Professional Documents

Culture Documents

Acs800 207lc HW Manual Rev A

Uploaded by

pwmvsiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acs800 207lc HW Manual Rev A

Uploaded by

pwmvsiCopyright:

Available Formats

ACS800

Hardware Manual

ACS800-207LC IGBT Supply Units

ACS800 liquid-cooled multidrive manuals

GENERAL DRIVE MANUALS

1) Code (EN)

ACS800 Liquid-cooled Multidrive and Multidrive Modules

Safety Instructions

3AFE68715318

ACS800 Liquid-cooled Multidrive and Multidrive Modules

Planning the Electrical Installation

3AFE68715423

ACS800 Liquid-cooled Multidrive Modules Planning the

Cabinet Installation

3AFE68818559

ACS800 Liquid-cooled Multidrive Mechanical Installation 3AFE68715466

SUPPLY UNIT HARDWARE AND FIRMWARE MANUALS

2)

ACS800-307LC, -507LC, -1107LC, -1207LC Diode Supply

Unit Hardware Manual

3AFE68715474

ACS800 Liquid-cooled Diode Supply Control Program

Firmware Manual

3AFE68746299

ACS800-207LC IGBT Supply Unit Hardware Manual 3AFE68822092

ACS800 IGBT Supply Control Program Firmware Manual 3AFE68315735

INVERTER UNIT HARDWARE MANUALS

1)

ACS800-107LC Inverter Unit Hardware Manual 3AFE68715491

BRAKE CHOPPER MANUALS

3)

ACS800-607LC Brake Chopper Units Hardware Manual 3AFE68835861

ACS800 Brake Chopper Control Program Firmware Manual 3AFE68835631

INVERTER UNIT FIRMWARE MANUALS,

SUPPLEMENTS AND GUIDES

3)

Standard Application Program Firmware Manual and

Adaptive Program Application Guide

3AFE64527592,

3AFE64527274

System Application Program Firmware Manual and

Adaptive Program Application Guide

3AFE64670646,

3AFE68420075

Application Program Template Firmware Manual 3AFE64616340

Master/Follower Application Guide 3AFE64590430

Pump Control Application Program Firmware Manual 3AFE68478952

Extruder Control Program Supplement 3AFE64648543

Centrifuge Control Program Supplement 3AFE64667246

Traverse Control Program Supplement 3AFE64618334

Crane Control Program Firmware Manual 3BSE11179

etc.

OPTION MANUALS

3)

Manuals for Fieldbus Adapters, I/O Extension Modules etc.

LIQUID COOLING UNIT MANUAL

4)

ACS800-1007LC Liquid-cooling Unit User's Manual 3AFE68621101

1)

Always included in the delivery

2)

Included in the delivery with appropriate supply unit

3)

Included in the delivery with appropriate program or option device

4)

Included in the delivery with the optional liquid cooling unit

ACS800-207LC

IGBT Supply Units

Hardware Manual

3AFE68822092 Rev A

EN

EFFECTIVE: 30.03.2007

! 2007 ABB Oy. All Rights Reserved.

Table of contents

5

Table of contents

Table of contents

About this manual

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Intended audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Common chapters for several products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation and commissioning flowchart of the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Other documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

How the IGBT supply unit operates

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operation principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

AC voltage and current waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Hardware description

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Overview of a drive with an IGBT supply unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Composition of the supply unit cubicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Layout view Auxiliary control cubicle (option +Z010 or +Z020) . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Layout view Main contactor cubicle (option +F250) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Layout view Main breaker cubicles (option +F255) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

600 mm wide cubicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1000 mm wide cubicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Layout view Supply module and LCL filter cubicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Single-line diagram of a supply unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Overview of IGBT supply module R8i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Printed circuit boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Control interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Connections and use of the IO in the supply unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Connections to standard I/O terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Type designation labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Type code of cabinet-installed IGBT supply unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Basic code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Option codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table of contents

6

Type code of IGBT supply module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Basic code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Option codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Electrical installation

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Checking the insulation of the assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Input cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Motor and motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Checking the compatibility with IT (ungrounded) systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Power connections unit with in-built main breaker or contactor (option +F255 or +F250) . . . . . 32

Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Power connections unit without in-built main breaker or contactor (no option +F255 or +F250) 34

Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Control connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Main breaker/contactor control connections unit without in-built main breaker or contactor

(no option +F255 or +F250) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Installation of optional modules and PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

PC connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Installation of option modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Cabling of I/O and fieldbus modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Fibre optic links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Connections of the auxiliary voltage transformer (option +G344) . . . . . . . . . . . . . . . . . . . . . . . . . 38

Connection of external power supply for the auxiliary circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Connection diagram, case 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Connection diagram, case 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Connection diagram, case 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Installation checklist

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Installation checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Start-up and operation

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Fault tracing

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

LEDs of the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table of contents

7

Maintenance

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Replacing and reforming the capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Reforming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Capacitor replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Replacing the cooling fans in incoming cubicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Replacing the fan in 400 mm wide incoming cubicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Replacing the fan in 600 mm or 1000 mm wide incoming cubicle . . . . . . . . . . . . . . . . . . . . . . . 51

Replacing the cooling fans in supply module cubicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Installing the installation stand for supply module R8i replacement . . . . . . . . . . . . . . . . . . . . . . . . 53

Replacing the supply module R8i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Installing the winch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

The internal cooling circuit

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Internal cooling system diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Connection to a cooling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Connection to an ACS800-1007LC cooling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Connection to a custom cooling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

General requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Coolant temperature control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Filling up and bleeding the internal cooling circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Draining the internal cooling circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Adding inhibitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Temperature limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Pressure limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Water quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Freeze protection and corrosion inhibition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Glycol concentration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Technical data ACS800-207LC

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Temperature derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Altitude derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Auxiliary circuit current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Losses, coolant flow and quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Internal cooling circuit data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Input busbar and cable lead-through data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table of contents

8

Units with built-in main breaker (option +F255) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Input power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Output power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Internal cooling circuit data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Standards and markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

US patents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Technical data ACS800-104LC modules

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Temperature derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Altitude derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Type equivalence table and frame sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Auxiliary circuit current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

LCL filter types, data and use with supply modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Supply module capacitances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Losses, coolant flow and quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Internal cooling circuit data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

AC fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

DC fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Output connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Input power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Tightening torques for power connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Applicable standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

US patents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Dimensions and weights

Dimensions and weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Cubicle widths and positions in the cabinet line-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Cubicle widths and positions in the IGBT supply unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Motor control and I/O board (RMIO) specification

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

To which board type and revisions this chapter applies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

RMIO board specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Analogue inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Constant voltage output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Table of contents

9

Auxiliary power output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Analogue outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

DDCS fibre optic link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

24 V DC power input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

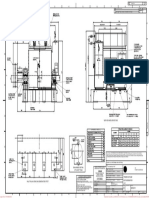

IGBT supply unit example circuit diagrams

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table of contents

10

About this manual

11

About this manual

What this chapter contains

This chapter describes the intended audience and contents of the manual. It also

contains an installation and commissioning flowchart and the ABB contact

information.

