Professional Documents

Culture Documents

Hoja de Datos API-674

Uploaded by

texwan_Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hoja de Datos API-674

Uploaded by

texwan_Copyright:

Available Formats

JOB NO. PURCHASE ORDER NO. SPECIFICATION NO.

ITEM NO.

RECIPROCATING PUMP (API 674-2ND) DATA SHEET SI UNITS

1 APPLICABLE TO: 2 FOR 3 SITE 4 SERVICE 5 MANUFACTURER 6 NOTE: 7 8 NO. MOTOR DRIVEN 9 PUMP ITEM NO'S 10 MOTOR ITEM NO'S

11 MOTOR PROVIDED BY 12 MOTOR MOUNTED BY 13 MOTOR DATA SHEET NO. 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 48 50 51

REVISION NO. PAGE 1 OF 5

DATE BY

PROPOSAL

PURCHASE

AS BUILT UNIT NO. OF PUMPS REQUIRED SIZE AND TYPE SERIAL NO. BY MANUFACTURER

INDICATES INFORMATION TO BE COMPLETED BY PURCHASER GENERAL OTHER DRIVER TYPE PUMP ITEM NO'S DRIVER ITEM NO'S DRIVER PROVIDED BY DRIVER MOUNTED BY DRIVER DATA SHEET NO.

GEAR ITEM NO'S GEAR PROVIDED BY GEAR MOUNTED BY GEAR DATA SHEET NO. LIQUID TYPE OR NAME OF LIQUID

OPERATING CONDITIONS CAPACITY @ PT (m/h): @ MAXIMUN VISCOSITY @ MINIMUM VISCOSITY

PUMPING TEMPERATURE (C): NORMAL SPECIFIC GRAVITY SPECIFIC HEAT VISCOSITY (cp) MAXIMUM

COMPRESSIBILITY % MINIMUM MINIMUM Cp (kJ/kg C)

DISCHARGE PRESSURE (kPa)(BARG): MAXIMUM MINIMUM

MAXIMUM

SUCTION PRESSURE (kPa)(BARG): MAXIMUM MINIMUM

MINIMUM

MAXIMUM

DIFFERENTIAL PRESSURE (kPa)(BARG): MAXIMUM MINIMUM

CORROSIVE/EROSIVE AGENTS CHLORIDE CONCENTRATION (PPM) H2S CONCENTRATION (PPM) LIQUID TOXIC FLAMMABLE OTHER

NPSH AVAILABLE (m) WITHOUT ACCELERATION HEAD ACCELERATION HEAD (APP G) PERFORMANCE RATED CAPACITY (m/h) NPSH REQUIRED (m) PISTON SPEED (m/h) DISPLACEMENT (m/h) VOLUMETRIC EFFICIENCY (%) MECHANICAL EFFICIENCY(%) kW @ MAXIMUM VISCOSITY kW @ RELIEF VALVE SETTING MAXIMUM ALLOWABLE SPEED (RPM) MINIMUM ALLOWABLE SPEED (RPM) PINION SHAFT (RPM) HYDRAULIC kW BRAKE kW NET

SITE AND UTILITY DATA LOCATION HEATED INDOOR UNHEATED GROUP OUTDOOR UNDER ROOF DIV

ELECTRICAL AREA CLASS WINTERIZATION REQ'D SITE DATA RANGE OF AMBIENT TEMPS: MIN/MAX UNUSUAL CONDITIONS DUST OTHER UTILITY CONDITIONS ELECTRICITY VOLTAGE HERTZ PHASE COOLING WATER TEMPF PRESS.(kPa)(BARG) SOURCE INSTRUMENT AIR PRESSURE (kPa)(BARG) APPLICABLE SPECIFICATIONS MAX INLET RETURN MAX MIN DRIVERS HEATING FUMES

TROPICALIZATION REQ'D

SALT ATMOSPHERE

CONTROL

SHUTDOWN

FOR DIRECT-ACTING PUMPS: DRIVE GAS GOVERNOR TYPE INLET PRESSURE (kPa)(BARG) INLET TEMPERATURE (C) EXHAUST PRESSURE (kPa)(BARG) STALL PRESSURE (kPa)(BARG) GAS CONSUMPTION (kg/kW-h)

DESIGN

MAX

MIN

47 API 674 POSITIVE DISPLACEMENT PUMPS-RECIPROCATING

GOVERNING SPECIFICATION (IF DIFFERENT)

49 REMARKS:

06/95

SHT 1 OF 5

API674SI.XLS

REV 0

JOB NO.

