Professional Documents

Culture Documents

Wire Rope Sling Inspection and Load Test Report (Sample)

Uploaded by

yips0001Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wire Rope Sling Inspection and Load Test Report (Sample)

Uploaded by

yips0001Copyright:

Available Formats

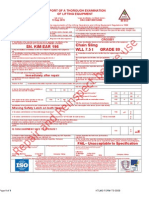

WIRE-ROPE SLING INSPECTION

AND LOAD TEST REPORT

Notes: 1. Qualified inspector must witness and verify all steps below.

2. When required, proof-test to 200% for mechanical-splice and endless slings and 125% for

hand tucked slings of rated capacity to certify new equipment procured without manufacturers

certification. Test loads must be accurate to within 5%, +0% of the stipulated values.

Wire rope must be immediately removed from service if any of the following conditions are present:

INSPECTION

_______ 1. Ten randomly distributed broken wires in one rope lay or five broken wires in one

stranding one rope lay.

_______ 2. Wear or scraping of 1/3 the original diameter of the outside individual wire.

_______ 3. Kinking, crushing, birdcaging, or any other damage resulting in distortion of the

wire rope structure.

________4. Heat damage.

________5. Cracked, deformed, or worn end attachments.

________6. Hooks with any distortion causing an increase in the throat opening of 5% not

to exceed of original throat opening, hooks with any visible bend or twist from

the original plane of the hook, and hooks having any wear exceeding 10% of

original shall be replaced.

_______ 7. Corrosion of the rope or end attachments.

Manufacturer: _______________________________

Serial # ____________________________

Size: (Length, Diameter, Etc.)_____________________

Capacity (SWL) _________________________

Actual Load Test: ________________lb.

Load Test % ________________________________

Operator: __________________________

BNL Insp. Tag # _____________________________

REMARKS____________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

A qualified inspector must inspect hook/rings by visual examination, liquid penetrant examination or

magnetic particle examination.

Acceptance: No cracks, linear indications, laps, or seams.

QUALIFIED INSPECTOR____________________________

6.1/12911e091.pdf

DATE______________________

(12/2007)

You might also like

- GD380A-L ListDocument6 pagesGD380A-L ListNam Won HongNo ratings yet

- FRP Tank Inspection 2Document2 pagesFRP Tank Inspection 2Faheem zaidiNo ratings yet

- Crane Inspection ChecklistDocument2 pagesCrane Inspection ChecklistRahul DhaneNo ratings yet

- Maintenance: 1.3 General Maintenance Chart For Hitachi S6R EngineDocument34 pagesMaintenance: 1.3 General Maintenance Chart For Hitachi S6R EngineKolo BenduNo ratings yet

- Let Us Install Jyoti VT Pumps PDFDocument55 pagesLet Us Install Jyoti VT Pumps PDFGary Estay MonasteriosNo ratings yet

- Breach of Contract AssignmentDocument7 pagesBreach of Contract AssignmentSamiul RatulNo ratings yet

- AS 1742.5-1997 Traffic Control DevicesDocument29 pagesAS 1742.5-1997 Traffic Control DevicesBenNo ratings yet

- Checklist For Equipment Inspection Batching PlantDocument1 pageChecklist For Equipment Inspection Batching Plantstansilous100% (1)

- Crawler Crane ChecklistDocument2 pagesCrawler Crane ChecklistAnuraj100% (1)

- RFQ Crane (MHE - DEMAG)Document6 pagesRFQ Crane (MHE - DEMAG)Agung Pandega PutraNo ratings yet

- Sling FailuresDocument1 pageSling FailuresAyman64No ratings yet

- MS Notice 8 of 2013Document37 pagesMS Notice 8 of 2013afreddy19580% (1)

