Professional Documents

Culture Documents

Box Pushing Methodology

Uploaded by

Tamizhan_KCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Box Pushing Methodology

Uploaded by

Tamizhan_KCopyright:

Available Formats

CONTENTS

1.0 2.0

INTRODUCTION ........................................................................................................ 2 STRUCTURAL COMPONENT ........................................................................................ 3 2.1 2.2 2.3 Thrust bed ........................................................................................................ 3 Precast R.C.C. Box ............................................................................................. 4 Front Cutting Shield & Rear Jacking Shield ........................................................... 5 Hydraulic Equipment .......................................................................................... 7 Intermediate Jacking Station .............................................................................. 8 Introduction .................................................................................................... 10 Box pushing methodology ................................................................................ 10 Analysis and Design methodology ..................................................................... 10 Material properties........................................................................................... 11 Primary load cases........................................................................................... 11 Detailed design calculations .............................................................................. 11

3.0

PUSHING OPERATION OF THE BOX............................................................................. 6 3.1 3.2

4.0

DESIGN EXAMPLE .................................................................................................... 10 4.1 4.2 4.3 4.4 4.5 4.6

5.0

CONCLUSION .......................................................................................................... 11 APPENDIX A APPENDIX B

1.0

INTRODUCTION

This Present day Intensity of Traffic, both Rail & Road due to the fast development of Industries and other Infrastructures, is very heavy and so it cannot the disturbed, for construction of under bridges or Canal Crossings, drainage etc by conventional construction methods. So to construct such structures, Box Pushing Technique is developed where in R.C.C. Boxes in segments are cast outside and pushed through the heavy embankments of Rail or Road by Jacking. The required thrust is generated through thrust bed, as well as line and level of precast boxes are also controlled

2.0 2.1

STRUCTURAL COMPONENT Thrust bed

The thrust bed, thrust Beam and keys are designed in R.C.C. to resist the required Thrust extorted by Jacking force and transfer it to soil at bottom and sides. In cohesive soils even shallow piles are required to transfer the load. Provision for jacking supports is made by providing suitable pockets in the thrust bed to accommodate pin supports. During the construction of precast box segments on the thrust bed, the thrust bed are filled with sand or any other filling material, and the same is covered with screed layer of cement mortar of 50mm thickness.

2.1 Casting bed showing jacking pin pockets in position

2.2 Construction of casting bed

2.2

Precast R.C.C. Box

The Precast Box is cast in segments of convenient lengths of Total pushing length. The Box section is designed as per IRS / IRC codes of practice for loading. Concrete grade normally kept as M-35. Front face of the precast box segment which pierce into the embankment is provided with inclined edge as shown in the following figure.

2.3 Front face of concrete precast segment

2.3

Front Cutting Shield & Rear Jacking Shield

The First Segment of the precast box is provided with a specially designed structure named as cutting shield which forms the front working face with a cutting edge fabricated from 16 to 20 mm thick M.S. Plates and housed on RCC Box section with suitable anchor bolts. Necessary strengthening is provided by stiffeners and face plates of Box in front on completion of jacking the outer shell of the shield is cut and removed The Rear Jacking shield is provided by anchoring steel plate on the face of Bottom slab of RCC Box suitably designed to distribute the jacking load uniformly on concrete area.

3.0

PUSHING OPERATION OF THE BOX

The purpose of pushing of Box is to form a horizontal opening below ground or through embankments, can say a tunnel, by providing precast box units underground or an embankment, without disturbing the overhead amenities, like traffic & structures. To reduce the frictional resistance, a thin film of Grease and thick gauge plastic sheet is provided between the top of the thrust bed & Bottom of the Box. This is done before casting of the Bottom slab of the box. A Glossy Epoxy layer is also provided to reduce friction on the top and prevent the disturbance of the mass over box to least during progress of pushing Where mass of embankment is less or the soil is of poor quality, drag sheet system is also considered for least resistance of friction and disturbance of mass above box. This avoids disturbance of track structure due to the pushing operation where minimum depth of earth cushion is provided over the top of box. Typical drag sheet arrangement is shown in the following figure.

