Professional Documents

Culture Documents

Crystallization Equipment

Uploaded by

Madeline NgoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crystallization Equipment

Uploaded by

Madeline NgoCopyright:

Available Formats

Crystallization

Equipment

NGO. TlONGCO.

Outline of Report

l. Crystallization: Definition and Industrial Importance

ll. Crystallization Equipment

A. Tank and Batch-Type Crystallizers

l. Agitated Batch Crystallizer

2. Swenson-Walker Crystallizer

3. Wulff-Bock Crystallizer

B. Evaporative Crystallizers

C. Vacuum Crystallizers

Crystallization: Definition and

Industrial Importance

lt is a process whereby a solution is supersaturated so

as to cause the formation of crystals.

lt is the removal of a solute such as a salt from a solution

by precipitating the solute from the solution.

Crystallization is an important operation in the chemical

industry as a method of purification and as a method of

providing crystalline materials in the desired size range.

Crystallization Equipment

Crystallizing equipment can be classified according to the

methods used to bring about supersaturation as follows:

1. Tank and Batch-Type Crystallizers supersaturation is

produced by cooling the solution with negligible evaporation.

. Crystallizin! E"aporators supersaturation is produced by

evaporation of the solvent with little or no cooling.

#. $acuum Crystallizers supersaturation is produced by

combined cooling and evaporation in an adiabatic evaporator.

Tank and

Batch-Type

Crystallizers

Agitated

Batch

Crystallizer

Swenson-

Walker

Crystallizer

Wulff-Bock

Crystallizer

Tank and Batch-Type Crystallizers

These are crystallizers which produce supersaturation by

cooling.

The material must have a solubility that varies greatly

with temperature.

3 types:

!itated Batch Crystallizer

Water is circulated

through the cooling

coils and the solution

is agitated by the

propellers mounted

on the central shaft.

See Figure l8-79,

Perry's HB, 8th ed.

!itated Batch Crystallizer

%&'CTI(') (% T*E +,IT+T(-

l. lt increases the rate of heat transfer and keeps the

temperature of the solution more uniform.

2. lt also keeps the fine crystals in suspension, thus it

gives them an opportunity to grow uniformly instead of

forming large crystals or aggregates.

!itated Batch Crystallizer

+D$+'T+,E)

l. Production of more uniform crystals compared to older tanks.

2. The crystals formed are very much finer than that from the

older tanks.

. DI)+D$+'T+,E)

l. lt is a batch or discontinuous crystallizer.

2. The solubility is the least at the surface of the cooling coils.

Therefore, crystal growth is most rapid at this point and the

coils rapidly build up with a mass of crystals that decreases the

rate of heat transfer.

"#enson-$alker Crystallizer

lt consists of an open

trough with a semicircular

bottom having a cooling

water jacket welded

outside.

lt is about 2 ft wide and l0

ft long.

The hot concentrated

solution to be crystallized is

fed at one end of the trough

and cooling water usually

flows through the jacket in

counter current to the

solution.

"#enson-$alker Crystallizer

A slow-speed spiral agitator, set as close as possible to

the bottom of the trough, rotates and suspends the

growing crystals on turning.

Blades pass close to the wall and break off any

deposits of crystals on the cooled wall.

ln order to control crystal size, it is sometimes

desirable to introduce an extra amount of water into

certain sections in the jacket.

A number of units may be joined together to give

increased capacity.

"#enson-$alker Crystallizer

+D$+'T+,E):

l. Large saving in floor space.

2. Large saving in material in process.

3. Saving in labor.

4. Free from inclusions and aggregations.

DI)+D$+'T+,E):

l. The product generally have a somewhat wide crystal-

size distribution.

$ulff-Bock Crystallizer

lt has similar characteristics

as that of the Swenson-

Walker crystallizer,

however, it depends on air

cooling.

lt consists of a shallow

trough set inclined and

mounted on rollers so that it

can be rocked from side to

side.

The slow rate of cooling in

this crystallizer results in low

capacity but it gives uniform

crystals.

$ulff-Bock Crystallizer

+D$+'T+,E:

lt gives more uniform crystals as compared to Swenson-

Walker Crystallizer.

.