ITEM NO. DATE OF 5 BY

RECIPROCATING PUMP (API 674-2ND) DATA SHEET SI UNITS

1 2 3 LIQUID END: 4 5 6 7 SIMPLEX DUPLEX SINGLE ACTING DOUBLE ACTING (2.7.1.1 THROUGH 2.7.1.4) MULTIPLEX NO. OF CYLINDERS HORIZONTAL VERTICAL PLUNGER PISTON REMOVABLE LINERS NO LINERS

REVISION NO. PAGE CONSTRUCTION 2

ANSI NOZZLES LIQUID SUCTION LIQUID DISCHARGE GAS INLET GAS EXHAUST GLAND FLUSH NUMBER SUCTION DISCHARGE DISC WING 2'BLE PORTED BALL AREA (mm) VELOCITY (m/h) DRAINS OTHER OTHER OTHER SIZE RATING FACING LOCATION

8 VALVES PER CORNER: 9 10 11

12 VALVE TYPE: 13 14 15 CYLINDER 16 LINER PART

MATERIALS LIQUID END ASTM NO. GAS END

17 PISTON OR PLUNGER 18 PISTON RINGS 19 PISTON ROD 20 VALVES/VALVE SEATS 21 GLAND 22 THROAT BUSHING 23 PACKING 24 LANTERN RING 25 BOLTING 26 OTHER 27 OTHER 28 29 30 31 32 33 34 35 36 MAXIMUM PRESSURE (kPa)(BARG) 37 MAXIMUM TEMPERATURE (C) 38 HYDROSTATIC TEST PRESS. (kPa)(BARG) 39 OTHER 40 41 42 43 44 45 46 47 48 49 50 REMARKS: 51 06/95 SHT 2 OF 5 API674SI.XLS REV 0 DIRECT COUPLED DRIVE MECHANISM V-BELT OR COG GEAR PACKING LUBE FLUSH SOURCE LUBRICATOR MAKE SIZE NO. OF FEEDS PRESSURE RATINGS LIQUID CYLINDER GAS CYLINDER NO. OF RINGS SIZE OF RINGS OTHER QA INSPECTION AND TEST COMPLIANCE WITH INSPECTORS CHECK LIST CERTIFICATION OF MATERIALS FINAL ASSEMBLY CLEARANCES SURFACE AND SUBSURFACE EXAMINATIONS RADIOGRAPHY ULTRASONIC MAGNETIC PARTICLE LIQUID PENETRANT CLEANLINESS PRIOR TO FINAL ASSEMBLY SKID HARDNESS OF PARTS, WELDS & HEAT AFFECTED ZONES FURNISH PROCEDURES FOR OPTIONAL TESTS TESTS HYDROSTATIC PERFORMANCE NPSH OTHER REQ'D X W/T OBS LIQUID END LUBRICATION LIQUID END PACKING GAS END VALVE ROD

COUPLING MANUFACTURER SOLEPLATES BASEPLATE

BY PUMP MANUFACTURER EXTENDED FOR

SUITABLE FOR EPOXY GROUT

SUBPLATES BY PUMP MANUFACTURER DRAIN-RIM LEVELING PADS DRAIN-PAN SUITABLE FOR COLUMN MOUNTING

JOB NO.

ITEM NO. DATE OF 5 BY CONTROLS

RECIPROCATING PUMP (API 674-2ND) DATA SHEET SI UNITS

1 2 MAXIMUM FRAME RATING: 3 kW @ RPM POWER FRAME

REVISION NO. PAGE 3

TYPE: MANUAL AUTOMATIC CAPACITY CONTROL: FLOW BYPASS ONLY YES NO VARIABLE SPEED ONLY REMOTE LOCAL

SIGNAL: PNEUMATIC ELECTRONIC

4 MAXIMUM PRESSURE RATING(kPa)(BARG) 5 CRANKSHAFT MATERIAL 6 NO. OF MAIN BEARINGS 7 TYPE OF MAIN BEARINGS 8 INTERNAL GEARS 9 10 GEAR RATIO GEAR SERVICE FACTOR