Figure 3.1 Drag sheet arrangement over box

Figure 3.2 Drag sheet arrangement over box with truss

Auxiliary beds are also provided for casting of the other segments with thin film of grease and plastic and segments are then brought in alignment of pushing as and when required as pushing progresses. With the progress of jacking, the front unit with shield penetrates into the embankment and there after excavation within the shield is done either manually or mechanically and the excavated stuff is transported outside the working area. After the first segment advances to the end of the thrust bed, the second segment is brought in alignment of the front Box & intermediate jacking space is lift between the two. The progress of pushing is kept continuous and the system of side shifting of remaining box segments from Auxiliary bed and bring in pushing alignment is adopted till total length is pushed.

3.1

Hydraulic Equipment

The entire Box Pushing system is matter of proper selection of Hydraulic equipments, as tremendous driving force is required for pushing of medium to large size of Boxes. So for this, Number of Jack units are provided in series for distribution of pushing load evenly on the face of the

concrete, and all Jacks are operated simultaneously with a common power pack, which supplies uniform flow of pressure through network of Hydraulic pipes of required pressure capacity, commencing from front unit to rear unit. Jacking force is applied in sequence. This way pushing cycles are repeated till total pushing is completed.

Figure 3.3 Jacking of end segment of box from thrust bed

3.2

Intermediate Jacking Station

As total length of Box is casted in Segments, each segment is pushed turn by turn with necessary jacking force and so for this necessary intermediate jacking stations are provided, with jacking pockets in bed & walls.

Figure 3.4 Jacking of intermediate segment

4.0 4.1

DESIGN EXAMPLE Introduction

Design of RUB which is proposed for a rail connectivity taking off from railway station is covered in this document. The RUB is a RCC box of size 1 x 7.5 x 5.888m which has to be constructed below the railway track. It is proposed to use Box pushing methodology for making the underpass without interrupting the rail traffic above it. Barrel length of the box is 22.0m.

4.2

Box pushing methodology

Box pushing Methodology is a well suited construction method for making underpass below the rail tracks without disturbing the rail traffic. Number of RCC box segments to be pushed is depending upon the barrel length of the RUB. In this project, two box segments of 11.0m each is used. The entire operation takes place by pushing the box against thrust bed, and removing the soil at the front end of the first box segment. Thrust bed consists mainly of thrust wall, pin pockets and keys for additional resistance. Thrust bed is designed for box pushing force which depends on the frictional resistance of the soil.

4.3

Analysis and Design methodology

Analysis of the box has been done by moment distribution method by considering all the loads on it and with suitable load combinations. IRC-6 : 2010 has been followed for arriving the effect of road traffic on the base slab. In addition to these loads pushing force on the box and frictional resisting force due to soil also considered for the design. Design bending moments and design shear forces have been taken from the moment distribution method. The design of structural elements has been carried out using IRS codes - Limit state method as per codes: IRS Substructure Code, Concrete Bridge Code and Bridge rules.

4.4

Material properties

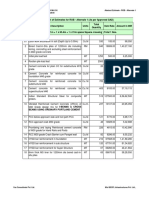

Table 4.1 Material Properties

Material Grade of Concrete for box Grade of Steel reinforcement Grade of Steel reinforcement for Shear

Grade M35 Fe 500 Fe 415

4.5

Primary load cases

i. ii. iii. iv. v. vi. vii. Self weight, and earth fill over the box Super imposed dead load Rail Live load and traction forces (Bridge rules, IRS) Box pushing forces and resisting forces from the soil Earth Pressure Surcharge Pressure(Due to DL & LL) Road traffic loads

4.6

Detailed design calculations

Detailed load calculation, analysis, Calculation of pushing force, Design of RUB and thrust bed are provided in Appendix A

5.0

CONCLUSION

The entire system is purely technical, dependent on Hydraulic system, & safest method of crossing underground / Embankment, without disturbing overhead traffic / structures for R.U.B., Canal siphon and other drainage crossings.

