Professional Documents

Culture Documents

Shakedown Algorithm PDF

Uploaded by

Tamara KnoxOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shakedown Algorithm PDF

Uploaded by

Tamara KnoxCopyright:

Available Formats

An iterative method for shakedown analysis

Raaele Casciaro

*

, Giovanni Garcea

Dipartimento di Strutture, Universit aa della Calabria, 87030 Arcavacata di Rende (Cosenza), Italy

Received 11 March 2002; received in revised form 1 August 2002

Abstract

Shakedown analysis for elasticperfect plastic structures is discussed and a fast incremental-iterative solution

method is proposed, suitable for the FEM analyses of large structures.

The theoretical motivations of the proposed method are discussed in detail and an example of its implementation is

described with reference to plane frame analysis.

Some numerical results are presented showing the numerical performances of the method.

2002 Elsevier Science B.V. All rights reserved.

Keywords: Plasticity; Shakedown analysis; Limit analysis; Nonlinear methods

1. Introduction

The elasticplastic analysis has assumed a great importance also in civil engineering due to the diusion

of the semi-probabilistic approach to limit states, such as that established in Eurocodes (the European

proposal codes), which allows the design of structures beyond the elastic limit.

When considering a single set of external loads, monotonically increasing with a load parameter, the

safety factor of an elasticplastic structure can be eectively evaluated by numerical implementations of the

classical theorems of limit analysis [913] or, even more eciently, by recovering the equilibrium path by

means of path-following algorithms [14,15], based on the Riks arc-length method [16] and well suited to be

implemented in general purpose FEM codes (see [18,19] for an overview of these topics). It is known,

however, that the collapse multiplier doesnt furnish a reliable safety index when the structure is subject to a

combination of loads that can vary, cyclically or in a generic way, inside a given loads domain. In this case,

in fact, other dierent failure modes are possible that also have to be prevented. A continuous increase in

plastic deformations, along successive plastically admissible load cycles, could lead to a loss of the structure

functionality (incremental collapse or ratchetting) or produce the collapse due to fatigue (alternating

plasticity). Then, a further requirement has to be met, that the rising amount of plastic deformations be

Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792

www.elsevier.com/locate/cma

*

Corresponding author. Tel.: +39-984-494031; fax: +39-984-494045.

E-mail address: rcasciaro@labmec.unical.it (R. Casciaro).

0045-7825/02/$ - see front matter 2002 Elsevier Science B.V. All rights reserved.

PII: S0045- 7825( 02) 00496- 6

conned only to an initial phase after which the structure behavior, for any combination of load contained

in the loads domain, is purely elastic. If this happens, we say that the structure shakes down to an elastic

state or, simply, shakedown occurs.

The denition of conditions that imply shakedown of elasticperfectly plastic structures has been

widely studied, at least from a theoretical point of view, and shakedown theorems [20,36] currently

represent one of most important achievements of the theory of plasticity [20]. Noticeable developments

have been made that extend and generalize the shakedown theory. In particular a deeper insight into the

extensions of the classical theory to material with hardening eects, nite displacements, thermal and

dynamics eects can be found in the papers by Ceradini [21,22], Capurso [12], Gokhfeld e Cherniavsky

[23], K oonig e Maier [2], Ponter [24], Stein et al. [25], Yan and Nguyen [26] and Polizzotto et al. [27,28].

The reader can refer to the book by K oonig [3] and to the reviews [16], for a general overview and

historical details.

The use of these theoretical results suers, still today, from the lack of ecient computational algo-

rithms able to calculate the shakedown safety factor, that is, the maximum load amplier that ensures

shakedown, for large life-scale structures modeled using standard nite element formulations. As under-

lined by Gro-Weege [31] and by Zhang [30] and Janas and et al. [29], the proposed solution methods

appear to be aimed more at academic purposes or to the analysis of specic problems than to be eectively

implemented in FEM codes suitable for general technical applications. In eect most of the proposed

numerical methods attempt to evaluate the shakedown multiplier directly from the shakedown theorems

(direct methods). In this way, shakedown analysis is formulated as a standard constrained optimization

problem to be solved by general methods of mathematical programming without exploiting the particular

features of the structural problem. That implies a low computational eciency in the overall solution

process and practically prevents shakedown analysis from being easily implemented in commercial nite

element codes.

More recently, an indirect approach has been proposed by Ponter et al. [24] that is based on the so-called

elastic compensation methods. The shakedown safety factor is evaluated through an iterative sequence of

pseudo-elastic solutions that produces a monotonically decreasing sequence of upper bounds that con-

verges to the exact solution (obviously except for the approximations due to the nite element discreti-

zation). The method appears to be more ecient than direct methods and more suitable to a nite element

implementation but it can still hardly be considered completely satisfactory from a computational point of

view when compared with standard limit analysis algorithms. In fact it is characterized by a relatively slow

convergence and requires a large number of complete elastic re-analyses (including the assemblage of the

pseudo-elastic stiness matrix and its Choleski decomposition).

A new method for the evaluation of the shakedown safety factor for elasticperfectly plastic structures

is presented in this paper. It is based on an iterative technique which has some analogies with the Riks

path-following algorithm, currently used in elasticplastic analysis to evaluate the equilibrium path of a

structure, and oers the same characteristics of robustness, eciency and computational requirements as

that method. The full theoretical and computational aspects of the proposed method are discussed in

detail, including the convergence proof of solution algorithms and numerical testings. The simple case of

plane frames has been used here for exemplifying the implementation details and the numerical perfor-

mances of the proposed method. Its extension to more complex structures can be considered quite

straightforward.

The paper is organized as follows: Section 2 provides an introductory summary of classical shake-

down theory; a reformulation of this theory, suitable for numerical analysis, is given in Section 3 and

some preliminary results are provided; the proposed iterative method is described in Section 4 and

its convergence properties are discussed; Sections 5 and 6 use the plane frame context to show an ex-

ample of the actual implementation of the method; further comments and conclusions are given in

Section 7.

5762 R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792

2. Shakedown theory

In order to render the paper as self-contained as possible, we recall in this section a brief overview of the

elasticplastic theory and of the shakedown problem. The reader can refer to the general presentation by

Koiter [20] or to the book by K oonig [3], for a more detailed discussion.

2.1. Basic rules of the elasticplastic theory

The basic rules of the classical elasticplastic theory for perfect-plastic materials can be summarized as

follows:

1. Stress and strain elds r[x[ R

d

and e[x[ R

d

, x B can be dened, d being the number of independent

components of both r and e (d = 6 in 3D Cauchy model), and B is the body domain. The dot-product

r

T

e is also dened for each x B and we have

Z

B

rr

T

_ ee dv = 0 (2:1)

for all self-equilibrated stress rr and kinematically compatible strain increment eld _ ee. Eq. (2.1) mutually

denes the subspaces S and K collecting all self-equilibrated stress elds and all kinematically com-

patible strain increments. We will generally omit, when referring to eld relationships, explicit citations

to \x B, which will be taken as implicit, for a lighter notation.

2. Stress r is constrained to belong to the admissible domain

E := r : f [r[ 60; (2:2)

where f [r[ is a convex yield function in R

d

, such that f [0[ < 0. Obviously, E will be closed and convex in

R

d

and its boundary oE is characterized by f [r[ = 0.

3. The total strain increment _ ee can be subdivided into the elastic part _ ee

e

and the plastic part _ ee

p

, and the two

strain components are additive:

_ ee = _ ee

e

_ ee

p

: (2:3)

4. The elastic component _ ee

e

is linearly linked to the stress through the elastic law:

_ rr = E_ ee

e

= E(_ ee _ ee

p

); (2:4)

where E is the elastic tensor, symmetric and positive denite.

