Professional Documents

Culture Documents

43 Heg Low

Uploaded by

Bqdcc6Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

43 Heg Low

Uploaded by

Bqdcc6Copyright:

Available Formats

P

U

B

L

IC

A

T

IO

N

S

M

A

IL

A

G

R

E

E

M

E

N

T

N

O

.

4

0

0

6

9

2

7

0

HEAVY

EQUIPMENT

GUIDE

HEAVY

EQUIPMENT

GUIDE

Volume 23, Number 10

November/December 2008

www.heavyequipmentguide.ca

10 HEG NovDec 08 FINAL.indd 1 12/8/2008 3:27:20 PM

TM

TM

PPPPPPPPPPPPPPPPPPPPPPPPPPPPRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRROOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVEEEEEEEEEEEEEEEEEEEEEENNNNNNNNNNNNNNNNNNNN....... RRRRRRRRRRRRRRRRRRRRRRRRUUUUUUUUUUUUUUUUUUUUUUUUUUGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGEEEEEEEEEEEEEEEEEDDDDDDDDDDDDDDDDDDDDD......... LLLLLLLLLLLLLLLLLLLEEEEEEEEEEEEEEEEEEEGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGEEEEEEEEEEEEEEEEEEEEEENNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNDDDDDDDDDDDDDDDDDDDDDDDAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAARRRRRRRRRRRRRRRRRRRRRRRRRYYYYYYYYYYYYYYYYYYYYYYYYYYYY.......... PPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPPRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRROOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEENNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN............................ RRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDD........................... LLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEENNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAARRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYY............................ PROVEN. RUGGED. LEGENDARY.

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaayyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyy!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

VVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVViiiiiiiiiiiiiiiiiiiiiiiiiisssssssssssssssssssssssssssssssssssiiiiiiiiiiiiiiiiiiiiiiiiiiittttttttttttttttttttttttttttttttttt yyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyoooooooooooooooooooooooooooooooooouuuuuuuuuuuuuuuuuuuuuuuuuuuuuuurrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrr llllllllllllllllllllllloooooooooooooooooooooooooooooooooooccccccccccccccccccccccccccccccccccccaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaalllllllllllllllllllll ppppppppppppppppppppppppppppppppaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaarrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrttttttttttttttttttttttttttttttttttttiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiccccccccccccccccccccccccccccccccccccccccciiiiiiiiiiiiiiiiiiiiiiiiiiiiippppppppppppppppppppppppppppppppppppaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaatttttttttttttttttttttttttttttttttttttiiiiiiiiiiiiiiiiiiiiiiiiiiiiiinnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnngggggggggggggggggggggggggggggggggg IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIInnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnttttttttttttttttttttttttttttttttttttttttttttteeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeerrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaattttttttttttttttttttttttttttttttiiiiiiiiiiiiiiiiiiiiiiiiiooooooooooooooooooooooooooonnnnnnnnnnnnnnnnnnnnnnnnnnaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaallllllllllllllllllllllll

dddddddddddddddddddddddddddddddddddeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaalllllllllllllllllllllllllllllleeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeerrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrr fffffffffffffffffffffffffffffffffffffffoooooooooooooooooooooooooooooooooooooooooooorrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrr tttttttttttttttttttttttttttttttttttttttthhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhheeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeee bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeessssssssssssssssssssssssssssttttttttttttttttttttttttttttttttttt

ppppppppppppppppppppppppppppppppprrrrrrrrrrrrrrrrrrrrrrrrrrrrriiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiicccccccccccccccccccccccccccccccccccceeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeedddddddddddddddddddddddddddddddddddd SSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeevvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvveeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeerrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrreeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeee SSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeerrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvviiiiiiiiiiiiiiiiiiiiiiiiiiiicccccccccccccccccccccccccccccccccccceeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeee ppppppppppppppppppppppppppppppppppppprrrrrrrrrrrrrrrrrrrrrrrrrrrrroooooooooooooooooooooooooooodddddddddddddddddddddddddddddddddduuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuucccccccccccccccccccccccccccccccccccctttttttttttttttttttttttttttttttttttt.................... EEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEE 0000000000000000000000000999999999999999999999999999999999999................... vvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvveeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeennnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnntttttttttttttttttttttttttttttttt eeeeeeeeeeeeeeeeeeeeeeeeeeeeeennnnnnnnnnnnnnnnnnnnnnnnnnnnddddddddddddddddddddddddddddddddsssssssssssssssssssssssssss JJJJJJJJJJJJJJJJJJJJJJJJJJJJJJJJaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaannnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaarrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrryyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyy 3333333333333333333333333333333333333111111111111111111111111111111111111sssssssssssssssssssssssssssssstttttttttttttttttttttttttttttttttttttttt,,,,,,,,,,,,,,,,,,,, 222222222222222222222222222222222222222222222200000000000000000000000000000000000000000000000000000000000

WWWWWWWWWWWWWWWWWWWWWWWWWWWWWWWWWWWWWWWWhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyy wwwwwwwwwwwwwwwwwwwwwwwwwwwwwwwwwwaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaiiiiiiiiiiiiiiiiiiiiiiiiiiiiittttttttttttttttttttttttttttttttttttttttt uuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuunnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnttttttttttttttttttttttttttttttttttttiiiiiiiiiiiiiiiiiiiiiiiiiiiiiilllllllllllllllllllllllllll sssssssssssssssssssssssssssssssssssssssppppppppppppppppppppppppppppppppppppppppppprrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrriiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiinnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnngggggggggggggggggggggggggggggggggg???????????????????????????????????????

TTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaammmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeee ttttttttttttttttttttttttttttttttttttttttttttttttttthhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhheeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeee eeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeerrrrrrrrrrrrrrrrrrrrrrrrrrrrrccccccccccccccccccccccccccccccccccccceeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeessssssssssssssssssssssssssssssssssssttttttttttttttttttttttttttttttttttt jjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjoooooooooooooooooooooooooooooooooooooobbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb ssssssssssssssssssssssssssssssssssssssssssssssssssssssiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiittttttttttttttttttttttttttttttttttttttttteeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeessssssssssssssssssssssssssssssssssssssss bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyy bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiinnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnggggggggggggggggggggggggggggggggggggggggggggggg ttttttttttttttttttttttttttttttttttttttttttttttooooooooooooooooooooooooooooooooooddddddddddddddddddddddddddddddddddddddddddddddddaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Why wait until spring?

Tame the ercest job sites by buying today!

Visit your local participating International

dealer for the best

priced Severe Service product. Event ends January 31st, 2009.

Enter 9500 on Reader Reply Card

10 HEG NovDec 08 FINAL.indd 2 12/8/2008 3:27:51 PM

Heavy Equipment Guide November/December 2008 / 3

Recognizing leadership

The construction equipment industry has a Hall

of Fame whose mission is to recognize, celebrate

and preserve the history of outstanding people

in the construction equipment industry whose

inventions, ideas, leadership and courage have

made supreme contributions to the industry and

to our quality of life.

It was originally created in 1993, and after a

period of inactivity, the Association of Equip-

ment Manufacturers (AEM) re-introduced it this year as the AEM

Hall of Fame with ve new inductees. Candidates were judged by an

independent panel of industry experts and supporters on how well they

exemplied ve guiding principles: innovation, industry contributions,

leadership, corporate citizenship/social responsibility and sustainability.

Our inductees this year represent some of the most inuential

minds in the history of construction and equipment manufacturing,

AEM President Dennis Slater said at the induction ceremony.

This issue, I will present two of these people to you and in an up-

coming issue, I will cover the other three.

Sir Anthony Bamford

Before he became chairman of JCB in 1975,

Sir Anthony Bamford established JCB SA, the

companys French subsidiary in Paris, which has

become the model for JCBs worldwide devel-

opment. Under his leadership, the company has

grown from a regional equipment manufacturer to

one with 300 products and manufacturing plants

on four continents selling to over 150 nations.

JCB has won more than 50 awards for exports, marketing, design, tech-

nology and for its care for the environment, among them 23 Queens

Awards for Technological and Export achievement. He has also over-

seen efforts to promote industry workforce development. One is a

company educational centre now being developed to educate students

in engineering, manufacturing processes and international business.