Appendix A Design Calculations

Appendix B Drawings

You might also like

- Box Pushing Technology PresentationDocument21 pagesBox Pushing Technology Presentationrakeshraj mahakudNo ratings yet

- Box PushingDocument44 pagesBox PushingAnonymous UebIaD8A8C50% (2)

- Box Pushing Technique MethodologyDocument1 pageBox Pushing Technique MethodologyMALLUGARI SAIGNAN0% (1)

- Methodology For Precast Box CulvertsDocument3 pagesMethodology For Precast Box Culvertsyash_monu05No ratings yet

- Box Pushing Technology PresentationDocument20 pagesBox Pushing Technology PresentationRavindra RajuNo ratings yet

- Land Transportation Implementation Cross (Bridge) Using Box Pushing TechnologyDocument5 pagesLand Transportation Implementation Cross (Bridge) Using Box Pushing TechnologyNaresh KumarNo ratings yet

- Construction of Under Bridge.Document16 pagesConstruction of Under Bridge.Ankit Panwar100% (1)

- Box PushingDocument4 pagesBox PushingNArendra REddy100% (3)

- Box Pushing Tech SeminarDocument20 pagesBox Pushing Tech SeminarVaishnavi Hallikar75% (4)

- Morth 2900 Pipe CulvertsDocument5 pagesMorth 2900 Pipe CulvertsRamesh100% (3)

- HI-SI Toll Plaza Marking R2-23-01-2020 Final PDFDocument4 pagesHI-SI Toll Plaza Marking R2-23-01-2020 Final PDFRamBhuvan SonkarNo ratings yet

- Re-Wall MethodologyDocument9 pagesRe-Wall Methodologytitus100% (3)

- Paper Presented at CRRI On Bottom Plug in Well FoundationsDocument11 pagesPaper Presented at CRRI On Bottom Plug in Well FoundationskishoredataNo ratings yet

- PSC Girder MethodologyDocument12 pagesPSC Girder MethodologySaurabh KumarNo ratings yet

- Analysis of tremie technique in well bottom plug concretingDocument16 pagesAnalysis of tremie technique in well bottom plug concretingtangkokhong67% (3)

- Well FoundationsDocument6 pagesWell FoundationsNithin Sudersanan100% (1)

- RDSO Guidelines On Seismic Design of Railway Bridges PDFDocument95 pagesRDSO Guidelines On Seismic Design of Railway Bridges PDFSreeraja Sreevilasan57% (7)

- Analysis and Design of Well FoundationDocument40 pagesAnalysis and Design of Well Foundationdhanabal100% (1)

- Design of Plum Concrete Breast Wall Design Note No: SAI/TKD-219016/PKG-5/DN/STR/BW-04Document9 pagesDesign of Plum Concrete Breast Wall Design Note No: SAI/TKD-219016/PKG-5/DN/STR/BW-04Rishikesh Majumdar100% (2)

- Technical Justification For Anchor Beam - Terminal SlabsDocument1 pageTechnical Justification For Anchor Beam - Terminal SlabsSudeep Joshi100% (1)

- Construction of Four Lane Fly OverDocument8 pagesConstruction of Four Lane Fly Overvenkateswara rao Pothina100% (2)

- Guidelines for Conventional, Thin, and Ultra-Thin WhitetoppingDocument31 pagesGuidelines for Conventional, Thin, and Ultra-Thin WhitetoppingSri Ramya100% (1)

- PCC retaining wall dimension detailsDocument11 pagesPCC retaining wall dimension detailsKushaldas patel100% (2)

- RCC Retaining Wall-01Document1 pageRCC Retaining Wall-01HegdeVenugopalNo ratings yet

- White Topping ReportDocument21 pagesWhite Topping Reporttondare73% (11)

- Is 14458Document9 pagesIs 14458thirumalaichettiar0% (1)

- Methodology For RCC Rectangular DrainDocument4 pagesMethodology For RCC Rectangular DrainAkash Yadav100% (2)

- Typical Design Calculations of PierDocument40 pagesTypical Design Calculations of PierAjayvidyanand Sharma100% (1)