5. The plastic component _ ee

p

can be dierent from zero only if the stress r belongs to oE and is dened by

the plastic ow rule:

_ ee

p

= _ llg[r[; _ llP0; _ ll

_

ff = 0; _ llf = 0; (2:5)

vector g being contained in the subdierential

1

of [r[ of the function f in r.

By these hypotheses, the following Druckers conditions holds:

r

y

T

_ ee

p

P0; \r E; (2:6)

1

We briey recall that the subdierential of a function f in a point r is the cone dened by the gradients of the function computed at

all points adjacent to r at innitesimal distance and in all directions. It coincides with the classical gradient in regular points. The

reader can refer to [34] for a general overview on convex analysis.

R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792 5763

r

y

and _ ee

p

being related by the ow rule (2.5). Since r = 0 is internal to E, by denition, we also have

r

T

y

_ ee

p

> 0; \_ ee

p

,= 0: (2:7)

2.2. Basic assumptions of shakedown analysis

We assume that the external load p[t[ is expressed as a combination of basic loads p

i

, varying arbitrarily

with time t but, in any case, belonging to the admissible load domain

P := p[t[ :=

X

p

i=1

a

i

[t[p

i

: a

min

i

(

6a

i

[t[ 6a

max

i

; \t

)

; (2:8)

where the factors a

i

[t[ are contained in a polyhedron in R

p

[27,29]. Such an assumption conforms to the

external load description used in many civil engineering norm codes and derives from the fact that the real

loads evolution is often unknown while, in some statistical way, the excursion of the minimum and

maximum values for every basic load p

i

is known or, at least, we can get meaningful reference values for the

maximum or minimum of the load factors for a given life-time of the structure. Obviously P is closed and

convex, by denition.

If denoting with r

ei

the elastic solution due to the single basic load p

i

we can dene the domain S

e

of the

elastic stresses r

e

[t[ associated to p[t[ in the form

S

e

:= r

e

[t[ :=

X

p

i=1

a

i

[t[r

ei

: a

min

i

(

6a

i

[t[ 6a

max

i

; \t

)

: (2:9)

Set S

e

, represents the envelope of the elastic stresses, and collects the local values of the elastic stresses

produced, at dierent instants, by load paths p[t[ contained in P. Obviously S

e

is also closed and convex.

It is worth mentioning that time is assumed here as an evolution variable since we always consider

negligible the dynamic eects due to the external loads. However, our presentation can be easily generalized

to the presence of dynamic eects (see Ceradini [21,22] and [27,28]).

We can now state the following denition:

Denition 2.1 (Shakedown). We say that a structure shakes down to an elastic state or, simply, shakedown

occurs if, after an initial phase during which the occurrence and the accumulation of plastic strain incre-

ments are possible, the structural response, for every load path p[t[ P; tends to be purely elastic and is

characterized by a nite total plastic work. That is

Z

t=0

Z

B

r[t[

T

_ ee

p

[t[ dv

& '

dt < ;

where r[t[ and e

p

[t[ are the stress and plastic strain produced during the loading process, a superposed dot

indicates time dierentiation and t = 0 refers to the initial virgin state (e

p

[0[ = 0):

An obvious corollary of this denition is that shakedown implies the existence of, at least, one time

independent stress eld rr S such that

f [r

e

[t[ rr[ 60; \r

e

[t[ S

e

; (2:10)

because, due to Eq. (2.7), we necessarily have lim

t

_ ee

p

[t[ = 0, \p[t[ P and then, due to the uniqueness

of the incremental elastic solution, lim

t

_ rr[t[ _ rr

e

[t[ = 0, that is, lim

t

r[t[ = r

e

[t[ rr, \r

e

[t[ S

e

.

Furthermore, r[t[ and r

e

[t[ being equilibrated by the same load p[t[, by denition, their dierence rr is self-

equilibrated.

5764 R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792

2.3. Shakedown theorems

Sucient and necessary conditions for shakedown are given in the classic BleichMelans static theorem

[35,36] and Koiters kinematic theorem [37]. For the readers convenience, we recall both theorems in some

detail here.

Theorem 2.1 (Static theorem of shakedown). Shakedown occurs if there exists a time-independent self-

equilibrated stress field rr such that

r

+

[t[ = r

e

[t[ rr; f [r

+

[ < 0; \r

e

[t[ S

e

: (2:11)

Proof. For all loading paths p[t[ P the evolution law for stress r[t[ and strain e[t[ acting in the structure

can be expressed as:

r[t[ = r

e

[t[ Dr[t[;

e[t[ = E

1

(r

e

[t[ Dr[t[) e

p

[t[:

&

Dr[t[ being a self-equilibrated stress eld and e

p

[t[ the plastic strain associated to r[t[. If the following

positive function is introduced

W[t[ :=

1

2

Z

B

(r r

+

)

T

E

1

(r r

+

) dv P0

by dierentiating with respect to t and denoting by _ ee

e

[t[ = E

1

_ rr

e

[t[ the strain associated to _ rr

e

[t[, we have

_

WW[t[ =

Z

B

(r r

+

)

T

E

1

( _ rr[t[ _ rr

e

) dv =

Z

B

(r r

+

)

T

(_ ee[t[ _ ee

e

[t[) dv

Z

B

(r r

+

)

T

_ ee

p

dv:

Obviously, both _ ee[t[ and _ ee

e

[t[ are kinematically compatible and r r

+

is self-equilibrated. So the rst in-

tegral in the right side of the equation is zero. Furthermore, r[t[ E being associated by the ow rule (2.5)

to _ ee

p

and r

+

being internal to E, we can apply inequality (2.6) in strict form. We obtain

_

WW[t[ =

Z

B

(r r

+

)

T

_ ee

p

dv < 0 if _ ee

p

,= 0:

So, function W[t[ is both lower bounded and monotonically decreasing during a plastic process. To avoid

contradiction, this implies that

lim

t

_

WW[t[ = 0 = lim

t

_ ee

p

= 0:

Furthermore, by assuming m > 0 small enough to satisfy

f [(1 m)r

+

[t[[ 60;

we have, because of Eq. (2.6),

(r[t[ (1 m)r

+

[t[)

T

_ ee

p

[t[ P0;

that is, integrating on B and remembering the denition of

_

WW[t[,

m

Z

B

r[t[

T

_ ee

p

dv 6(1 m)

Z

B

(r[t[ r

+

[t[)

T

_ ee

p

dv = (1 m)

_

WW[t[:

R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792 5765

Then, integrating on the overall loading process, we obtain

Z

t=0

Z

B

r[t[

T

_ ee

p

[t[ dv

& '

dt 6

1 m

m

(W[0[ W[[) 6

1 m

2m

Z

B

rr

T

E

1

rrdv <

because of e

p

[0[ = 0, i.e. r[0[ = r

e

[0[, by denition and W[[ P0. So shakedown condition is satised.

Theorem 2.2 (Kinematical theorem of shakedown). The structure does not shakedown if there exists a

kinematical admissible strain field _ ee

p

=

P

k

_ ee

p

k

K such that

r

ek

S

e

:

Z

B

X

k

(r

ek

r

yk

)

T

_ ee

p

k

dv > 0; (2:12)

where _ ee

p

k

; k = 1; 2; . . . is a set of plastic strain increments and r

yk

are associated to _ ee

p

k

through the flow rule

(2.5).