COMBINATION

VENDOR FURNISHES CS GOVERNOR & VALVE VENDOR TO FURNISH CONTROL PANEL FREESTANDING TACHOMETER REQUIRED ON UNIT OTHER TYPE

11 POWER END LUBRICATION: 12 TYPE 13 OIL PUMP: 14 15 16 MAIN AUXILIARY DRIVEN BY SPLASH POSITIVE PRESSURE GRAVITY

OTHER PURCHASE REQUIREMENTS NAMEPLATE UNITS U.S. CUSTOMARY SI

VENDOR REVIEW FURNISHED PROCESS PIPING

VENDOR REVIEW PIPING DRAWINGS VENDOR FURNISHED PULSATION SUPPRESSION DEVICES MAKE MODEL VENDOR FURNISHED RELIEF VALVE INTERNAL RELIEF VALVE SETTING (kPa)(BARG) LIQUID-FILLED PRESSURE GAUGES REQUIRED TECHNICAL DATA MANUAL REQUIRED DRIVERS MAXIMUM SOUND PRESSURE LEVEL @ m dBA dBA EXTERNAL

17 OIL FILTER: 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 06/95 SHT 3 OF 5 API674SI.XLS REV 0 REQUIRED NO. OF BELTS SIZE OF BELTS CHAIN DETAILS TOTALLY ENCLOSED GUARD SLIDE RAILS FOR ADJUSTMENT REQUIRED MANUFACTURER MODEL TYPE SERVICE FACTOR RATING V-BELT OR CHAIN DRIVE STEAM TURBINE OTHER (SEE SEPARATE DATA SHEETS) GEAR REDUCER MOTOR MANUFACTURER TYPE FRAME NO. CONSTANT SPEED VARIABLE SPEED kW VOLTS HERTZ ENCLOSURE RPM PHASE SERVICE FACTOR TYPE FILTRATION SIZE OIL COOLER TYPE SIZE

OVERSIZE NOZZLE MATING PARTS BY VENDOR QUENCH-TYPE GLANDS REQUIRED PROVIDE PACKING COLLECTION CHAMBER PROVIDE LANTERN RING PURGE SIZE OIL HEATER CONNECTION REQUIRED DISTANCE PIECE COVERS SAFETY GUARDS LOUVERED WEATHER COVERS ADDITIONAL OIL SYSTEM ITEMS FLOW INDICATOR STRAINER PRESSURE GAUGES OTHER TEMPERATURE GAUGES SOLID COVERS

OIL HEATER REQUIRED STEAM ELECTRIC

MECHANICAL LUBRICATION REQUIRED MINIMIM DESIGN METAL TEMPERATURE C GEARS COMPLY WITH API 613 API 677

API 671 COUPLINGS AND GAUGES REQUIRED PREPARATION FOR SHIPMENT DOMESTIC EXPORT WEIGHTS (kg) PUMP BASE GEAR DRIVER EXPORT BOXING

OUTDOOR STORAGE MORE THAN 6 MONTHS

JOB NO.

ITEM NO. DATE OF 5 BY

RECIPROCATING PUMP (API 674-2ND) DATA SHEET SI UNITS

1 2

REVISION NO. PAGE 4

PULSATION SUPPRESSION DEVICES FOR RECIPROCATING PUMPS(CONTD) THESE SHEETS TO BE FILLED OUT FOR EACH SERVICE AND /OR STAGE PROPOSAL PURCHASE AS BUILT

SERVICE STAGE NO.

3 APPLICABLE TO: 4 FOR/USER 5 SITE/LOCATION 6 PUMP SERVICE 7 PUMP MFG. 8 SUPPRESSOR MFG. 9 NOTE: 10 11

AMBIENT TEMPERATURE MIN/MAX NUMBER OF PUMPS MODEL/TYPE

Data Completed Purch.