LeRoy G. Hagenbuch

LeRoy G. Hagenbuch, P.E. is co-Founder

and president of the engineering rm Philippi-

Hagenbuch, Inc. His patent for the rst commer-

cially available tailgate designed for off-highway

haul trucks was only the beginning. He is now

credited with 89 patents, 51 in the United States

and 38 in other countries. The most recent patent

renes rear-ejection technology, allowing opera-

tors to push the load from the back of a haul truck instead of raising the

bed. To advance the process of mine reclamation, he developed many

products to efciently haul overburden and other materials. Hagenbuch

has made outreach and industry progress a mainstay of his career. He

has written white papers on vital industry topics, spoken at conferences

and trade shows worldwide, and been active with many associations on

behalf of the industry. His operating philosophy has been to extend the

safety focus beyond training and awareness; each Philippi-Hagenbuch

engineer is challenged on the safety of their product designs. In ad-

dition, each staff and production meeting at the company starts with a

discussion of a critical safety topic.

Best wishes for 2009.

HEAVY

EQUIPMENT

GUIDE

7

A Baum

Direct Response

Publication

2009

PRODUCT GUIDE

DEPARTMENTS

November/December 2008

Volume 23, Number 10

Published by Baum Publications Ltd.

201 - 2323 Boundary Road

Vancouver, BC, Canada V5M 4V8

Phone (604) 291-9900

Fax (604) 291-1906

Internet: www.baumpub.com

Lawrence Buser - Editorial Director

lbuser@baumpub.com

Lee Toop - Associate Editor

ltoop@baumpub.com

Tina Anderson - Production Manager

production@baumpub.com

Robin McCabe - Circulation Manager

circulation@baumpub.com

Ariel Savion-Lemieux - Web Master

ariel@baumpub.com

John Harbottle - Regional Manager

jharbottle@baumpub.com

Justin Barone - Regional Manager

jbarone@baumpub.com

Bruce Barden - Associate Publisher /

Sales Director, bbarden@baumpub.com

Margaret Goh - Comptroller

mgoh@baumpub.com

Engelbert J. Baum - Publisher

ebaum@baumpub.com

Heavy Equipment Guide is published ten times

a year: January/February, March, April, May,

June, July, August, September, October, and

November/December.

Advertising closes 20th of previous month.

The publication is distributed to key personnel

across Canada in the construction, open-pit

mining, truck, forestry, municipal and rental

elds having interest in and responsibility for

heavy equipment.

One year subscription rates to others: Canada

$49.00 + 2.94 GST = $51.94; U.S.A. $60; other

countries $99. Single copies $6.50 + 0.39 GST

= $6.89; outside Canada $8.00. All prices in

Canadian funds.

Heavy Equipment Guide accepts no respon-

sibility or liability for reported claims made by

manufacturers and/or distributors for products or

services; the views and opinions expressed are

those of the authors and not necessarily those

of Baum Publications Ltd.

Copyright 2008, Baum Publications Ltd. No

portion of this publication may be reproduced

without permission of the publishers.

Printed in Canada, on recycled paper, by Mitchell

Press Ltd. ISSN 1485-6085.

PUBLI CATI ONS MAI L AGREEMENT NO.

40069270. PAP Registration No. 10911.

We acknowledge the financial

support of the Government of

Canada through the Publications Assistance

Program towards our mailing costs.

Return undeliverable Canadian addresses to:

Circulation Dept., 201-2323 Boundary Road,

Vancouver, B.C. V5M 4V8; email: circulation@

baumpub.com.

HEAVY

EQUIPMENT

GUIDE

30 News, Events and Advertisers Directory

4 Earthmoving Equipment

12 Concrete Equipment

14 Trucks & Trailers

16 Compaction Equipment

18 Material Processing

20 Asphalt Equipment

22 Lift Equipment

25 Attachments

28 Miscellaneous Equipment

10 HEG NovDec 08 FINAL.indd 3 12/9/2008 1:42:43 PM

4 / Heavy Equipment Guide November/December 2008

Loader evolution

ASVs PT-60 Rubber Track Loader has

undergone the most signicant evolution of

all of ASVs new product line and includes

a powerful new two-speed powertrain that

gives operators the choice of higher torque

in low for digging and tough excavation, or

faster travel in high with a maximum speed

of 11 mph (17.7 kph). There are also new,

more durable, steel rear-idler wheels in the

rubber track undercarriage.

The PT-70 and PT-80 models feature

larger standard interiors and improved

torque when in the high speed range. The

largest unit, the PT-100, delivers 99.5 hp

(74 kW).

ASV

Enter 9506 on Reader Reply Card

4WD compact tractors

Bobcats new line of compact tractors fea-

ture four-wheel drive for travelling over and

working in rough terrain, and hydrostatic

transmissions for easy operation.

The compact tractors can be used with

Bobcat implements, including an angle

blade, auger, backhoe, box blade, nish

mower, seeder and tine rake, as well as a

front-end loader and attachments.

The 2,055-pound Bobcat CT120 com-

pact tractor features a 20-hp diesel engine

and two travel speed ranges.

The two-speed CT122, and the thee-

speed CT 225, CT230 and CT235 have 22-,

17-, 30- and 34-hp, respectively. Weights

for these models range from 2,055 pounds

to 3,055 pounds.

Bobcat Company

Enter 9508 on Reader Reply Card

New track-type tractors

Lever efforts for Caterpillars new D3K,

D4K and D5K dozers are decreased by as

much as 90 percent compared to conven-

tional mechanical control levers. The left

joystick incorporates a thumb wheel for

on-the-go speed adjustments, plus a speed

recall button that lets the operator quickly

select a pre-programmed operating speed.

The right joystick includes an automatic

blade shake button for easy removal of

excess material, as well as a thumb roller

for low-effort blade angle adjustments.

A single oor pedal controls the de-

celeration and service brake functions.

Pressing the pedal past the speed control

detent activates the service brakes.

The D3K, D4K and D5K have 74-hp

(55kW), 84-hp (63kW) and 96-hp (72kW)

engines, respectively, and are available with

extra long (XL) and low ground pressure

(LGP) track frames.

Caterpillar Inc.

Enter 9501 on Reader Reply Card

Reaches difcult spots

The low-prole, telescoping-boom action

of the new Gradall XL 4100 III excavator

allows the unit to work where conventional

knuckle booms cannot, under bridges and

tree limbs or in tunnels. A live boom exten-

sion gives the ability to reach over obstacles

and into ditches.

The carrier is available in two versions:

a 6 x 4 model which weighs approximately

47,500 pounds (21,545 kg); and a 6 x 6

model that weighs approximately 49,420

pounds (22,416 kg). The operator can also

select the Gradall, Deere or SAE joystick

pattern.

Rated bucket force is 24,900 pounds

(111 kN) while the telescoping boom crowd

force is 24,500 pounds (109 kN). Unlike

conventional excavators, the telescoping

boom forces are constant through the en-

tire dig cycle. The versatile boom delivers

a maximum reach of 30 feet, 3 inches (9.22

m) at grade; a dig depth of 20 feet, 3 inches

(6.17 m); and a lift height of 22 feet, 6 inches

(6.83 m).

The excavator is suitable for grading

and nishing work, pavement removal and

demolition.

Gradall Industries

Enter 9507 on Reader Reply Card

Versatile backhoe loader

The John Deere 410J backhoe loader has

the versatility to dig deep, load trucks,

Fuel-saving wheel loader

The Liebherr driveline on the L 528 and

L 550 wheel loaders, combined with

low operating weight, result in savings

of up to 25 percent in fuel consumption

compared to conventional-drive wheel

loaders.

An ultra-modern cab design allows the

operator to achieve better performance

and productivity. The displays, controls

and drivers seat are carefully coordin-

ated to form a perfect ergonomic unit.

The combination of the Liebherr

hydrostatic driveline and the unique

position of the diesel engine allows for

higher tipping loads at low operating

weight. This leads to signicantly higher

productivity with no need for unnecessary

counterweight.

The large Liebherr wheel loaders are

equipped with the 2plus2 gearbox, so

tractive force and speed are automatic-

ally adjusted to the demands of the job

without the driver having to shift.