Proof. We will prove the statement by absurd. By assuming that shakedown occurs, due to Eq. (2.10),

a self-equilibrated time-independent stress state rr will exist such that

f [r

e

rr[ 60; \r

e

S

e

:

From the Drucker condition (2.6) we obtain:

(r

yk

r

ek

rr)

T

_ ee

p

k

P0; \k and \r

ek

S

e

:

Then, by summing on k and integrating on the body volume B, we obtain:

Z

B

X

k

r

yk

r

ek

T

_ ee

p

k

dv

Z

B

rr_ ee

p

dv P0:

The last integral being zero because rr is self-equilibrated, the previous condition implies

Z

B

X

k

r

ek

r

yk

T

_ ee

p

k

dv 60; \r

ek

S

e

which is absurd by being in contradiction with the theorem requirements.

2.4. Shakedown safety factor

Structural safety with respect to shakedown can be evaluated by relating to the larger multiplier factor

that can be used for amplifying the load domain P or, equivalently, the stress domain S

e

allowing for the

structure shakedown.

We call shakedown safety factor (or shakedown multiplier) k

a

this value and can dene it more precisely,

by referring to the amplied elastic stresses kr

e

, as the sup of strictly safe

kk

s

multipliers that satises the

requirements of the static theorem. that is,

rr S : f [

kk

s

r

e

rr[ < 0; \r

e

S

e

: (2:13)

Equivalently, it can be dened as the inf of strictly unsafe multipliers

kk

u

that satises the requirements of the

kinematical theorem, that is

_ ee

p

:=

X

k

_ ee

p

k

K r

ek

S

e

:

Z

B

X

k

(

kk

u

r

ek

r

yk

)

T

_ ee

p

k

dv > 0; (2:14)

5766 R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792

r

yk

and _ ee

p

k

being associated through the ow rule (2.5). The two denitions actually coincide, that is,

k

a

:= sup

kk

s

= inf

kk

u

: (2:15)

This can be easily proved by assuming k

a

be characterized by the condition

k

a

: min

rr

max

r

e

;x

f [k

a

r

e

&

rr[

'

= 0; rr S; r

e

S

e

; x B:

Due to convexity of f [r[ and the assumption f [0[ < 0, we have

f [cr[ 6cf [r[ (1 c)f [0[ < 0 if 0 6c < 1; f [r[ 60

and then we obtain

min

rrS

f

kk

s

r

e

"

kk

s

k

a

rr

#

< 0; \r

e

S

e

if

kk

s

< k

a

:

Therefore,

kk

s

< k

a

is strictly safe according to denition (2.13). Conversely, due to Eq. (2.6), we have

min

rrS

max

r

e

S

e

(r

y

&

k

a

r

e

rr)

T

_ ee

p

'

P0; \_ ee

p

;

r

y

and _ ee

p

being associated by the ow rule (2.5) and the equal sign being attained for some r

+

yk

:= k

a

r

+

ek

rr

+

and _ ee

p+

k

, by denition. We can characterize this solution by the condition

min

_ ee

p

k

; rrS

Z

B

X

k

(r

yk

k

a

r

+

ek

rr)

T

_ ee

p

k

dv = 0;

summation being extended to all k. That implies

Z

B

d rr

T

X

k

_ ee

p+

k

dv = 0; \d rr S;

that is, because of Eq. (2.1),

P

k

_ ee

p+

k

K. Due to Eq. (2.7), we have furthermore

Z

B

X

k

k

a

r

+T

ek

_ ee

p+

k

dv =

Z

B

X

k

r

+T

yk

_ ee

p+

k

dv > 0

and consequently

Z

B

X

k

(

kk

u

r

+

ek

r

+

yk

)

T

_ ee

p+

k

dv > 0 if

kk

u

> k

a

:

Therefore

kk

u

> k

a

is strictly unsafe according to denition (2.14).

In the sequel it will be convenient to refer to the safe multipliers k

s

and unsafe multipliers k

u

dened

through Eqs. (2.13) and (2.14) by relaxing the < and > conditions into 6 and P ones. Obviously

we obtain

k

a

= max k

s

= min k

u

:

2.5. Some comments

It is worth noting that the static shakedown theorem is a generalization of the static limit analysis

theorem for a combination of independent external loads varying in an admissible domain P. In particular

the static limit analysis theorem is a special case of the static shakedown theorem for a single external load

R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792 5767

(p = 1; 0 6a

1

6k). Analogously, the kinematical shakedown theorem is a generalization of the kinematical

theorem of the limit analysis and the latter can be considered its specialization for a single load. As in limit

analysis, a constant self-equilibrated prestress is without inuence on the shakedown multiplier.

Also note that static shakedown theorem assures the elastic multiplier

k

e

= max k : f [kr

e

[ 60; \r

e

S

e

to be smaller (or, at least not larger) than the shakedown multiplier k

a

. In fact, by adding to the elastic

stresses kr

e

[t[ a constant (zero) self-equilibrated stress, we are able to satisfy the theorem requirements.

Conversely, the shakedown kinematic theorem assures that, for each load combination p P, the collapse

multiplier

k

c

= min k :

Z

B

(r

y

kr

e

)

T

_ ee

p

dv = 0; \r

e

S

e

; \_ ee

p

K

is larger (or, at least, not smaller) than k

a

. The shakedowm multiplier is then bounded as follows:

k

e

6k

a

6k

c

:

We can mention that the previous statements provide rational motivations for the use of the elastic

multiplier in practical structural design. In fact in this way it is possible to surpass the shakedown analysis

while banally fullling its requirements. However, it has to be considered that an explicit shakedown

analysis is necessary when the design is based on nonlinear methods, procedures based on the evaluation of

the collapse multiplier being unsafe.

3. A shakedown formulation suited to FEM analysis

A reformulation of the shakedown problem, suitable for FEM implementation, is presented in this

section and some preliminary results are obtained that will be useful for discussing the convergence

properties of the proposed solution method.

3.1. Shakedown admissible domain

It is convenient to introduce the shakedown yield function dened as

f

s

[r; k[ := max

r

e

S

e

f [kr

e

r[ (3:1)

and the related shakedown admissible domain

E

s

[k[ := r : f

s

[r; k[ 60 (3:2)

that represents the set of all possible translations r of domain kS

e

within E (see Fig. 1). Obviously, due to

the assumption f [0[ < 0, E

s

[k[ is not void for suciently small positive values of k. Furthermore, since both

S and E are closed and convex, so E

s

[k[ it is. We also have:

E

s

[k

1

[ ,= O; E

s

[k

1

[ internal to E

s

[k

2

[ if k

2

< k

1

<

kk := supk : E

s

[k[ ,= O: (3:3)

Denition (3.2) implies the equivalence between the following statements

(kr

e

r) E == r E

s

[k[:

5768 R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792

Then, for k 6

kk and r

y

oE

s

[k[, one or more tension elds r

yk

= kr

ek

r

y

oE can be associated to r

y

,

as shown in Fig. 1. We have, from condition (2.6)

(r

y

r)

T

e

p

=

X

k

(r

yk

r

k

)

T

_ ee

p

k

P0; \r E

s

[k[; (3:4)

where r

k

:= kr

ek

r E, _ ee

p

k

are the plastic strains associated to r

yk

, and e

p

, dened by the combination

e

p

:=

X

k

_ ee

p

k

(3:5)

is a plastic strain increment we can associate to r

y

. Condition (3.4) implies the convexity of function f

s

[r; k[

and a normality rule between r

y

and e

p

:

e

p

= lg; g of

s

[r

y

; k[; l P0; lf

s

= l

_

ff

s

= 0: (3:6)

3.2. The shakedown problem

Using the previous denitions, we can derive a simple characterization for the shakedown safety factor.