Compatibility

This manual is compatible with ACS800-207LC, the liquid-cooled and cabinet-

installed IGBT supply units.

Intended audience

This manual is intended for people who plan the installation, install, commission, use

and service the supply unit. Read the manual before working on the drive. The

reader is expected to know the fundamentals of electricity, wiring, electrical

components and electrical schematic symbols.

The manual is written for readers worldwide.

Common chapters for several products

Some chapters apply also to ACS800-104LC IGBT supply module or the complete

multidrive. This is indicated in the introduction of the chapter.

Contents

The ACS800-207LC Hardware Manual:

describes the operation basics and hardware of the supply unit

instructs in safe installation, start-up, fault tracing and maintenance of the supply

unit

presents or refers to the essential reference data, such as technical data, system

and circuit diagrams, that help the customer in planning the installation, installing,

commissioning, using and maintaining the supply unit.

About this manual

12

Installation and commissioning flowchart of the drive

Task Additional information

Plan the installation, e.g:

select cables and motors

define/check supply disconnecting means, protections,

emergency stop means, prevention of unexpected start-

up means

See ACS800 Liquid-cooled Multidrive and Multidrive

Modules Planning the Electrical Installation

[3AFE68715423 (English)], chapter Technical data

ACS800-207LC, and the technical data in ACS800-107LC

Inverter Unit Hardware Manual [3AFE68715491 (English)].

verify that the ratings (voltage, current, power) of input

power line, drive and motors match with each other

check the ambient conditions See chapter Technical data ACS800-207LC, page 67.

check that the cooling arrangements both in internal and

external cooling circuits meet the requirements: materials,

coolant quality, coolant flow, coolant temperature and

pressure.

See chapters The internal cooling circuit, page 59 and

Technical data ACS800-207LC, page 67 and

ACS800-1007LC Liquid Cooling Unit User's Manual

[3AFE68621101 (English)].

Unpack the drive and make the delivery check.

Check that all necessary optional modules and equipment

are present and correct.

Only intact units may be started up!

See Option codes, page 27.

If the drive has been non-operational for more than one

year, reform the converter DC link capacitors.

Contact your local ABB representative.

Route the cables. See ACS800 Liquid-cooled Multidrive and Multidrive

Modules Planning the Electrical Installation

[3AFE68715423 (English)].

Fasten the transportation lengths and mount the cabinet

line-up.

See ACS800 Liquid-cooled Multidrive Mechanical

Installation [3AFE68715466 (English)].

Check the insulation of the input power cable, motor cable

and motor.

See chapter Electrical installation, page 31.

Connect the power cables. Connect the control cables.

Connect the external power supply for the auxiliary circuits

(if needed).

See chapter Electrical installation, pages 31, 34, 36 and 39.

See the circuit diagrams delivered with the drive.

Connect cooling circuits.

About this manual

13

Other documents

User documentation of a multidrive delivery contains technical drawings and a set of

manuals. Technical drawings are tailor-made for each delivery. The composition of

the manual set depends on the composition of the drive. For the list of manuals, see

the inside of the front cover.

Terms and abbreviations

Inquiries

Address any inquiries about the product to the local ABB representative, quoting the

type code and serial number of the unit. If the local ABB representative cannot be

contacted, address inquiries to ABB Oy, AC Drives, PO Box 184, 00381 Helsinki,

Finland.

Product and service inquiries

Address any inquiries about the product to your local ABB representative, quoting

the type code and serial number of the unit in question. A listing of ABB sales,

support and service contacts can be found by navigating to www.abb.com/drives and

selecting Drives World wide service contacts on the right pane.

Check the installation. See chapter Installation checklist, page 41.

Commission the drive. See chapter Start-up and operation, page 43.

Term Definition

APBU PPCS Branching and Data logger Unit. Handles the communication between the control

board (RMIO) and parallel supply modules or inverter modules.

DDCS Serial communication protocol used in ABB drives

R8i Inverter module or IGBT supply module frame size

RAIO Analogue I/O extension module (optional)

RAPI 24 V DC back-up accumulator board for auxiliary power of RMIO board

RDCO DDCS Communication Option. A satellite board that can be snapped on the RMIO board

to add the no. of fibre optic channels available.

RDCU Drive Control Unit. The RDCU houses the RMIO board inside a plastic casing which can

be snapped on a standard installation rail.

RDIO Digital I/O extension module (optional)

RMIO Motor Control and I/O Board. In ACS800 multidrive, there is one RMIO board in each

supply unit, inverter unit, brake unit and cooling unit.

Task Additional information

About this manual

14

Product training

For information on ABB product training, navigate to www.abb.com/drives and select

Drives Training courses on the right pane.

Providing feedback on ABB Drives manuals

Your comments on our manuals are welcome. Go to www.abb.com/drives, then

select successively Drives Document Library Manuals feedback form on the right

pane.

How the IGBT supply unit operates

15

How the IGBT supply unit operates

What this chapter contains

This chapter describes how the IGBT supply unit operates. The information is valid

for cabinet-installed IGBT supply units (ACS800-207LC), and IGBT supply modules

(ACS800-104LC) if they are equipped with similar auxiliary devices.

Operation principle

The IGBT supply unit consists of an IGBT supply module, an LCL filter, AC and DC

fuses and optional devices such as main breaker, etc. The IGBT supply module

rectifies three-phase AC current to direct current for the intermediate DC link of the

drive. The intermediate DC link is further supplying the inverter that runs the motor.

There might be one inverter only (single drive) or several inverters (multidrive)

connected to the intermediate circuit. The line filter suppresses the AC voltage

distortion and current harmonics.

