Professional Documents

Culture Documents

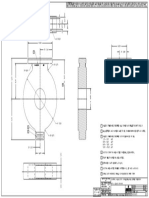

Specification of Helical Compression Spring EN 15800:2010 Designed To EN 13906-1: 2002 Part No: 001 Issue No: 001

Uploaded by

Rafael TellezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specification of Helical Compression Spring EN 15800:2010 Designed To EN 13906-1: 2002 Part No: 001 Issue No: 001

Uploaded by

Rafael TellezCopyright:

Available Formats

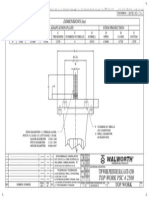

SPECIFICATION OF HELICAL COMPRESSION SPRING EN 15800:2010 Designed to EN 13906-1: 2002

d De Di D Dd Dh L0 L1 L2 Ln Lc Sh e1 e2 F1 F2 Fn Fc = = = = = = = = = = = = = = = = = =

Part no: 001

1.188 7.000 4.624 5.812 0 0 12.000 in in in in in in in in in in in in in in Lbf Lbf Lbf Lbf

Issue no: 001

9.798 8.910

5585.35 7837.68

k1 k2 kn c kh

R w k

= = = =

Lbf/in^2 Lbf/in^2 49302 Lbf/in^2 69183 Lbf/in^2

Type 1 - Closed and ground end coils 1 Active coils Total coils 2 Direction of coils n = 5.500 7.500

Type 2 - Closed end coils 10 Optional Right Left No Inside Outside

Stress range Spring rate R Spring index Stress correction factor

= Lbf/in^2 = 2536.47 Lbf/in = 4.892 = 1.302

Permissable deviations to EN 15800: 2010 Tolerance grade 2 3 Specified

nt =

1 De L0 F1 F2 e1 e2 R 11

Value

Chamfer of spring ends

4 5 6 7

Working deflection Stress cycle frequency

Sh =

in Not specified

Production compensation (a) if the spring force and the spring length are specified (b) if the spring force, the spring length and L0 are specified (c) if two spring forces and the spring lengths are specified

by: L0 n and d n and De/Di L0, n and d L0, n and De/Di

Range of working temperature Application Not specified Shot peened

Not specified

No

8 9

Surface protection

001

Material standard: ASTM A313 631 17/7 Aged - CH900 Permissable shearing stress, using lower tensile zul = Unprestressed, Lbf/in^2 zul = Prestressed, Lbf/in^2 Rigidity modulus G = 11000000 Lbf/in^2 Additional information Special requirements:

12

Prestressing Not specified

13

Software Copyright 2002-2011 Institute of Spring Technology, Sheffield, UK (V1.0)

You might also like

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document8 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)Liu YangtzeNo ratings yet

- Connection Design ProcedureDocument3 pagesConnection Design ProcedurewendyNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Publication Hilti RebarDocument234 pagesPublication Hilti RebarRedwan HendiNo ratings yet

- Half Bridge An-1160 PDFDocument32 pagesHalf Bridge An-1160 PDFAshok Kumar100% (1)

- Columns DesignDocument60 pagesColumns DesignifsrebraNo ratings yet

- 05 - Recessed Down LightersDocument72 pages05 - Recessed Down Lighterschaminda100% (1)

- The Design and Construction of The Westgate Shopping Centre Suspended Post Tensioned SlabDocument13 pagesThe Design and Construction of The Westgate Shopping Centre Suspended Post Tensioned SlabtoddNo ratings yet

- Hkouksa VKSJ Lajpukvksa Osq Fy, Fmtkbu Yksm (Hkwdai DH Vu ) JHFR LafgrkDocument62 pagesHkouksa VKSJ Lajpukvksa Osq Fy, Fmtkbu Yksm (Hkwdai DH Vu ) JHFR LafgrkSudhakar Krishnamurthy100% (1)

- Catalogo de Punzones Dayton ProgreDocument28 pagesCatalogo de Punzones Dayton ProgreOdiseo Kratos SacuraguiNo ratings yet

- MOMENT EndplateDocument8 pagesMOMENT Endplatemoseslugtu6324No ratings yet

- XXG-Ceramic Tube Directional: Max. Penetrate A3 Steel (MM)Document2 pagesXXG-Ceramic Tube Directional: Max. Penetrate A3 Steel (MM)SerkanNo ratings yet

- Durable, Long-Lasting Punches & Punch Blanks: Heads-Above-The-Rest PerformanceDocument12 pagesDurable, Long-Lasting Punches & Punch Blanks: Heads-Above-The-Rest PerformanceCristhian Graef100% (1)

- En - Steval-Iss001v2 Bom PDFDocument5 pagesEn - Steval-Iss001v2 Bom PDFaducbkfetNo ratings yet

- Joh. Heinr. Bornemann GMBH Postfach 1162, D-31676 Obernkirchen Phone: +49 5724 390-0 Fax +49 5724 390 290Document6 pagesJoh. Heinr. Bornemann GMBH Postfach 1162, D-31676 Obernkirchen Phone: +49 5724 390-0 Fax +49 5724 390 290vuthanhNo ratings yet