Liebherr Canada

Enter 9502 on Reader Reply Card

Greater lift and stability

The 34.8-ton, 107-hp (143-kW) Volvo

ECR305CL short-swing excavator can

work in conned areas and still perform

well, and sets a new standard in the indus-

try for not only lifting capacity but also

stability. With better weight distribution

and increased swing torque, it also offers

superb swing performance when working

on slopes.

Even when not working close to obstruc-

tions, the short front/rear radius has other

uses highway work being a prime ex-

ample where the machine can safely swing

within a typical single road lane width,

minimizing disruption to trafc ow.

The new rounded cab on Volvos short

swing models is also designed to stay

within the rear swing radius.

The bucket range on t he Vol vo

ECR305CL is from 1.0 to 2.1 cubic metres

and a wide range of Volvo attachments is

available, as are quick attach options.

Volvo Construction Equipment

Enter 9504 on Reader Reply Card

break surfaces, crane pipe and more.

Powerful and quick high-pressure hydraul-

ics deliver generous breakout and lift cap-

acity at both ends, along with impressive

backhoe crowd power and swing torque.

With the tool carrier version, operators

get true parallel lift throughout the lift arc,

making this 15-foot machine a master of

material-handling tasks.

Standard limited-slip, mechanical front-

wheel drive delivers 80 percent of available

power to the wheel with the best traction.

A tool-carrier version with quick coupler

boasts increased lift capability, plus set-

and-forget parallel lift, return-to-carry, and

boom height kick-out. A ride-control option

smoothes roading over rough terrain.

There are three hydraulic speeds: fast,

for up to 20-percent quicker cycle times;

medium, for normal digging; or slow, for

craning objects, working in conned spaces

or excavating around existing utilities.

John Deere

Enter 9503 on Reader Reply Card

Expanded excavator line

The 64,595-pound

JS290 Auto and

the 77,162-pound

JS360 Auto boosts

JCBs offeri ng

in the important

62,000-pound to

85, 000- pound

cat egory. Bot h

machines feature

a new undercar-

riage design, re-

ned boom and dipper arm layout, ground

level service access, and increased cooling

capacity.

The JS290 Auto is powered by a 216-hp

engine and can be supplied with long or

narrow tracks, a choice of three dipper arm

lengths and an XD heavy duty version for

more arduous operating conditions.

The JS290 Auto offers six percent more

engine power, four percent more hydraulic

power and 11 percent higher dipper tearout

force than the class average. The slew

torque and bucket tearout forces are also 14

percent and 19 percent ahead of the class

average respectively.

JCB

Enter 9509 on Reader Reply Card

Unique ADT suspension

Terexs TA30 articulated dump truck (ADT)

has a unique independent front suspension

system with integral wet disc brakes. It was

developed in conjunction with Timoney

Mobility Systems of Navan (Ireland) and

is a purpose-designed, parallel-linkage,

coil-spring system. This system addresses

the increasing emphasis on driver comfort.

It also signicantly adds to the potential

for increased productivity by providing a

smooth ride and improved handling, which

can result in faster cycle times.

All Terex TA articulated haulers are

tted with the latest Tier 3 engines for opti-

mum performance and fuel efciency. The

TA30 has the 350-hp Cummins QSM11

engine. Maximum payload for this models

is 30.9 tons.

All-round, fully-enclosed wet-disc

brakes on all wheels provide long-life and

fade-free braking. This not only improves

overall braking performance and operating

efciency, but it also greatly increases ser-

vice life and reduces operating costs.

Terex Construction Americas

Enter 9505 on Reader Reply Card

More control for TLB

Rated at 59-hp, the new M59TLB is

Kubotas most powerful tractor-loader

backhoe ever. The operators work area is

improved substantially with more room,

comfort and visibility. Kubotas Intellipanel

provides the operator with more control.

The new three-range HST PLUS trans-

mission includes Hydro Dual Speed (Hi/

Lo) and Load Sensing features which

EARTHMOVING EQUIPMENT

10 HEG NovDec 08 FINAL.indd 4 12/8/2008 3:10:03 PM

Expect results

Metso Minerals Canada Inc. Tel. 519 821 7070 www.metsominerals.com

Lokotrack LT96 feeding LT200HP

Powerful Partnership

Lokotrack Multi-Stage Crushing

Metso Minerals is far and away the industry leader in tracked crushing technology.

Our Lokotrack mobile crushers can handle anything from hard rock to minerals-based

demolition material. These powerful plants are built to work together seamlessly to

meet your demands for:

high production

quality end products

advanced crushing control

And only Lokotrack oers such fast set up that you can be up and crushing in less than

an hour. Call today or visit Metso Minerals online to nd a distributor near you.

Enter 9510 on Reader Reply Card

10 HEG NovDec 08 FINAL.indd 5 12/8/2008 3:10:12 PM

HEAVY-METAL ROCK STAR.

Youre paid by the foot, so profitability boils down to getting efficient production

out of your trencher on every job. Vermeer understands this better than anyone.

We have the tools and equipment to help boost production and your bottom

line. When it comes to demanding trenching conditions, look to an industry

leader Vermeer. Call 1-888-VERMEER or visit Vermeer.com.

WE HOLD

RELIABILITY

TO A HIGHER

STANDARD.

YOURS.

VERMEER and the VERMEER LOGO are trademarks of Vermeer Manufacturing Company in the United States and / or other countries.

2008 Vermeer Corporation. All Rights Reserved.

BECAUSE ITS PROFIT PER FOOT THAT MATTERS.

Enter 9519 on Reader Reply Card

6 / Heavy Equipment Guide November/December 2008

Four work and power modes

The Case 621E wheel loader features

an electronically controlled engine that

delivers 168 net hp and offers multiple

idle settings to reduce fuel consumption.

Limited-slip axles are standard.

Operators can match power and fuel

economy to their application by choosing

from among three power curves max,

standard and economy power, and four

work modes max, standard, economy

and auto.

In auto mode, the electronically con-

trolled engine adjusts between power

curves to move the maximum amount of

material per gallon of fuel.

The Case 621E is also available in XT

(tool carrier) and XR (extended reach)

congurations.

Case Construction Equipment

Enter 9518 on Reader Reply Card

Optimum use of power

The rst model in the new Dash-9 ser-

ies of Hyundai Robex excavators is the

46,000-pound (21-metric-ton) Robex

R210LC-9. This particular model is pow-

ered by the latest Cummins QSB 6.7 143-hp

Easier joystick control

Operating the 240-net-horsepower (179-

kW) TD20M Extra crawler dozer is easy

with the new left-hand, single-lever joy-

stick control. The joystick replaces two left-

hand steering levers and one gear shift lever

used on the previous model. The operator

can pre-select travel speed and down shift

functions from the joystick.

Several blade options are available, in-

cluding a new 11.1-cubic-yard (8.45-cubic-

metre) full-U blade, and an increased

capacity 9.2-cubic-yard (7.04-cubic-metre)

semi-U blade.

The standard version of the TD20M

Extra has an operating weight of 52,139

pounds (23,650 kg), while the LT version

weighs 53,373 pounds (24,210 kg) and

the LGP version is 54,410 pounds (24,680

kg).

Dressta North America

Enter 9517 on Reader Reply Card

More versatile excavators

New Holland is increasing the versatility

and productivity of their compact excavator

line with the introduction of an optional

deliver a smoother transfer of power. The

unique Auto Throttle Advance links the

HST pedal and the engine throttle, syn-

chronizing tractor speed and engine revolu-

tion. The innovative Repositioning System

allows you to move at creep speed while

at the controls of the backhoe.

The sleek loader has a hydraulic self

levelling valve (with on/off switch) for spill

prevention and safe operation. Removing

the quick-attach 12-foot backhoe is quick

and easy, and the optional three-point

hitch can operate a host of rear-mounted

attachments efciently with the hydraulic

independent PTO.

Kubota Canada

Enter 9515 on Reader Reply Card

angle blade for the E30B, E35B and E50B

models.

These compact yet powerful machines

already come with fuel efcient, state-of-

the-art Tier IV diesel engines, and provide

maneuverability and precision to operate in

tight spaces. Now the optional angle blade

further increases the speed and accuracy of

backlling and grading applications.