The IGBT supply module is a four-quadrant switching-mode converter, i.e. the power

flow through the converter is reversible. As default, the converter controls the DC link

voltage to the peak value of the line-to-line voltage. The DC voltage reference can be

set also higher by a parameter. Two line currents and the DC link voltage are

measured and used for the control.

The LCL filter is an essential part of the IGBT supply unit. The high AC inductance

smooths the line voltage waveform distorted by the high-frequency switching of the

converter. Capacitive component of the filter effectively filters the high-frequency

(over 1 kHz) harmonics.

LCL filter DC fuses IGBT supply module AC fuses

DC output

AC input

How the IGBT supply unit operates

16

AC voltage and current waveforms

The AC current is sinusoidal at a unity power factor. The IGBT supply unit does not

generate characteristic current or voltage harmonics like a traditional 6- or 12-pulse

bridge does.

The Total Harmonic Distortion (THD) in voltage depends slightly on the Short Circuit

Ratio in the Point of Common Coupling (PCC). See chapter Technical data

ACS800-104LC modules, page 73. The voltage ripple depends on the ratio of supply

line inductance (L

supply line

) to total line inductance (L

supply line

+ L

LCL filter

).

Typical line current (i

U

) and voltage (u

UV

) waveforms are shown below.

Typical current distortion at the input of the supply transformer is shown below. Each

harmonic is presented in relation to a reference current of 200 A.

-1200

-800

-400

0

400

800

1200

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38

u

UV

t [ms]

i

U

I [A], U [V AC]

0.00

0.20

0.40

0.60

0.80

1.00

1.20

2 6 10 14 18 22 26 30 34 38 42 46 50

T

H

D

C

u

r

r

e

n

t

[

%

]

Ordinal no. of

harmonic

Hardware description

17

Hardware description

What this chapter contains

This chapter describes the hardware of the IGBT supply unit. The information is valid

for cabinet-installed IGBT supply units (ACS800-207LC), and IGBT supply modules

(ACS800-104LC) if they are equipped with similar auxiliary devices.

Overview of a drive with an IGBT supply unit

The figure below shows an example of a multidrive line-up. Every line-up typically

includes a supply unit, inverter units and liquid cooling unit. The composition, and

size of the units vary. The line-up may also include additional units and cubicles, e.g

an auxiliary control unit (or cubicle), a control unit, adapter cubicles, etc.

Composition of the supply unit cubicles

The composition of supply unit depending on the selected options is described in

chapter Cubicle widths and positions in the IGBT supply unit. The layout drawings of

the cubicles are shown below.

No. Description

1. Supply unit

1a. Auxiliary control cubicle

1b. Main breaker

(contactor) cubicle

1c. LCL filter cubicle

1d. Supply module cubicle

2. Inverter unit

3. Inverter unit

4. Cooling unit

1b 1d 2 3 4 1c

0 1

1

1a

Hardware description

18

Layout view Auxiliary control cubicle (option +Z010 or +Z020)

Layout view Main contactor cubicle (option +F250)

No. Description

1. Main switch for auxiliary circuits

2. Auxiliary voltage transformer

3. Control relays, breakers, etc.

4. Cooling fan

5. Air to liquid heat exchanger

Door closed Door open

1

2

3

5

4

No. Description

1. Emergency stop, reset (optional)

2. Meters (optional)

3. Operating switch of the supply unit (Off/

On/Start)

4. PE main busbar of the cabinet (behind the

cooling liquid pipe)

5. Busbars for input power cables

6. Main disconnector (option +F254)

7. Earthing switch (option +F259)

8. Charging circuit/switch

9. Main contactor

10. Heat exchanger and fan

Door closed Door open

1

2

3

10

6

8

7

9

4

5

Hardware description

19

Layout view Main breaker cubicles (option +F255)

600 mm wide cubicle

1000 mm wide cubicle

Door closed Door open

No. Description

1. Emergency stop, reset (optional)

2. Meters (optional)

3. Operating switch of the supply unit (Off/

On/Start)

4. PE main busbar of the cabinet (behind the

cooling liquid pipe)

5. Busbars for input power cables

6. Charging circuit switch

7. Main breaker

8. Earthing switch

9. Heat exchanger and fans

3

1

2

6

7

9

8

4

5

No. Description

1. Emergency stop, reset (optional)

2. Meters (optional)

3. Operating switch of the supply unit (Off/

On/Start)

4. PE main busbar of the cabinet (behind the

cooling liquid pipe)

5. Busbars for input power cables

6. Charging circuit switch

7. Main breaker

8. Earthing switch

9. Heat exchanger and fans

Doors closed Doors open

1

2

3

6

7

8

4

5

9

Hardware description

20

Layout view Supply module and LCL filter cubicles

Figure below is an example showing a unit with two parallel R8i modules.

No. Description

1. Control panel (option +J400)

2. LED panel (option +J401)

3. AC fuses

4. LCL filter components (2 L, 1 C)

5. Swing-out frame for the supply unit control

electronics

6. Supply modules (behind the swing-out

frame)

7. Fans

8. DC fuses

Doors closed Doors open

1 2

3

6

7

8

4

5

Hardware description

21

Single-line diagram of a supply unit

The single-line diagram below shows a two-module IGBT supply unit with a built-in

main breaker and an earthing switch (option +F259).

Overview of IGBT supply module R8i

The figure below shows the IGBT supply module size R8i. The control unit (type

RDCU) containing the RMIO board is external and not shown here.

U<

LCL

2ACS800

RMIO

Control circuitry

board

-104LC

~

=

APBU

board

~

=

5) 6)

1. Input power connection

2. DC supply for inverters

3. Power supply for fans

4. Power supply for control circuitry

5. Temperature supervision

6. IGBT supply module control via

fibre optic link

0

START

1

1

2

3

4

1. Input busbars/knives (U2,V2,W2). Fit into

quick connector on the rear assembly plate of

the cabinet.

2. Output busbars (+, -)

3. Fibre optic connectors. V1, V2: control board

(RMIO) connection. Other fibre optic

connectors are not in use in supply units.

4. Coolant in connection

5. Coolant out connection

6. Handle

7. Air/liquid heat exchanger

8. Terminal block X17 (not in use in supply units)

1

2

3

4

5

7

6

8

Hardware description

22

Printed circuit boards

The figure below shows the interconnections between the boards.