- Webbing SlingDocument3 pagesWebbing Slingmoha19841No ratings yet

- Sn. Kim Ear 196 Chain Sling WLL 7.5 T Grade 80: Report of A Thorough Examination of Lifting EquipmentDocument1 pageSn. Kim Ear 196 Chain Sling WLL 7.5 T Grade 80: Report of A Thorough Examination of Lifting Equipmentoriza100% (1)

- Certificate: of Test and Thorough Examination of Electrical Overhead Travelling Crane (EOTC)Document1 pageCertificate: of Test and Thorough Examination of Electrical Overhead Travelling Crane (EOTC)SOUMEN100% (1)

- C05.Safety Inspection Checklist For Four WheelerDocument1 pageC05.Safety Inspection Checklist For Four WheelerSRR OHSENo ratings yet

- Bar Cutting Machine Safety Inspection ChecklistDocument1 pageBar Cutting Machine Safety Inspection ChecklistsanjeetNo ratings yet

- FIDIC Contracts - Contemporary Records and Contractors' Claims - International Law OfficeDocument2 pagesFIDIC Contracts - Contemporary Records and Contractors' Claims - International Law OfficeNahla KhanNo ratings yet

- Ra Elevatorr Maintenance ManualDocument8 pagesRa Elevatorr Maintenance ManualBahman MatouriNo ratings yet

- Scissor Lift ChecklistDocument1 pageScissor Lift ChecklistDIBNESH PANDITA100% (1)

- RG 01 Rev 00 - Guidelines For The Registration of Conformity Assessment Bodies (CABs) in UAEDocument6 pagesRG 01 Rev 00 - Guidelines For The Registration of Conformity Assessment Bodies (CABs) in UAEAnonymous G6ceYCzwtNo ratings yet

- Construction Safety Acts - RulesDocument11 pagesConstruction Safety Acts - RuleslrpatraNo ratings yet

- SN. 20859 Webbing Sling WLL 8t Length 3m: Certificate of A Thorough Examination of Lifting EquipmentDocument1 pageSN. 20859 Webbing Sling WLL 8t Length 3m: Certificate of A Thorough Examination of Lifting EquipmentorizaNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Lift Rope Inspection PDFDocument2 pagesLift Rope Inspection PDFcarlosorizaba100% (1)

- Boom Lift - Man Lift Inspection ChecklistsDocument3 pagesBoom Lift - Man Lift Inspection ChecklistsAgung Tri SugihartoNo ratings yet

- Cmci Cmci: Cemtec 200Document2 pagesCmci Cmci: Cemtec 200pravi3434No ratings yet

- Checklist For Equipment Inspection CONCRETE PUMPDocument1 pageChecklist For Equipment Inspection CONCRETE PUMPbagas prakosoNo ratings yet

- Hose Test MethodsDocument5 pagesHose Test MethodstriagusmanNo ratings yet

- Excavators - Cleaning Checklist Guidelines 1Document3 pagesExcavators - Cleaning Checklist Guidelines 1dialameat2123No ratings yet

- Safe Operating Manual of Vibro HammerDocument1 pageSafe Operating Manual of Vibro HammerDan AlbertNo ratings yet

- Sling Safety Inspection Record PDFDocument2 pagesSling Safety Inspection Record PDFcio davinsiNo ratings yet

- Load Test Inspection FormDocument3 pagesLoad Test Inspection FormIziyon Harrison OsalobohNo ratings yet

- Rigging Platform 25-05-2022-1Document1 pageRigging Platform 25-05-2022-1dele jimohNo ratings yet

- HSE Alert 07-16 Damage To Drilling Mast IncidentDocument1 pageHSE Alert 07-16 Damage To Drilling Mast IncidentSajid HussainNo ratings yet

- Form Inspection Premob - Quarterly (1) - 2Document26 pagesForm Inspection Premob - Quarterly (1) - 2Ryan RhamdhaniNo ratings yet

