Professional Documents

Culture Documents

Lab Manual Jan2013 Air Flow

Uploaded by

Laila FaeizahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab Manual Jan2013 Air Flow

Uploaded by

Laila FaeizahCopyright:

Available Formats

Experiment 2 Gas Flow Plant Control

Process Dynamics & Control Lab

EXPERIMENT NO. 2 Air Flow Process Control (AF 922)

OBJECTIVES 1. To identify the important components of the air pressure control system and to mark them in the P&I Diagram. 2. To carry out the start-up procedures systematically. 3. To study gas volumetric flow rate measurement using orifice plate. 4. To study gas mass flow rate measurement using orifice plate and perfect gas law to compute the gas density from the pressure and temperature measurements. 5. To study gas mass flow rate (Fm) control using PID controller. 6. To design a PID controller using Ziegler Nichols closed loop method. KEYWORDS Gas flow rate, gas flow measurements, PID controller, Controller tuning 1.0 INTRODUCTION The air flow process control training system (Model AF922) uses air to simulate a gas or vapor phase flow process. Gas/vapor volumetric flow can be measured either by the differential pressure across orifice or by a variable area flow meter. Compensation for pressure and temperature variation using Perfect Gas Law can be made to the flow measurement by the differential pressure measurement. 2.0 EXPERIMENTAL EQUIPMENT 2.1 AIR FLOW PROCESS PLANT (AF 922) The equipment uses in this experiment is the air flow process control training system, Model AF922. The model consists of a main pipeline, PLI where process air flows from vessel T90 and then discharge to atmosphere via the process vent manual valve, VF or to another air process control training system (Air Pressure, AP 922). If the air flow through PLI too low, the air will flow through second pipeline, PLII automatically. Air flow is measured using an orifice plate (FE91) and a differential pressure transmitter with a square foot function (FT91). A variable are flow meter (rotameter, FI91) is also provided to measure volumetric flow rate of the air.

2.2 CONTROL SYSTEM AND INSTRUMENTATIONS Gas volumetric/mass flow measurement system 1. Integral orifice flow element, FE91. 2. Differential pressure flow transmitter with square root function, FT91. 3. Absolute pressure transmitter, PT91. 4. RTD temperature transmitter, TE91/TIT911. Control System 1. PID Flow Control: A) Measurement: Flow computation inside FIC91 using the measurements from FE91, FT91, PT91, TE91/TIT911. B) Controller: FIC91, panel mount PID controller. C) Final Control Element: FCV91, control valve with current-to-air converter, FCY91 and a pneumatic positioner. 2. ON/OFF Flow Control: A) Measurement: Flow computation inside FIC91 using the measurements from FE91, FT91. B) Controller: FIC90, panel mount ON/OFF controller within FIC91. C) Final Control Element: FCV90, ON/OFF control valve with solenoid valve FSV90 as ON/OFF. 3. Temperature Control: A) Measurement: TE91/TIT911, RTD temperature transmitter. B) Controller: TIC911, panel mount ON/OFF controller, within FIC90. C) Final Control Element: TCV911, control valve with solenoid valve TSV911 as pilot. 4. Flow Recorder: FPTR91 with 3 pens. 5. Variable area flow meter (Rotameter), FI911. 6. Pressure Gauges: PG900, PG902. 7. Temperature Gauge: TG900.