DI)+D$+'T+,E:

The slow rate of cooling in this crystallizer results in low

capacity.

E%aporati%e Crystallizers

These are crystallizers which produce supersaturation by

e"aporation of solvent.

The material must have a solubility that changes little

with (or is independent of) temperature.

&acuum Crystallizers

These are crystallizers which produce supersaturation by

adia.atic e"aporation /ith coolin!.

The method of producing supersaturation in these

crystallizers is the most important one for large-scale

production.

Hot solution is introduced into a vacuum where the

solvent evaporates and the solution is cooled

adiabatically.

'orced Circulation Crystallizer

an "active volume" to get both required residence time for

crystal growth and mother liquor desupersaturation

agitation rate

Control the extent of supersaturation arising from the

evaporation,

Control the temperature difference in the heat exchanger

a special design of the liquid-vapor separation area to

avoid the formation of an excessive amount of fines, which

is highly detrimental to crystal growth.

'orced Circulation Crystallizer

These systems can be either single or multiple effects.

Usually operate from low vacuum to atmosphere pressure.

Used for high evaporation rates and when crystal size is

not of the utmost importance.

Almost any material of construction can be considered for

the fabrication of these crystallizers.

Use vacuum cooling or evaporation method

'orced Circulation Crystallizer

Typical products are:

NaCl (food or technical grade)

KNO3Na2

SO4

K2 SO4

NH4Cl

Na2CO3H2O

Citric acid

Draft Tu(e Baffle )DTB*

Crystallizer

AKA Messo-turbulence

Employ magma recirculation to control supersaturation

generation

Use cooling, vacuum cooling and evaporation

The concept is such that if no (or little) heat make-up is

required, it results in a rather compact arrangement;

therefore the initial investment is minimized

operate with a rather low supersaturation so that very

large coarse and uniform crystals can be produced only by

providing extensive and costly dissolving of fines.

Draft Tu(e Baffle )DTB*

Crystallizer

When destruction of fines

not needed or wanted,

baffles are omitted and the

internal circulation rate is set

to have the minimum

nucleating influence on the

suspension

Draft Tu(e Baffle )DTB*

Crystallizer

Typical products are:

boric acid

Na2SO4. l0H20 (Glauber salt)

melamine

citric acid

NaClO3

Induced Circulation Crystallizer

provide additional agitation of the active volume of forced

circulation crystallizers with the use of only one pump.

operates similarly to a Draft Tube Baffle crystallizer but

without the internal agitation device

main applications are for evaporative crystallization cases

produce a narrow crystal size distribution

can be fabricated in almost any material of construction

limited to non-viscous solutions

Induced Circulation Crystallizer

Typical products are:

NaCl

NH4ClO4

NH4Cl

"urface-cooled )"C* Crystallizer

Same with surface-cooled-baffle (SCB) crystallizers

Use only surface cooling to generate supersaturation

Employ magma recirculation to control supersaturation

generation

Do not provide mechanism for classified product removal

provide a mechanism for fines dissolution when baffle is

present (SCB ONLY)

The heat exchanger surface is the coldest part of the process

and is prone to solids build-up so it is operated such that the

tube-side and shell-side does not exceed 5-l0C

Oslo Type Crystallizer

AKA classified-suspension crystallizer

Oldest design for large, coarse crystals

Design Criteria:

Employ liquor recirculation to control supersaturation generation

Use surface cooling, evaporation or adiabatic evaporative cooling

to generate supersaturation

Provide a built-in mechanism for fines dissolution and classified

product removal.

keeping most of the crystals in suspension without contact by a

stirring device, thus enabling the production of large crystals of

narrow size distribution

Oslo Type Crystallizer

classifying crystallization

chamber is the lower part of

the unit

upper part is the liquor-vapor

separation area

Used for reaction-

crystallization and separation-

crystallization when several

chemical species are involved.

Oslo Type Crystallizer

Usually "close type"

the "open" type is to be considered when very large settling areas are

required or when the vessel must be fabricated out of high cost alloys or

metals.