- Method Statement Wet Mix Macadam PatelDocument2 pagesMethod Statement Wet Mix Macadam Patelp.v.n. lakshman0% (1)

- RE Wall ConstructionDocument80 pagesRE Wall ConstructionV Venkata Narayana88% (8)

- Morth 2700 Wearing Coat and AppurtenancesDocument7 pagesMorth 2700 Wearing Coat and AppurtenancesRamesh100% (1)

- 9 Sacrificial - Shuttering-1 by RMDocument18 pages9 Sacrificial - Shuttering-1 by RMASHISANo ratings yet

- Cust Design by IIT Pave Software - 08-05-2020Document117 pagesCust Design by IIT Pave Software - 08-05-2020ARTI PALEKAR75% (8)

- Truck Lay-Bye PDFDocument1 pageTruck Lay-Bye PDFSanjeev KumarNo ratings yet

- Marth 1800 PrestressingDocument17 pagesMarth 1800 PrestressingRamesh100% (4)

- RoB Cost Estimates For Alt - 1, 63m Bowstringer GirderDocument10 pagesRoB Cost Estimates For Alt - 1, 63m Bowstringer GirderHegdeVenugopal100% (1)

- T Girder BridgeDocument54 pagesT Girder BridgebhupendraNo ratings yet

- Slip Form and Fixed Form PaversDocument63 pagesSlip Form and Fixed Form PaversShubham Pawar100% (1)

- Syphon Aqueduct DesignDocument7 pagesSyphon Aqueduct DesignSanjeev Mishra100% (2)

- Analysis of PCC/Random Rubble Stone Masonry TOE Wall StabilityDocument3 pagesAnalysis of PCC/Random Rubble Stone Masonry TOE Wall StabilityKamlesh Parihar100% (1)

- RE Wall-Construction Methodology-15-23Document9 pagesRE Wall-Construction Methodology-15-23NITESH SINGH80% (5)

- SMART TITLEDocument47 pagesSMART TITLErajibchattarajNo ratings yet

- Hydraulic Calculation For Box Type Minor Bridge Bridge at CH - 08+967Document17 pagesHydraulic Calculation For Box Type Minor Bridge Bridge at CH - 08+967Nilay Gandhi100% (3)

- Is 458-1988Document46 pagesIs 458-1988Rajashekhar Katta100% (2)

- MOST Specifications For Road & BridgesDocument654 pagesMOST Specifications For Road & Bridgespbalakrishnan90% (59)

- Dynamic Prestress Technical Guidelines PDFDocument8 pagesDynamic Prestress Technical Guidelines PDFdhopat kalpesh100% (1)

- Link Road DRGSDocument8 pagesLink Road DRGSBasava Sowmya100% (2)

- MORTH-Specification For Road & Bridge Works-5th Edn PDFDocument903 pagesMORTH-Specification For Road & Bridge Works-5th Edn PDFTarun Kant Goyal90% (10)

- Toe Wall-GantryDocument1 pageToe Wall-GantrySumant kumarNo ratings yet

- 1.1 Necessity For Construction of Road Under BridgeDocument14 pages1.1 Necessity For Construction of Road Under BridgeApoorva RSNo ratings yet

- Jet Irby 06017Document19 pagesJet Irby 06017renishkavukattNo ratings yet

- Roofing ChannelDocument16 pagesRoofing ChannelarchayuNo ratings yet

- Superstructure, Substructure and CostingDocument44 pagesSuperstructure, Substructure and Costingdear_tora100% (1)

- Anbu Colony 28.11.12Document45 pagesAnbu Colony 28.11.12Priya PadmaNo ratings yet

- 150 IndDocument13 pages150 Ind2022486166No ratings yet

- DesignDocument9 pagesDesignSai PalaniNo ratings yet

- Track Structures in An Urban Environment: Prof - Dr.ir. C. EsveldDocument23 pagesTrack Structures in An Urban Environment: Prof - Dr.ir. C. EsveldAli Mubarack CKNo ratings yet