- Lenton PlusDocument2 pagesLenton PlusAndrei PantuNo ratings yet

- Cambridge Audio A1 A2 Parts List SchematicsDocument10 pagesCambridge Audio A1 A2 Parts List SchematicsEu ToteuNo ratings yet

- AMRI ISORIA 10 Type Series Booklet Data PDFDocument20 pagesAMRI ISORIA 10 Type Series Booklet Data PDFMurrali Raj Jeyagapal50% (2)

- FRP Lamella V3 Manual EngDocument96 pagesFRP Lamella V3 Manual Engtopnoch5454No ratings yet

- f0211 300 NP FLG X FLG Data SheetDocument1 pagef0211 300 NP FLG X FLG Data SheetRay LujanNo ratings yet

- KORLOYTESTDEHAYEDocument36 pagesKORLOYTESTDEHAYEnicodehayeNo ratings yet

- Aeroelastic GallopingDocument17 pagesAeroelastic GallopingMalika NavaratnaNo ratings yet

- JVC Autoradio Schaltplan GEA10232ab MA398schDocument10 pagesJVC Autoradio Schaltplan GEA10232ab MA398schcopykill23No ratings yet

- 1le1502 2BB03 4aa4Document3 pages1le1502 2BB03 4aa4Atlanta Bolivia100% (1)

- RK3066 Mid PDFDocument17 pagesRK3066 Mid PDFSharon MurphyNo ratings yet

- A Comparative Study On Failure Pressure Estimations of Unflawed Cylindrical VesselsDocument14 pagesA Comparative Study On Failure Pressure Estimations of Unflawed Cylindrical VesselsBrighton JohnNo ratings yet

- Discipline Build GuideDocument12 pagesDiscipline Build Guidekatherine bellmanNo ratings yet

- 1.1 APS Powder Insert: Parts List PL 40993 EN 13Document16 pages1.1 APS Powder Insert: Parts List PL 40993 EN 13Alexandre VecaNo ratings yet

- Epcos PFC Catalog 14Document1 pageEpcos PFC Catalog 14Ursula JohnsonNo ratings yet

- Sch40 80 ASTM A53 - Brochure - 042512 PDFDocument2 pagesSch40 80 ASTM A53 - Brochure - 042512 PDFMohamed AmmarNo ratings yet

- Tonepad TubescreamerDocument1 pageTonepad TubescreamerWasabiRockNo ratings yet

- Shear Design of A Hollow Core SlabDocument17 pagesShear Design of A Hollow Core SlabjrandeepNo ratings yet

- Structural Engineering - Internal Actions - Problem Set & AnswersDocument11 pagesStructural Engineering - Internal Actions - Problem Set & AnswersSew KariyawasamNo ratings yet

- Ramset Specifiers Anchoring Resource Book ANZ Chemical Anchoring Anchor StudsDocument59 pagesRamset Specifiers Anchoring Resource Book ANZ Chemical Anchoring Anchor StudsjlolhnpNo ratings yet

- Load CalculationDocument13 pagesLoad CalculationJahidul IslamNo ratings yet

- Hilti-Fischer Anchor BoltDocument2 pagesHilti-Fischer Anchor Boltpavitrakedar100% (1)

- Item:130ST Series Servo Motor: SpecificationsDocument4 pagesItem:130ST Series Servo Motor: Specificationsn13t0314No ratings yet

- Heladito O2Document2 pagesHeladito O2Pablo RagoNo ratings yet

- KX-TDA0174XJ KX-TDA0174X: 16port Single Line Telephone Extension CardDocument55 pagesKX-TDA0174XJ KX-TDA0174X: 16port Single Line Telephone Extension Cardjuanka_ing_2010No ratings yet

- LTS 6 TableOfContents PDFDocument29 pagesLTS 6 TableOfContents PDFTAHANo ratings yet

- Whirlpool AWM 5080 ManualDocument21 pagesWhirlpool AWM 5080 ManualCharles ThompsonNo ratings yet

- 2A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesDocument14 pages2A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesGioVoTamNo ratings yet

- Maintenance Arpex enDocument39 pagesMaintenance Arpex enPatrick BaridonNo ratings yet

- Bis Code1Document12 pagesBis Code1Starla HillNo ratings yet

- Purlin SoleroDocument1 pagePurlin SoleroJoseph Cloyd L. LamberteNo ratings yet

- Panasonic KX-TC1466LAB 1466LAW Telefono Inalambrico Manual de ServicioDocument89 pagesPanasonic KX-TC1466LAB 1466LAW Telefono Inalambrico Manual de ServicioBruné0% (2)

- Sinorix™: A6V10867394 - en - c2 Building Technologies 2017-06-06 Control Products and SystemsDocument4 pagesSinorix™: A6V10867394 - en - c2 Building Technologies 2017-06-06 Control Products and SystemsEngineering TFINo ratings yet

- Tying Resistance 635Document7 pagesTying Resistance 635jo0rodriguesNo ratings yet

- CAESAR II Input Echo and OutputDocument264 pagesCAESAR II Input Echo and OutputSanjayNo ratings yet