Oslo Type Crystallizer

Typical products are:

(NH4)2 SO4

Na2SO4

AgNO3

hydrated mono sodium glutamate

mono ammonium phosphate (MAP)

Crystallizer Confi!urations

Crystallizer Comparison

Crystallizer Equipment -ou!h Cost

Estimate

011hi!hest2

Forced Circulation

Crystallizer

4

lnduced Circulation

Crystallizer

2

Draft Tube Baffle (DTB)

Crystallizer

l

Surface-cooled (SC)

Crystallizer

5

Oslo Type Crystallizer 3

Crystallizer

Equipment

+d"anta!es Disad"anta!e

Forced Circulation

Crystallizer

Least expensive type of

crystallizer

Large range of sizes

available

High rate of circulation

reduces particle deposits on

vessel walls

Crystal size difficult to

control

Draft Tube Baffle

(DTB) Crystallizer

Crystal size easy to control

Economic due to

recyclability of fines

More energy efficient than

forced-circulation

crystallizers

Frequent flushings

required to minimize

deposits on the

crystallizer wall

Cannot effectively

handle a high density

slurry

Not easily reproduced

in small scale

Surface-cooled (SC)

Crystallizer

Can handle high boiling

point solution

Can handle solution that has

such low temperature boiling

point that evaporation by

vacuum is not possible

Crystallizer Equipment +d"anta!es Disad"anta!e

Oslo Type Crystallizer operating costs of the

Oslo type crystallizer

unit are much lower

than with any other

type when both large

and coarse crystals

are required

Since crystals are not

in contact with any

agitation device, the

amount of fines to be

destroyed is lower

and so is the

corresponding energy

requirement.

allows long cycles of

production between

washing periods.

Not easily reproduced

in small scale

C

r

y

s

t

a

l

l

i

z

a

t

i

o

n

o

f

+

o

n

o

s

o

d

i

u

m

,

l

u

t

a

m

a

t

e

Crystallization of

+onosodium ,lutamate

&ideo

Forced Circulation Crystallizer

C:\Users\Chong\Documents\PARTECH\Crystallization\gea-wiegand-animation-forced-video.mp4

References

Samant, K.D. & O'Young, L. (2006). Understanding

Crystallization and Crystallizer. Clearwaterbay

Technology, lnc.

http://www.niroinc.com/evaporators_crystallizers/crystalliz

ation.asp

http://www.alaquainc.com/Crystalizers.aspx

http://video.geap.com/video/852l92/gea-wiegand-

animation-forced

http://video.geap.com/channel/4l033l9/crystallization

http://www.slideshare.net/saravanamoorthy/crystallization

You might also like

- Ion Exchange Resins and Adsorbents in Chemical Processing: Second EditionFrom EverandIon Exchange Resins and Adsorbents in Chemical Processing: Second EditionRating: 5 out of 5 stars5/5 (1)

- CrystallizationDocument43 pagesCrystallizationKathleen May Dayao0% (1)

- Crystallizer SelectionDocument8 pagesCrystallizer SelectionKTINE08No ratings yet

- CrystallizationDocument71 pagesCrystallizationRoselyn PaladoNo ratings yet

- Equipment Used in Crystallization Group 2Document4 pagesEquipment Used in Crystallization Group 2eliyaht05100% (1)

- CRYSTALLIZATION YIELD AND HEAT REMOVALDocument29 pagesCRYSTALLIZATION YIELD AND HEAT REMOVALRA Memije33% (3)

- Swenson CrystallizationDocument12 pagesSwenson Crystallization陳盈佃No ratings yet

- Crystallization Equipment GuideDocument37 pagesCrystallization Equipment GuideMirza Salkić100% (1)

- CrystallizationDocument29 pagesCrystallizationYawar QureshiNo ratings yet

- CRYSTALLIZER DESIGN (Rev02)Document33 pagesCRYSTALLIZER DESIGN (Rev02)Shai Sta CatalinaNo ratings yet

- Crystallization and EvaporationDocument15 pagesCrystallization and EvaporationYawn D Artist100% (1)

- MSG CrystallizerDocument22 pagesMSG CrystallizerRonel MendozaNo ratings yet

- Crystallization Material BalanceDocument5 pagesCrystallization Material BalanceAron BalinesNo ratings yet