We obtain, from static theorem and Eq. (3.1),

k

s

6k

a

if rr S : f

s

[ rr; k

s

[ 60 (3:7)

and, from kinematic theorem and the assumptions r

y

= r

yk

kr

ek

and e

p

=

P

k

_ ee

p

k

,

k

u

Pk

a

if e

p

K :

Z

B

r

T

y

e

p

dv 60; e

p

,= 0: (3:8)

Fig. 1. Elastic domains E and E

s

[k[.

R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792 5769

We can now dene the shakedown problem:

Denition 3.1 (Shakedown problem). Determine the shakedown safety factor

k

a

:= max k

s

= min k

u

;

k

s

and k

u

being the safe and unsafe multipliers dened according to Eqs. (3.7) and (3.8).

3.3. Return mapping to the admissible domain

Starting from a given amplier k 6

kk and a stress r

+

, not necessarily contained in the admissible do-

main E

s

[k[, we can dene the following process, which we call return mapping to the admissible domain

(Fig. 2)

r = r

a

[r

+

; k[ := r

+

Ee

p

; r E

s

[k[ (3:9)

that allows us to determine an associated stress r, contained in E

s

[k[ and related to e

p

by the ow rule

condition (3.6) we can rewrite

e

p

= lg; g of

s

[r; k[; l :

=0; if f

s

[r

+

; k[ < 0;

P0; f

s

[r; k[ = 0; if f

s

[r

+

; k[ P0:

&

(3:10)

We know (see [18]) that the reduction scheme (3.9) and (3.10) corresponds to the so-called return mapping

by closest-point projection and can be conveniently obtained by minimizing the HaarKaarmaan function,

that is, by the condition:

/[r r

+

[ :=

1

2

(r r

+

)

T

E

1

(r r

+

) = min; \r E

s

[k[; (3:11)

which will prove to be better suited for the numerical implementation. Obviously, dened as the minimum

of a strictly convex function on a convex domain, r

a

is a single valued function of both e and k.

Fig. 2. Elastic domain E

s

[k[ for k

2

> k

1

.

5770 R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792

3.4. Basic properties of the return mapping scheme

In order to better understand the solution algorithm, that will be proposed in the next section, and prove

its convergence properties, it is convenient to state some basic characteristics of the return mapping scheme

(3.9) and (3.10).

Let k <

kk; r

0

be an initial state and let r

+

= r

0

Ee, we can express r as a function of e:

r = r

a

[e; k[ := r

a

[r

0

Ee; k[ = r

0

E(e e

p

): (3:12)

Noticeable properties of this function are given by the following lemmas:

Lemma 3.1. Function r

a

[e; k[ is directionally differentiable with respect to both e and k. Furthermore there

exists a convex potential function W[e; k[ such that

r

a

[e; k[ =

oW[e; k[

oe

so the tangent operator

E

t

[e; k[ :=

or

a

oe

=

o

2

W

oe

2

(3:13)

is self-adjoint: E

t

= E

T

t

.

Proof. This is a classical result in incremental plasticity (e.g. see [38,39]) and derives directly from the

denition of r

a

[e; k[ through HaarKaarmaan condition (3.11). It can be easily proven by considering that,

due to the assumption on f [r[ and denition (3.1), function f

s

[r; k[ is a bounded, single valued continuous

mapping R

d1

R, so it is directionally dierentiable. Therefore, for any path e t^ee; k t

^

kk, t P0, we

can dene the directional derivatives r

t

[e; k;

^

kk[ and E

t

[e; k; ^ee[ such that

dr = E

t

de r

t

dk:

The existence of the potential function W is assured if

I

C

r

a

[e; k[

T

de = 0

along any closed curves C in the e space. Letting de = E

1

dr

a

de

p

we can write

r

T

a

de = r

T

a

E

1

dr

a

r

T

a

de

p

= d

1

2

r

T

a

E

1

r

a

r

T

a

e

p

dr

T

a

e

p

that implies

I

C

r

T

a

de =

I

C

dr

T

a

e

p

:

Now, due to the ow rule (3.10), we have e

p

= 0 if r

a

is internal to E

s

[k[; we have dr

a

= 0 if r

a

corresponds

to a corner point of oE

s

[k[ and e

p

is internal to the cone of normals, and dr

T

a

e

p

= 0 in other cases. Therefore,

we obtain

H

c

dr

T

a

e

p

= 0, by proving the second part of the statement.

Lemma 3.2. Let k <

kk, r

0

be an initial stress and r

1

and r

2

be stresses obtained from the strain increments

e

1

and e

2

through return mapping (3.11):

r

1

= r

a

[e

1

; k[ = r

0

E(e

1

e

p

1

);

r

2

= r

a

[e

2

; k[ = r

0

E(e

2

e

p

2

);

&

R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792 5771

where e

p

1

and e

p

2

are related to r

1

and r

2

through the flow rule (3.6). The following conditions hold:

0 6(r

2

r

1

)

T

(e

2

e

1

) 6(e

2

e

1

)

T

E(e

2

e

1

)

and the occurrence of (r

2

r

1

)

T

(e

2

e

1

) = 0 implies

r

1

= r

2

:

Proof. Drukers condition (2.6) provides

(r

2

r

1

)

T

e

p

2

P0; (r

1

r

2

)

T

e

p

1

P0;

then, by their combination, we obtain

(r

2

r

1

)

T

(e

p

2

e

p

1

) P0:

From Eq. (3.2) we also have

(r

2

r

1

) = E(e

2

e

1

) E(e

p

2

e

p

1

):

We nally obtain:

(r

2

r

1

)

T

(e

2

e

1

) = (e

2

e

1

)

T

E(e

2

e

1

) (e

p

2

e

p

1

)

T

E(e

p

2

e

p

1

) (r

2

r

1

)

T

(e

p

2

e

p

1

)

6(e

2

e

1

)

T

E(e

2

e

1

) (e

p

2

e

p

1

)

T

E(e

p

2

e

p

1

) 6(e

2

e

1

)

T

E(e

2

e

1

);

(r

2

r

1

)

T

(e

2

e

1

) = (r

2

r

1

)

T

E

1

(r

2

r

1

) (r

2

r

1

)

T

(e

p

2

e

p

1

) P(r

2

r

1

)

T

E

1

(r

2

r

1

)

that proves the lemma statement.

Lemma 3.3. Matrix E

t

[e; k; e[ satisfies the conditions

0 6e

T

E

t

e 6e

T

Ee; \e:

Proof. The proof derives directly from Lemma 3.2 by taking e := e

2

e

1

for e

2

e

1

.

Lemma 3.4. Let r

1

:= r

a

[e

1

; k

1

[ and r

2

:= r

a

[e

2

; k

2

[ we can write their difference in the form

r

2

r

1

= r

s

[e

1

; k

1

; k

2

[(k

2

k

1

) E

s

[k

2

; e

1

; e

2

[(e

2

e

1

):

Furthermore, we have

E

s

= E

T

s

; 0 6e

T

E

s

e 6e

T

Ee; \e

and

r

s

[e

1

; k

1

; k

2

[

T

e

p

< 0 if e

p

:=

e

p

11

if k

1

6k

2

e

p

12

if k

2

< k

1

& '

,= 0;

where e

p

11

and e

p

12

are the plastic strain associated to r

a

[e

1

; k

1

[ and r

a

[e

1

; k

2

[, respectively.