1)

The RDCU can optionally equipped be with an auxiliary power interface board (RAPI). The RAPI

board ensures the POWER FAIL function of the RMIO board can be carried out in case the 24 V

auxiliary power to the RDCU is interrupted, i.e. the fault and alarm loggers have enough time to write

collected data into the flash memory.

Item Explanation

RDCU Drive control unit. Note that in units with several modules in parallel, there is a branching

unit (APBU or NPBU) between the modules and the control unit.

RMIO Control board

APOW Power supply board

NRED Voltage reduction board (in 690 V AC units only)

AINT Main circuit interface board

AGDR Gate driver board (interface to IGBTs)

AINT

Intermediate

DC link

NRED

1

3

X4

X2

2

AGDR

X10 X2

AGDR

X10 X2

AGDR

AINT

X10 X2

X1

X7

APOW

X1

X2 X8

Phase current

measurements

(3)

IGBT control

pulses

V2

RMIO

RDCU

V68 V1

V57

X2

X34

IGBT supply module

2

V5

24 V

1)

n

X2

X3

Hardware description

23

Control interfaces

The following diagram shows the control interfaces and I/O options of the supply

unit.

~

= ~

=

Motor Control

and I/O Board

(RMIO)

Supply unit control circuitry

including door switches, charging

circuit control, main contactor

control, etc.

Input power

To motor

Optional module 1: Fieldbus adapter (e.g.

RMBA, RDNA, RPBA)

Optional module 2: Not in use when the

board controls an IGBT supply module.

Optional module 3: DDCS communication

option (RDCO-0x)

The fibre optic channels provided by the

RDCO module can be used for fieldbus

connection (Nxxx fieldbus adapter modules),

or PC connection (DriveWare

PC tools). See

ACS800 IGBT Supply Control Program

Firmware Manual [3AFE68315735 (English)].

Drive Control Unit

(RDCU)

Control panel or LED

panel

Supply unit Inverter unit

0

St

1

Reset

Em. stop

Hardware description

24

Connections and use of the IO in the supply unit

The table and the figure below describe the connections and use of the IO in the

supply unit. The use of IO is fixed in the supply unit control program and the wiring to

RMIO terminals are made accordingly at the factory. The settings of the supply

control program and the connections of the supply unit IO must not be changed by

the user.

IO Name Use in the control program Connected device / Purpose

RDCU standard IO channel

AI1 Not in use Not in use as default. Not in use as default.

A12 Not in use Not in use as default. Not in use as default.

AI3 Not in use Not in use as default. Not in use as default.

DI1 ALARM / FAULT Overtemperature supervision: 1->0: Alarm.

0: Fault (after preset time delay).

LCL filter temperature sensors (in series)

DI2 ON / OFF Supply module on/off control. 0->1: On.

0: Off.

Operating switch, control circuitry

DI3 ACK MAIN

CONTACTOR

Main breaker/contactor supervision. 1:

closed (enables supply unit start)

Contact in main breaker/contactor control

circuit

DI4 EARTH FAULT Earth fault supervision. Can be activated or

inactivated by parameter. 1: No fault. Not in

use as default.

Insulation monitoring device (optional IRDH

unit by Bender, +Q951 or +Q952).

DI5 ALARM / FAULT Supervision of cooling unit. Can be activated

or inactivated by parameter. 1->0: Alarm.

0: Fault (after preset time delay). Not in use

as default.

Cooling unit monitoring circuit. Not in use but

hard-wired to +24 VDC of RDCU when no

optional cooling unit is in use.

DI6 RESET Supply module reset. 1: Reset. Not connected as default. Fault reset can be

given from control panel.

DIIL Not in use Not in use as default. Not in use as default.

RO1 CHARGING On/off control of charging contactor. 1: On. Charging circuit control relay

RO2 LCU ON / OFF Liquid cooling unit on/off control. 1: On. Cooling unit control relay. Not connected

when no optional cooling unit is in use

(+C138 or +C139).

RO3 MAIN

CONTACTOR

CONTROL

Main breaker/contactor control. 1: On. Breaker control circuit

Hardware description

25

Connections to standard I/O terminals

X20

1 VREF- Reference voltage -10 V DC, 1 kohm < R

L

< 10

kohm

2 AGND

X21

1 VREF+ Reference voltage 10 V DC, 1 kohm < R

L

< 10

kohm

2 AGND

3 AI1+ Not in use. 1) 0(2)10 V, R

in

> 200 kohm

4 AI1-

5 AI2+ Not in use. 1) 0(4)20 mA, R

in

= 100 ohm

6 AI2-

7 AI3+ Not in use. 1) 0(4)20 mA, R

in

= 100 ohm

8 AI3-

9 AO1+ Not in use. 1) 0(4)20 mA, R

L

< 700 ohm

10 AO1-

11 AO2+ Not in use. 1) 0(4)20 mA, R

L

< 700 ohm

12 AO2-

X22

1 DI1 ALARM / FAULT

2 DI2 ON / OFF

3 DI3 ACK MAIN CONTACTOR

4 DI4 EARTH FAULT 1)

5 DI5 ALARM / FAULT 1)

6 DI6 RESET 1)

7 +24V +24 V DC max. 100 mA

8 +24V

9 DGND1 Digital ground

10 DGND2 Digital ground

11 DIIL Not in use 1)

X23

1 +24V Auxiliary voltage output, non-isolated, 24 V DC

250 mA

2 GND

X25

1 RO1 Charging contactor control: Open (0) /

close (1)

2 RO1

3 RO1

X26

1 RO2 LCU control: Off (0) / on (1)

2 RO2

3 RO2

X27

1 RO3 Main breaker/contactor control: open (0)

/ close (1)

2 RO3

3 RO3

1) Not in use as default.

For details, see the delivery specific

circuit diagrams of the cabinet-installed

unit. The diagrams show:

- supply unit on/off control

- main breaker supervision and on/off

control

- charging contactor on/off control

- optional auxiliary circuit wiring.

WARNING! Starting sequence, i.e.

charging, acknowledgements, main

breaker/contactor control and the

supply unit start, follows a certain order.

Never change the order by by-passing

signals (using jumpers), etc. That will

cause a malfunction that may damage

the unit.