By Pump/Supp. Mfg. w/Proposal

By Mfg(s) after order

By Mfg(s)/Purchaser as Applicable

GENRAL INFORMATION APPLICABLE TO ALL SUPPRESSORS

12 TOTAL NUMBER OF SERVICES AND /OR STAGES 13 14 15 16 17 18 19 HYDROTEST 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 06/95 SHT 4 OF 5 API674SI.XLS REV 0 COMBINATION INLET SUPP SEPARATOR/INTERNALS NO. (QTY) OF INLET &DISCH. SUPP. PER STAGE ALLOWABLE PEAK-PEAK PULSE @ LINE SIDE NOZZLE ALLOWABLE PEAK-PEAK PUSLE @ CYL FLANGE NOZZLE MIN. REQ'D WORKING PRESSURE & TEMPERATURE NOTE: After design, the actual Mawp & temp are to be determined based on the weakest component and stamped on the vessel. The actual Mawp is to be shown on pg. 5 line 11 and on the U1A Forms. (kPa)(BARG) @ C (kPa)(BARG) @ C (kPa)(BARG) (kPa)(BARG) % % (kPa)(BARG) (kPa)(BARG) % % YS. PUMP MANUFACTURER'S RATED CAPACITY LINE SIDE OPERATING PRESSURE OPERATING TEMP WITHIN SUPRESSORS ALLOWABLE PRESSURE DROP THROUGH SUPPRESSORS LIQUID HANDLED -SEE DATA SHEET PG. 1 PUMP DATA, THIS SERVICE OR STAGE ONLY NOTES: BORE DIA mm STROKE mm RPM OPERATING AND SUPPRESSOR DESIGN DATA NUMBER OF CYL. INTERNAL PASSAGES WITNESS OBSERVE DESIGN APPROACH: 1 W/SIMPLIFIED MANUAL ANALYSIS OF PIPING SYSTEM 2 ACOUSTIC SIMULATION STUDY STUDY TO BE WITNESSED: YES NO AMSE CODE STAMP STATE/COUNTRY/PROVINCE OF CODE AND REGULATIONS APPLY

OTHER APPLICABLE PRESSURE VESSEL SPEC. OR CODE RADIOGRAPHY (X-RAY OF WELDS): SHOP INSPECTION NONE SPOT 100% IMPACT TEST SPECIAL WELDING REQUIREMENTS

OUTDOOR STORAGE OVER 6 MONTHS

SPECIAL PAINT SPEC

PUMP VALVE DATA TYPE LIFT N mm WEIGHT LIFT AREA g

SPRING PRELOAD FULL PROJECTED AREA NORMAL OPERATING

SPRING RATE

EFF. FULL LIFT AREA

CORR. PRESENT (DESCRIBE) SPECIFIC GRAVITY COMPRESSIBILITY% OPERATION N PARALLEL W/ GPM INLET INLET P (kPa)(BAR) INLET SUPPRESSOR NO / YS. NO (kPa)(BARG) C % DISCHARGE DISCHARGE P (kPa)(BARG) DISCHARGE SUPPRESSOR / YES NO (kPa)(BARG) C %

JOB NO.

ITEM NO. DATE OF 5 BY

RECIPROCATING PUMP (API 674-2ND) DATA SHEET SI UNITS

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 PUMP MFG'S SUPP. OUTLINE OR DRAWING NO. SUPPRESSOR MFG'S OUTLINE OR DRAWING NO. LINE SIDE FLANGE, PUMP FLANGE(S),QTY: FLANGE FINISH, SUPPORTS, TYPE/QUANTITY

REVISION NO. PAGE 5

PULSATION SUPPRESSION DEVICES FOR RECIPROCATING PUMPS (CONT'D) THESE SHEETS TO BE FILLED OUT FOR EACH SERVICE AND/OR STAGE CONSTRUCTION REQUIREMENTS & DATA BASIC MATERIAL REQUIRED, CS, SS, ETC. ACT.MAT.,ASTM OR SA DESIGNATION SPECIAL HARDNESS LIMITATIONS Rc CORROSION ALLOW. (mm) WALL THICKNESS, (mm) NOM. SHELL DIA x OVERALL LGTH. YES REQUIRED SHELL/HEAD mm/VOL.m x PIPE DP mm/ mm/ SHELL/HEAD NO / SHELL & HEADS WELDS mm mm m ROLLED PLATE C % kg YES NO DP INLET SUPPRESSOR

SERVICE STAGE NO. DISCHARGE SUPPRESSOR

/ SHELL & HEADS WELDS mm mm/ x PIPE mm/ mm m ROLLED PLATE C % kg YES NO

PIPE OR ROLLED PLATE CONSTRUCTION ACT MAX ALLOW. WORKING PRESS AND TEMPERATURE MAX EXPECTED PRESSURE DROP D P, (kPa)(BAR)% LINE PRESS WEIGHT, kg EACH INSUL NUTS & ALLOW. FOR INSULATION REQUIRED EXPECTED P-P PULSE @ LINE SIDE CYL FLG, % LINE PRESS BASED ON FINAL SUPPRESSOR DESIGN