- Production PlanningDocument14 pagesProduction PlanningAmira AdzmiNo ratings yet

- Procedure of Inserting RH Girder Method in Road Under BridgeDocument4 pagesProcedure of Inserting RH Girder Method in Road Under BridgeesatjournalsNo ratings yet

- Tower Transmission Foundation Barrette FoundationDocument6 pagesTower Transmission Foundation Barrette FoundationWr ArNo ratings yet

- Vemana Satakamu: C P Brown AcademyDocument66 pagesVemana Satakamu: C P Brown Academypankajssim100% (1)

- Energy MethodsDocument0 pagesEnergy MethodsCuong Hoang VietNo ratings yet

- Structural Analysis - I Unit-IDocument22 pagesStructural Analysis - I Unit-ITamizhan_KNo ratings yet

- VemanaDocument16 pagesVemanaTalluri RambabuNo ratings yet

- Advance SolverDocument1 pageAdvance SolverTamizhan_KNo ratings yet

- Chapter 7 98Document30 pagesChapter 7 98andhityaputraNo ratings yet

- Eijcse2033 PDFDocument9 pagesEijcse2033 PDFTamizhan_KNo ratings yet

- Cameras and LensesDocument37 pagesCameras and LensesMahmood MushtaqNo ratings yet

- Red Rice Note3 Parameters - Millet MallDocument8 pagesRed Rice Note3 Parameters - Millet MallTamizhan_KNo ratings yet

- Unrestrained BeamDocument3 pagesUnrestrained BeamGanesh Konar100% (1)

- Piercap Strut and TieDocument55 pagesPiercap Strut and TieTamizhan_KNo ratings yet

- Earthquake Base Shear Calculation for 3-Story Office BuildingDocument4 pagesEarthquake Base Shear Calculation for 3-Story Office Buildinggendadeyu552625100% (1)

- Chapter 7 98Document30 pagesChapter 7 98andhityaputraNo ratings yet

- Plastic DeformationDocument29 pagesPlastic Deformationmadhumitha_chetas100% (1)

- Energy MethodsDocument0 pagesEnergy MethodsCuong Hoang VietNo ratings yet

- StabilityDocument1 pageStabilityTamizhan_KNo ratings yet

- 200 Questions and Answers On Practical Civil Engineering Works 2008Document84 pages200 Questions and Answers On Practical Civil Engineering Works 2008ramdj100% (4)

- Mass Concreting HistoryDocument16 pagesMass Concreting HistoryTamizhan_KNo ratings yet

- StabilityDocument1 pageStabilityTamizhan_KNo ratings yet

- Delta AnalysisDocument1 pageDelta AnalysisTamizhan_KNo ratings yet

- Bridge ConstructionDocument14 pagesBridge ConstructionTamizhan_KNo ratings yet

- AggregatesDocument8 pagesAggregatesmark_torreonNo ratings yet

- Fracture MechanicsDocument2 pagesFracture MechanicsTamizhan_KNo ratings yet

- Externally Post-Tensioned Carbon FRP Bar System For Deflection ControlDocument20 pagesExternally Post-Tensioned Carbon FRP Bar System For Deflection ControlTamizhan_K100% (1)

- Fluide Structure InteractionDocument29 pagesFluide Structure InteractionTamizhan_KNo ratings yet

- Self Compacting ConcereDocument27 pagesSelf Compacting ConcereTamizhan_KNo ratings yet

- Fuel Truck ComponentDocument56 pagesFuel Truck ComponentRezhaNo ratings yet

- EMI Railways PDFDocument15 pagesEMI Railways PDFLaurence MichaelNo ratings yet

- WGH Fullbooklet 2014Document24 pagesWGH Fullbooklet 2014l1nt4n9luku100% (2)

- (TCRP Report 155) Parsons Brinckerhoff, Incorporated - Track Design Handbook For Light Rail Transit (2012)Document622 pages(TCRP Report 155) Parsons Brinckerhoff, Incorporated - Track Design Handbook For Light Rail Transit (2012)INGVIASNo ratings yet