- Design of Falling Film Evaporators U09CH152-U09CH157Document7 pagesDesign of Falling Film Evaporators U09CH152-U09CH157Kailasham RamalingamNo ratings yet

- Falling Film EvaporatorDocument3 pagesFalling Film EvaporatordhavaleshNo ratings yet

- Crystallizer DesignDocument20 pagesCrystallizer DesignJabel Pates100% (11)

- Crystallization With ProbsDocument5 pagesCrystallization With ProbsEzekiel100% (1)

- CrystallizationDocument6 pagesCrystallizationJemar Lim100% (1)

- Solvate: Extremely Pure FormDocument22 pagesSolvate: Extremely Pure FormNayan HalderNo ratings yet

- Engineering Design and Scale up of Crystallization ProcessesDocument72 pagesEngineering Design and Scale up of Crystallization Processesamo60% (5)

- CrystallizationDocument11 pagesCrystallizationjinNo ratings yet

- CrystallizationDocument27 pagesCrystallizationaaaNo ratings yet

- Crystallizer DesignDocument8 pagesCrystallizer DesignPatricia MirandaNo ratings yet

- Rachel Adams Jana Dengler Megan Macleod Kyla Sask Rachel Adams Jana Dengler Megan Macleod Kyla SaskDocument31 pagesRachel Adams Jana Dengler Megan Macleod Kyla Sask Rachel Adams Jana Dengler Megan Macleod Kyla Saskbetengaan2100% (1)

- Crystal IzationDocument10 pagesCrystal IzationJavier Eduardo Penagos VazquezNo ratings yet

- Crystallization Technology HandbookDocument782 pagesCrystallization Technology HandbookkhadidjaBOUCHENTOUF100% (3)

- Ion ExchangeDocument33 pagesIon ExchangeDivaan Raj Karunakaran100% (1)

- Evaporator SDocument23 pagesEvaporator SMehwish NoorNo ratings yet

- Crystallizer Specification SheetDocument22 pagesCrystallizer Specification Sheetkennethmsoriano100% (2)

- CrystallizationDocument13 pagesCrystallizationAnonymous P1iMib50% (2)

- Latihan Uas CH 4-6Document16 pagesLatihan Uas CH 4-6rizkaNo ratings yet

- Crystal Size Distribution AnalysisDocument48 pagesCrystal Size Distribution AnalysisAjeet SinghNo ratings yet

- Tubular Bowl CentrifugeDocument22 pagesTubular Bowl Centrifugesuramajid50% (2)

- Design of CrystallizerDocument13 pagesDesign of CrystallizerABDULLAHI HAGAR FARAH HERSI STUDENTNo ratings yet

- Forced Circulation Evaporator Final ReportDocument40 pagesForced Circulation Evaporator Final ReportManvi SharmaNo ratings yet

- Swenson Walker CrystallizerDocument6 pagesSwenson Walker CrystallizerAshish Verma33% (3)

- Mto I Class 9 10Document128 pagesMto I Class 9 10Mriganabh SarmaNo ratings yet

- Chapter#8 CrystallizationDocument49 pagesChapter#8 Crystallization07216738950% (1)

- CrystallizationDocument18 pagesCrystallizationsyafiqNo ratings yet

- ERT 317 Biochemical Engineering Tutorial 1 CalculationsDocument3 pagesERT 317 Biochemical Engineering Tutorial 1 CalculationschristinaNo ratings yet

- Crystallizer PDFDocument8 pagesCrystallizer PDFTra Phan Thu100% (2)

- Unit Ops CrystallizationDocument32 pagesUnit Ops CrystallizationJahz ChannelNo ratings yet

- Chapter 6-Equipment Design (Production of Lactic Acid From Sugarcane Bagasse)Document78 pagesChapter 6-Equipment Design (Production of Lactic Acid From Sugarcane Bagasse)kennethmsorianoNo ratings yet

- Prof Mahajani's Lecture on Crystallization ProcessDocument18 pagesProf Mahajani's Lecture on Crystallization Processsravankumar6686% (7)

- Falling Film Evaporator PDFDocument28 pagesFalling Film Evaporator PDF^o100% (2)

- CrystallizationDocument30 pagesCrystallizationMuhamadYazid50% (4)