(kPa)(BARG) @ (kPa)(BAR) /

(kPa)(BARG) @ (kPa)(BAR) /

%/

%/

CONNECTION REQUIREMENTS & DATA SIZE RATING/FACING/TYPE SIZE RATING/FACING/TYPE SPECIAL (SPECIFY) PER ASME 16.5 INSPECTION OPENINGS REQUIRED SPEC. QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING *QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING VENT CONNECTIONS REQUIRED SPEC. QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING *QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING DRAIN CONNECTIONS REQUIRED SPEC. QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING *QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING PRESSURE CONNECTIONS REQUIRED SPEC. QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING *QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING TEMPERATURE CONNECTIONS REQUIRED SPEC. QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING CYL NOZZLE MAIN BODY YES NO YES NO YES NO YES NO YES NO YES NO YES NO YES NO YES NO BLINDED YES NO BLINDED

*QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING

OTHER DATA AND NOTES

45 NOTES* = AS BUILT 46 47 48 49 50 51 06/95 SHT 5 OF 5 API674SI.XLS REV 0

(kPa)

You might also like

- Reciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsDocument10 pagesReciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsÆmanuel J Silva100% (1)

- Api 674,2Nd Edition: Reciprocating Pump Data Sheet Revision Record SheetDocument22 pagesApi 674,2Nd Edition: Reciprocating Pump Data Sheet Revision Record SheetmaruthigabbitaNo ratings yet

- AJAX 2801 15in CylinderDocument18 pagesAJAX 2801 15in CylinderUmair A. KhanNo ratings yet

- Specification For Rotary Pump: Pt. Pertamina Ep Matindok Gas Development Project (MGDP)Document27 pagesSpecification For Rotary Pump: Pt. Pertamina Ep Matindok Gas Development Project (MGDP)roronoa_zorro11No ratings yet

- PTIMS-OPS-DS-013 - Chemical Injection Pump Rev 3Document2 pagesPTIMS-OPS-DS-013 - Chemical Injection Pump Rev 3Hua Tien DungNo ratings yet

- Sparger Calc MotDocument5 pagesSparger Calc MotRajesh NareNo ratings yet

- Book 08 (CS)Document35 pagesBook 08 (CS)dirgan_udyanaNo ratings yet

- Calculation Note - Tank Rev 1Document3 pagesCalculation Note - Tank Rev 1Steve WanNo ratings yet

- AJAX Brochure PDFDocument8 pagesAJAX Brochure PDFupper20cNo ratings yet

- Gear Pump Datasheets 1Document12 pagesGear Pump Datasheets 1MauliNo ratings yet

- Filtro Separador de Agua 900fhDocument2 pagesFiltro Separador de Agua 900fhale alvarezNo ratings yet

- 3E AND 110H/210H SERIES Canned Motor Pumps: R S P W C I MDocument16 pages3E AND 110H/210H SERIES Canned Motor Pumps: R S P W C I Mari_prasNo ratings yet

- RDS-003 1st 1994 Reciprocating PumpDocument10 pagesRDS-003 1st 1994 Reciprocating PumpDesaiNo ratings yet

- Vent To Flare 1683883352Document31 pagesVent To Flare 1683883352saheem_783617392No ratings yet

- Natural Gas Conversion Guide PDFDocument52 pagesNatural Gas Conversion Guide PDFTinuoye Folusho OmotayoNo ratings yet

- Calculation and Specification of Engine Lubricating Oil SystemDocument34 pagesCalculation and Specification of Engine Lubricating Oil SystemM Taufiq Khan100% (1)

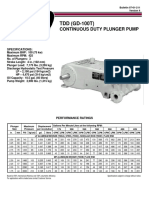

- Data Sheet TDD-GD100T PDFDocument2 pagesData Sheet TDD-GD100T PDFjhon peñaNo ratings yet

- Separator 42x10Document3 pagesSeparator 42x10Praveen VelathNo ratings yet

- Malmedi 50HZ 14-09-04Document538 pagesMalmedi 50HZ 14-09-04rhusseinpos4765No ratings yet

- A11627SE-08 - CVDS Rev B Technical Specification 840GDocument2 pagesA11627SE-08 - CVDS Rev B Technical Specification 840GMichael Adu-boahenNo ratings yet

- Engine Lubricating Oil System: Design Iv Machinery System Department of Marine EngineeringDocument22 pagesEngine Lubricating Oil System: Design Iv Machinery System Department of Marine EngineeringRaka Adhwa MaharikaNo ratings yet

- Standard Procedure For Vacuum Decay Test (Advisory Procedure)Document7 pagesStandard Procedure For Vacuum Decay Test (Advisory Procedure)Jonathan MoralesNo ratings yet

- Nger Ko Nccal 00 39082Document41 pagesNger Ko Nccal 00 39082Osas AsemotaNo ratings yet