The angle blade adjusts 23 degrees

and allows the operator to push dirt to

either side of the machine. In addition, the

new four-way blade design offers up to 22

inches of lift height, and dig depth capabil-

ity up to 17 inches.

New Holland Construction

Enter 9516 on Reader Reply Card

10 HEG NovDec 08 FINAL.indd 6 12/8/2008 3:10:13 PM

Enter 9524 on Reader Reply Card

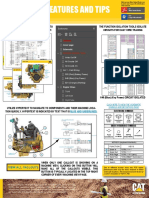

Not every mix and application is the same, so your asphalt compactor should be versatile

and easy to set up to match performance to ever-changing conditions. If it isnt easy to use,

how can it be productive?

Cat

Asphalt Compactors get the work done on the breakdown pass, when the mat

temperatures are higher and conditions are optimal for compaction. They are comfortable

and simple to operate: high amplitude for aggressive compaction, low amplitude for gentle

massaging. They match high paving speeds with high frequency, and low paving speeds with

low frequency. Simple and reliable, with predictable density every time in minimal passes.

No complexity and constant tweaking, as there is using non-aggressive compaction

technologies; no hoping your density numbers will catch up on the intermediate or final pass.

Caterpillar is the market leader because we offer proven technology that makes turning a

profit easier. Isnt that what technology is supposed to do? To get the real story on asphalt

compaction, visit your Cat Dealer today.

www.cat.com

SAFELY HOME. EVERYONE. EVERYDAY. SAFETY.CAT.COM

Versatile Cat

Asphalt Compactors use proven technology

that is easy to set up for any mix or application.

CAT, CATERPILLAR, their respective logos, Caterpillar Yellow and the POWER EDGE trade

dress, as well as corporate and product identity used herein, are trademarks of Caterpillar

and may not be used without permission. 2008 Caterpillar All Rights Reserved

AGGRESSIVE

WHEN YOU

WANT IT,

GENTLE WHEN

YOU NEED IT.

Heavy Equipment Guide November/December 2008 / 7

Utility-class excavator

The new Hitachi ZX120-3 utility-class ex-

cavator can easily be towed behind a dump

truck and is available with rubber crawler

pads and a backll blade.

Heavy-duty undercarriage

Mustangs MTL312 is the most compact

of their track loader lineup, which also

includes the MTL16, MTL20 and MTL25.

It has a dedicated track design, meaning the

unit is built as a track loader with a heavy-

duty undercarriage system versus being

built as a skid-steer loader with a bolt-on

undercarriage. The result of this exclusive

engineering is a stronger track loader.

With an operating weight of 5,952

pounds and a width of just under 58 inches,

the MTL312 gives operators the small

size they need outside the operators com-

partment, yet offers operators a spacious

and comfortable cab. A nger tip-control

joystick system promises a fatigue-free,

high-productivity day on the job.

Mustang Manufacturing Company

Enter 9521 on Reader Reply Card

Super-slant nose

The standard D39EX-22 and low ground

pressure D39PX-22 crawler dozers are

equipped with Komatsus proven Hydro-

static Transmission (HST). The D39EX-22

features a super-slant nose coupled with

a new cab forward design that moves the

operator closer to the blade while improv-

ing machine balance, ride and stability.

Joystick-controlled grader

The 117-hp, LeeBoy 705 motor grader

provides smooth grading at high and slow

speeds with its six-speed forward and three-

speed reverse power shift hydrostatic trans-

mission. Right- and left-hand joysticks,

integral to the adjustable suspension oper-

ators chair, control all grader functions.

The 10-foot sliding and tilting mold-

board with 18-inch, right- or left-side

shift, and shoulder reach of 36 inches al-

lows the operator to shift the blade in or out

of hard to reach areas.

Maneuverability of the 705 motor grader

is enhanced with 18-degree, right or left

articulation behind the cab. This gives the

705 an outside turning radius of 17.5 feet.

Grading functions are assisted with front-

axle oscillation of 20 degrees, front-wheel

lean of 15 degrees and front-wheel steering

angle of 50 degrees.

LeeBoy

Enter 9522 on Reader Reply Card

(107-kW), Tier 3 rated engine, which is

exceptionally quiet.

Optimum use of the available power

is the core feature of the new Dash-9 ser-

ies. The smart hydraulic systems feature

new, tough, variable-volume high-pressure

pumps coupled with an advanced control

valve system. The synergy between the

pumps and main control valve offers

enormous operational benets to the oper-

ator. Additionally, working with auxiliary

attachments is made easier now that ow

and pressure settings can be programmed

through the CAPO system from within

the cab.

Hyundai

Enter 9520 on Reader Reply Card

The 28,498-pound, 93-hp excavator fea-

tures a patented HIOS III hydraulic system.

It can generate 24,720 pounds of drawbar

pull and 25,077 foot pounds of swing

torque, wield an impressive 12,823-pound

breakout force, and lift a maximum of

11,443 pounds over the front at a distance

of 15 feet (with the blade on ground). In

addition, it has three power modes, two

travel modes, and one work mode.

The ZX120-3 features a large, comfort-

able cab. Auxiliary attachment ow can be

programmed in the cab, using the wide-

screen multilingual colour LCD monitor.

The monitor also provides easy access to

maintenance and operational information.

Hitachi

Enter 9523 on Reader Reply Card

10 HEG NovDec 08 FINAL.indd 7 12/8/2008 3:10:15 PM

8 / Heavy Equipment Guide November/December 2008

The dozers range in operating weight

from 20,834 to 21,804 pounds. Komatsus

4.5-litre SAA4D107E-1 engine has 105 net

horsepower at 2,400 rpm.

The steering system provides smooth

agile movement when dozing, even in

gradual turns, permitting the operator to

approach objects accurately in corner grad-

ing and sidewall operations. The D39-22

dozers employ a large, power angle-tilt

blade with a capacity of 2.89 to 3.01 cubic

yards, which results in more material stay-

ing on the blade.

Komatsu America Corp.

Enter 9530 on Reader Reply Card

Next generation hydraulics

The new Cat 992K wheel loader efciently

matches with the Caterpillar 777 and 775

off-highway trucks. It delivers fast cycles

and high bucket-ll factors for productive

truck loading.

The 992K features the Cat C32 ACERT

engine which produces 801 net hp (597

kW). The same engine powers the 993K

loader, 777F truck and D11T tractor, which

effectively reduces inventory needs.

Also boosting productivity is Positive

Flow Control (PFC) hydraulics the next

generation of load-sensing hydraulics.

Additional sensors at the pumps provide

enhanced responsiveness that the operator

can feel and use.

The Cat-exclusive, sleeve bearing pins

eliminate the need for daily greasing of the

front linkage.

Caterpillar Inc.

Enter 9531 on Reader Reply Card

Digging and dozing

Kobelcos ED195 and ED150 ACERA

Blade Runner excavators have the features

and benets of both an excavator and a

dozer.

With 42,566 lb-ft of drawbar pull force,

pulling and uphill grading are a breeze for

the 121-hp ED195. The six-way, power

angle-tilt dozer blade allows for precise

dozing and backlling, and power boost

and heavy lift circuits provide 10 percent

more power, on command and without time

limit. Overall weight with bucket is 44,800

pounds, and maximum digging depth is

21 feet, 5 inches. Bucket breakout force is

24,900 pounds and the arm crowding force

is 17,200 pounds when the Power Boost

is engaged.

Kobelcos ITCS (Intelligent Total

Control System) recognizes an operators

actions and assists with repeated functions

by providing progressive power. This is

especially important for ne levelling and

grading applications.

The totally redesigned Kobleco ED150

Completely revised chassis

JCB has totally revised its compact wheel

loader line with the introduction of an

all-new, 409 loader. It has the lowest cab

design on the market, a Tier III-compliant,

four-cylinder, 75-hp turbocharged engine,

and hydrostatic transmission to both axles,

providing all-wheel drive.