Page 1

Experiment 2 Gas Flow Plant Control

Process Dynamics & Control Lab

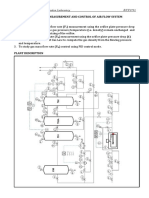

3.0 EXPERIMENTAL PROCEDURES 3.1 IDENTIFICATION OF MAJOR COMPONENTS IN THE PLANT 1. Walk around the experimental equipment, IDENTIFY and MARK the following major components of the system in the P&I Diagram provided at the end the lab manual. a. T90 AirTank b. FE91 Orice meter c. FT91 Differential Pressure Transmitter, with a square root function. d. PT91 Absolute Pressure Transmitter. e. TE91 RTD Temperature Sensor. f. TIT911 Temperature Transmitter. g. FIC90 ON/OFF controller. h. FIC91 Flow Controller (PID). i. FCV90 Pneumatic ON/OFF control valve with Solenoid valve, TSV90. j. FCV91 Control valve with FCY91 current-to-air (I/P) converter and pneumatic positioner, PP. k. FPTR91 Recorder. 3.2 START-UP PROCEDURES 1. The following steps constitute the start-up procedure. Go through these steps before starting any experiment. 2. Switch the "PANEL, SCADA/DDC" selector switch at the front of the cubicle to "PANEL,SCADA"position. Switch ON the main power supply at the front of the cubicle. All the panel instruments will lit up. 3. If any annunciator gets activated, press the ACKNOWLEDGE button to silence the buzzer. 4. Set the instrument air supply regulator to the pressure indicated at the air regulators at the pneumatic control valves FCV90 and FCV91. Purge if there is any condensed water in the air regulators. 5. From the process air supply, trace the two pipelines, PLI and PLII as follows: Pipeline I (PLI): AR900-MV900A-T90-MV900D-PLI-FI911-TE911-FE91/FT91-FCV91-FCV1-VF Pipeline II (PLII): AR900-MV900A-T90-MV900D-PLII-FCV90-PG902-V

6. Open fully the pipelines PLI and PLII at their various manual valves. Close fully the manual by-pass valve around the control valve FCV91 and the ON/OFF control valve FCV90. 7. The pipeline PLI has two discharge manual valves, VF and MV901. Open the vent VF and close the valve MV901. 8. Make sure the valves MV900A and MV900D are open and valves MV900B and MV900C are shut. 9. Place the panel controller FIC91 in the Manual (M) mode. Make sure the control valve positioner PP is connected (i.e. Not by-passed). 10.Open fully the control valve FCV91 by setting the MV of FIC91 to -6.3%. 11.Shut fully the manual valve MV900A and set AR900 to the pressure indicated at AR900. 12.Adjust the manual valve MV900A till the air flow rate is about 50 kg/hr (Read the flow rate from PV of FIC91). 13. Step (10), (11) and (12) have set the process air supply pressure and flow rate. DO NOT re-adjust AR900 and MV900A hereafter. 14. Check that vent valve and bottom drain valve of vessel T90 are shut. Set MV = 106.3% at FIC91 to fully shut the control valve FCV91. 15. Check control valve FCV91 (in the plant) is fully shut and FI911 reads the air volumetric flow rate as ZERO. Also check the mass flow rate Fm at FIC91 is ZERO. 16.Now set the MV = 50% at FIC91 and check control valve FCV91 (in the plant) is 50% opened. 17. Note the variables that are recorded in each channel of the recorder FPTR91. Red Pen - Mass flow rate (kg/hr) Green Pen - Volumetric flow rate (m3/hr) Blue Pen - Temperature (C) 3.3 AIR FLOW MEASUREMENT This experiment is carried out with the air is the medium and at ambient conditions. 1. Make sure that you have gone through the start up procedures carefully. 2. Set the MV = -6.3% (in Manual mode) so that control valve FCV91 is fully opened. 3. Record the reading/data in Column I of the tabular column as shown in results section. Data to be taken AT THE CONTROL PANEL: i) Access the following data by pressing the corresponding push buttons in FIC91 and FIC90:

Page 2

Experiment 2 Gas Flow Plant Control

Process Dynamics & Control Lab

FIC91 PID1(main page): I/O DATA: PV - Fm, kg/hr X1 - FT91, % of

II PB = 150%

III PB = 100% TI = 6 s TD = 0 s

, 0 - 100

TI = 6 s TD = 0 s

X2 - TIT911, % of 0 - 120C X3 - PT911, % of 0 - 60 psia FIC90 P/T REGISTER: PO1 - Fv, m3/hr

DO NOT FORGET TO MARK THE PID VALUES AND THE SET-POINT ON THE CHART PAPER WHENEVER THE VALUES ARE CHANGED. ALSO MARK ON THE CHART THE BEGINNING OF EACH PART OF THE EXPERIMENT. 9. Repeat the experiment for the above 3 sets of PID trial values with step change in