Terminal block size:

cables 0.3 to 3.3 mm

2

(22 to 12 AWG)

Tightening torque:

0.2 to 0.4 Nm (0.2 to 0.3 lb.ft)

START

1

0

3

4

1

2

Control circuitry

Main breaker/contactor

Charging contactor

Operating switch

Hardware description

26

Type designation labels

The type designation label includes the ratings, valid markings, a type code and

a serial number. The supply module label is attached to the front panel of the module

and the label of the supply unit is attached to the inner side of the unit door. Example

labels are shown below.

No. Description

1. Serial number. The first digit of the serial number refers to the manufacturing plant. The next

four digits refer to the units manufacturing year and week, respectively. The remaining digits

complete the serial number so that there are no two units or modules with the same number.

2. Type code. See sections Type code of cabinet-installed IGBT supply unit on page 27 and

Type code of IGBT supply module on page 30.

3. Valid markings

4. Ratings of supply unit

5. Ratings of converter module when in supply module use

6. Ratings of converter module when in inverter use

Type designation label of ACS800-207LC supply unit

1

2

4 3

Type designation label of ACS800-104LC supply and inverter module

1

2

3

6

5

Hardware description

27

Type code of cabinet-installed IGBT supply unit

Type code describes the composition of the unit in short. The type code is visible on

the type designation plate (sticker) which is attached to the cabinet. The complete

code is divided in sub-codes:

The first 19 digits form the basic code. It describes the basic construction of the

unit. The fields in the basic code are separated with hyphens.

The option codes follow the basic code. Each option code starts with an

identifying letter (common for the whole product series), followed by descriptive

digits. The option codes are separated by plus signs.

Basic code

Option codes

This is a common list for the liquid-cooled supply units of ACS800 liquid-cooled

multidrive. Not all options are available for the IGBT Supply Unit (ACS800-207LC).

Option codes starting with the symbol zero (0) are selections that are not shown on

the nameplate (internal codes for the factory use). Default selections are marked by

* in the table below.

Digit no. Name Alternatives Description

16 Product series ACS800 Industrial drives

810 Construction 207 IGBT Supply Unit

11, 12 Cooling LC Liquid-cooling

1417 Size 2405450 Size of the unit

19 Voltage rating 3 380415 V

5 380500 V

7 380690 V

Class Code Description

Supply frequency A012 Supply frequency 50 Hz *

A013 Supply frequency 60 Hz

Degree of protection B054 IP42, UL type 1, NEMA 1 *

B055 IP54, UL type 12, NEMA12

Cabinet construction 0C121 Industrial construction *

C121 Marine construction

Standards 0C129 IEC standards *

C134 CSA-approved components

C129 UL-approved components

Cooling unit type 0C138 No cooling unit *

C138 Line-up connected cooling unit

C139 Stand-alone cooling unit

Pipe connection side C143 Pipe connection on right *

C144 Pipe connection on left

Connection flange 0C145 DIN flanges *

C145 ANSI flanges

EMC/RFI-filters 0E202 No E202 *

E202 EMC/RFI-filter, 1st environment, restricted (A-limits,

earthed network)

Hardware description

28

EMC 0E210 No E210 *

E210 2nd environment

Line options 0F250 No E250 *

F250 Line contactor

F254 Switch fuse

Breaker option 0F255 No F255 *

F255 Circuit breaker

Earthing switch 0F259 No F259 *

F259 Earthing switch

Cabinet options G300 Cabinet heater

Control voltage for relays and fans G320 230 V AC *

G304 115 V AC

Terminals for external control voltage 0G307 No G307 *

G307 Terminals for external control voltage

DC bus material G315 Tin plated copper

Wiring materials 0G330 Standard wire material *

G330 Halogen free wiring

Supply conductor type G316 Cable supply conductors *

G317 Busbar supply conductors

Arc monitoring 0G336 No G336 (no arc monitoring) *

G336 Arc monitoring

G337 Arc monitoring with current sensing unit

Electrical disconnect button 0G332 No G332 *

G332 Electrical disconnect push button on the door (black)

Q959 Supply transformer braker disconnect push button (red)

on the door

Meters 0G334 No G334 (no meters on door) *

G334 V-meter with selector switch

G335 A-meter in one phase

3G335 A-meter in three phases

G333 kW-meter

Auxiliary voltage transformer 0G344 No G344 *

G344 Auxiliary transformer

Power cabling entry H350 Bottom entry *

H351 Top entry

Control cabling H367 Control cable bottom *

H368 Control cable top

Cable gland

0H365 No H365 (no cable glands) *

H365 Cable gland plates (brass 6mm, undrilled)

H364 Cable gland plates (aluminium 3mm, undrilled)

H358 Cable gland plates (steel 3mm, undrilled)

Auxiliary control unit (ACU) 0Z010 No Z010 (no ACU) *

Z010 ACU width 400

Z020 ACU width 600

Drive window option Z040 Drive window selected (plastic + silica)

DriveBus branching unit 0Z050 No Z050 *

Z050 NDBU-44

Emergency stop acknowledgment Z150 Via RMIO

Z160 Via AC800

Emergency stop location Z170 Standard

Z180 Master

Z190 Follower

CDP-panels 0J400 No J400

J400 Control panel CDP 312R *

LMD-panels 0J401 No J401 *

J401 Drive monitoring display

Panels 0K450 No K450 (no panels) *

J410 Drive control panel connection kit

K450 Panel Bus selected

Class Code Description

Hardware description

29

ON/OFF control type 0J411 No J411 *

J411 Remote supply control

Fieldbus type 1 0K451 No K451 (no fieldbus type 1) *

K451 RDNA-01 (DeviceNet)

K452 RLON-01 (LONWorks)

K454 RPBA-01 (Profibus)

K458 RMBA-01 (Modbus)

K462 RCNA-01 (Control Net)

K464 RETA-01 (Ethernet)

Fieldbus type 2 0ZK458 No ZK458 (no fieldbus type 2) *

ZK458 RMBA-01 (Modbus adapter) with another fieldbus

Fieldbus type 3 0K453 No K453 (no fieldbus type 3) *

K453 NIBA-01 (Interbus-S)

K455 NMBP-01 (Modbus Plus)

K456 NAFA-01 (AF100)

K457 RCAN-01 (CANOpen)

I/O options L503 DDCS communication 3

L509 DDCS communication 2 *

L508 DDCS communication 1

Special options G343 Corrosion coupon in ACU

P902 Customised (described in technical appendix)

P904 Extended warranty

P913 Special colour (described in technical appendix)