Sturdy, parallel loader arms offer im-

proved visibility to the front of the machine

and the tips of the bucket. With a standard

1.3-cubic-yard bucket, the 409 offers a

straight tipping load of 10,840 pounds and a

full-turn tipping load of 8,628 pounds. With

optional pallet forks tted, the machine can

easily handle a 5,500-pound load. Operat-

ing weight is 12,831 pounds.

A completely revised chassis design

uses an oscillating, central pivot to maintain

ground contact for all four wheels.

The 409 benets from grouped service

points and eye level gauges.

JCB

Enter 9538 on Reader Reply Card

Easy hydraulic connection

The A 900 C is the latest offering from the

worlds largest manufacturer of wheeled

excavators. Weighing in at 39,500 pounds,

the machine is powered by a purpose-built

Liebherr D-924 Tier III compliant diesel

engine producing 118 hp at 1800 rpm.

Liebherr-designed electronics precisely

control all engine functions to optimize per-

formance and efciency, and four operating

modes allow the operator to match engine

and hydraulic output to achieve maximum

production and efciency.

The optional Liebherr quick coupler

automatically makes the hydraulic con-

nections from the tool to the machine,

allowing the operator to change hydraulic

tools without ever leaving the cab.

Liebherr Canada

Enter 9536 on Reader Reply Card

Choice of controls

Volvos B-Series skid steer loaders have

an all-new operator cab available in open

canopy or enclosed cab configurations.

Isolation mounts reduce vibration and noise

to the operator.

There is also a choice of foot-and-hand

mechanical controls or hand-operated hy-

draulic pilot controls. The latter uses dual

joysticks to activate all loader functions

Offset tracks give stability

The Yanmar s

S V 1 0 0 e x -

c a va t or i s a

20, 730-pound,

73.5-hp blend of

big performance

and ultra-tight

maneuverability.

Front and rear

turning radius

is so small that

the boom bracket

stays entirely within the width of the tracks.

The stability of a conventional style excav-

ator is achieved with Yanmars distinctive

offset tracks, that have a total width of

seven feet seven inches, and are designed

to create excellent grip and stability.

Maximum bucket digging force is

12,216 pounds and the total digging depth

is 15 feet 3 inches.

The SV100 uses the rst tailor-made

hydraulic Quick Coupler in the industry as

standard equipment. This makes attachment

changes a one-person job.

The ViO progressive 3-pump system

increases power and speed along with

improved fuel economy. It also allows

simultaneous multi-function operation to

increase job productivity.

Yanmar Construction Equipment Co.

Enter 9539 on Reader Reply Card

High-lift skid steer

The Thomas

185 Skid Steer

Loader replaces

t he popul a r

Thomas 175,

and features a

high-lift bucket

height over 11

feet, an operat-

ing weight of

7,200 pounds,

lift capacity of

1,850 pounds

and over two tons of breakout force.

It is powered by a 4-cyclinder 59-hp

Tier-3 engine, moves at nearly eight mph,

features an easy-to-service universal joint

rather than traditional bands, and has a

100-chain-drive to deliver tremendous

traction.

The Thomas 185 also includes standard

features such as a sound suppression sys-

tem around the engine and self-level valve

control.

The Thomas 185 Skid Steer Loader also

features: two in-line hydrostatic pumps to

lift, pull, and hoist; dump height over nine

feet; sure grip 8-ply or 10-ply tires for

Increased boom force

The B95B and B95BTC (tool carrier)

backhoe loaders feature a sloped, ip-up

hood for easier engine access and increased

visibility, and a curved boom design for

additional clearance when transporting.

The curved boom also provides in-

creased breakout force. Continuing with

New Hollands tradition of narrow boom

design, the new boom allows excellent

visibility of the bucket, the trench and

near-by co-workers throughout its full

operating range.

New Holland Construction

Enter 9533 on Reader Reply Card

Elevated-drive dozer

The newest member in the HX lineup of

crawler dozers is the SD9, which features

a fully-electronic Tier III-certied QSX15

Cummins engine and an elevated Hi-Drive

System. Other features include a variety

of blade options, single shank ripper, for-

estry sweeps and guarding, ROPS, heated

and air conditioned cab, and various track

congurations.

The six-sided cab is designed for all-

around visibility and operator comfort, and

excellent ergonomics. Blade congurations

include straight, angled, semi-U and U.

The HX dozers are available with Berco

undercarriage components.

HX

Enter 9534 on Reader Reply Card

stability and pushing power; and a range

of attachments and options.

Thomas Equipment Inc.

Enter 9532 on Reader Reply Card

with the right hand, and to control all drive

functions with the left. Electro-proportional

auxiliary hydraulics and a foot throttle are

also standard on pilot control machines to

increase operational precision. All operator

controls are designed for low-effort, high

efciency and minimal fatigue.

Operating capacities range from 1,350

pounds (612 kg) to 2,250 pounds (1020

kg) and engine power from 45 net hp (36.9

kW) to 81 net hp (64 kW).

Volvo Construction Equipment

Enter 9535 on Reader Reply Card

Blade Runner excels in tight spaces that

require maneuverability and precision. The

94-hp engine delivers over 19 feet of dig-

ging depth and 19,000 pounds of breakout

force on a short radius platform.

The patented, exclusive INDR (Inte-

grated Noise and Dust Reduction) system

on the ED150 lowers operating noise levels

by up to seven percent (ve decibels).

Kobelco Construction Machinery

Enter 9537 on Reader Reply Card

10 HEG NovDec 08 FINAL.indd 8 12/8/2008 3:08:50 PM

control

(productivity runs in this family)

Youre committed to getting things done on time and on budget, and you need dependable,

hard-working machines to meet your deadlines day after day. The Komatsu D31, D37

and D39 dozers all feature the reliability and versatility that have made Komatsu the

choice of owners and operators for years:

KomStat II Hydrostatic Transmission (HST) for superb accuracy and smooth control

Excellent blade visibility that minimizes operator guesswork and reduces cycle times

All the daily maintenance items centralized in one location for convenient access

Whether youre looking for a 75, 85 or 95 horsepower machine, you can be condent

youll get a full days workand then somefrom dozers that are

100%

100% Komatsu. 847.437.5800 www.komatsuamerica.com

Enter 9544 on Reader Reply Card

Heavy Equipment Guide November/December 2008 / 9

Maximized cab space

The size of the operators compartment

on the 283Z is maximized by placing the

20.4-hp Yanmar diesel on the side of the

Fingertip control

Pilot-operated joystick controls provide

precise, ngertip control of the loader and

travel functions on the Takeuchi TL120

compact track loader. This is a turbo pow-

ered, 52-hp machine with an operating

weight of just under 6,000 pounds.

Power and precision

For the rst time in the Terex mid-sized

wheel loader range, the power transfer in

the hydrostatic drive unit of the TL210 is

carried out via a hydrotransmatic trans-

mission with two regulating motors and

a pump.

The loading system on the new 162-hp

TL210 wheel loader is equipped with Terex

modied toolcarrier linkage. This combines

the advantages of Z kinematics powerful

breakout force, bucket reaction force and

unloading time with the precise parallel

control of the parallel kinematics in the

bucket and forklift attachment, across the

entire movement range.

The discharge height is 9 feet 11 inches

(3,010 mm) at an angle of 45 degrees. The

TL210 moves a payload of 8,699 pounds

(3,945 kg), direct mounted with a 2.75

cubic yard bucket. Payload over the entire

lift and steering range for forks is 9,921

pounds (4,500 kg).

Terex Construction Americas

Enter 9540 on Reader Reply Card

Big breakout force

Kawasakis new 95ZV-2 has the highest

breakout force in its size class.

A Machine Operations Diagnostic Mod-

ule (MODM) provides essential operational

and diagnostic machine information, and

offers a new Efficient Loading System

(ELS) that increases rimpull power while

demanding less fuel.

The unit uses a heavy box-frame design

for additional strength, and a larger centre

pin than competitive models. It has the

tightest turning radius in its size class.

The 95ZV-2 also features limited slip

differentials, adjustable declutch, dual

boom kickout control, idle management

system, dual-mode engine switch, and Ef-

cient Loading System (ELS).