- Manual Flare Sim ExproDocument69 pagesManual Flare Sim ExproJuan Pablo AlonsoNo ratings yet

- API-14E Gas CondensateDocument2 pagesAPI-14E Gas Condensatenwosu_dixonNo ratings yet

- Calculation of Maximum Discharge RateDocument1 pageCalculation of Maximum Discharge Ratech3g44No ratings yet

- 254624-400-DS-PRO-310, Rev F - Datasheet of VRUDocument18 pages254624-400-DS-PRO-310, Rev F - Datasheet of VRURamesh SharmaNo ratings yet

- E07 QDocument20 pagesE07 QSoledad Fernández SantosNo ratings yet

- NPSH Calculations For Reciprocating PumpDocument1 pageNPSH Calculations For Reciprocating PumpMadan YadavNo ratings yet

- Full Page GA DrawingDocument1 pageFull Page GA DrawingHENDRIK2011No ratings yet

- Action Plan Flame DetectorDocument2 pagesAction Plan Flame DetectorardipangulihiNo ratings yet

- Service PerformanceDocument1 pageService PerformancewalleyranNo ratings yet

- Criteria To Determine Adequacy of Existing Pump - Industrial Professionals - CheresourcesDocument3 pagesCriteria To Determine Adequacy of Existing Pump - Industrial Professionals - CheresourcesDhamotharan ChinnaduraiNo ratings yet

- DR - Reciprocating Compressor Table of Contents (Process)Document5 pagesDR - Reciprocating Compressor Table of Contents (Process)rutujaNo ratings yet

- 48" X 15' Three Phase Test SeparatorDocument2 pages48" X 15' Three Phase Test Separatorpraash bhattNo ratings yet

- Ficha Técnica - ElectricaDocument8 pagesFicha Técnica - ElectricainspeccionestecnicasnfpaNo ratings yet

- Notes Information Below To Be Completed: by Manufacturer or PurchaserDocument5 pagesNotes Information Below To Be Completed: by Manufacturer or Purchaserrajindo1No ratings yet

- Data Sheet Centrifugal Pump ASME B73.1 B73.2: CUS TOM LOG ODocument4 pagesData Sheet Centrifugal Pump ASME B73.1 B73.2: CUS TOM LOG Ogabriel riveroNo ratings yet

- Volumetric Flow ControlDocument15 pagesVolumetric Flow Controlavi_ca22100% (1)

- Increasing The Profits & Production of Mature Fields Through Optimized Jet Pump Design & Operational ConsiderationsDocument9 pagesIncreasing The Profits & Production of Mature Fields Through Optimized Jet Pump Design & Operational ConsiderationsIndra BayuNo ratings yet

- pR6-40-10-4 HPDocument2 pagespR6-40-10-4 HPS.DharanipathyNo ratings yet

- Separator 1 Sizing Spread Sheets PDF FreeDocument21 pagesSeparator 1 Sizing Spread Sheets PDF FreeHenry WicaksanaNo ratings yet

- ChecklistDocument3 pagesChecklistAndy Noven KrisdiantoNo ratings yet

- Multiphase Pump MPC 208 - 38/1 / N: 1.0 Project DataDocument2 pagesMultiphase Pump MPC 208 - 38/1 / N: 1.0 Project DataRabah Semassel100% (1)

- CEN-ING-18011-MEE-PL-001-2 Trampa de Despacho JF PDFDocument1 pageCEN-ING-18011-MEE-PL-001-2 Trampa de Despacho JF PDFAlexanderNo ratings yet

- 41000Document36 pages41000tetiospamNo ratings yet

- Api 2005Document2 pagesApi 2005Madeline DacianNo ratings yet

- Flare Stack - FinalDocument7 pagesFlare Stack - FinalIoana Popescu0% (1)

- A 01 Pumps, Valves & CoolersDocument24 pagesA 01 Pumps, Valves & CoolersСергей КороткийNo ratings yet

- Goulds PumpsDocument44 pagesGoulds PumpscridavarNo ratings yet

- Gemini A, D, E, F Series Unbalanced CouplesDocument10 pagesGemini A, D, E, F Series Unbalanced Couplesgustavoespinosam100% (1)

- Ipa-Water SeparationDocument8 pagesIpa-Water SeparationkashifwarsiNo ratings yet

- API STD 676-2009 - Hoja de RequisiciónDocument28 pagesAPI STD 676-2009 - Hoja de RequisiciónRicardo CastroNo ratings yet

