroz khanNo ratings yet

- Catalyst Filling & SeggregationDocument3 pagesCatalyst Filling & SeggregationMohammed MinhajNo ratings yet

- Building De-Dusting JSADocument3 pagesBuilding De-Dusting JSAJayesh J PillaiNo ratings yet

- HIRA-22 Logistic & Commissioning Activity OKDocument8 pagesHIRA-22 Logistic & Commissioning Activity OKadityajailani19No ratings yet

- Asian Paints - Prem Gloss EnamelDocument1 pageAsian Paints - Prem Gloss EnamelwilliumstNo ratings yet

- Crane Jsa TGPDocument2 pagesCrane Jsa TGPSuryakant SurajNo ratings yet

- JSA of Charging UnitDocument3 pagesJSA of Charging UnitMuhammad AliNo ratings yet

- Breaker Machine Safety ChecklistDocument1 pageBreaker Machine Safety ChecklistNair R RakeshNo ratings yet

- HIRA 008 Height Work.Document4 pagesHIRA 008 Height Work.srinibas mohapatraNo ratings yet

- JSA NO 2 Piling WorkDocument6 pagesJSA NO 2 Piling WorkfadliNo ratings yet

- JSA NO 3-Pile CapDocument8 pagesJSA NO 3-Pile Capknabpsho50% (2)

- Webbing Sling Safety Inspection Checklist Report PilotDocument1 pageWebbing Sling Safety Inspection Checklist Report PilotThirumaran MuthusamyNo ratings yet

- 024 - Mobile Scaffold Inspection ChecklistDocument1 page024 - Mobile Scaffold Inspection ChecklistFaiez AripiNo ratings yet

- SWP-10 Loading & Unloading Using Lorry & Mobile Crane DaimanDocument2 pagesSWP-10 Loading & Unloading Using Lorry & Mobile Crane DaimanHassan AbdullahNo ratings yet

- JHA Jack Hydraulic PalletDocument1 pageJHA Jack Hydraulic PalletIndranil Mitra100% (1)

- JHA Arc WeldingDocument2 pagesJHA Arc WeldingechaNo ratings yet

- DRL - Project Check List For Metal Cutting Machine: .RPM .RPMDocument1 pageDRL - Project Check List For Metal Cutting Machine: .RPM .RPMSachin Hse Rohtak100% (1)

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- Jha New Format-Painting Revision)Document8 pagesJha New Format-Painting Revision)Kenny Hassan100% (1)

- Tool Box Talk - 8 Lifting EquipmentDocument2 pagesTool Box Talk - 8 Lifting EquipmentMoaatazz Nouisri100% (1)

- Bar Bending Checklist: Contractor NameDocument1 pageBar Bending Checklist: Contractor NameAfroz AlamNo ratings yet

- SOP - ForkliftDocument4 pagesSOP - ForkliftGyanendra Narayan Nayak100% (1)

- 01 JSA CLEANING MgO Rev 05 017 BIDocument7 pages01 JSA CLEANING MgO Rev 05 017 BIMohd KhaidirNo ratings yet

- Jsa For Alignment of Vessel and DrumDocument3 pagesJsa For Alignment of Vessel and DrumMohammed MinhajNo ratings yet

- 972 99 100 (Mobile) : Job Safety AnalysisDocument8 pages972 99 100 (Mobile) : Job Safety AnalysisSreeraj Reghunathan Nair VanmazhyNo ratings yet

- GUIDLINES FOR Contr AICDocument5 pagesGUIDLINES FOR Contr AICmadhulikaNo ratings yet

- JHA For Steam PipingDocument17 pagesJHA For Steam PipingM8Rskn6wcNo ratings yet

- Step No. Sequence of Activities Hazard Who or What May Be Harmed? Control Measures / Recovery Measures Action / Responsible PartyDocument7 pagesStep No. Sequence of Activities Hazard Who or What May Be Harmed? Control Measures / Recovery Measures Action / Responsible PartyameeraliNo ratings yet

- JSA Safety AnalysisDocument3 pagesJSA Safety AnalysisLusy Gusti EfendiNo ratings yet

- Job Hazard Analysis for Deep Well Drilling with HotworksDocument2 pagesJob Hazard Analysis for Deep Well Drilling with Hotworksjay RNo ratings yet

- JSA Machinal PipingDocument7 pagesJSA Machinal PipingNaitik Desai48100% (1)

- Sogetrap JSA Lifting Cabin by ForkliftDocument2 pagesSogetrap JSA Lifting Cabin by ForkliftTSP HSENo ratings yet

- Tbam: Dikkowita Fisheries HarbourDocument8 pagesTbam: Dikkowita Fisheries HarbourkskahatadeniyaNo ratings yet

- Mezzanine Installation InstructionDocument19 pagesMezzanine Installation InstructionfaustomariottNo ratings yet