- Beam ClampDocument1 pageBeam ClampTrust EmmaNo ratings yet

- Shaft ConnectionsDocument6 pagesShaft ConnectionsDr_M_SolimanNo ratings yet

- UTA AST-Fall Protection SafetyDocument72 pagesUTA AST-Fall Protection SafetyNyoman SaktiNo ratings yet

- Electrofusion Welding HDPE PipeDocument4 pagesElectrofusion Welding HDPE PipeTRISTAR TEKZONENo ratings yet

- Gunnebo Lifting Standard Shackle No 854: Bow ShacklesDocument1 pageGunnebo Lifting Standard Shackle No 854: Bow ShacklesTito FebriantoNo ratings yet

- Load Test Report Format of Rotor Lifting Beam-4Document1 pageLoad Test Report Format of Rotor Lifting Beam-4M8Rskn6wcNo ratings yet

- Warranty CertificateDocument3 pagesWarranty CertificateSupreet SinghNo ratings yet

- Catalogo 511Document4 pagesCatalogo 511Luis Oswaldo R PNo ratings yet

- Risk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelDocument3 pagesRisk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelMohamed ElnagdyNo ratings yet

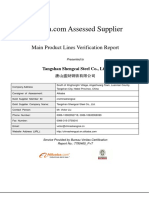

- Main - Product - Report-Tangshan Shengcai Steel Co., Ltd.Document10 pagesMain - Product - Report-Tangshan Shengcai Steel Co., Ltd.hbookNo ratings yet

- LEEA Correspondence Courses: Assignment 1.10Document6 pagesLEEA Correspondence Courses: Assignment 1.10ikponmwonsaNo ratings yet

- HDPE Pipe Safety SheetDocument4 pagesHDPE Pipe Safety SheetHemant ChauhanNo ratings yet

- MST of Road KerbDocument2 pagesMST of Road KerbMital DamaniNo ratings yet

- TCVN Water PipeDocument43 pagesTCVN Water PipeTuan DangNo ratings yet

- Mobile Cranes Check ListDocument6 pagesMobile Cranes Check ListBanesco TemplarisNo ratings yet

- Krulex Services Limited: InternationalDocument5 pagesKrulex Services Limited: InternationalikponmwonsaNo ratings yet

- Care and Use Guide Rig Mate Creeper WinchDocument8 pagesCare and Use Guide Rig Mate Creeper Winchmoha19841No ratings yet

- Crane Inspection Form: Carry-In CertificateDocument2 pagesCrane Inspection Form: Carry-In CertificateWisnu Suryo Andriyanto AndriyantoNo ratings yet

- Check ListDocument88 pagesCheck ListRaafat SaadNo ratings yet

- Witness Joint ChecklistDocument1 pageWitness Joint ChecklistAustin J AlfredNo ratings yet

- Pc200 TrobleshootingDocument315 pagesPc200 Trobleshootingdavid ballenNo ratings yet

- Camesa Recommended Cable Maintenance Program: Inspections Performed After Every JobDocument2 pagesCamesa Recommended Cable Maintenance Program: Inspections Performed After Every JobHariomNo ratings yet

- Botoneras de Paro - FederalSignal - MPEX - InstruccionesDocument12 pagesBotoneras de Paro - FederalSignal - MPEX - InstruccionesJuan Pablo Herrera PoppeNo ratings yet

- Audel Guide to the 2005 National Electrical CodeFrom EverandAudel Guide to the 2005 National Electrical CodeRating: 4 out of 5 stars4/5 (1)

- Criteria of Design Improvement of Shaped ChargesDocument253 pagesCriteria of Design Improvement of Shaped Chargesyips0001100% (1)

- Oilfield Review Winter 2012Document60 pagesOilfield Review Winter 2012yips0001No ratings yet

- Accessoires Retaining Ring Plier DYNAWELL FP06004AADocument1 pageAccessoires Retaining Ring Plier DYNAWELL FP06004AAyips0001No ratings yet

- API Casing ChartDocument2 pagesAPI Casing Chartyips0001No ratings yet