(ii) At the Recorder: Fv (Channel 2, Green) and Fm (Channel 1, Red) Data to be taken AT THE PLANT: Locate the rotameter FI911 and pressure gauge PG900. Take both instruments readings and also note the units used. (Rotameter reading should be taken as 0.5 Nm3/hr) 4. Now, take another sets of readings for MV = 50% and MV = 70% and record them in the tabular column in the results section. 3.4 CONTROL OF AIR FLOW SYSTEM 1. If your are starting this experiment in a new session, then go through the start-up procedures given in Section 3.2. 2. With FIC91 in Manual (M) mode, open the control valve FCV91 fully with MV = -6.3%. (For confirmation, check the stem position indicator of control valve FCV91. FCV91 is an Air-To-Close (ATC) valve) 3. With FIC91 still in Manual mode, adjust its setpoint, SV = 25 kg/hr. 4. Access the PID parameters of FIC91 and set the first (I) PID trial values: PB = 200%, TI = 6 s, TD = 0 s 5. Start the recorder chart drive by pressing RCD pushbutton at FPTR91. 6. Switch FIC91 to Auto (A) mode and watch the recorder response (i.e. air flow response) until the air flow (red pen) is fairly steady. 7. Introduce a pulse disturbance by quickly opening and shutting fully the by-pass valve around control valve FCV91. Observe the response till it becomes fairly steady. 8. Repeat step (7) (i.e. introducing pulse disturbaance) with the second (II) and third (III) sets of PID trial values:

setpoint for the mass flow rate by changing the present setpoint of FIC91 from SV= 25 kg/hr to SV = 30 kg/hr. Observe and record the response till it becomes fairly steady. 10. Switch back the setpoint SV = 25 kg/hr. Use the first (I) PID trial value but now with TD = 20 s. Mark the PID values on the chart paper simultaneously. 11. Apply the disturbance by opening and shutting fully the by-pass valve around control valve FCV91 and observe the response. 3.5 PID CONTROLLER TUNING 1. Set FIC91 in Manual (M) mode with setpoint SV = 25 kg/hr. Adjust the PID values to the following: PB = about 100%, TI = 9999 s (Maximum), TD = 0 s (Minimum) By setting TI to maximum value and TD to minimum value, we can eliminate these two modes in a PID controller (use PB only). 2. Adjust MV in FIC91 until the PV value closes to the setpoint SV value (SV = 25 kg/hr). 3. Transfer FIC91 to Auto (A) mode. Introduce a setpoint pulse disturbance as follows: i) Set increase SV to 28 kg/hr ii) Hold the value for a few seconds iii)Bring back the SV to 25 kg/hr 4. Observe the mass flow rate (red pen) response. Repeat the Closed Loop Tuning Method as above with a decreasing PB value until uniform oscillation (constant amplitude) is observed. (To increase oscillation, decrease PB value and vice versa)

Figure 2.1: Uniform oscillation

Page 3

Experiment 2 Gas Flow Plant Control

Process Dynamics & Control Lab

5. Examine the chart response for the uniform oscillation. New PID value from tuning procedures can be obtained as follows: i) PB corresponds to uniform oscillation = PB* ultimate (correspons to ultimate gain, Kcu) ii) Distance between two adjacent peaks = Tn* ultimate (ultimate period, Pu) Tn* can be calculated from this formula:

Tn * ( sec s ) =

are:

measurement ( mm ) ! 3600 chartspeed (500 mm hr )

iii) The approximate PI controller settings by using Ziegler Nichols formula PB = 2 x PB*, TI = Tn*/1.2 6. To test this new PI controller settings, set this value into FIC91 (in Auto mode). Perform the test with a pulse disturbance. Increase PB value to damp the oscillation and fine tune the PB and TI values to get as close to Quarter Amplitude Damping response. 4.0 SHUTDOWN PROCEDURES 1. Stop the recorder chart by pressingRCD pressbutton at recorder FPTR91. 2. Switch FIC91 to Manual mode with MV = 0%. 3. Switch off the main power supply. 4. Shut off the process air supply at AR900. 5. Shut off the instrument air supply. 5.0 RESULTS 1. The recorder FPTR91 records the results of the experiments. Suitable portions of the recorder chart paper should be submitted as RESULTS of the experiment. 2. The report should contain: i) The P&I Diagram with all major components marked clearly. ii) The instruments readings taken simultaneously and recorded for different valve opening positions. iii) Comparison between direct instrument data with calculated data for Fvb and Fm. iv) The PID ow control responses for disturbances and setpoint changes for different controller settings. v) Discussion on the response characteristics for different controller settings. vi)Tuning by Ziegler Nichols method and its response. Figure 2.2: Quarter Amplitude Damping Response (Blue pen)