Proof. The rst part of the statement is obtained directly by dening E

s

and r

s

by the secant ratios

r

s

[e

1

; k

1

; k

2

[ :=

Z

1

0

or[e

1

; k[t[[

ok

dt =

Z

1

0

r

t

[e

1

; k[t[[ dt; k[t[ := tk

1

(1 t)k

2

;

E

s

[k

2

; e

1

; e

2

[ :=

Z

1

0

or[e[t[; k

2

[

oe

dt =

Z

1

0

E

t

[e[t[; k

2

[ dt; e[t[ := te

1

(1 t)e

2

:

5772 R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792

The second part of the lemma is simply obtained by observing that E

s

is obtained as an average, on the

segment t [0 1[, of matrix E

t

and recalling Lemmas 3.1 and 3.3. Finally, the third part is obtained by

observing that, due to Eqs. (2.6) and (3.3), we have

(r

a

[e

1

; k

1

[ r

a

[e

1

; k

2

[)

T

e

p

11

> 0 if k

1

< k

2

; e

p

11

,= 0;

(r

a

[e

1

; k

2

[ r

a

[e

1

; k

1

[)

T

e

p

12

> 0 if k

2

< k

1

; e

p

12

,= 0

and, for k

2

k

1

we obtain, by continuity,

r

s

[e

1

; k

1

; k

1

[e

p

11

< 0 if e

p

11

,= 0:

4. An iterative algorithm for shakedown analysis

A solution method, suitable to FEM analysis, is proposed in this section for the shakedown problem 3.1.

The method is based on an incremental-iterative process producing a sequence k

(k)

, k = 1; 2; . . . of multi-

pliers which, apart from the errors implied by the discretization, are safe according to Eq. (3.7) and con-

verge monotonously to the shakedown safety factor k

a

.

4.1. Finite element discretization

Assuming the structure has already been modeled by a standard FEM discretization, let u R

N

be the

vector collecting all free nodal displacements, u

0

its initial value and e[u[ := D(u u

0

) the (kinematically

compatible) local strains associated to the displacement increment u u

0

through compatibility matrix

D[x[. Assuming k 6

kk we can dene the internal force vector s[u; k[ R

N

expressing the structural response

consequent to the nodal displacements u:

s[u; k[ :=

Z

B

D

T

r[u; k[ dv; r[u; k[ := r

a

[r

0

Ee; k[ (4:1)

and the symmetric, positive denite elastic stiness matrix K

e

R

N

R

N

K

e

:=

Z

B

D

T

EDdv; K

e

= K

T

e

> 0 (4:2)

by the energy identities:

du

T

s[u; k[ =

Z

B

de

T

r[u; k[ dv; du

T

K

e

du =

Z

B

de

T

Ede dv; \du; de := Ddu; (4:3)

E being the elastic matrix, linking the strain vector e to the stress vector r and r

0

the initial stress state. Note

that r[u; k[ E

s

[k[, by denition. According with Eq. (2.1), self-equilibrated stresses are characterized, for

the discrete model, by the condition

s[u; k[ = 0: (4:4)

Using previous notations, the shakedown problem in Denition 3.1 can be rewritten in discrete

(approximate) form. We have to determine

k

a

:= max k : u : s[u; k[ = 0: (4:5)

So formulated, the shakedown problem looks very similar to the discrete formulation of the static theorem

of limit analysis, the only dierence being the role of the safety multiplier k which acts as an internal

parameter of function f

s

[r; k[ in spite of being an external load multiplier. However, this dierence can

R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792 5773

hardly be considered meaningful. For instance, in the case of monotonous loading, we can write the limit

analysis problem exactly in the form (4.5) if using the safety factor as multiplier for the elastic stress so-

lution in place of a load multiplier.

The analogies between the two problems suggest that the methods available for solving limit analysis

problems can be directly extended to the solution of shakedown ones. The solution method proposed in this

paper actually follows this line. It can be considered a direct adaptation to shakedown of the so-called strain

driven algorithm for incremental elasticplastic analysis [39] and corresponds to a direct extension of the

arc-length path-following method described in [14].

Some comments are useful here, before entering into the details of the proposed method. First of all,

note that, constitutive laws being locally dened, the return mapping scheme

r := r

a

[r

0

Ee; k[; e := D(u u

0

) (4:6)

can apply separately for each element (or Gauss point, if the element is dened by numerical integration).

Therefore, the evaluation of the internal force vector s[u; k[ for given u and k through Eq. (4.1) is actually a

very simple and computationally fast process. Some caution however has to be used in order to reduce

discretization errors and avoid generating incoherencies. It is known in fact (see [7,8]) that strictly com-

patible formulations can produce discretization locking; equally, a careless use of collocation procedures

can lose energy conservation laws.

Acomplete discussion of this topic is not possible here. As a general rule, we can suggest that discrete stress

eld r be dened by extending HaarKaarmaan equation (3.11) to the whole element, that is by the condition

/

e

:=

1

2

Z

B

e

(r r

+

)

T

E

1

(r r

+

)dv = min; r[x[ E

s

[k[; \x x

1

; . . . ; x

n

; (4:7)

where B

e

is the element volume, r

+

:= r

0

Ee. x

i

; i = 1; . . . ; n is a discrete set of control points, such that to

discretize, at least approximately, admissibility condition r E

s

[k[, \x B

e

, and r is self-equilibrated within

the element or, at least, satises Eq. (2.1) in B

e

for any de := Ddu. The implementation of condition (4.7) is

quite easy. An example will be given in Section 5.3, with reference to the simple case of beam elements.

Note also that, as a consequence of Lemmas 3.1 and 3.4, two dierent states (u

1

; k

1

) and (u

2

; k

2

), satisfy

the equation

r[u

2

; k

2

[ r[u

1

; k

1

[ = E

s

[k

2

; e

1

; e

2

[(e

2

e

1

) r

s

[e

1

; k

1

; k

2

[(k

2

k

1

);

where e

1

= Du

1

, e

2

= Du

2

. Then, by integrating on the volume and introducing the secant operators

K

s

[k

2

; u

1

; u

2

[ :=

Z

B

D

T

E

s

[k

2

; e

1

; e

2

[Ddv; y

s

[u

1

; k

1

; k

2

[ :=

Z

B

D

T

r

s

[e

1

; k

1

; k

2

[ dv; (4:8)

we obtain

s[u

2

; k

2

[ s[u

1

; k

1

[ = K

s

[k

2

; u

1

; u

2

[(u

2

u

1

) (k

2

k

1

)y

s

[u

1

; k

1

; k

2

[: (4:9)

Due to Lemma 3.4, matrix K

s

is obviously symmetric by construction and satises the conditions

0 6du

T

K

s

du 6du

T

K

e

du; \du: (4:10)

Finally, it is worth mentioning that, the return mapping scheme (4.6) requires k

j

6

kk; \j. We can compute

kk very easily as the smallest k value that renders E

s

void for some x B, which is obtained by scanning all

control points, once for all, at the beginning of the analysis.

