Professional Documents

Culture Documents

AWS D1.i/Di.iM:2010 Clause 6 inspection criteria

Uploaded by

gigiphiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AWS D1.i/Di.iM:2010 Clause 6 inspection criteria

Uploaded by

gigiphiCopyright:

Available Formats

AWS D1.i/Di.

iM:2010

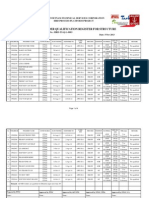

CLAUSE 6. INSPECTION

Table 6.1 Visual Inspection Acceptance Criteria (see 6.9)

Statically Cyclically Loaded Loaded Tubular Non tubular Nontubular Connections Connections Connections (All Loads)

X X X

Discontinuity Category and Inspection Criteria

(1) Crack Prohibition Any crack shall be unacceptable, regardless of size or location. (2) Weld/Base-Metal Fusion Complete fusion shall exist between adjacent layers of weld metal and between weld metal and base metal. (3) Crater Cross Section All craters shall be filled to provide the specified weld size, except for the ends of intermittent fillet welds outside of their effective length. (4) Weld Profiles Weld profiles shall be in conformance with 5.24. (5) Time oflnspection Visual inspection of welds in all steels may begin immediately after the completed welds have cooled to ambient temperature. Acceptance criteria for ASTM A 514, A 517, and A 709 Grade 100 and 100 W steels shall be based on visual inspection performed not less than 48 hours after completion of the weld. (6) Undersized Welds The size of a fillet weld in any continuous weld may be less than the specified nominal size (L) without correction by the following amounts (U): U, L, allowable decrease from L, in [mm] specified nominal weld size, in [mm] ::; 3/16 [5] ::;1/16[2] ::; 3/32 [2.5] 1/4 [6] ::; l/8 [3] ::::5/16 [8] In all cases, the undersize portion of the weld shall not exceed 10% of the weld length. On web-to-flange welds on girders, underrun shall be prohibited at the ends for a length equal to twice the width of the flange.

(7) Undercut (A) For material less than I in [25 mm] thick, undercut shall not exceed 1/32 in [I mm], with the following exception: undercut shall not exceed 1116 in [2 mm] for any accumulated length up to 2 in [50 mm] in any 12 in [300 mm]. For material equal to or greater than I in [25 mmj thick, undercut shall not exceed 1116 in [2 mm] for any length of weld.

(B) In primary members, undercut shall be no more than 0.01 in [0.25 mm] deep when the weld is transverse to tensile stress under any design loading condition. Undercut shall be no more than 1132 in [ 1 mm] deep for all other cases.

(8) Porosity (A) CJP groove welds in butt joints transverse to the direction of computed tensile stress shall have no visible piping porosity. For all other groove welds and for fillet welds, the sum of the visible piping porosity 1/32 in [ 1 mm] or greater in diameter shall not exceed 3/8 in [10 mm) in any linear inch of weld and shall not exceed 3/4 in [20 mml in any 12 in [300 mm] length of weld.

(B) The frequency of piping porosity in fillet welds shall not exceed one in each 4 in [1 00 mm] of weld length and the maximum diameter shall not exceed 3/32 in [2.5 mm]. Exception: for fillet welds connecting stiffeners to web, the sum of the diameters of piping porosity shall not exceed 3/8 in [10 mm] in any linear inch of weld and shall not exceed 3/4 in [20 mm] in any 12 in [300 mm]length of weld. (C) CJP groove welds in butt joints transverse to the direction of computed tensile stress shall have no piping porosity. For all other groove welds, the frequency of piping porosity shall not exceed one in 4 in [I 00 mm] of length and the maximum diameter shall not exceed 3/32 in [2.5 mm].

Note: An "X" indicate' applicability for the connection type; a shaded area indicates non-applicability.