Page 4

Experiment 2 Gas Flow Plant Control

Process Dynamics & Control Lab

Calculation: Volumetric ow rate (with or without pressure and temperature compensation): Without P/T compensation: With P/T compensation:

h = differential pressure, mm H2O P = absolute pressure, psia T = temperature, K For the given 6.35 mm bore orice plate: k1 = 0.256 kvb = 1.356 km = 1.753

Fv = k1 h

Fvb = kvb

hP T

Fm = km hP T

Based on perfect gas law, mass ow rate:

Figure 2.3: P&I Diagram for Air Flow Process Control Plant

Page 5

You might also like

- UFO and PentagonDocument69 pagesUFO and PentagonNur Agustinus100% (3)

- A Filter PressDocument0 pagesA Filter Pressraneshkumar1992No ratings yet

- Building Sentences ModuleDocument76 pagesBuilding Sentences ModuleAireen Azura100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Low Carbon Cities Framework and Assessment SystemDocument91 pagesLow Carbon Cities Framework and Assessment SystemLaila Faeizah100% (1)

- L-04 Analysis and Design of Two-Way Slab With Beams (Coloured)Document63 pagesL-04 Analysis and Design of Two-Way Slab With Beams (Coloured)Hidayat Ullah100% (3)

- Hvac ExperimentDocument9 pagesHvac ExperimentShadan MuNo ratings yet

- Air Flow System Process Control (DCS)Document8 pagesAir Flow System Process Control (DCS)JoannaJames100% (1)

- CPB30004 Process Dynamics and Control Experiment 4: Gas Pressure Process Control Lab ReportDocument18 pagesCPB30004 Process Dynamics and Control Experiment 4: Gas Pressure Process Control Lab ReportSiti Hajar Mohamed100% (19)

- Control Philosophy - UpdatedDocument13 pagesControl Philosophy - UpdatedAlvin SmithNo ratings yet

- VisualizationDocument4 pagesVisualizationspanglemaker3719349No ratings yet

- An Introduction To Applied GeostatisticsDocument92 pagesAn Introduction To Applied GeostatisticsAllan ErlikhmanNo ratings yet

- Rizal and The Theory of NationalismDocument37 pagesRizal and The Theory of NationalismLiza Betua Sotelo78% (58)

- Lab Report PDC Gas PressureDocument9 pagesLab Report PDC Gas PressureHaziq AzliNo ratings yet

- Title DefenseDocument3 pagesTitle DefenseLiezl Sabado100% (1)

- Co2 Utilization ReviewDocument20 pagesCo2 Utilization ReviewLaila FaeizahNo ratings yet

- Experiment 5 - Heat Exchanger Process ControlDocument11 pagesExperiment 5 - Heat Exchanger Process ControlIzhamGhaziNo ratings yet

- HPBP Writeup Dadri-IIDocument17 pagesHPBP Writeup Dadri-IIrajan_me083No ratings yet

- Secondary ReformerDocument50 pagesSecondary Reformerwaheed_bhatti50% (2)

- Deep Face Lab PDFDocument29 pagesDeep Face Lab PDFHenry MorenoNo ratings yet

- Temperature Control Lab Report MuzDocument18 pagesTemperature Control Lab Report MuzAhmad Muzammil75% (8)

- Exp 6 Gas Temperature Process ControlDocument13 pagesExp 6 Gas Temperature Process Controlmohamad ashaziq100% (8)

- MS 06 21 - Boiler Startup Frim Cold (Rev A - 03.01.12)Document12 pagesMS 06 21 - Boiler Startup Frim Cold (Rev A - 03.01.12)Prakash WarrierNo ratings yet

- Process Control ExperimentDocument10 pagesProcess Control ExperimentYasserAbyNo ratings yet

- Close Up b1 AnswersDocument6 pagesClose Up b1 Answersmega dragos100% (1)

- Intelligent Building FacadeDocument32 pagesIntelligent Building FacadeVeè Vêk JåyswãlNo ratings yet

- Ped Pressure Equipment Certification PDFDocument8 pagesPed Pressure Equipment Certification PDFProkopNo ratings yet

- Example AHU AdvancedDocument8 pagesExample AHU AdvancedKaliyappan Somasundaram100% (2)