- Chapter 8-Extraction and LeachingDocument55 pagesChapter 8-Extraction and LeachingGovind Kumar90% (10)

- NPTEL Chemical Engineering Design Module on Evaporator Types and CalculationsDocument31 pagesNPTEL Chemical Engineering Design Module on Evaporator Types and Calculationstpcho100% (5)

- Rising Film EvaporatorsDocument10 pagesRising Film EvaporatorsPelin Yazgan BirgiNo ratings yet

- Film Evaporation TechnologyDocument12 pagesFilm Evaporation TechnologyAditya Bayu SalaksaNo ratings yet

- DistillationDocument22 pagesDistillationAhmed Omar Amine100% (1)

- Understanding SedimentationDocument23 pagesUnderstanding SedimentationJohnNo ratings yet

- Lab Report 11 Electrochemical CellsDocument5 pagesLab Report 11 Electrochemical CellsAdlin Lina0% (1)

- The Production of Acetylsalicylic Acid Project - Barbra Dozier's BlogDocument43 pagesThe Production of Acetylsalicylic Acid Project - Barbra Dozier's BlogAnonymous 4EWKYOzJeNo ratings yet

- Scraped Surface Crystallizer Process and DesignDocument2 pagesScraped Surface Crystallizer Process and Designnas_101303No ratings yet

- Solid–Liquid Separation: Chemical Engineering SeriesFrom EverandSolid–Liquid Separation: Chemical Engineering SeriesRating: 3 out of 5 stars3/5 (2)

- Solvent Extraction: Classical and Novel ApproachesFrom EverandSolvent Extraction: Classical and Novel ApproachesRating: 4 out of 5 stars4/5 (2)

- Distillation: Equipment and ProcessesFrom EverandDistillation: Equipment and ProcessesAndrzej GorakRating: 3 out of 5 stars3/5 (2)

- Crystallization and Precipitation: Proceedings of the International Symposium, Saskatoon, Saskatchewan, Canada, 5-7 October 1987From EverandCrystallization and Precipitation: Proceedings of the International Symposium, Saskatoon, Saskatchewan, Canada, 5-7 October 1987G L StrathdeeRating: 4 out of 5 stars4/5 (5)

- Jepsen Soy Sauce Corporation (JSC) BioreactorDocument13 pagesJepsen Soy Sauce Corporation (JSC) BioreactorMadeline NgoNo ratings yet

- Choosing The Best Patty Using AHPDocument21 pagesChoosing The Best Patty Using AHPMadeline NgoNo ratings yet

- Style Guide For Chemical Engineering Theses 3Document19 pagesStyle Guide For Chemical Engineering Theses 3Madeline NgoNo ratings yet

- CH 07Document12 pagesCH 07Madeline NgoNo ratings yet

- Choosing The Best Patty Using AHPDocument21 pagesChoosing The Best Patty Using AHPMadeline NgoNo ratings yet

- Assign SolutionsDocument4 pagesAssign SolutionsMadeline NgoNo ratings yet

- Disasters & SAFETYDocument45 pagesDisasters & SAFETYMadeline Ngo100% (1)

- Gold Silver Phase DiagramDocument1 pageGold Silver Phase DiagramMadeline NgoNo ratings yet

- Assign SolutionsDocument4 pagesAssign SolutionsMadeline NgoNo ratings yet

- Assign SolutionsDocument4 pagesAssign SolutionsMadeline NgoNo ratings yet

- Assign SolutionsDocument4 pagesAssign SolutionsMadeline NgoNo ratings yet

- Giving Out Energy As ElectricityDocument2 pagesGiving Out Energy As ElectricityShahid Ur RehmanNo ratings yet

- Thermal Physics: Kinetic Molecular Model and Thermal PropertiesDocument18 pagesThermal Physics: Kinetic Molecular Model and Thermal PropertiesHakim Abbas Ali Phalasiya100% (1)

- Calorimetry & Heat Transfer (QB)Document16 pagesCalorimetry & Heat Transfer (QB)Raju SinghNo ratings yet

- HPLC ExperimentDocument4 pagesHPLC ExperimentFrances PaulineNo ratings yet

- Elements Periodic TableDocument168 pagesElements Periodic TablejackzhangNo ratings yet