239

You might also like

- Aws d1.1 2010 Table 6.1 VT PT MTDocument1 pageAws d1.1 2010 Table 6.1 VT PT MTRonel John Rodriguez Custodio0% (1)

- API 1104 2014 EditionDocument17 pagesAPI 1104 2014 EditionekkyNo ratings yet

- AWS D1.1 Welding Code GuideDocument10 pagesAWS D1.1 Welding Code GuideGautam SunnyNo ratings yet

- AWS D1.1 - Acceptance Criteria For RTDocument11 pagesAWS D1.1 - Acceptance Criteria For RTHoras Canman67% (3)

- Acceptance Criteria Radiography Test 2018 PDFDocument7 pagesAcceptance Criteria Radiography Test 2018 PDFSigit Pratikno100% (1)

- American Welding Society StandardsDocument2 pagesAmerican Welding Society StandardsGeorge Nicolaides100% (1)

- Guided Bend Test Jig Dimension ASME 9Document3 pagesGuided Bend Test Jig Dimension ASME 9esamhamad50% (2)

- AWS D1.2 GuidesDocument3 pagesAWS D1.2 GuidesTuan DangNo ratings yet

- Specification For The Qualification of Welding Inspectors: AWS B5.1:2013-AMD1 An American National StandardDocument28 pagesSpecification For The Qualification of Welding Inspectors: AWS B5.1:2013-AMD1 An American National StandardRodolfo MartinezNo ratings yet

- AWS Part BDocument32 pagesAWS Part Balefeli260% (2)

- Weld Matrix Format 1Document7 pagesWeld Matrix Format 1Arslan WaheedNo ratings yet

- Song Hong Co., Ltd Welding Procedure SpecificationDocument5 pagesSong Hong Co., Ltd Welding Procedure SpecificationTrinh DungNo ratings yet

- AWS D1.1 (2020) - Essential Variable For WPS & WeldersDocument7 pagesAWS D1.1 (2020) - Essential Variable For WPS & WeldersFouad OudinaNo ratings yet

- Aws D1.6 - SS316 WPSDocument1 pageAws D1.6 - SS316 WPSBoby Thomas0% (1)

- Tolerances As Per Aws D1.1: Structural Welding CodeDocument34 pagesTolerances As Per Aws D1.1: Structural Welding Codeegy pureNo ratings yet

- Radiographic Testing Procedure for Structural Steel Welds (AWS D1.1Document14 pagesRadiographic Testing Procedure for Structural Steel Welds (AWS D1.1MohanadNo ratings yet

- WPS - D1.1 - Prequalified Procedures QSSLDocument26 pagesWPS - D1.1 - Prequalified Procedures QSSLfazeel mohammedNo ratings yet

- AWS D1.1 structural steel code radiographic inspection standardsDocument2 pagesAWS D1.1 structural steel code radiographic inspection standardsrohim100% (1)

- Visual Examination ProcedureDocument10 pagesVisual Examination ProceduresantanuriniNo ratings yet

- Table 6.2Document1 pageTable 6.2AngelTinocoNo ratings yet

- Visual Inspection WeldsDocument35 pagesVisual Inspection Weldsaravindan100% (8)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Table 6.3Document1 pageTable 6.3AngelTinocoNo ratings yet

- AWS Errata Sheet CorrectionsDocument6 pagesAWS Errata Sheet CorrectionsDarwin EnriqueNo ratings yet

- AWS D1.1 Acceptance CriteriaDocument9 pagesAWS D1.1 Acceptance CriteriaNguyễn Giang Nam100% (1)

- Acceptance Craiteria of API1104, ASME B31.3 and AWS D.1.1Document7 pagesAcceptance Craiteria of API1104, ASME B31.3 and AWS D.1.1MJ Magdy100% (1)

- AsmeDocument11 pagesAsmeManoj BallaNo ratings yet

- Destructive Test ReportDocument5 pagesDestructive Test ReportAnonymous r4Pd1KR0100% (1)

- Welder Performace Qualification Report 2014..Document132 pagesWelder Performace Qualification Report 2014..Kayra Riri ChirulNo ratings yet

- Astm A 516 Gr.60n Plate SpecificationDocument3 pagesAstm A 516 Gr.60n Plate Specificationharishbabuek100% (1)

- AWS D1.1 Body of Knowledge QuizDocument7 pagesAWS D1.1 Body of Knowledge QuizjacquesmayolNo ratings yet