Emergency stop 0Q951 No Q951 (no emergency stop) *

G331 Emergency stop push button on the door (red)

Q951 Emergency stop, stop category 0

Q952 Emergency stop, stop category 1

Earth fault monitoring 0Q953 No Q953 (no earth fault monitoring device) *

Q953 Earth fault monitoring, earthed mains TN

Q954 Earth fault monitoring, unearthed mains IT

Safety category 0Q962 No Q962 (no safety category selected) *

Q962 Safety category 1

Q961 Safety category 3

Documentation languages R700 English *

R701 German

R702 Italian

R703 Dutch

R704 Danish

R705 Swedish

R706 Finnish

R707 French

R708 Spanish

R709 Portuguese (spoken in Portugal)

R710 Portuguese (spoken in Brazil)

R711 Russian

R712 Chinese

Power rating of control voltage

transformer

0Z260 No Z260 (no control voltage transformer) *

Z260 2500 VA

Z280 4000 VA

Z290 6300 VA

Z300 9000 VA

Z310 12000 VA

External control voltage supply / UPS

size

Z225 Max. current 16 A

Z230 Max. current 25 A

Z240 Max. current 40 A

Z250 Max. current 63 A

Motor options Z1220 Supply for motor fan

Z1230 Supply for motor heater

Class Code Description

Hardware description

30

Type code of IGBT supply module

Each module has a type designation label attached, containing e.g. the type code of

the module. The type code contains information on the specifications and

configuration of the module.

The first 19 digits form the basic code. It describes the basic construction of the

module. The fields in the basic code are separated by hyphens.

The option codes follow the basic code. Each option code starts with an

identifying letter (common for the whole product series), followed by descriptive

digits. The option codes are separated by plus signs.

Basic code

Option codes

Digit no. Name Alternatives Description

16 Product series ACS800 Industrial drives

810 Construction 104 IGBT supply module or inverter module

11, 12 Cooling LC Liquid-cooling

1417 Size 3106620 Size of the module

19 Voltage rating 3 380415 V

5 380500 V

7 380690 V

Ident.

letter

Name/Description Alternatives Description

A Supply frequency A013 60 Hz

E Filters E205 Internal (du/dt) filters. This feature is standard.

Frames R8i and nR8i only.

G Supply voltage for

fan

G304 115 V AC

Electrical installation

31

Electrical installation

What this chapter contains

This chapter instructs how to check the insulation of the assembly and how to install

the input power cables and control cables. The information is valid for cabinet-

installed IGBT supply units (ACS800-207LC), and IGBT supply modules

(ACS800-104LC) if they are equipped with similar auxiliary devices.

For information on the mechanical installation of the cabinet line up, see ACS800

Liquid-cooled Multidrive Mechanical Installation [3AFE68715466 (English)].

For information on the installation planning, i.e. cable selection, protections, etc. see

ACS800 Liquid-cooled Multidrive and Multidrive Modules Planning the Electrical

Installation [3AFE68715423 (English)].

Before installation

Checking the insulation of the assembly

WARNING! Before start, read and follow the instructions given in manual ACS800

Liquid-cooled Multidrive and Multidrive Modules Safety Instructions

[AFE68715318 (English)]. Ignoring the instructions can cause physical injury or

death, or damage to the equipment.

Drive

Every drive has been tested for insulation between the main circuit and the chassis

(2500 V rms 50 Hz for 1 second) at the factory. Therefore, do not make any voltage

tolerance or insulation resistance tests (e.g. hi-pot or megger) on any part of the

drive.

Input cable

Check the insulation of the input cable according to local regulations before

connecting it to the drive.

Motor and motor cable

Check the insulation of the motor and motor cable as follows:

Check that all motor cables are disconnected from the drive output terminals U2,

V2 and W2.

Measure the insulation resistance of the motor cable and motor between each

phase and the Protective Earth by using a measuring voltage of 1 kV DC. The

insulation resistance must be higher than 1 Mohm. PE

ohm

M

Electrical installation

32

Checking the compatibility with IT (ungrounded) systems

EMC filter +E202 is not suitable for use in an IT (ungrounded) system. If the drive is

equipped with EMC filter +E202, disconnect the filter before connecting the drive to

an ungrounded power line. For detailed instructions on how to do this, please

contact your local ABB representative.

Power connections unit with in-built main breaker or contactor

(option +F255 or +F250)

Connection diagram

U<

Q1

PE

L1

L2

L3

2)

1)

3)

Main breaker cubicle

~

=

Notes:

1)

Input power connection: L1, L2, L3 and PE. To be wired by the user.

For selection of input power cables, see manual Planning the Electrical installation

[3AFE68818559 (English)].

For the power cable terminal sizes and cabinet lead-through sizes, see section Input busbar and

cable lead-through data on page 70.

For the power cable terminal tightening torques, see section Connection procedure on page 33.

2)

Main breaker (option code +F255)

Type of the main switching and disconnecting devices vary. Contactor and switch fuse are used

instead in smaller units (options +F250 and +F254). The unit may also include a grounding switch

(option +F259).

3)

Charging circuit

Supply module and LCL

filter cubicles

Electrical installation

33

Connection procedure

1. Release the handle and open the door of the main breaker or contactor cubicle.

2. Remove the shroud that protects the input busbars and cable lead-throughs.

3. Lead the cables into the inside of the cabinet and connect as follows:

Twist the cable shields to bundles and connect to cabinet PE (ground) busbar.

Connect the separate PE conductors/cables (if exist) to cabinet PE (ground)

busbar. Tightening torque = 70 Nm [55 lb.ft].

Connect the phase conductors to the input power terminals. Tightening

torque = 70 Nm [55 lb.ft].

4. Replace the protecting shroud and close the door.

Detail of cable lead-through

To suppress interference, use shielded

three-phase cables and ground the

shields 360 at the lead-through.

2

3

Input busbars

Electrical installation

34

Power connections unit without in-built main breaker or contactor

(no option +F255 or +F250)

Connection diagram

U<

PE

L1

L2

L3

Notes:

1)

Input power connection: L1, L2, L3 and PE. To be wired by the user.

For selection of input power cables, see manual ACS800 Liquid-cooled Multidrive and Multidrive

Modules Planning the Electrical installation [3AFE68818559 (English)].

For the power cable terminal sizes and cabinet lead-through sizes, see section Input busbar and

cable lead-through data on page 70.