- Mining EsriDocument30 pagesMining EsriCipta Nur Asa100% (1)

- Lab Report Full Air Flow Process ControlDocument22 pagesLab Report Full Air Flow Process ControlMuhammad Asyraf II100% (1)

- 2013 - To and Fro. Modernism and Vernacular ArchitectureDocument246 pages2013 - To and Fro. Modernism and Vernacular ArchitecturesusanaNo ratings yet

- Experimental ProceduresDocument5 pagesExperimental ProceduresahmadmohdNo ratings yet

- Jotter Notes Name: Pugallan A/L Nadarajah Date: 11/4/2016 ID No: 55213114377 Experiment No. and Title: Air Flow Process Control (AF922) ObjectivesDocument4 pagesJotter Notes Name: Pugallan A/L Nadarajah Date: 11/4/2016 ID No: 55213114377 Experiment No. and Title: Air Flow Process Control (AF922) Objectivestusen krishNo ratings yet

- S-Lab Manual Exp 3 - Air Flow Process ControlDocument12 pagesS-Lab Manual Exp 3 - Air Flow Process Controlarif arifinNo ratings yet

- Experiment 2 FullDocument15 pagesExperiment 2 FullAkuwh SyaSyaNo ratings yet

- Pc7 Air FlowDocument8 pagesPc7 Air FlowNoor FadzleenaNo ratings yet

- Air Pressure Process Control Lab ManualDocument11 pagesAir Pressure Process Control Lab ManualFaris Putera100% (1)

- Lab Manual Exp 3 - Gas Temperature Process ControlDocument8 pagesLab Manual Exp 3 - Gas Temperature Process ControlAhmad DanialNo ratings yet

- Exp 1Document5 pagesExp 1tusen krishNo ratings yet

- Experiment 8: Temperature Control: 8.1 Objective of The ExperimentDocument11 pagesExperiment 8: Temperature Control: 8.1 Objective of The ExperimentHemavathy RtNo ratings yet

- CHE373 Exp2 Air FLow - 1Document12 pagesCHE373 Exp2 Air FLow - 1muhammad izzulNo ratings yet

- Exp 9 Lab IiiDocument12 pagesExp 9 Lab IiiMuhammad AnwarNo ratings yet

- Process Control Laboratory: Section of Chemical Process Malaysian Intitute of Chemical & Bioengineering TechnologyDocument16 pagesProcess Control Laboratory: Section of Chemical Process Malaysian Intitute of Chemical & Bioengineering Technology9xqyk4dpwbNo ratings yet

- Manual For Flow ControlDocument4 pagesManual For Flow ControlReeve Tang CsvNo ratings yet

- Experiment 1 Air Pressure Control System: 1.0 ObjectiveDocument5 pagesExperiment 1 Air Pressure Control System: 1.0 ObjectiveHan GasNo ratings yet

- CHE373 Exp1 PressureDocument15 pagesCHE373 Exp1 PressureomarNo ratings yet

- Ratio ControlDocument7 pagesRatio ControlRuhul FityahNo ratings yet

- Two Tank Non-Interacting Liquid Level SystemDocument9 pagesTwo Tank Non-Interacting Liquid Level SystemHimanshu JatNo ratings yet

- Exp3 - Air Pressure ControlDocument8 pagesExp3 - Air Pressure ControlDon LawrenceNo ratings yet

- Exp - P7 - UPCTDocument11 pagesExp - P7 - UPCTSiddesh PatilNo ratings yet

- Experiment 3: Measurement and Control of Air Flow System ObjectiveDocument4 pagesExperiment 3: Measurement and Control of Air Flow System ObjectivePMNo ratings yet

- Vapor Recovery Test Procedure: Adopted: October 8, 2003Document10 pagesVapor Recovery Test Procedure: Adopted: October 8, 2003pondpawee_337421255No ratings yet

- Level Flow PCDocument10 pagesLevel Flow PCMurali TharanNo ratings yet

- Furnace Pressure ControlDocument5 pagesFurnace Pressure ControlAshvani ShuklaNo ratings yet

- Manual For Temperature Control PDFDocument4 pagesManual For Temperature Control PDFReeve Tang CsvNo ratings yet

- PC1Document11 pagesPC1Allen Low100% (1)