4.2. The proposed solution method

We determine the shakedown limit state, that is the limit shakedown multiplier k

a

, the related admissible

self-equilibrated stress eld r

a

and the corresponding induced displacement eld u

a

, though a sequence of

5774 R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792

admissible safe states x

(k)

:= k

(k)

; r

(k)

; u

(k)

, k = 1; 2; . . ., starting from the elastic limit state x

(0)

:=

k

e

; 0; 0, such that s

(k)

:= s[u

(k)

; k

(k)

[ = 0, \k and monotonous non decreasing in k

(k)

. The sequence is ar-

rested when the limit shakedown state x

a

is reached, which is obtained when k

(k1)

= k

(k)

.

In each step of the process, the new state x

(k)

is obtained from the previous one x

(k1)

using an iterative

scheme which, starting from x

0

:= x

(k1)

, produces a convergent sequence of values x

j

:= k

j

; r

j

; u

j

, j =

1; 2; . . . by recursively updating the displacement vector and the load multiplier:

u

j1

:= u

j

_ uu

j

;

k

j1

:= k

j

_

kk

j

;

&

(4:11)

corrections _ uu

j

and

_

kk

j

being dened in order to satisfy, at least approximately, the equilibrium condition

s[u

j1

; k

j1

[ = 0 required by Eq. (4.5), while r

j1

is dened by the return mapping (4.6).

We have already seen that obtaining r

j1

from k

j1

and u

j1

is quite straightforward, so we can con-

centrate on the updating of u

j

and k

j

, which is obtained by dening corrections _ uu

j

and

_

kk

j

as the solution of

the linear system

K

e

y

j

y

T

j

0

!

;

_ uu

j

_

kk

j

!

=

s

j

0

!

; s

j

:= s[u

j

; k

j

[; (4:12)

where K

e

is the elastic stiness matrix dened by Eq. (4.3) and vector y

j

is dened, according to Eq. (4.8), as

y

j

:=

Z

B

D

T

r

s

[e

j

; k

j

; k

j1

[ dv =

1

k

j1

k

j

(s[u

j

; k

j1

[ s[u

j

; k

j

[): (4:13)

Eq. (4.12) is conveniently solved by partitioning. In explicit form, we obtain:

_

kk

j

=

y

T

j

K

1

e

s

j

y

T

j

K

1

e

y

j

; _ uu

j

= K

1

e

s

j

_

kk

j

K

1

e

y

j

: (4:14)

Note that k

j1

= k

j

_

kk

j

is required in Eq. (4.13) for obtaining y

j

, so Eq. (4.13) couples with the rst of

(4.14). However, k

j1

can easily be obtained by iteration as the limit of the sequence

~

kk

i

:= k

j

~yy

T

i

K

1

e

s

j

~yy

T

i

K

1

e

~yy

i

; ~yy

i

:=

1

~

kk

i

k

j

(s[u

j

;

~

kk

i

[ s

j

) (4:15)

which is initialized by assuming the rst evaluation for y

j

be dened as the initial tangent

y

j

~ ~yy

1

:= y[u

j

; k

j

; k

j

[: (4:16)

The sequence implements the secant iteration, so it is always convergent. Actually it converges very fast

and, considering that its solution is used within an external iteration scheme, only one loop is usually

needed. For obvious reasons, it is also convenient to introduce the constraint k

j

_

kk

j

6

kk.

The proposed solution algorithm is described in pseudo-code form in Table 1. Note that the iterative

process (4.11) and (4.12), for the kth step, is initialized by assuming

k

1

:= k

(k1)

b

(k)

(k

(k1)

k

(k2)

);

u

1

:= u

(k1)

b

(k)

(u

(k1)

u

(k2)

);

(4:17)

b

(k)

being an appropriate scaling factor we can relate to iteration loops performed in the previous step

by taking

R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792 5775

b

(k)

=

n

(k1)

nn

n

(k1)

nn

;

where n

(k1)

is the number of loops performed in the previous step and nn its assumed reference value

(typically nn ~ 4; . . . ; 8). The same formula is used in the rst step of the algorithm by making

u

(0)

= 0; r

(0)

= 0; k

(0)

= 0; u

(1)

= 0; r

(1)

= 0; k

(1)

= k

e

and assuming b

1

as a small fraction (b

1

~ 0:01).

The iteration process stops and the step is assumed to have been performed when

|s

j

| 6tol

1

; |s|

2

:= s

T

K

1

e

s: (4:18)

Finally, the algorithm is arrested when k

(k)

= k

(k1)

, within the assigned tolerance tol

2

. As we will see, that

implies the required shakedown solution has already been reached.

In the following subsections we will show the eectiveness of this strategy by proving that:

1. The sequence x

j

produced by the iterative scheme (4.11) and (4.12) converges to a new solution

x

(k)

:= k

(k)

; r

(k)

; u

(k)

, characterized by r

(k)

E

s

[k

(k)

[ and s[u

(k)

; k

(k)

[ = 0. Then, according to Eq. (4.5),

it provides a lower bound k

s

for the shakedown safety factor k

a

.

2. The succession of shakedown states x

(k)

satises the condition k

(k)

Pk

(k1)

. Furthermore, the occurrence

of k

(k)

= k

(k1)

implies k

(k)

= k

a

, so providing the shakedown solution.

Table 1

Pseudo-code for the proposed solution algorithm

1. Assemble and decompose matrix K

E

2. Compute the elastic solutions (u

e

i

; r

e

i

) for each basic load p

i

u

i

:= K

1

E

p

i

; r

i

:= EDu

i

:

3. Compute the elastic limit multiplier k

e

and initialize the solution process

u

(0)

:= 0; r

(0)

= 0; k

(0)

:= 0; u

(1)

:= 0; r

(1)

= 0; k

(1)

:= k

e

:

4. Repeat for k = 2; 3; . . .

(a) Evaluate, using Eq. (4.17):

k

1

:= k

(k1)

b(k

(k1)

k

(k2)

);

u

1

:= u

(k1)

b(u

(k1)

u

(k2)

):

(b) Repeat for j = 1; 2; . . .

v Compute r

j

through Eq. (4.6)

v Compute vectors s

j

and y

j

through Eqs. (4.12) and (4.16)

v Evaluate the new estimate x

j1

:

k

j1

= k

j

_

kk

j

u

j1

= u

j

K

1

E

(s

j

_

kk

j

y

j

)

(

;

_

kk

j

=

y

T

j

K

1

E

s

j

y

T

j

K

1

E

y

j

:

Until |s

j

| 6tol

1

(c) Update the solution

k

(k)

= k

j

; u

(k)

:= u

j

; r

(k)

:= r

j

:

Until k

(k)

k

(k1)

6tol

2

5. Obtain the solution of the shakedown problem

k

a

:= k

(k)

; u

a

:= u

(k)

; r

a

:= r

(k)

:

5776 R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792

4.3. Convergence of the iterative scheme (4.11) and (4.12)

In order to discuss the convergence of the iterative scheme, it is convenient to refer to the solution l

i

; z

i

of the eigenvalue problem

[lK

e

K

j

[z = 0:

Both matrices K

j

and K

e

being symmetric and the rst being positive dened, we know that l

i

and z

i

are

characterized by the conditions:

z

T

i

K

e

z

j

=

1 if i = 0;

0 if i ,= j;

&

z

T

i

K

j

z

j

=

l

i

if i = 0;

0 if i ,= j:

&

(4:19)

Obviously, due to Eq. (4.10) we also have

0 6l

i

61; \i: (4:20)

We are now ready to prove the following theorem:

Theorem 4.1 (convergence of the iterative scheme to a self-equilibrated solution). The sequence x

j

produced

by the iterative scheme (4.11) and (4.12) is convergent and its limit x

(k)

:= k

(k)

; r

(k)

; u

(k)

is characterized by

r

(k)

E

s

[k

(k)

[ and s[u

(k)

; k

(k)

[ = 0.