For the power cable terminal tightening torques, see section Connection procedure on page 35.

2)

Main breaker. To be acquired and installed by the user.

The actual main disconnecting and switching solution may differ from above. Note, however, that

the disconnecting device is compulsory (refer to local safety regulations).

Wire the main breaker also to the breaker control and supervision circuits in the supply unit

(connections are not shown above). See the circuit diagrams delivered with the unit.

3)

Charging circuit connection. To be wired by the user.

If there is a main breaker (or contactor) in between the supply transformer and the supply unit, wire

as shown above.

If there is no main breaker, use another power source which has the same voltage rating and

phasing as the supply unit and which is capable of delivering the charging current.

2) 1)

3)

Q2.1

~

= 35

46

Incoming

cubicle

Supply module and LCL

filter cubicles

Electrical installation

35

Connection procedure

1. Release the handle and open the door of the incoming cubicle.

2. Remove the shroud that protects the input busbars and cable lead-throughs.

3. Lead the input power cables into the inside of the cabinet and connect as follows:

Twist the cable shields to bundles and connect to cabinet PE (ground) busbar.

Connect the separate PE conductors/cables (if exist) to cabinet PE (ground)

busbar. Tightening torque = 70 Nm [55 lb.ft].

Connect the phase conductors to the input power terminals. Tightening

torque = 70 Nm [55 lb.ft].

4. Lead the charging circuit supply cables into the inside of the cabinet and connect

to charging circuit main switch Q2.1.

5. Replace the protecting shroud and close the door.

Detail of cable lead-through

To suppress interference, use shielded

three-phase cables and ground the

shields 360 at the lead-through.

2

3

Input busbars

Charging circuit main

switch (Q2.1)

Electrical installation

36

Control connections

General

As standard, the cabinet-installed IGBT supply unit is controlled using the local

control devices mounted on the cabinet door: The off/on/start switch, the reset

button and the emergency stop button. No additional control connections are

needed. However, it is also possible to:

halt the unit by an external emergency stop button. If the unit is equipped with a

local emergency stop button, external buttons can be connected in series.

control the unit with a control panel (option +J411)

control the unit through a serial communication interface (option +J411).

See the circuit diagrams delivered with the unit for the default control connections

and the connection terminals. See also start/stop instructions in chapter Start-up and

operation.

Note: Route the control cables away from motor cables.

Main breaker/contactor control connections unit without in-built main breaker or

contactor (no option +F255 or +F250)

Wire the breaker control circuit and supervision circuits to the breaker. See the circuit

diagrams delivered with the unit.

Installation of optional modules and PC

PC connection

WARNING! Read and follow the instructions given in manual ACS800 Liquid-cooled

Multidrive and Multidrive Modules Safety Instructions [3AFE68715318 (English)].

Ignoring the instructions can cause physical injury or death, or damage to the

equipment.

Connect PC to CH3 of RDCO board via a fibre optic link. RDCO is attached to an

option slot of the RDCU unit. See also Fibre optic links below.

Installation of option modules

WARNING! Read and follow the instructions given in manual ACS800 Liquid-cooled

Multidrive and Multidrive Modules Safety Instructions [3AFE68715318 (English)].

Ignoring the instructions can cause physical injury or death, or damage to the

equipment.

Insert optional modules (such as fieldbus adapters, I/O extension modules and pulse

encoder interfaces) into the optional module slots of the RDCU unit and secure with

Electrical installation

37

two screws. The slots on the RDCU unit are described in Control interfaces on page

23. See also the appropriate optional module manual for information on the cable

connections.

Cabling of I/O and fieldbus modules

Fibre optic links

DDCS fibre optic links are provided by RDCO module for PC tools, master/follower

link, NDIO, NTAC, NAIO, AIMA I/O module adapter and fieldbus adapter modules of

type Nxxx. See the RDCO Users Manual [3AFE64492209 (English)] for the details.

Observe colour coding when installing fibre optic cables. Blue connectors go to blue

terminals and grey connectors to grey terminals.

When installing multiple devices on the same channel, connect them in a ring.

Shield

Module

234 1

Keep unshielded portion as

short as possible

To nearest PE terminal

Electrical installation

38

Connections of the auxiliary voltage transformer (option +G344)

The transformer connections have been done at the factory as default. Normally

there is no need to change or adjust the ready-made connections.

500 V AC

460 V AC

440 V AC

415 V AC

400 V AC

380 V AC

0 1

21

22

23

24

25

26

0 (Ground)

115 V AC

230 V AC

2

3

4

5

6

7

690 V AC

660 V AC

600 V AC

575 V AC

525 V AC

0 1

21

22

23

24

25

26

0 (Ground)

115 V AC

230 V AC

2

3

4

5

6

Transformer for 380500 V AC input voltage

Transformer for 525690 V AC input voltage

Electrical installation

39

Connection of external power supply for the auxiliary circuits

There are four alternative means to arrange the power supply for the auxiliary circuit

(= fans and control circuitry). See manual ACS800 Liquid-cooled Multidrive and

Multidrive Modules Planning the Electrical Installation [3AFE68715423 (English)] for

details. This section illustrates the user connections for those three cases (case 2, 3

and 4) in which the drive fans and/or control circuitry must have an external supply.

Note that case 1 drive with an auxiliary voltage transformer and with no terminals

for external control voltage (UPS) does not require any external wiring and

therefore it is not shown here.

Connection diagram, case 2

>

L N

Note:

Connect the external auxiliary power supply for control circuitry to terminal block X11 in the auxiliary

control unit cubicle (fans are supplied from internal auxiliary voltage transformer - no user

connections required). Dimension the supply on basis of the auxiliary devices used in the drive. See

ACS800 Liquid-cooled Multidrive and Multidrive Modules Planning the Electrical Installation.

L1

L2

L3

PE

>

L N

N L

Power supply for control

circuitry

Power supply for fans

Option selections

+G344 Auxiliary voltage transformer = Yes

+G307 Terminals for external control

voltage (UPS)

= Yes

T10

Q10

F11 F19

X11

1 2

PE

PE5

Electrical installation

40

Connection diagram, case 3

Connection diagram, case 4

>

Power supply for control

circuitry and fans

PE

>

L N

Note:

Connect the external auxiliary power supply (control circuitry and fans) to X11 in the supply module

cubicle. Dimension the supply on basis of the auxiliary devices used in the drive. See ACS800

Liquid-cooled Multidrive and Multidrive Modules Planning the Electrical Installation.