- NT3036 - Air Conditioning Lab Report Assessment Brief (HK) 30oct2021Document14 pagesNT3036 - Air Conditioning Lab Report Assessment Brief (HK) 30oct2021ho Po wongNo ratings yet

- Experiment 1 - Control ValveDocument13 pagesExperiment 1 - Control ValveRobert Gilmore100% (3)

- Experiment 2 Level Control System: 1.0 ObjectiveDocument6 pagesExperiment 2 Level Control System: 1.0 ObjectiveElla Iloe IggoNo ratings yet

- CLD 20202 Exp 1-Control ValveDocument15 pagesCLD 20202 Exp 1-Control ValveAbu RectifyNo ratings yet

- S-Lab Manual Exp 6 - Level Flow Process Control (Electronic)Document14 pagesS-Lab Manual Exp 6 - Level Flow Process Control (Electronic)IzhamGhazi0% (1)

- Mukriz: PV (What Is PV?)Document5 pagesMukriz: PV (What Is PV?)Mukriz MahaderNo ratings yet

- ExercisesDocument18 pagesExercisescetec1234No ratings yet

- Pid Controller Tuning: S.no Name of The ChapterDocument35 pagesPid Controller Tuning: S.no Name of The ChapterAmit TripathiNo ratings yet

- B9 - Nitrogen GeneratorDocument12 pagesB9 - Nitrogen Generatorefendi kaptanNo ratings yet

- Lab Che 239 Liquid Flow G5Document9 pagesLab Che 239 Liquid Flow G5Muhd FirdausNo ratings yet

- Fixed Bed Adsorption Column M7Document3 pagesFixed Bed Adsorption Column M7Mayank VashishthaNo ratings yet

- Lab Report Heat ExchangerDocument17 pagesLab Report Heat ExchangerFirdaus Zainal AbidinNo ratings yet

- Exp 2 WLFDocument4 pagesExp 2 WLFKirah KasnanNo ratings yet

- CPB30004 Process Dynamics and Control Experiment 5: Heat Exchanger Process Control Lab ReportDocument24 pagesCPB30004 Process Dynamics and Control Experiment 5: Heat Exchanger Process Control Lab ReportSiti Hajar Mohamed100% (1)

- 06 Mem341Document17 pages06 Mem341Muhammad AbdullahNo ratings yet

- Exp 1Document12 pagesExp 1Anonymous T7vjZG4otNo ratings yet

- Operation: Section IIIDocument9 pagesOperation: Section IIIAnonymous XbmoAFtINo ratings yet

- Circulation Over An Airfoil ExperimentDocument15 pagesCirculation Over An Airfoil ExperimentGabriel DaniliucNo ratings yet

- The Feasibility of Carbon Capturing, Storage and UtilizationDocument6 pagesThe Feasibility of Carbon Capturing, Storage and UtilizationLaila FaeizahNo ratings yet

- Upsr Model Test 1: PAPER 013Document14 pagesUpsr Model Test 1: PAPER 013Laila FaeizahNo ratings yet

- Playbook PG Students 2019 1 PDFDocument82 pagesPlaybook PG Students 2019 1 PDFLaila FaeizahNo ratings yet

- CO2 Emissions From Fuel Combustion Highlights 2015Document152 pagesCO2 Emissions From Fuel Combustion Highlights 2015Laila FaeizahNo ratings yet

- Citations Referencing SlidesDocument54 pagesCitations Referencing SlidesLaila FaeizahNo ratings yet

- Design INFODocument2 pagesDesign INFOLaila FaeizahNo ratings yet

- POLY-MTL 2017-Winter RI BrochureDocument47 pagesPOLY-MTL 2017-Winter RI BrochureLaila FaeizahNo ratings yet

- 3.4 DeodorizationDocument33 pages3.4 DeodorizationLaila FaeizahNo ratings yet

- 1.0 Objectives: Mass Transfer 2Document12 pages1.0 Objectives: Mass Transfer 2Laila Faeizah100% (1)

- KeyWorld Statistics 2015 PDFDocument81 pagesKeyWorld Statistics 2015 PDFLaila FaeizahNo ratings yet

- Environmental Issues Waste Management (CPB 40103) BriefingDocument2 pagesEnvironmental Issues Waste Management (CPB 40103) BriefingLaila FaeizahNo ratings yet