- API 674 Pump Data SheetDocument5 pagesAPI 674 Pump Data SheetEason Ng100% (2)

- Pump DatasheetDocument10 pagesPump DatasheetPaulusIwan100% (1)

- 674 Reciprocating Pump DatasheetsDocument6 pages674 Reciprocating Pump DatasheetsAKSHEYMEHTANo ratings yet

- API 674 Pump Data SheetDocument5 pagesAPI 674 Pump Data SheetFahmi AtriadiNo ratings yet

- DATA SHEET MULTIPHASE PUMP REV0 BornermanDocument5 pagesDATA SHEET MULTIPHASE PUMP REV0 BornermanJessika López100% (1)

- Api 676 UsDocument2 pagesApi 676 UsAbhai Gupta100% (1)

- EHB en 0-IntroductionDocument0 pagesEHB en 0-IntroductionAquos78No ratings yet

- Steam TurbineDocument8 pagesSteam TurbineWalid FattahNo ratings yet

- Hrd-f02!02!0412 Bio Data DC (Rev 02)Document1 pageHrd-f02!02!0412 Bio Data DC (Rev 02)texwan_No ratings yet

- Williams W Series Pump IomDocument25 pagesWilliams W Series Pump Iomtexwan_No ratings yet

- EHB en File 2.2-Loading-PrincipleDocument1 pageEHB en File 2.2-Loading-Principletexwan_No ratings yet

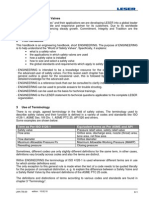

- Valves Brame HydrogenengineeriDocument3 pagesValves Brame Hydrogenengineeritexwan_No ratings yet

- Leser PSV SizingDocument83 pagesLeser PSV SizingjrfmlNo ratings yet

- EHB en 10-ConnectionsDocument102 pagesEHB en 10-Connectionstexwan_No ratings yet

- EHB en 11 Quality and Environmental ManagementDocument23 pagesEHB en 11 Quality and Environmental Managementtexwan_No ratings yet

- Leser PSV SizingDocument83 pagesLeser PSV SizingjrfmlNo ratings yet

- EHB en 9-MaterialsDocument0 pagesEHB en 9-MaterialsAquos78No ratings yet

- Pumping Station Design For EngineersDocument171 pagesPumping Station Design For EngineersMuhammad Irfan AwanNo ratings yet

- EHB en 10-ConnectionsDocument102 pagesEHB en 10-Connectionstexwan_No ratings yet

- EHB en 6 Installation and Plant DesignDocument64 pagesEHB en 6 Installation and Plant Designtexwan_No ratings yet

- Previews HI 9 6 1 2012 PreDocument12 pagesPreviews HI 9 6 1 2012 Pretexwan_100% (2)

- EHB en 2 Design FundamentalsDocument30 pagesEHB en 2 Design FundamentalstdecebalusNo ratings yet

- EHB en 3-TerminologyDocument32 pagesEHB en 3-Terminologytexwan_No ratings yet

- Turbo Tutorial API 619 5thDocument33 pagesTurbo Tutorial API 619 5thmishraengg100% (2)

- D 512Document1 pageD 512texwan_No ratings yet

- BAV BAVM 9510-070-EnDocument23 pagesBAV BAVM 9510-070-Entexwan_No ratings yet

- Propane PropertiesDocument4 pagesPropane Propertiestexwan_No ratings yet

- DeaDocument2 pagesDeatexwan_No ratings yet

- Bisnis SapiDocument5 pagesBisnis SapiIlham AdinusaNo ratings yet

- EHB en 1 History and Basic FunctionDocument0 pagesEHB en 1 History and Basic FunctionAquos78No ratings yet

- 22 G3512 C555Document4 pages22 G3512 C555texwan_No ratings yet

- Pipe Flow Design 1: Results DataDocument7 pagesPipe Flow Design 1: Results Datatexwan_No ratings yet

- Pipe Flow Design 1: Results DataDocument7 pagesPipe Flow Design 1: Results Datatexwan_No ratings yet

- Ansi Atex LR CompleteDocument148 pagesAnsi Atex LR Completetexwan_No ratings yet

- Pipe Flow Design 1: Results DataDocument7 pagesPipe Flow Design 1: Results Datatexwan_No ratings yet

- Triplex Pump Design PDFDocument56 pagesTriplex Pump Design PDFManatchai BattōsaiNo ratings yet