Option selections

+G344 Auxiliary voltage transformer = No

+G307 Terminals for external control

voltage (UPS)

= No

X11

F19 F11

1 2 PE5 3 4 PE6

PE

>

Power supply for control

circuitry

Power supply for fans

L N PE

>

L N

Note:

Connect the external auxiliary power supplies to terminal block X11 in the supply module cubicle.

Dimension the supply on basis of the auxiliary devices used in the drive. See ACS800 Liquid-cooled

Multidrive and Multidrive Modules Planning the Electrical Installation.

Option selections

+G344 Auxiliary voltage transformer = No

+G307 Terminals for external control

voltage (UPS)

= Yes

F19

F11

1 2 PE5

X11

3 4 PE6

Installation checklist

41

Installation checklist

What this chapter contains

This chapter contains a list for checking the mechanical and electrical installation of

the drive.

Installation checklist

Check the mechanical and electrical installation of the drive before start-up. Go

through the checklist below together with another person.

WARNING! Read and follow the instructions given in ACS800 Liquid-cooled

Multidrive and Multidrive Modules Safety Instructions [3AFE68715318 (English)].

Ignoring the instructions can cause physical injury or death, or damage to the

equipment.

Check

MECHANICAL INSTALLATION

The ambient operating conditions are within the allowed limits. See chapter Technical data ACS800-207LC,

page 71.

The unit has been fixed properly to floor, and if necessary (e.g. marine application) also at the top. See

1)

.

ELECTRICAL INSTALLATION

The motor and the driven equipment are ready for start.

The drive is grounded properly.

The insulation of the input cable, motor cable and motor have been measured. See page 31.

The supply (input power) voltage matches the nominal input voltage of the drive. See page 82.

The supply (input power) connection to the input terminals is OK. See page 32 and

1)

.

Appropriate supply (input power) disconnector is installed.

The motor connections at the output terminals are OK. See

2)

and

3)

.

The motor cable is routed away from other cables. See

4)

.

No power factor compensation capacitors are connected to the motor cable.

The external control connections to the drive are OK. See

2)

.

There are no tools, foreign objects or dust from drilling inside the drive.

Supply (input power) voltage cannot be connected to the output of the drive (with a bypass connection).

For drives with Category 1 Emergency stop function (option +Q952): The time relay has been set to a suitable

value (e.g. somewhat longer than the stop ramp of the inverter units). See

2)

.

Installation checklist

42

1)

ACS800 Liquid-cooled Multidrive Mechanical Installation [3AFE68715466 (English)]

2)

Circuit diagrams delivered with the drive.

3)

ACS800-107LC Inverter Unit Hardware Manual [3AFE68715491 (English)]

4)

ACS800 Liquid-cooled Multidrive and Multidrive Modules Planning the Electrical Installation

[3AFE68715423 (English)]

COOLING CIRCUIT See chapter The internal cooling circuit.

The cooling circuit joints at the shipping split joining cubicles are tight.

Bleed and drain valves in all cubicles are closed.

The internal cooling circuit is filled up and bleeded.

Check

Start-up and operation

43

Start-up and operation

What this chapter contains

This chapter instructs how to perform the first start-up and how to operate the supply

unit. The information is valid for cabinet-installed IGBT supply units

(ACS800-207LC), and IGBT supply modules (ACS800-104LC) if they are equipped

with similar auxiliary devices.

WARNING! Only qualified electricians are allowed to commission the drive. Read

and follow the safety instructions delivered with the drive. Neglecting the safety

instructions can cause injury or death.

Start-up

Action Additional information

WARNING! Ensure that the disconnector of the supply transformer is

locked to open position, i.e. no voltage is, or cannot be connected to

drive inadvertently. Check also by measuring that there is no voltage

connected.

Ensure that the mechanical and electrical installation of the drive has

been checked according to chapter Installation checklist.

Basic checks with no voltage connected

If the unit is equipped with an air circuit breaker, set the current trip limits

of the breaker.

General rule

Ensure that the selectivity condition is fulfilled i.e. the breaker trips at a

lower current than the protection device of the supplying network, and

that the limit is high enough not to cause unnecessary trips during the

intermediate DC circuit load peak at start.

Long-term current limit

As a rule of thumb, this should be set to the rated AC current of the

supply unit.

Peak current limit

As a rule of thumb, this should be set to a value 3-4 times the rated AC

current of the supply unit.

Option +F255. See the delivery specific

circuit diagrams and the breaker

manual.

The trip limits have been preset to

generic values by the breaker

manufacturer. The generic limits do not

correspond the protection requirements

of the application.

Check the settings of the relays and breakers/switches of the auxiliary

circuits.

Optional devices. See delivery specific

circuit diagrams.

Disconnect any unfinished or unchecked 230/115 VAC cables that lead

from the terminal blocks to the outside of the equipment.

Drives with parallel-connected IGBT supply modules and/or inverter

modules: locate the PPCS branching unit (APBU-xx) at the supply

module cubicle (or inverter module cubicle) swing-out frame. Enable

memory backup battery by setting actuator 6 of switch S3 to ON.

By default, memory backup is switched

off to save the battery.

Start-up and operation

44

Fill up and bleed the internal cooling circuit. Ensure that the coolant can

flow freely in all cubicles. Start the cooling unit up.

See chapter The internal cooling circuit.

For drives with the cooling unit (options

+C140 or +C141), see ACS800-1007LC

Liquid Cooling Unit Users Manual

[3AFE68621101 (English)].

Install all shrouds and close the doors.

Connecting voltage to input power terminals and auxiliary circuit

WARNING! When voltage is connected to the input terminals, voltage

may also be connected to the auxiliary circuits of the drive.

Make sure that it is safe to connect voltage. Ensure that:

- nobody is working on the unit or circuits that are wired from outside

into the cabinets

- cabinet doors are closed

- covers of motor terminal boxes are in place.

Units that have earthing/grounding switch (option +F259): Open the

grounding switch.

The switch and the main disconnecting

device are either mechanically or

electrically interlocked so that the

grounding switch can only be closed

when the main disconnecting switch is

open, and vice versa.

Close the main breaker on the primary side of the supply transformer.

Close the main disconnecting device of the drive:

- Units with a built-in main breaker (option +F255): Unlock the withdrawn

breaker and rack it in.

See the breaker manual.