- WPS Format For AWS D1.1 - PQR - SMAWDocument3 pagesWPS Format For AWS D1.1 - PQR - SMAWThe Welding Inspections Community100% (3)

- Welding Report BQ 42 97Document4 pagesWelding Report BQ 42 97Shahid YNo ratings yet

- AWS Inspector's Pocket Hand Book PDFDocument40 pagesAWS Inspector's Pocket Hand Book PDFsamado100% (1)

- WPS Steps of MakingDocument51 pagesWPS Steps of MakingSaut Maruli Tua Samosir100% (1)

- Anchor Bolt ProcedureDocument7 pagesAnchor Bolt ProcedureAthanasius Kurniawan Prasetyo Adi100% (1)

- Practical Exam Instructions: Canadian Welding BureauDocument4 pagesPractical Exam Instructions: Canadian Welding BureauRajesh KunaNo ratings yet

- Ut ProcedureDocument7 pagesUt Procedurearavindan100% (1)

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- 17) Welding Visual Inspection Report PDFDocument9 pages17) Welding Visual Inspection Report PDFMuhammad Fitransyah Syamsuar Putra100% (1)

- AWS Welding Symbol Chart PDFDocument1 pageAWS Welding Symbol Chart PDFmpica100% (1)

- Welding Procedure Specification Register (Structural Steel) : AWS D1.1Document14 pagesWelding Procedure Specification Register (Structural Steel) : AWS D1.1murshid badshah100% (2)

- AL Wps PDFDocument4 pagesAL Wps PDFprem nautiyalNo ratings yet

- Module 18 Radiographic InspectionDocument63 pagesModule 18 Radiographic InspectionPamela Stewart100% (1)

- Norma Astm D 4259 2012Document2 pagesNorma Astm D 4259 2012Carlos Corral De León100% (1)

- 1 E-1742Document15 pages1 E-1742punitg_2No ratings yet

- CSA W47.1 W59 13 Guides WeldCanadaDocument5 pagesCSA W47.1 W59 13 Guides WeldCanadamehdi810100% (2)

- AISE Anchor Bolt Details PDFDocument1 pageAISE Anchor Bolt Details PDFYash PaulNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEDocument18 pagesAcceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEEngineersEDGE CoimbatoreNo ratings yet

- API 1104 TestDocument5 pagesAPI 1104 Testmohsen100% (1)

- 05-Welder Certification PDFDocument11 pages05-Welder Certification PDFAnonymous bfxeE1zvY100% (1)

- Torque ReportDocument1 pageTorque Reportjarofidz100% (1)

- SUBTEXT On Weld Defect For AWS Standard.Document2 pagesSUBTEXT On Weld Defect For AWS Standard.fammacat100% (1)

- AWS D1.1-D1.1M-2015 (WeldingWorld) 250Document1 pageAWS D1.1-D1.1M-2015 (WeldingWorld) 250Ali Clubist100% (1)

- Table 6 1 AWS D1 1 D1 1M 2010 PDFDocument1 pageTable 6 1 AWS D1 1 D1 1M 2010 PDFAhmed Ben NoumaNo ratings yet

- Weld Acceptance StandardDocument2 pagesWeld Acceptance StandardLalit Bom Malla100% (2)

- VISUAL Acceptance CriteriaDocument1 pageVISUAL Acceptance CriteriaTuvshintur AnkhbayarNo ratings yet

- Aws D1.1-Tabla 8.1 - Seccion 8Document1 pageAws D1.1-Tabla 8.1 - Seccion 8cesarNo ratings yet

- Visual Defect Classification and Acceptance Criteria TablesDocument13 pagesVisual Defect Classification and Acceptance Criteria Tablesunnamed10100% (2)

- VGL 65Document1 pageVGL 65gigiphiNo ratings yet

- Piston check drawingDocument1 pagePiston check drawinggigiphiNo ratings yet

- HRD Process Platform Project MC Inspection & Test Record: Pressure Test Certificate P05-A Sheet 1 of 1Document1 pageHRD Process Platform Project MC Inspection & Test Record: Pressure Test Certificate P05-A Sheet 1 of 1gigiphiNo ratings yet