- Properties of Lubricants and Lubrication PDFDocument74 pagesProperties of Lubricants and Lubrication PDFZegera MgendiNo ratings yet

- Potential of Air Lift PumpsDocument6 pagesPotential of Air Lift Pumpsmiguelq_scribd100% (1)

- Phy ss2Document5 pagesPhy ss2sulayajannyNo ratings yet

- Alloying ElementsDocument81 pagesAlloying Elementsdrackensohn100% (1)

- Work With FunDocument8 pagesWork With FunnooriNo ratings yet

- Chapter 9 Design of Flowing Well System - 1987 - Developments in Petroleum ScienDocument48 pagesChapter 9 Design of Flowing Well System - 1987 - Developments in Petroleum ScienFalokid RaboNo ratings yet

- Condensation: Condensation in The BathroomDocument1 pageCondensation: Condensation in The BathroomAlex ZhangNo ratings yet

- 50-125 Kotron RF Sensing ProbesDocument8 pages50-125 Kotron RF Sensing ProbesAbdul Shaharlal ENo ratings yet

- Article - CO2 Diffusion From PET Bottles - For Packaging India April 19Document8 pagesArticle - CO2 Diffusion From PET Bottles - For Packaging India April 19Darshan VartakNo ratings yet

- Cold Pad Batch CPB - A Sustainable Dyeing Process For Woven and Knit IndustryDocument5 pagesCold Pad Batch CPB - A Sustainable Dyeing Process For Woven and Knit IndustryJohurul HoqueNo ratings yet

- GS 140 1 Glycol DehydrationDocument16 pagesGS 140 1 Glycol DehydrationPedro Diaz100% (1)

- Combination Air Valve For Wastewater - Short Version: DescriptionDocument4 pagesCombination Air Valve For Wastewater - Short Version: DescriptionVanderson LimaNo ratings yet

- How Do You Make LiquidDocument2 pagesHow Do You Make LiquidjukortaNo ratings yet

- Scientific Instruments ListDocument12 pagesScientific Instruments Listanon-257658100% (11)

- General Chemistry 2 - Q3 - SLM6Document11 pagesGeneral Chemistry 2 - Q3 - SLM6Jonnel RoqueNo ratings yet

- CBSE Class 9 Science Sample Paper SA 1 Set 2 PDFDocument2 pagesCBSE Class 9 Science Sample Paper SA 1 Set 2 PDFharish gupta0% (1)

- Kinetic Molecular Model of Solids and Liquids Activity 1: Color DropDocument12 pagesKinetic Molecular Model of Solids and Liquids Activity 1: Color DropElaine Mae G. EsqueroNo ratings yet

- Airlift CFD SimulationDocument7 pagesAirlift CFD Simulationlrodriguez_892566No ratings yet

- The Efficacy of KamiasDocument12 pagesThe Efficacy of KamiasHannah ۦۦNo ratings yet

- Title: Aim:: Arushi Sinha Coordinated Sciences BDocument5 pagesTitle: Aim:: Arushi Sinha Coordinated Sciences BSIDDHANo ratings yet

- Lecture - 3 Surface and Interfacial PhenomenaDocument19 pagesLecture - 3 Surface and Interfacial PhenomenaAshique Farhad60% (5)

- Us 4597889Document5 pagesUs 4597889topguitarNo ratings yet

- Density, Viscosity & Drag (Multiple Choice) QPDocument4 pagesDensity, Viscosity & Drag (Multiple Choice) QPSam JoeNo ratings yet

- Ch1 Introduction Fundamentals of Fluid MechanicsDocument45 pagesCh1 Introduction Fundamentals of Fluid MechanicsAsif SunnyNo ratings yet

- 3117Document14 pages3117Umar SabaNo ratings yet

- Tutorial 2 - Physical OperationsDocument2 pagesTutorial 2 - Physical OperationsnasuhaNo ratings yet

- Hydraulic LiftDocument9 pagesHydraulic LiftAkshay ThakareNo ratings yet

- 1.0-Hydraulics and Fluid Mechanics CompletedDocument18 pages1.0-Hydraulics and Fluid Mechanics Completedwaleed AlkaseriNo ratings yet

- Fluxes For Electroslag Refining: Dr. Satadal GhoraiDocument21 pagesFluxes For Electroslag Refining: Dr. Satadal GhoraiGarry's GamingNo ratings yet

- OGP Ignition Probability 436 6Document30 pagesOGP Ignition Probability 436 6Lieu Dinh PhungNo ratings yet