- Method Statement of Survey Work PDFDocument49 pagesMethod Statement of Survey Work PDFUdayan Chakraborty100% (1)

- R3.105 Final Report UpdatedDocument77 pagesR3.105 Final Report UpdatedSamNo ratings yet

- FA4Document4 pagesFA4Malikat AlwroodNo ratings yet

- Design and Proof Checking of Foundation, Substructure and Superstructure of Rail Cum Road Bridge at Munger, Bihar, IndiaDocument7 pagesDesign and Proof Checking of Foundation, Substructure and Superstructure of Rail Cum Road Bridge at Munger, Bihar, IndiaGregory Cámara SánchezNo ratings yet

- Anleitung Hinowa Fahrwerk EnglischDocument37 pagesAnleitung Hinowa Fahrwerk EnglischIvan MarianNo ratings yet

- List of Railway AnnexuresDocument5 pagesList of Railway AnnexuresDigambar JadhavNo ratings yet

- Train Detection by Track CircuitDocument8 pagesTrain Detection by Track CircuitJavierNo ratings yet

- General Guidelines For Design of Railway Bridges and StructuresDocument168 pagesGeneral Guidelines For Design of Railway Bridges and StructuresRey Sol100% (1)

- Exhibit ListDocument6 pagesExhibit ListDylan Yorath-Batman EvansNo ratings yet

- 2.02 MM AgarwalDocument16 pages2.02 MM AgarwalShishir KumarNo ratings yet

- Method Statement For GroutingDocument43 pagesMethod Statement For GroutingMohd Syaril Mohd Ali100% (5)

- As 7639 (2013) - Track Structure and SupportDocument8 pagesAs 7639 (2013) - Track Structure and SupportbriankimbjNo ratings yet

- (Notes on Numerical Fluid Mechanics and Multidisciplinary Design 126) Jens C.O. Nielsen, David Anderson, Pierre-Etienne Gautier, Masanobu Iida, James T. Nelson, David Thompson, Thorsten Tielkes, David.pdfDocument724 pages(Notes on Numerical Fluid Mechanics and Multidisciplinary Design 126) Jens C.O. Nielsen, David Anderson, Pierre-Etienne Gautier, Masanobu Iida, James T. Nelson, David Thompson, Thorsten Tielkes, David.pdfDiego ZapataNo ratings yet

- Uromac Catalogue 2014Document16 pagesUromac Catalogue 2014DavidNo ratings yet

- Innotrack Concl 20techn Report LowresDocument148 pagesInnotrack Concl 20techn Report LowresugljesamilovicNo ratings yet

- Steel SleepersDocument7 pagesSteel Sleepersapi-23179831150% (2)

- 22403-2019-Winter-Model-Answer-Paper (Msbte Study Resources)Document11 pages22403-2019-Winter-Model-Answer-Paper (Msbte Study Resources)ShantanuNo ratings yet

- Railway Board Orders on Minutes of 80th Meeting of Track Standards CommitteeDocument109 pagesRailway Board Orders on Minutes of 80th Meeting of Track Standards CommitteecdmNo ratings yet

- Ce503 RBTDocument2 pagesCe503 RBTTarang ShethNo ratings yet

- Government of India agenda for 83rd Track Standards Committee meetingDocument141 pagesGovernment of India agenda for 83rd Track Standards Committee meetingkailash chandra pradhan0% (1)

- Classic 750VDC Rail ElectrificationDocument17 pagesClassic 750VDC Rail ElectrificationSemifallen100% (1)

- LRT Track Design-TCRP ReportDocument91 pagesLRT Track Design-TCRP Reportlakshmi1011100% (1)

- CivilDocument7 pagesCivilEnd EndNo ratings yet

- Railways: Mechanical Stabilisation of Track Ballast and Sub-BallastDocument12 pagesRailways: Mechanical Stabilisation of Track Ballast and Sub-BallastJohn Archie Dela CruzNo ratings yet

- BA 4691 EnglDocument197 pagesBA 4691 Engljesus david franco barriosNo ratings yet

- MK 6Document4 pagesMK 6Lluque_19No ratings yet