Kawasaki

Enter 9541 on Reader Reply Card

With a width of 59.5 inches and a length

of 126.8 inches, the TL120 is easy to trans-

port. This model features a tipping load of

3,549 pounds, with a bucket breakout force

in the bucket cylinders of 4,821 pounds, and

5,042 pounds in the lift arm cylinders.

Rubber tracks combine the capabilities

of a track loader with the versatility of

operation on improved surfaces. A high

sprocket planetary drive system provides

the most efcient and durable method of

speed reduction and torque amplication,

and eliminates drive chains, chain cases,

axles and hubs which require periodic

maintenance and could cause failure.

Takeuchi-US

Enter 9542 on Reader Reply Card

machine, and fuel tanks and hydraulics at

the rear of the machine. This provides the

operator with more space and legroom.

The excavator also has improved trac-

tion and increased service life for the tracks,

which have a narrow width of 11.8 inches

(300 mm) and provide a low ground pres-

sure of 3.8 psi. In addition, an optional

250-pound rear weight increases stability

with no tail projection.

The new Gehl 283Z compact excavator

features zero tail swing. It weighs 5,681

pounds (2,577 kg) with a canopy and 5,886

pounds (2,670 kg) with a cab.

Gehl Company

Enter 9543 on Reader Reply Card

10 HEG NovDec 08 FINAL.indd 9 12/8/2008 3:08:56 PM

Enter 9554 on Reader Reply Card

Take, for example, the XP.

Unmatched power, four-way indexable

cutting blades, eld-proven regeneration

valve for more cuts per hour, and the

most durable piercing tips available.

Plus customer inspired engineering,

revolutionary design and a promise of

world-class customer service that began

over a decade ago and continues today.

Why do we put this much effort into

every product we build?

Its simple. To keep you productive

and successful.

You have our word on it.

10 / Heavy Equipment Guide November/December 2008

Added stability and lift

Komatsus WB146-5 and the WB146PS-5

backhoe loaders have operating weights

from 16,090 to 18,740 pounds, and a large,

1.25-cubic-yard loader bucket.

The drivetrain includes a 4-speed

synchro-shuttle transmission with standard

Extra speed and power

The Case 750L dozer has a 4.5-litre, four-

cylinder electronic engine, which delivers

84 net hp (63kW). The 850L is powered by

a 6.7-litre, six-cylinder electronic engine,

which provides 96 net hp (72 kW).

Case-exclusive PowerStat hydrostatic

drive features one-lever control of speed

and direction.

The large pump and cylinders deliver

high-performance blade hydraulics, with

extra speed and power for optimum control

and breakout force. Rated blade capacity

ranges from 2.16 to 2.73 cubic yards (1.65

to 2.09 cubic metres).

The hydrostatic drive features electronic

straight tracking with counter rotation, and

selectable settings for shuttle and steering

for slow, normal and fast control reaction.

Case Construction Equipment

Enter 9552 on Reader Reply Card

Compact TLB

The Allmand TLB-325 heavy-duty com-

pact tractor loader backhoe features an

ESL (Extended Service Life) backhoe

design. Units are powered by a Kohler 25-

hp gasoline engine, weigh 4,045 pounds

and feature an industrial-class backhoe.

The backhoe offers a 4,611-pound digging

force as well as an 8-foot, 10-inch digging

depth. Dual cylinder, 180-degree, hydraulic

cushioned swing allows precise work in

tight areas, and units have a 2,100-pound

maximum lift capacity and 3,400-pound

breakout force, with a maximum loading

height of 90 inches for the 1/2-cubic-yard

loader bucket. Additionally, a load-sensing

hydraulic steering system ensures hydraulic

ow is used only when the operator is turn-

ing the steering wheel.

Allmand Bros. Inc.

Enter 9550 on Reader Reply Card

Solid state electronics

New Teammate IV front and rear axles on

the John Deere 544J, 624J, 644J and 724J

wheel loaders include inboard planetary

nal drives, a standard front differential

lock, and self-adjusting wet disk brakes.

Solid state electronics a Deere exclu-

sive give long-term electrical reliability

by greatly reducing the number of wires,

plug-in relays and unsealed connections,

as well as providing a sealed fuse box with

sealed wire connections.

The smooth shifting transmission adapts

to speed and load while providing smooth

gear and directional shifts. Efficient,

excavator-style hydraulics are load-sensing

and pressure-compensating for the right

amount of power efficiency, providing

quick hydraulic response and excellent

digging power.

John Deere

Enter 9553 on Reader Reply Card

Compact wheel loaders

Wacker Neusons new line of six compact

wheel loaders includes four articulated

units and two all-wheel-steer models.

According to Jay Baudhuin, compact

class product manager, The new Wacker

Neuson compact wheel loaders can perform

the same tasks as a higher powered skid

loader but deliver up to 30 percent in fuel

savings.

The three-metric-ton member of the

line is the WL 30 compact wheel loader

(shown here) with a straight load capacity

of 4,437 pounds and a fully articulated tip-

ping capacity of 3,647 pounds when using

a standard 0.59-cubic-yard bucket. It is

powered by a 4-cylinder, 48 horsepower

Perkins diesel. As with all four of their

compact, articulated wheel loaders, the

new WL30 features a side-tilting operators

platform that provides easy access to the

engine and other components.

Wacker Neuson

Enter 9551 on Reader Reply Card

10 HEG NovDec 08 FINAL.indd 10 12/8/2008 3:08:59 PM

Enter 9559 on Reader Reply Card

THE NEW VOLVO F-SERIES WHEEL LOADERS.

EVERYTHING YOU NEED.

BUILT IN.

MORE CARE. BUILT IN.

A new standard of power, fuel efciency, and cost control. The new Volvo F-Series

Wheel Loader has everything you need to get your job done better than ever before.

New large Volvo Care Cab for all-day comfort and maximum visibility.

New low-emission, high-torque-at-low-rpms Volvo engine leads the industry in fuel

efciency.

New electric-hydraulic transmission with Volvos Fully Automatic Powershift shifts

seamlessly through all gears.

Proven load-sensing hydraulics provides full ow at low rpms to minimize fuel

consumption power and precision when you need it.

Volvos patented Torque-Parallel Linkage gives you high breakout force and parallel

lift throughout the entire range.

More power. More productivity. More comfort. More efciency. More reliability.

More care. Built in. The new Volvo F-Series Wheel Loaders.

Volvo Construction Equipment www.volvoce.com/na

Heavy Equipment Guide November/December 2008 / 11

use and ngertip control reduces operator

fatigue.

The cab is ready for auxiliary hydraul-

ics. Regenerative hydraulics make arm

Largest model in line-up

The new 181,880-pound R800LC-7A is

the largest member of Hyundais family

of excavators. The new Cummins 460 net

horsepower engine is built to last and uses

an advanced, high-pressure, common-rail

fuel delivery system, designed to improve

combustion efciency, reduce emissions

and maximize fuel economy.

Hyundais CAPO computer system ties

the hydraulic system and engine technology

together for maximum synergy. The CAPO

system offers two operator power mode

Maximum bucket power

The Dressta 560E features a Z-bar linkage

that transfers maximum breakout force to

the bucket to pry out hard packed material.

The wheel loader is easy to operate ,with

directional transmission and speed shifts

controlled by two levers at the operators

ngertips. It features an articulated frame

with a tight turning radius of only 26 feet 4

inches (8.03 m). Hydrostatic steering pro-

vides smooth control at any engine speed.

Dresstas 560E Extra features joystick

boom and bucket controls, hydrostatic

steering, and a high visibility cab. It has

a payload capacity of 7 to 15 cubic yards

(5.35 to 11.5 cubic metres) to go along

with a 92,549-pound (41,980-kg) operat-

ing weight. The turbocharged six-cylinder

Cummins engine provides 427 net hp (319

kW). A 6,390-pound (2,900-kg) counter-

weight, previously optional equipment, is

now standard.

Dressta North America

Enter 9556 on Reader Reply Card

four-wheel drive for greater traction in

adverse soil conditions. The WB146PS-5

incorporates a full PowerShift transmission

with twist grip, gear control.

The new S shaped backhoe boom is

narrower and stronger for better visibility,

increased lifting capacity, greater truck

loading and excellent breakout force. Com-

bine these features with a telescopic arm

and the backhoe can achieve digging depths

up to 18 feet 4 inches. The slim loader arms

also enhance operator visibility and allow

for easier truck loading.