- Food PoisoningDocument18 pagesFood PoisoningLaila FaeizahNo ratings yet

- Data StreamDocument9 pagesData StreamLaila FaeizahNo ratings yet

- Pergamon: Optimal Design of An Ammonia Synthesis Reactor Using Genetic AlgorithmsDocument6 pagesPergamon: Optimal Design of An Ammonia Synthesis Reactor Using Genetic AlgorithmsLaila FaeizahNo ratings yet

- CEB 40603 - Lab ManualDocument21 pagesCEB 40603 - Lab ManualLaila FaeizahNo ratings yet

- Atr SelectivityDocument9 pagesAtr SelectivityLaila FaeizahNo ratings yet

- 4 FertilizerDocument12 pages4 FertilizerEnrique CastañedaNo ratings yet

- Result Exp2Document4 pagesResult Exp2Laila FaeizahNo ratings yet

- Ammonia HAZARDDocument6 pagesAmmonia HAZARDLaila FaeizahNo ratings yet

- 1.5 Quality Control AssuranceDocument7 pages1.5 Quality Control AssuranceLaila FaeizahNo ratings yet

- 1.6 PomeDocument22 pages1.6 PomeLaila FaeizahNo ratings yet

- Buffer DiscussDocument4 pagesBuffer DiscussLaila FaeizahNo ratings yet

- Citations Referencing SlidesDocument54 pagesCitations Referencing SlidesLaila FaeizahNo ratings yet

- Solid-State Fermentation: Ashok PandeyDocument4 pagesSolid-State Fermentation: Ashok PandeycarloscarinelliNo ratings yet

- EnergyUpdate 2011 REPORTDocument16 pagesEnergyUpdate 2011 REPORTLaila FaeizahNo ratings yet

- Music, Arts, Pe & HealthDocument2 pagesMusic, Arts, Pe & HealthEvan Maagad LutchaNo ratings yet

- Report On Mango Cultivation ProjectDocument40 pagesReport On Mango Cultivation Projectkmilind007100% (1)

- 2 Mathematics For Social Science-1-1Document58 pages2 Mathematics For Social Science-1-1ሀበሻ EntertainmentNo ratings yet

- Understanding The Self Lecture Lesson 1 Revised PDFDocument41 pagesUnderstanding The Self Lecture Lesson 1 Revised PDFKylie CuadraNo ratings yet

- Best IIT JEE NEET and ICSE, CBSE, SSC Classes in Hadapsar PuneDocument18 pagesBest IIT JEE NEET and ICSE, CBSE, SSC Classes in Hadapsar PuneTrinity AcademyNo ratings yet

- Real-World Data Is Dirty: Data Cleansing and The Merge/Purge ProblemDocument29 pagesReal-World Data Is Dirty: Data Cleansing and The Merge/Purge Problemapi-19731161No ratings yet

- Indian Standard: Methods of Test For Aggregates For ConcreteDocument22 pagesIndian Standard: Methods of Test For Aggregates For ConcreteAnuradhaPatraNo ratings yet

- Soft-Starter: Programming ManualDocument162 pagesSoft-Starter: Programming ManualThaylo PiresNo ratings yet

- Psyc 1100 Research ExperimentDocument10 pagesPsyc 1100 Research Experimentapi-242343747No ratings yet

- Module 1-Grade 9Document19 pagesModule 1-Grade 9Charity NavarroNo ratings yet

- Semiconductor Application Library ManualDocument494 pagesSemiconductor Application Library ManualValerioApicellaNo ratings yet

- HYSYS Basis PDFDocument306 pagesHYSYS Basis PDFsalman hussainNo ratings yet

- Collimation of Binoculars With A LampDocument33 pagesCollimation of Binoculars With A LampchristianNo ratings yet

- Daily ReportDocument39 pagesDaily ReportLe TuanNo ratings yet

- C PM 71.v2016-12-11 PDFDocument31 pagesC PM 71.v2016-12-11 PDFbobi2201No ratings yet

- 3838-Article Text-7786-1-10-20230403Document8 pages3838-Article Text-7786-1-10-20230403Ramona Elena SpiridonNo ratings yet

- UK TV StreamingDocument22 pagesUK TV StreamingSuhanto KastaredjaNo ratings yet

- Questionaire Abusive Supervision SurveyDocument2 pagesQuestionaire Abusive Supervision SurveyAabee SyedNo ratings yet