- SWP 02 - Use of Mobile ScaffoldDocument4 pagesSWP 02 - Use of Mobile ScaffoldGerald Wong NttNo ratings yet

- Job Safety Analysis Form HydrotestDocument4 pagesJob Safety Analysis Form HydrotestMarvin BerrensteinNo ratings yet

- 33 01 32 Sewer and Manhole TestingDocument4 pages33 01 32 Sewer and Manhole TestingHussamAlmustafaNo ratings yet

- 1Document96 pages1Habina ZoranNo ratings yet

- Viking Grill Catalog 2008Document57 pagesViking Grill Catalog 2008Steve Jade100% (1)

- LiteDeck Book 2013-1 WebDocument48 pagesLiteDeck Book 2013-1 WebGonzalo Gomez CastilloNo ratings yet

- NiMH Vs Li-IonDocument3 pagesNiMH Vs Li-IonJohn Arjay CedNo ratings yet

- Maintenance Infusion Pump PDFDocument2 pagesMaintenance Infusion Pump PDFroydityanaziNo ratings yet

- Izlomljena Greda Autodesk Robot Structural Analysis Professional 2014Document3 pagesIzlomljena Greda Autodesk Robot Structural Analysis Professional 2014tovarNo ratings yet

- HydrojettingSafeWorkProcedureRPNC151982 PDFDocument21 pagesHydrojettingSafeWorkProcedureRPNC151982 PDFasdfse100% (2)

- 121 Master CatalogDocument60 pages121 Master CatalogericlearnNo ratings yet

- Lidos Lwe Webservice: LTM 1120-1-015 Z23358 Z23358 2970 913948608Document5 pagesLidos Lwe Webservice: LTM 1120-1-015 Z23358 Z23358 2970 913948608mohamedNo ratings yet

- List SSOP Rig 2 - Bridging DocumentDocument11 pagesList SSOP Rig 2 - Bridging DocumentRizki YanuarNo ratings yet

- BFWDocument35 pagesBFWanand003No ratings yet

- Gate 1533Document7 pagesGate 1533Darshit D RajNo ratings yet

- Brooklyn Mp35Document36 pagesBrooklyn Mp35Florian LeordeanuNo ratings yet

- Fluor: Gulf Asia Contracting Company LLCDocument7 pagesFluor: Gulf Asia Contracting Company LLCRajesh JoeNo ratings yet

- HL300 Rock Drill - Sandvik Mining & Rock TechnologyDocument2 pagesHL300 Rock Drill - Sandvik Mining & Rock TechnologymegamNo ratings yet

- 40 Power Microscope Is Available For Inspecting Bearing Journals On Crankshafts (0777, 1202)Document3 pages40 Power Microscope Is Available For Inspecting Bearing Journals On Crankshafts (0777, 1202)TASHKEELNo ratings yet

- Simulation Study of Cryogenic Air Separation PDFDocument58 pagesSimulation Study of Cryogenic Air Separation PDFAHMEDNo ratings yet

- Recognizing Units and Assemblies for Automated Banknote ProcessingDocument8 pagesRecognizing Units and Assemblies for Automated Banknote ProcessingAlberto SS AhijadoNo ratings yet

- DeformationDocument1 pageDeformationRoham Afghani KhorasganiNo ratings yet

- AmbiatorDocument39 pagesAmbiatorRajeeth JaisonNo ratings yet

- CM On BrickworkDocument55 pagesCM On BrickworkRahul SharmaNo ratings yet

- 30hx-8pd ChillerDocument76 pages30hx-8pd ChillermagaliNo ratings yet

- 12204-1000 MSU Bio Engineering Facility - Volume 2 - Bid Release - 2 - Bids (2014 - 01 - 08) PDFDocument101 pages12204-1000 MSU Bio Engineering Facility - Volume 2 - Bid Release - 2 - Bids (2014 - 01 - 08) PDFJesus RobinsonNo ratings yet

- Cement Grouted Rock Bolts PDFDocument28 pagesCement Grouted Rock Bolts PDFSushmit SharmaNo ratings yet

- Motivation Letter ExampleDocument1 pageMotivation Letter ExampleDavidNo ratings yet

- UNDERGROUND CABLES LOW VOLTAGEDocument5 pagesUNDERGROUND CABLES LOW VOLTAGEpdyba13No ratings yet

- LT 4041 Aam Deere BrochureDocument28 pagesLT 4041 Aam Deere Brochurechristian vergaray gonzalesNo ratings yet

- ARC 213 History of Architecture Lecture NotesDocument137 pagesARC 213 History of Architecture Lecture NotesMar Cariaga Opeña57% (7)

- Dalamatic Dust Collector PDFDocument12 pagesDalamatic Dust Collector PDFdanielbustNo ratings yet

- Safety OS PressRelease 201302 enDocument3 pagesSafety OS PressRelease 201302 enRevathy chandaranNo ratings yet