- F3213-6115a - r0 - Piping Ga (Train-A) Top Deck Elevation View5Document1 pageF3213-6115a - r0 - Piping Ga (Train-A) Top Deck Elevation View5gigiphiNo ratings yet

- Engineering Services Functional Specification for Piping SpecialtiesDocument25 pagesEngineering Services Functional Specification for Piping Specialtiesgigiphi100% (1)

- f3213-6751 - r1 Piping Specialty Item ListDocument4 pagesf3213-6751 - r1 Piping Specialty Item ListgigiphiNo ratings yet

- F3213-6107.01a - r0 - Piping Ga (Train-A) Main Deck Plan View11 NorthDocument1 pageF3213-6107.01a - r0 - Piping Ga (Train-A) Main Deck Plan View11 NorthgigiphiNo ratings yet

- HRD Process Platform Project MC Inspection & Test Record: P03-A Sheet 1 of 1Document2 pagesHRD Process Platform Project MC Inspection & Test Record: P03-A Sheet 1 of 1gigiphiNo ratings yet

- SheetDocument1 pageSheetgigiphiNo ratings yet

- f3213-6500r0 - General Notes For Piping Support FabricationDocument11 pagesf3213-6500r0 - General Notes For Piping Support FabricationgigiphiNo ratings yet

- Weld Profiles - AWS D1.1 D1.1M-2010Document1 pageWeld Profiles - AWS D1.1 D1.1M-2010gigiphiNo ratings yet

- Welder List For Structure 2Document4 pagesWelder List For Structure 2gigiphiNo ratings yet

- F3213-6108.01a - r0 - Piping Ga (Train-A) Top Deck Plan View12 NorthDocument1 pageF3213-6108.01a - r0 - Piping Ga (Train-A) Top Deck Plan View12 NorthgigiphiNo ratings yet

- f3213-61m1.02r1 - Linewise Pipe Mto (4-Inch and Below)Document13 pagesf3213-61m1.02r1 - Linewise Pipe Mto (4-Inch and Below)gigiphiNo ratings yet

- Extract Pages From ASME B16.9 - 2003 - TEE (Factory-Made Wrought Buttwelding Fittings)Document4 pagesExtract Pages From ASME B16.9 - 2003 - TEE (Factory-Made Wrought Buttwelding Fittings)gigiphiNo ratings yet

- s1 Sorter BrochureDocument8 pagess1 Sorter BrochuregigiphiNo ratings yet

- SmokingDocument2 pagesSmokinggigiphiNo ratings yet

- Welder List For Structure 1Document7 pagesWelder List For Structure 1gigiphiNo ratings yet

- HUC Technical Exception (POS Response - 19 Oct 2011) - Rev 1Document37 pagesHUC Technical Exception (POS Response - 19 Oct 2011) - Rev 1gigiphiNo ratings yet

- App T8-Tech Excep - 21 Nov - Huc (Pos) - PMC 23nov11Document2 pagesApp T8-Tech Excep - 21 Nov - Huc (Pos) - PMC 23nov11gigiphiNo ratings yet

- STT PTSC NISCONI L 0xxx Electrical Cable ScheduleDocument1 pageSTT PTSC NISCONI L 0xxx Electrical Cable SchedulegigiphiNo ratings yet

- PMC - POS Split Scope of WorkDocument10 pagesPMC - POS Split Scope of Workgigiphi100% (1)

- WeldingDocument41 pagesWeldinggigiphiNo ratings yet

- App T8-Tech Excep - 21 Nov - Huc (Pos) - PMC 23nov11Document2 pagesApp T8-Tech Excep - 21 Nov - Huc (Pos) - PMC 23nov11gigiphiNo ratings yet

- Welding InspectionDocument137 pagesWelding InspectiongigiphiNo ratings yet

- Welding InspectionDocument137 pagesWelding InspectiongigiphiNo ratings yet

- Partial replacement of discarded rubber tyres with coarse aggregate in concreteDocument18 pagesPartial replacement of discarded rubber tyres with coarse aggregate in concretePrasanna Gayathri VinnakotaNo ratings yet