- LC Filter For Three Phase Inverter ReportDocument19 pagesLC Filter For Three Phase Inverter ReportMuthuRajNo ratings yet

- Compression PDFDocument49 pagesCompression PDFKhem Loid CumingNo ratings yet

- Unit IDocument142 pagesUnit IAnonymous yorzHjDBdNo ratings yet

- Helical Compressing Spring Calculation PDFDocument4 pagesHelical Compressing Spring Calculation PDFViktor KovtunNo ratings yet

- 20 Induction Motor DesignDocument20 pages20 Induction Motor DesignRavikumar GogulamandaNo ratings yet

- Design A Bell Crank'95Document27 pagesDesign A Bell Crank'95Al DrinNo ratings yet

- Mustang: Wood GroupDocument2 pagesMustang: Wood GroupayemyothantNo ratings yet

- 6 D Sub Connectors For SV Series ValvesDocument10 pages6 D Sub Connectors For SV Series Valvespaulomarques22No ratings yet

- Belts Tables PDFDocument30 pagesBelts Tables PDFM Hamdy EladwyNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Stelex ZR PDFDocument4 pagesStelex ZR PDFRafael TellezNo ratings yet

- FT GeofoamDocument2 pagesFT GeofoamMichael Angel0% (1)

- Stelex ProDocument4 pagesStelex ProRafael TellezNo ratings yet

- 33333Document1 page33333Rafael TellezNo ratings yet

- Steel GalvanizedDocument28 pagesSteel GalvanizedRafael TellezNo ratings yet

- 16B5605 Rev.DDocument1 page16B5605 Rev.DRafael TellezNo ratings yet

- ForexDocument83 pagesForexRafael TellezNo ratings yet

- Type Ø Nominal Class Ø PORT (In) Ø STEM (In) Pitch Lead Thrust (LB) Torque (LB-FT)Document1 pageType Ø Nominal Class Ø PORT (In) Ø STEM (In) Pitch Lead Thrust (LB) Torque (LB-FT)Rafael TellezNo ratings yet

- Lista de Material: Lote Id: Nivel Base Id: Descripcion Qty - Per Fixed - Qty Scrap Perc Qty Hand Drawing - IdDocument6 pagesLista de Material: Lote Id: Nivel Base Id: Descripcion Qty - Per Fixed - Qty Scrap Perc Qty Hand Drawing - IdRafael TellezNo ratings yet

- Specification of Helical Compression Spring EN 15800:2010 Designed To EN 13906-1: 2002 Part No: 001 Issue No: 001Document1 pageSpecification of Helical Compression Spring EN 15800:2010 Designed To EN 13906-1: 2002 Part No: 001 Issue No: 001Rafael TellezNo ratings yet

- PSC 18 900 PSC 10 900 PDFDocument1 pagePSC 18 900 PSC 10 900 PDFRafael TellezNo ratings yet

- Type Ø Nominal Class Ø PORT (In) Ø STEM (In) Pitch Lead Thrust (LB) Torque (LB-FT) Stroke (In) Turns To OPEN ( 1)Document2 pagesType Ø Nominal Class Ø PORT (In) Ø STEM (In) Pitch Lead Thrust (LB) Torque (LB-FT) Stroke (In) Turns To OPEN ( 1)Rafael TellezNo ratings yet

- Match Capacity TableDocument11 pagesMatch Capacity TableRafael TellezNo ratings yet

- B132043 Seat Ring MachDocument1 pageB132043 Seat Ring MachRafael TellezNo ratings yet

- Type Ø Nominal Class Ø PORT (In) Ø STEM (In) Pitch Lead Thrust (LB) Torque (LB-FT)Document1 pageType Ø Nominal Class Ø PORT (In) Ø STEM (In) Pitch Lead Thrust (LB) Torque (LB-FT)Rafael TellezNo ratings yet

- B132040 Steam MachDocument1 pageB132040 Steam MachRafael TellezNo ratings yet

- GC243C05MAA0006350Document1 pageGC243C05MAA0006350Rafael TellezNo ratings yet

- GC243C05MAA0006350Document1 pageGC243C05MAA0006350Rafael TellezNo ratings yet

- GT043C05MAA0095000Document1 pageGT043C05MAA0095000Rafael TellezNo ratings yet

- NPS 18" ANSI Class 1500 Pressure Seal Gate Valve Walworth DesignDocument1 pageNPS 18" ANSI Class 1500 Pressure Seal Gate Valve Walworth DesignRafael TellezNo ratings yet

- Calculo Torque A Presion EspecificaDocument1 pageCalculo Torque A Presion EspecificaRafael TellezNo ratings yet

- Lista de Material: Lote Id: Nivel Codigo Parte Descripcion Qty - Per Qty Hand Drawing - Id Base Id: WeightDocument2 pagesLista de Material: Lote Id: Nivel Codigo Parte Descripcion Qty - Per Qty Hand Drawing - Id Base Id: WeightRafael TellezNo ratings yet

- Top Work 4 2500 PSCDocument1 pageTop Work 4 2500 PSCRafael TellezNo ratings yet

- Asme Sec. ViiiDocument1 pageAsme Sec. ViiiRafael TellezNo ratings yet