- The Kinetic Energy of The Recoil ElectronDocument1 pageThe Kinetic Energy of The Recoil ElectronJu KaNo ratings yet

- Upkar Mechanical and Electrical MCQ PDFDocument95 pagesUpkar Mechanical and Electrical MCQ PDFGaurang Patel100% (1)

- Acids and BasesDocument13 pagesAcids and Basestismon86% (7)

- Calculate specific heat of unknown liquid from temperature changeDocument6 pagesCalculate specific heat of unknown liquid from temperature changeSuraj KarkiNo ratings yet

- En Product-Info Sigma Family Rel-2.5Document33 pagesEn Product-Info Sigma Family Rel-2.5Julio CasalloNo ratings yet

- Western Mindanao Chemistry WorksheetDocument2 pagesWestern Mindanao Chemistry WorksheetArvhenn BarcelonaNo ratings yet

- Humayun 2016Document6 pagesHumayun 2016elang revyNo ratings yet

- CBSE Class 12 Chemistry Question Paper Solution 2019Document6 pagesCBSE Class 12 Chemistry Question Paper Solution 2019Harish DNo ratings yet

- Design of A Continuous Distillation Column For A Multi Component MixtureDocument45 pagesDesign of A Continuous Distillation Column For A Multi Component MixtureSerkan73% (11)

- ChemSepTutorial SimpleDistillationDocument27 pagesChemSepTutorial SimpleDistillationEvangelista LindaNo ratings yet

- D399DDocument5 pagesD399DHilarie Jonathan100% (1)

- Assignment Topic: HPLC M.D & ApplicationDocument7 pagesAssignment Topic: HPLC M.D & ApplicationUsman GhaniNo ratings yet

- Carrier Transport in SemiconductorsDocument65 pagesCarrier Transport in SemiconductorsShivani GuptaNo ratings yet

- Rikken Keiki, HW Sensor, Gas DetectorDocument1 pageRikken Keiki, HW Sensor, Gas DetectorRangga TaufiqurahmanNo ratings yet

- 01 PDFDocument12 pages01 PDFMihai MihaiNo ratings yet

- 2017 Review Silane Mechanism AdhesionDocument16 pages2017 Review Silane Mechanism AdhesionDarell Josue Valdez AquinoNo ratings yet

- 2021 08 25 Atomic Notation Practice WorksheetDocument3 pages2021 08 25 Atomic Notation Practice WorksheetTimothy Urtz (Chicago)No ratings yet

- Zirconium Information Center Zirconium Information Center Properties, Applications and Research Properties, Applications and ResearchDocument6 pagesZirconium Information Center Zirconium Information Center Properties, Applications and Research Properties, Applications and ResearchLai Wei KhangNo ratings yet

- Phys2 CH1 MecafluidDocument55 pagesPhys2 CH1 MecafluidLam Pham Phuoc Loc100% (1)

- Materials and Design: K. Wieczerzak, P. Bala, M. Stepien, G. Cios, T. KozielDocument8 pagesMaterials and Design: K. Wieczerzak, P. Bala, M. Stepien, G. Cios, T. KozielNicolás Fernández CuervoNo ratings yet

- Crystal StructureDocument67 pagesCrystal StructureZahid HasanNo ratings yet

- P-i-n Diode Working and TypesDocument9 pagesP-i-n Diode Working and TypesAshwin JoshiNo ratings yet

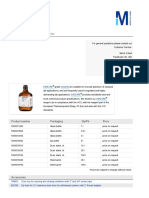

- Diethyl Ether: For Analysis EMSURE® ACS, ISO, Reag. PH EurDocument4 pagesDiethyl Ether: For Analysis EMSURE® ACS, ISO, Reag. PH EurMartua SaragihNo ratings yet

- Automotive Tests Show Strong PerformanceDocument1 pageAutomotive Tests Show Strong PerformanceMacNo ratings yet

- 2 - Chemistry - D&F Block Elements - 12 Classes PDFDocument42 pages2 - Chemistry - D&F Block Elements - 12 Classes PDFkrishna mohan G0% (1)