Komatsu America Corp.

Enter 9555 on Reader Reply Card

selections, three work mode selections and

two user mode selections to optimize ma-

chine performance for the job at hand.

When equipped with a mass excavator

23-foot 7-inch boom and 9-foot 8-inch

arm, the new R800LC-7A can handle a

5.9-cubic-yard bucket.

Hyundai

Enter 9557 on Reader Reply Card

Correction: In the October issue, the Blade

Runner excavator was listed under the New

Holland brand. This model is only sold

under the Kobelco name in Canada and the

U.S. (see page 8 for product information).

More horsepower

Hitachis new ZX135US-3 incorporates

Tier-3 engine standards and the new CRES

II cab, which is larger and has a wider

seatback, more legroom, and more glass on

the right-hand side for improved visibility.

Low-effort, short-throw levers are easy to

roll-in and the boom lower/arm movement

faster. Travel speed has been increased

and multifunction operations are smoother

than ever.

The new ZX135US-3 has greater horse-

power and excellent fuel economy. One of

the retained features which helps reduce

operating costs is WC (tungsten carbide)

thermal spraying at the arm-bucket joint for

greater wear resistance at its contact surface

with the bucket and HN bushings.

Hitachi Construction

Enter 9558 on Reader Reply Card

10 HEG NovDec 08 FINAL.indd 11 12/8/2008 3:09:03 PM

CONCRETE EQUIPMENT

12 / Heavy Equipment Guide November/December 2008

Multi-gang slab-rider drills

E-Z Drill offers a line of multi-gang slab-

rider drills for accurate concrete drilling

from an easily maneuverable machine.

The series consists of three self-propelled

models: the three-gang Model 210-3 SRA,

four-gang Model 210-4 SRA and ve-gang

Model 210-5 SRA.

The compact frame design allows each

drill to operate in a four-foot patch while

drilling to within six inches of a corner.

The bits drill to a standard 18-inch depth,

and each unit can be adjusted easily to

drill into the centre of a 24-inch slab.

Adjustable spacing can be set between 12

and 36 inches, with greater width settings

available through custom orders. The pneu-

matic drills feature an internal regulator to

prevent breakage caused by high-pressure

spikes.

E-Z Drill

Enter 9571 on Reader Reply Card

Placer and screen combined

GOMACOs roller-compacted concrete

(RCC) paver combines the power, capacity

and mobility of the RTP-500 rubber-tracked

placer with an RCC screed. The combina-

tion of the RTP-500 and RCC screed pro-

vides a durable paver capable of handling

the harsh, zero-slump RCC mix designs.

The GOMACO-designed auger-style

receiving hopper on the RTP-500 features a

working capacity of 4.75 cubic yards (3.63

cubic metres). It was built for strength and

durability to handle high-volume, end-

dump paving operations. A 14-inch (356

mm) diameter auger, with speeds up to

80 rpm, quickly moves the material to the

high-speed transfer conveyor. Shaft-mount-

ed, eccentric vibrators provide vibration,

for emptying the hopper after each load,

and increase material owability.

GOMACO Corporation

Enter 9565 on Reader Reply Card

Unique placing boom

Schwings new concrete pump with pla-

cing boom, the S 36 SX with RZ4 Boom,

combines the best features of two boom

types Roll and Fold, and Z tip section

in a unique four-section boom. It can place

concrete at distances of more than 118 feet

vertically and 104 feet horizontally.

Standard features of the S 36 SX include

740-degree slewing range, a pipeline diam-

eter of ve inches, unfolding height of 28

feet 10 inches, and a unique boom design.

In the travel position, the RZ4s second sec-

tion is angled minimizing travel length.

As the boom unfolds, the boom straightens

itself, keeping the pipeline close to the

boom, shortening pipe arm holders and re-

sulting in the smoothest 36 metre available.

An added benet is the ability to position

the boom in tighter areas.

Schwing America, Inc.

Enter 9572 on Reader Reply Card

Concrete pump trucks

Sermacs two newest concrete pump mod-

els, the Extreme 4ZR21 and the Scorpio

6RZ65, represent the extremes of the Ser-

mac product line as the shortest and longest

pumps offered, respectively.

The four-section 4ZR21 combines the

function and versatility of a Z-fold boom

with the exibility of a roll-and-fold, with

a nearly 67-foot vertical reach, a nearly

Composite mixer drum

McNeilus has made several performance

enhancements to its Revolution composite

mixer drum. Areas of improvement include

the interior surface of the drum, new water

channels, and a tougher exterior surface.

These changes all increase productivity and

drum longevity.

The drum has more durable interior

wear surfaces for better protection against

concrete buildup. The new interior also

provides superior wear resistance, ex-

tending the life of the ns and interior

surface. Surface imperfections that promote

concrete buildup have been removed from

the interior of the drum to ensure concrete

ows better. There are new two-inch chan-

nels that allow water to get behind the n,

Ready-mix reclaimer

The Liebherr LRS 708 concrete reclaimer

has been updated with features that let

ready-mix producers design a concrete

reclamation system that will easily adapt to

existing settling ponds, can evolve as en-

vironmental rules change, and still benet

from the ability to re-use the aggregate.

Featuring a 29-cubic-yard hourly cap-

acity and dual mixer truck discharge, the

LRS 708 can be used on mid-sized ready

mix plants. For larger operations, the LDP

Buffer can be added to the LRS 708 for up

to six mixer trucks to discharge. On the

LRS 708, Liebherr has addressed the prob-

lems associated with bres, light weight

aggregate, bearing lubrication and better

nes separation. An audible and visual

alert system informs the plant operator and

mixer truck driver about the operational

status of the system.

Liebherr Concrete Technology Co.

Enter 9570 on Reader Reply Card

Screed for challenging jobs

Multiquips WRS-Series SuperScreed is

ideal for challenging paving applications

such as suspended slabs, highway rehabili-

tation, white-topping, airport runways,

slab-on-grade, tilt-up panels, roads, post-

tension slabs, bridges, elevated decks, and

Redesigned riding trowel

The Allen MSP 425 is a totally re-designed

rider that replaces the Allen SP425 Riding

Trowel. The new torque-converter clutch,

and improved weight-to-horsepower ratio,

make the MSP 425 a torque-monster

among four-foot-diameter Mechanical

Drive Riders. Designed to pan through the

toughest pours, the MSP 425 is a concrete

nishers dream.

This trowels standard features include:

manual steering and pitch controls; 34-hp

liquid-cooled Vanguard gasoline engine;

torque converter clutch system; two 46-

inch diameter, 5-blade, non-overlapping

rotors; rotor speeds up to 170 rpm; electric-

powered spray system for application of

retardant; and a ip-up seat and removable

screens for superior accessibility to engine,

clutch and drive-line.

Allen Concrete Equipment

Enter 9573 on Reader Reply Card

runways. The self-propelled SuperScreed

features a bi-directional strike-tube design

that precisely cuts the surface to grade

and has a rotation speed of 450 rpm. The

SuperScreed is available in widths ranging

from 14 to 52 feet and is capable of strik-

ing off concrete with slumps as low as one

inch while covering up to 10,000 square

feet per hour.

The SuperScreed is hydraulically driven

and powered by a 28-hp liquid-cooled Van-

guard diesel engine that provides the high

torque necessary for the most demanding

applications. A wrap-around steel frame

with convenient lifting points provides

protection for the power unit, while four

transport wheels simplify storage when the

unit is not in use. The screeds standard 50-

Watt halogen lights offer improved visibil-

ity during night time applications.

Multiquip

Enter 9567 on Reader Reply Card

One-pass nishing

The new Somero Mini Screed small

enough to t easily into the bed of a pickup

truck is a portable and versatile Laser

Screed. Weighing only 352 pounds with a

six-foot head, the Mini Screed uses Som-

eros patented laser-levelling technology to

cut the concrete to a nished grade, screed it

at and vibrate it smooth in one pass. Resi-

dential atwork contractors working with

slab-on-grade and basement slabs using the

Mini Screed can consistently achieve laser

accuracy on various slump and mix designs.