- Mss SP 67 Butterfly Valves 2002a PDFDocument19 pagesMss SP 67 Butterfly Valves 2002a PDFJose Henrique GuimarãesNo ratings yet

- Effect of Alloying ElementDocument12 pagesEffect of Alloying ElementWhat'z Your'z Name'zNo ratings yet

- Special Materials and Nickel AlloysDocument12 pagesSpecial Materials and Nickel Alloysmurugn08No ratings yet

- Lime Stone Cleaning Station - Project Proposal-03Document4 pagesLime Stone Cleaning Station - Project Proposal-03vinodsnNo ratings yet

- Sikabit® W-15: Product Data SheetDocument3 pagesSikabit® W-15: Product Data SheetWWNNo ratings yet

- Catlogo Mangueiras Hidrulicas ManuliDocument3 pagesCatlogo Mangueiras Hidrulicas ManuliDomingos BarrosNo ratings yet

- ASME B36.19M Stainless Steel PipesDocument14 pagesASME B36.19M Stainless Steel Pipesdssscarface50% (2)

- The Basics of Tube & Pipe Bending: Tracto-Technik GMBH SpezialmaschinenDocument19 pagesThe Basics of Tube & Pipe Bending: Tracto-Technik GMBH SpezialmaschinenYasser BouktirNo ratings yet

- Insulflex Product CatalogueDocument12 pagesInsulflex Product CatalogueWan Abd Salam MuzakkirNo ratings yet

- API 571 Study GuideDocument8 pagesAPI 571 Study Guidenikafiq100% (4)

- Bar Bending MachineDocument1 pageBar Bending Machinesaurav royNo ratings yet

- Astm A263 2009Document6 pagesAstm A263 2009DenilsonRomãoNo ratings yet

- 6-44-0012 Rev 4-FABRICATION AND ERECTION OF PIPING PDFDocument15 pages6-44-0012 Rev 4-FABRICATION AND ERECTION OF PIPING PDFsumit tiwariNo ratings yet

- Ferrous MaterialsDocument73 pagesFerrous Materialsamrptl9010100% (1)

- 41 - en V Asme b31 1 and b31 3Document3 pages41 - en V Asme b31 1 and b31 3gigiphi1No ratings yet

- Tozen Valve CatalogueDocument45 pagesTozen Valve CatalogueMyo Kyaw Kyaw100% (1)

- Building Foundation Types and StructuresDocument42 pagesBuilding Foundation Types and StructuresVishal R100% (1)

- Cement Concrete Tiles and Paving BlocksDocument8 pagesCement Concrete Tiles and Paving BlocksNipan DekaNo ratings yet

- Astm F879M 1991Document5 pagesAstm F879M 1991Jesse ChenNo ratings yet

- En1092 Flange StandardDocument70 pagesEn1092 Flange Standardmubs997100% (3)

- Calex Auto Private LimitedDocument8 pagesCalex Auto Private LimitedVishalNo ratings yet

- Is SEM4 Air ConditionerDocument11 pagesIs SEM4 Air ConditionerKhushi ChauhanNo ratings yet

- Equipment Insulation SpecificationDocument7 pagesEquipment Insulation Specificationadel rihanaNo ratings yet

- Rolling FinalDocument7 pagesRolling FinalHaroon Karim BalochNo ratings yet

- PRESTRESSED CONCRETEDocument2 pagesPRESTRESSED CONCRETENicholas ThompsonNo ratings yet

- Teava Rect 50X50X3MM PDFDocument1 pageTeava Rect 50X50X3MM PDFCiprian ShaolinNo ratings yet

- Testing Precious Metals C.M HokeDocument88 pagesTesting Precious Metals C.M HokeAFLAC ............100% (10)

- 3.05 A. Welding Specification of Carbon Steel & Alloy SteelDocument40 pages3.05 A. Welding Specification of Carbon Steel & Alloy SteelVivek Patil100% (1)