Proof. By denition (4.14) we have

s

j1

s

j

= K

j

_ uu

j

_

kk

j

y

j

;

_

kk

j

:=

y

T

j

K

1

e

s

j

y

T

j

K

1

e

y

j

; _ uu

j

:= K

1

e

(s

j

_

kk

j

y

j

)

that provides

s

j1

= s

j

_

kk

j

y

j

K

j

K

1

e

(s

j

_

kk

j

y

j

):

Then, expanding y

j

, s

j

and s

j1

in terms of z

i

y

j

= K

e

X

i

b

i

z

i

; s

j

= K

e

X

i

a

i

z

i

; s

j1

= K

e

X

i

~ aa

i

z

i

; (4:21)

we obtain, due to Eq. (4.19),

~ aa

i

= (1 l

i

)(a

i

_

kk

j

b

i

) (4:22)

and therefore

|s

j1

|

2

=

X

i

~ aa

2

i

=

X

i

(1 l

i

)

2

(a

2

i

_

kk

2

j

b

2

i

2

_

kk

j

a

i

b

i

): (4:23)

Due to Eq. (4.1), we have

y

T

j

_ uu

j

= y

T

j

K

1

e

(s

j

_

kky

j

) = 0 =

X

i

b

i

(a

i

_

kk

j

b

i

) = 0;

so we can simplify Eq. (4.23) into

|s

j1

|

2

=

X

i

(1 l

i

)

2

(a

2

i

_

kk

2

j

b

2

i

):

By comparison with

|s

j

|

2

=

X

i

a

2

i

R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792 5777

and using Eq. (4.20), we obtain

|s

j1

| 6|s

j

|

while

|s

j1

|

|s

j

|

< 1 if i : l

i

a

i

,= 0 or

_

kk

j

,= 0:

We then stated that the sequence |s

j

| is monotonously non increasing. It is also bounded from below

(|s

j

| P0) so it is convergent, while not necessarily to the limit |s| = 0. We can prove, however, that the

occurrence lim

j

|s

j

| > 0 is impossible. In fact, assuming

lim

j

|s

j

| > 0;

this implies

lim

j

_

kk

j

= 0; lim

j

l

i

a

i

= 0; \i

and, because of Eqs. (4.21) and (4.22),

lim

j

(s

j1

s

j

) = 0:

The sequence s

j

is then convergent and, by assumption,

s

(k)

= lim

j

s

j

,= 0:

We obtain, because of Eqs. (4.14) and (4.11)

lim

j

(u

j1

u

j

) = uu := K

1

e

s

(k)

,= 0

while having

lim

j

Z

B

(r

j1

r

j

)

T

(e

j1

e

j

) dv = lim

j

(s

j1

s

j

)

T

(u

j1

u

j

) = 0:

Due to Lemma 3.2, the latter implies lim

j

(r

j1

r

j

) = 0, therefore

lim

j

(e

p

j1

e

p

j

) := lim

j

(e

j1

e

j

) =ee := Duu ,= 0:

As a consequence, we should have

lim

j

e

p

jk

= e

p

j

kee = lim

j;k

1

k

e

p

jk

=ee;

but this implies

lim

j;k

(u

jk1

u

jk

)

T

y

jk

= uu

T

y

jk

=

1

k

Z

B

e

p

jk

r

s

[e

jk

; k

jk

; k

jk

[ dv < 0

which is absurd being in contrast with the Eqs. (4.11) and (4.12) which give (u

jk1

u

jk

)

T

y

jk

= 0, \j; k.

Therefore, we necessarily have lim

j

|s

j

| = 0. This implies the convergence of s

j

to a null vector

s

(k)

:= lim

j

s

j

= 0

5778 R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792

and, as a consequence,

lim

j

(u

j1

u

j

) = lim

j

K

1

e

s

j

= 0; lim

j

(k

j1

k

j

) = lim

j

y

T

j

s

j

y

T

j

y

j

= 0:

Both sequences u

j

and k

j

are then also convergent and we can dene

u

(k)

= lim

j

u

j

; k

(k)

= lim

j

k

j

:

Furthermore, r

a

[u; k[ being continuous in both u and k, r

j

:= r

a

[u

j

; k

j

[ is also convergent. So, being r

j

E

s

[k

j

[, \j by denition, we have

r

(k)

= lim

j

r

j

E

s

[k

(k)

[

which completes the proof.

4.4. Convergence to the shakedown solution

The convergence of the sequence x

(k)

produced by the incremental process to the required shakedown

solution is stated by the following theorem:

Theorem 4.2 (convergence of the incremental process to the shakedown solution). The sequence k

(k)

is

characterized by

k

(k1)

6k

(k)

6k

a

:

Furthermore, the occurrence of k

(k)

= k

(k1)

and u

(k)

,= u

(k1)

implies the achievement of the shakedown

solution:

k

a

= k

(k)

:

Proof. We have, r

(k)

S (according to Eq. (4.4)) and r

(k)

E

s

for any k, by denition. So condition k

(k)

6k

a

comes directly from Eq. (3.7). We also obtain

Z

B

(r

(k)

r

(k1)

)

T

e

(k)

dv = (s

(k)

s

(k1)

)

T

(u

(k)

u

(k1)

) = 0:

Then, by letting

e

(k)

= e

(ke)

e

(kp)

and remembering Eq. (4.1), we have

Z

B

(r

(k)

r

(k1)

)

T

e

(kp)

dv =

Z

B

e

(ke)

T

Ee

(ke)

dv 60:

This implies that k

(k)

Pk

(k1)

. In fact, if assuming k

(k)

< k

(k1)

, r

(k1)

E

s

[k

(k1)

[ is internal to E

s

[k

(k)

[ be-

cause of Eq. (3.3), then we should have, due to Druckers inequality (3.4),

Z

B

(r

(k)

r

(k1)

)

T

e

(kp)

dv > 0

which is a contradiction.

The case k

(k)

= k

(k1)

is only possible if e

(ke)

= 0. This implies

e

(kp)

= e

(k)

= D(u

(k)

u

(k1)

)

R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792 5779

that is, e

(kp)

K and e

(kp)

,= 0. Remembering that r

(k)

S, we have

Z

B

r

(k)

T

e

(kp)

dv = 0;

r

(k)

and e

(kp)

being associated by ow rule (3.10), by construction. The condition implies k

(k)

Pk

a

, because

of Eq. (3.8). Conversely, we have k

(k)

6k

a

, as shown before. Therefore, we obtain k

(k)

= k

a

, as stated by the

theorem.

It is worth mentioning that the step-length is naturally forced by the arc-length strategy (4.17), (4.11) and

(4.12), so the solution process does not need any special artice for avoiding a premature stop due to the

occurrence of u

(k)

= u

(k1)

.

4.5. A comment about computational updating of domain E

s

[k]

The shakedown admissible domain E

s

[k[ dened in Section 3.2 is a key ingredient of the proposed

method. It has to be updated according to k

j

at each iteration loop of the incremental process. The

computational eciency of its updating plays an important role in the analysis and specialized, fully op-

timized problem-dependent formulas should be used in general.