The Mini Screed delivers better concrete

consolidation than hand-held vibratory

screeds, also making it an excellent choice

for small commercial contractors.

Somero Enterprises, Inc.

Enter 9568 on Reader Reply Card

ensuring that concrete does not build up.

A more durable drum surface McNeilus

new Revolution R-MOR drum finish

provides a tough, UV-resistant layer on the

Revolution drum.

McNeilus Companies, Inc.

Enter 9569 on Reader Reply Card

New Telebelt model

The new Telebelt TB 600 truck-mounted

telescopic belt conveyor features a rated

output of 600 cubic yards per hour (459

cubic metres per hour) and has been en-

gineered to meet high volume material

placement demands.

Designed with civil contractors in

mind, the TB 600 is perfect for those seek-

ing a 50 percent production increase, says

Putzmeister America Vice President of

Sales and Marketing, Bill Dwyer.

With a 24-inch-wide, high capacity main

conveyor and feeder belt, the TB 600 offers

versatility in material type and volume. The

machine will place all owable materials,

such as pervious concrete, roller-compacted

concrete (RCC), soil, cement, owable ll

and large aggregates up to 6 inches (152

mm) in diameter. The feed conveyor also

offers fully hydraulic variable speed ca-

pabilities. Both belts feature 360-degree,

continuous rotation.

Putzmeister America

Enter 9566 on Reader Reply Card

10 HEG NovDec 08 FINAL.indd 12 12/8/2008 3:15:43 PM

Enter 9578 on Reader Reply Card

They perform on the job, they perform at resale. Thats why buying a Cat

Wheel Loader

is such a solid business decision. See for yourself. Visit the Web site below where youll

nd resale values provided by Top Bid, an independent third-party source. Then compare

a Cat Wheel Loader to your current brand or any other. Youll see why it makes sense

to own a Cat machine, and how it can help you Move More. Make More.

Cat

Wheel Loaders hold their

value better than any other brand.

Well prove it.

www.MoveMoreMakeMore.com

2008 Caterpillar Inc. All rights reserved. CAT, CATERPILLAR, their respective logos, Caterpillar Yellow and the POWER EDGE trade

dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

Heavy Equipment Guide November/December 2008 / 13

Compact curb machine

The LeeBoy LBC-24W concrete curber

is designed as a highly maneuverable,

compact curb and gutter machine in an

economical package. It has the ability to

smoothly and effectively pour a radius as

tight as 24 inches. It is built for slipform

curb and gutter, alley ribbons and sidewalks

up to four feet wide, along with the capabil-

ity for below-grade pours.

The unit is powered by a 44-hp diesel

engine and offers operators ngertip control

of all curbing functions from its front and

rear control panels. A responsive auto-

restart function gives clean starts and stops.

The 7,500-pound weight, low prole and

all-wheel hydrostatic drive give it stability,

traction and maneuverability in conned

spaces. The LBC-24W is guided by a Top-

Con System V Plus 1 electronic grade and

steering control system.

LeeBoy

Enter 9575 on Reader Reply Card

Horizontal reversing mixer

The CON-E-CO Horizontal Reversing

Mixer (HRM) delivers low maintenance

costs, quiet operation, and aggressive mix-

ing action. The reversing operation utilizes

state-of-the-art components to further mini-

mize maintenance costs.

Among its notable features are: a sealed

mixing drum with variable speed drive to

optimize mixing discharge rate and mini-

mize dust; climate controlled service panel

for longer life and a dust-free environment;

unique dual-element paddles supported

from the drum paddles, which eliminates

Improved ride-on trowels

Wackers expanded CRT 48 ride-on trowel

series offers improved steering and addi-

tional engine options. Three new models

54-foot horizontal reach, and an unfold-

ing height just under 14 feet. The 6ZR65

offers more than 211 feet of vertical reach

and more than 198 feet of horizontal reach

in a six-section, RZ-combination. Both

models include a cable and a radio remote,

hopper gate vibrator, high volume and high-

pressure water pumps, standard automatic

lubrication systems on the pump kit, 12-

foot end hose and a toolkit.

Sermac America, Inc.

Enter 9574 on Reader Reply Card

the need for a centre support and reduces

concrete build-up; drive motors wired to

individual disconnects for easier mainten-

ance and a reduced need for expensive eld

wiring; precise factory drive alignment

with built-in precision eld re-alignment

feature; and mixing and discharge paddles

with open slots between paddles and drum

for less daily clean up.

CON-E-CO

Enter 9576 on Reader Reply Card

offer a patent-pending torsion assist steer-

ing system that makes Wackers 48-inch

ride-on trowels easy to control. By reducing

the amount of force needed to control the

unit, Wackers CRT 48 series models of-

fer easy steering and operation as well as

reduced operator fatigue.

Three engine options are now avail-

able on the 48-inch CRT series. The CRT

48-34V comes with a premium 34-hp

liquid-cooled Vanguard engine. The CRT

48-35V is offered with a 35-hp air-cooled

Vanguard engine, and the CRT 48-35L is

equipped with a 4-cylinder, 35-hp liquid-

cooled diesel engine.

Wacker Neuson

Enter 9577 on Reader Reply Card

Next Issue Spotlight On

HORIZONTAL

DIRECTIONAL DRILLING

10 HEG NovDec 08 FINAL.indd 13 12/8/2008 3:15:52 PM

Enter 9586 on Reader Reply Card

Concrete Vibrators

Visit our website today for complete product specifications and features.

Hydraulic Paving Vibrator

Square Head

TM

Eliminates concrete build-up on

isolator components

Reduces downtime and

maintenance costs

Efficiently directs vibration into the

concrete instead of the paving machine

Larger eccentric weight is standard

Rugged new design hits

harder, at lower speeds

R

A

C

IN

E

FEDERATE

D

IN

C

.

IS

O

9

0

0

1

: 2000 FILE N

0

. A

6

8

5

6

TRUCKS & TRAILERS

14 / Heavy Equipment Guide November/December 2008

heavy construction applications.

The heart and soul of the Titan model is

the new Mack MP10 engine, an inline six-

cylinder diesel, with single overhead cam

and high-pressure fuel injection. It is avail-

able in three ratings, with peak horsepower

of 515 hp, 565 hp and 605 hp all with the

MaxiCruise torque rise. Maximum torque

ranges from 1,860 lb-ft to 2,060 lb-ft at

1,200 rpm. The Titan has a commanding

stance, with high ground clearance for

powering through conditions found in log-

ging, mining and construction sites. Its long

hood gives the 16-litre Mack MP10 engine

plenty of room to breathe, while the cab is

moved back and up on the chassis for the

classic heavy haul position and excellent

driver visibility.

Mack Trucks

Enter 9584 on Reader Reply Card

Safety updates for 2009

Sierra heavy-duty trucks are available in

Work Truck, SLE and SLT trims. Sierra

2500HD and 3500HD are offered in regu-

lar, extended and crew cab congurations,

which are complemented with standard

(1.98 metre / 6-foot 6-inch) and long (2.4

metre / 8-foot) cargo box lengths. Sierra

Rugged utility, performance

The 2009 Titan is offered in four mod-

els XE, SE, PRO-4X and LE; two cab

styles King Cab and Crew Cab; four bed

lengths ve feet six inches, and seven feet

for Crew Cab, six feet six inches, and eight

Tilt trailer adds safety

Transporting equipment such as tractors,

backhoes and front loaders is safer and

easier with Pequeas T100 and T200 tilt

trailers. The decks on these trailers tilt to the

ground, eliminating the need for navigating

ramps when loading equipment.

The T100 offers an 18-foot tilt deck

with a 10-degree load angle, and the T200

provides a 16-foot deck with a 13-degree

load angle. Pequea tilt trailers deck widths

are 81 inches between the fenders.

Each tilt trailer has a gross vehicle

weight rating of 10,000 pounds and six

standard weld-on D-rings that reliably

secure the trailers heavy load.

The T100 operates on a hydraulic pump

that powers the trailer bed up and down

for loading multiple pieces. The pump is

contained in the trailers toolbox and in-

cludes 20 feet of cord. The T200s closed

hydraulic system is designed to handle