We discuss here the case when the yield conditions are piecewise linearized, that is, function f [r[ reduces

to a the m-faces polyhedron:

f [r[ := max

k

n

T

k

r

c

k

60; k = 1; . . . ; m: (4:24)

A very simple and fast formula is obtained in this case. According to Eq. (3.1), we have

f

s

[r; k[ = max

k

n

T

k

r

c

k

b

k

[k[

; b

k

[k[ := max

r

e

S

e

n

T

k

r

e

:

The elastic stress envelope S

e

being dened by the polyhedron

S

e

:= r

e

[t[ :=

X

p

i=1

a

i

[t[r

ei

: a

min

i

(

6a

i

[t[ 6a

max

i

; \t

)

;

we have

b

k

[k[ = k

X

p

i=1

a

ki

; a

ki

:=

a

min

i

n

T

k

r

ei

if n

T

k

r

ei

< 0;

a

max

i

n

T

k

r

ei

if n

T

k

r

ei

P0;

(

so f

s

[r; k[ is simply obtained in the form

f

s

[r; k[ = max

k

n

T

k

r

n

c

k

k

bb

k

o

; (4:25)

where

bb

k

:=

P

p

i=1

a

ki

is computed, once and for all, at the beginning of the process.

4.6. Some further comments

The described solution process can be viewed as a step-by-step incremental process aiming at simulating

the case of a proportional increasing loading evolution such that, in each step k, the load recycles within all

possible values in k

(k)

P up to the achievement of elastic adaptation.

Within this interpretation, the proposed solution process corresponds to a standard path-following

incremental process. Iteration scheme (4.11) and (4.12) actually corresponds to an implementation of the

Riks arc-length scheme [16,17]. We know (e.g. see [40]) that this scheme can be written in the form

5780 R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792

e

KK ~yy

Du

T

M c

!

_ uu

j

_

kk

j

& '

=

s

j

0

& '

;

where matrix

e

KK and vector ~yy are approximations for the Hessian K

t

:= os=ou and y

t

:= os=ok, Du := u

j

u

0

and M and c express the metric used for measuring the distance in the u; k space:

|Du; Dk|

2

:=

Du

Dk

& '

T

M

c

!

Du

Dk

& '

:

So Eq. (4.12) corresponds to the following assumptions:

y

t

:= y

j

;

e

KK := K

e

; MDu := y

j

; c = 0:

Dierent, even better, choices are obviously possible and could be usefully investigated. Actually, the

convenience of our assumptions lies in the fact that, with the particular choice made, we can easily prove

the convergence of both the iteration scheme and the solution process. It is worth mentioning that a similar

assumption has been proposed in [14] for implementing a path-following solution process for limit analysis

problems.

It is also useful to note that, in addition to k

(k)

and r

(k)

, the proposed solution process also produces a

solution in terms of both displacements u

(k)

and total (cumulated) plastic strains

X

k

i=0

e

(ip)

:=

X

k

i=0

Du

(i)

E

1

r

(i)

:

Obviously, these quantities are strictly related to the loading evolution law which is actually simulated and

then only dene lower bounds. However they can provide useful information about the elastic adaptation

process and can be taken as reference values to be used, within a conventional safety criterion, for eval-

uating safety factors for displacement and plastic deformation limit states (the available upper bounds on

plastic strains [4244] appears to wide for being suitable for technical purposes). Relations with the Ponter

Martin extremal paths theory [41] could also be usefully investigated.

Finally, it is worth mentioning that shakedown analysis reduces to limit analysis when the load domain

simplies to a single point p. So the proposed solution process can be directly used in limit analysis

problems. Actually it can be viewed as a slight variation of a standard path-following process for pro-

portionally increasing loads.

Dierences are related to the use of the additional stress r E

s

[k[. Path-following processes aiming to

recover limit analysis usually refer to the total stress r E and use k directly as a load amplier (see [14,17]).

So equilibrium is expressed by the condition

r[u; k[ := s[u[ kp = 0;

s being the nodal response due to the plastically admissible stress eld r associated to u, expressed in our

notations by

r := r

a

[r

0

Ee; 0[:

As a consequence, the correction scheme (4.12) becomes (see [14])

K

e

p

p

T

0

!

_ uu

j

_

kk

j

!

=

r[u

j

; k

j

[

0

!

; (4:26)

where p = or=ok is used in place of y

j

. Obviously, for every kinematically compatible plastic strain eld

e

p

:= Du

p

, we have

Z

B

r

T

e

p

dv = p

T

u

p

> 0;

R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792 5781

so this substitution also guarantees convergence for the same motivations as in Theorems 4.1 and 4.2. We

can expect quite similar behaviour and convergence properties for the two schemes, as conrmed by the

numerical tests shown in Section 6.4. Note however that scheme (4.12) requires the computation of vector

y

j

at each loop that is skipped by the standard scheme (4.26), so it is slightly more expensive. For this

reason it has to be considered as not particularly convenient for limit analysis problems, that is when we are

in the presence of a single loading case.

5. Shakedown analysis of plane frames

We now discuss some of the implementation details of the proposed solution method by referring to the

shakedown analysis of plane frames. This is a very simple but also technically meaningful application

context, so it is particularly suitable for exemplication purposes.

5.1. Finite element discretization

Let us consider a beam element and indicate with indices i and jths end-sections. Assuming a local

reference system x; y with the x axes coincident with the beam axis, the kinematics of the beam is de-

scribed by the motion of the normal sections in the x; y plane, that is, by its axial u[x[, transversal w[x[ and

rotational u[x[ components. Stresses are described by the strength elds N[x[, T[x[ and M[x[, which express

the axial and shear forces and the bending moment acting on beam sections, respectively. Obviously, a self-

equilibrated stress eld is expressed by

N[x[ = constant; M[x[ = linear; T[x[ = M

;x

= constant: (5:1)

It is convenient to refer to the so-called natural stresses:

m

a

:= N; m

s

:= M

i

M

j

; m

e

:= M

i

M

j

: (5:2)

We have:

N[x[ =

m

a

; T[x[ =

m

e

; M[x[ =

1

2

m

s

( m

e

(1 2n)); (5:3)

:= x

j

x

i

being the element length and n := (x x

i

)= a non-dimensional abscissa varying in [0 1[.

The element strain energy can be easily expressed as

U

b

:=

2

Z

1

0

N

2

EA

T

2

GA

+

M

2

EJ

dn; (5:4)

where A, A

+

and J are the area, the equivalent shear area and the inertia of the section, and E and G the

normal and transversal elastic moduli. We also have, from Clapeyrons theorem,

U

b

=

1

2

N(u

j

u

i

) T(w

j

w

i

) M

i

u

i

M

j

u

j

:

Therefore, by introducing the associated natural strains

/

a

:= (u

j

u

i

)=; /

s

:= (u

i

u

j

)=2; /

e

:= (u

i

u

j

)=2 (w

j

w

i

)=; (5:5)

we can write

U

b

=

1

2

m

a

m

s

m

e

8

<

:

9

=

;

T

/

a

/

s

/

e

8

<

:

9

=

;

: (5:6)

5782 R. Casciaro, G. Garcea / Comput. Methods Appl. Mech. Engrg. 191 (2002) 57615792

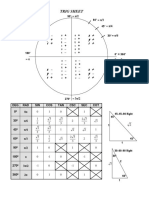

By combining Eqs. (5.3), (5.4) and (5.6), we obtain

U

b

=

1

2

/

a

/

s

/

e

8

<

:

9

=

;

T

k

a

k

s

k

e

2

4

3

5

/

a

/

s

/

e

8

<

:

9

=

;

; (5:7)

where

k

a

= EA; k

s

=

4EJ

; k

e

=

12EJ

(1 b)

; b :=

12EJ

GA

+

2

: