Professional Documents

Culture Documents

Properties and Testing of Concrete Materials

Uploaded by

CivilEngClubCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Properties and Testing of Concrete Materials

Uploaded by

CivilEngClubCopyright:

Available Formats

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

اﻟﺠﻤﺎهﻴﺮﻳﺔ اﻟﻌﺮﺑﻴﺔ اﻟﻠﻴﺒﻴﺔ اﻟﺸﻌﺒﻴﺔ اﻻﺷﺘﺮاآﻴﺔ اﻟﻌﻈﻤﻰ

آﻠﻴﺔ اﻟﻬﻨﺪﺳﺔ ﺟﺎﻣﻌﺔ اﻟﺘﺤﺪي

دورة ﺗﺪرﻳﺒﻴﺔ ﻓﻲ:

ﺧﻮاص وﻓﺤﻮﺻﺎت ﻣﻮاد اﻟﺨﺮﺳــﺎﻧﺔ

Properties and Testing

of Concrete Materials

ﻣﺸﺮف اﻟﺪورة :أ .ﺑﻠﺴﻢ ﺟﺎﺳﻢ ﻣﺤﻤﺪ ﻓﺮﻳﺪ

2008/7/6ف إﻟﻰ 2008 /7/17ف

Prepared by Balsam J. Farid 1

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Properties and Testing of Concrete Materials

The Theoretical Part:

Content

Subject Page

1-Introduction and Definitions …………………………………..…2

2-Aggregate:

a - Classification as to: Shape, Size, Surface Texture,

Source and Unit weight. …………………………………......3

b - Properties of aggregate

i- Main Properties required for compliance with specifications.…..6

ii- Properties required for choosing mix proportions ……… .…9

c- Moisture conditions. ……………………………………..….11

d- Deleterious materials ………………………………………11

e- Sampling and testing. …………………………………….…12

3-Cement:

a- Introduction and manufacture. …………………………13

b-The properties and composition of cement ………………..14

c- The hydration process …………………………..…….15

d- Types of cement. …………………………………………..16

e- Physical properties of cement. …………………………….18

4- Water:

a- Mixing water ……………………………………………….20

b-Curing water. ……………………………………………….21

Prepared by Balsam J. Farid 2

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Introduction and Definitions

Concrete: is a word of Latin derivation ( con – together ) ( crete – to grow ) and its history

can be charted from 5000 BC.

It is a composite material that consists essentially of a binding medium within which are

embedded particles or fragments of aggregate. In hydraulic cement concrete the binder is

formed from a mixture of hydraulic cement and water.

Concrete composites of :-

1- cement 2- Aggregates 3- Water 4- Admixtures

Cement: an organic material or a mixture of inorganic materials that sets and develops

strength by chemical reaction with water by formation of hydrates and is capable of doing so

under water.

Aggregates: Granular materials, such as sand, gravel, crushed stone, or iron blast- furnace

slag, used with cementing medium to form concrete or mortar. Aggregates act as a relatively

inexpensive inert filler, providing stability against volume changes and influencing strength

and stiffness.

Water: It reacts with the cement and also lubricates the fresh concrete enabling it to be

placed into position and compacted.

Admixtures: They are chemicals that can be added to the concrete immediately before or

during mixing and significantly change its fresh, early age or hardened state to economic or

physical advantage.

Prepared by Balsam J. Farid 3

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Aggregates

The mineral aggregates comprise the relatively inert filler materials in a Portland-cement

concrete. As the aggregate usually occupies from 70 to 75 percent of the total volume of a

mass of concrete, its selection and proportioning should be given careful attention in order to

control the quality of the concrete structure.

Classification of aggregates:

Aggregates can be classified as to :

1- Size:

a- Fine aggregate: Aggregate smaller than (5 or 4.75 mm) in diameter is classified as

fine aggregate or sand.

b-Coarse aggregate: Aggregate larger than (5 or 4.75mm) in diameter is classified as

coarse aggregate.

2- Source:

a- Natural aggregate: The natural sands and gravels are the product of weathering

and the action of running water, while the stone sands and crushed stones are

reduced from natural rock by crushing and screening of quarried material.

b- Artificial aggregate: are usually produced for some special purposes, for

example: burned expanded clay aggregate for making lightweight concrete.

Some artificial aggregates are a by-product of industrial process such as blast

furnace slag.

3- Unit weight:

a- Normal weight aggregate: It is usually the natural aggregate

for which the unit weight is between (1500 to1800) kg/m3.

Prepared by Balsam J. Farid 4

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Normal weight aggregate Lightweight aggregate (Pumic)

b- Lightweight aggregate: It can be artificial or natural.

The artificial lightweight aggregates are produced as both coarse and fine

materials. They have a lower density due to increase in porosity which results

in an overall lowering of the concrete strength ceiling.

Lightweight aggregates are not as dense as normal weight aggregates ( unit

weight less than 1000 kg/m3) and because their elastic modulus is lower,

produce concrete with a lower elastic modulus and a higher creep and

shrinkage.

Lightweight aggregates can be of natural sources such as Pumic ( a volcanic

rock).

c- Heavyweight aggregate: Where concrete of a high density is required, in

radiation shielding for example, heavyweight aggregates can be used. The unit

weight can be larger than 1800 kg/m3. Concrete densities of 3500-4500 kg/rn3

are obtained by using Barytes (a barium sulphate ore). Even greater concrete

densities are obtained using lead shot - around 7000 kg/m3.

Prepared by Balsam J. Farid 5

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

4- Particle Shape:

The particle shape is important in that it affects the workability of the plastic concrete.

The more rounded an aggregate the lower the inter particle friction, the smaller the

surface/unit volume and therefore less water is required for a given workability.

Therefore, a potentially higher strength is possible. Crushed aggregates can be used to

produce higher strength concrete ( greater than about 80 N/mm2 ) as a greater bond

strength can be achieved between the aggregate and the paste due to the rough angular

texture of the aggregate surface. Natural gravels and sands tend to have a more rounded

shape as a result of attrition water, whereas crushes rock aggregates tend to be more

angular in shape. Aggregates can be classified as to shape into:

Note: Rounded, Irregular and Angular particles are more suitable for concrete mixes.

5- Surface Texture

Smother particles tend to produce a more workable concrete. The bond strength is,

however likely to be higher with rough textured materials. The particles can be

Glassy, smooth, granular, rough, crystalline or honeycombed.

Properties of Aggregate

In fact, aggregate is not truly inert because its physical, thermal and, sometimes, chemical

properties influence the performance of the concrete, for example, by improving its volume

stability and durability over that of the cement paste. Generally Specifications require certain

properties of aggregate to be tested to accept the using of aggregate in the concrete mixes.

Other properties can be required for calculating concrete mix proportions.

Prepared by Balsam J. Farid 6

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

A-Main Properties required for compliance with specifications:

1- Particle size distribution.

2- Resistance to degradation of coarse aggregate by abrasion.

3- Presence of Materials finer than 75µm.

4- Presence of Clay lumps

5- Soundness.

6- Presence of sulfate or chloride ions in aggregates.

7- Flakiness or Elongation of the aggregate particles.

8- Presence of Organic Impurities in Fine Aggregates.

B- Properties required for choosing mix proportions

1- Specific gravity and absorption.

2- Moisture content.

3- Loose or rodded unit weight of aggregates.

4- Nominal maximum size of aggregate and fineness modulus.

There may be other properties needed for special uses or conditions. The above properties

will be discussed here shortly before talking about the laboratory tests used to determine

these properties.

A-Main Properties required for compliance with specifications:

1- Particle size distribution:

The actual size of the aggregate particles influence the concrete mix. In practice it is

desirable to have particles of different sizes.

The aggregate is usually split into at least two different portions for ease of batching:

The common dividing point is 5mm ( or 4.75mm). Material larger than 5mm is termed

coarse aggregate or gravel and the material smaller than 5mm is termed fine aggregate,

fines or sand.

The distribution of the different sizes of particles in the coarse or fine aggregates is termed

grading. The grading may be coarse or fine depending on the distribution of the particles and

may be continuous (particles of different sizes) or single sized (particles of predominantly

one size).

The particle size distribution is extremely important in the design of any concrete mix. For

most practical concretes it is desirable to have the particle sizes evenly distributed from the

maximum size of coarse aggregate down to the smallest sand particles. This will enable the

aggregate to compact in the densest form leaving the minimum number of voids to be filled

Prepared by Balsam J. Farid 7

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

by the more expensive cement paste. It will also minimize the risk of segregation of the

plastic concrete during handling & placing.

The test method covers the determination of the particle size distribution of fine and coarse

aggregates by sieving, is Sieve Analysis of Fine and Coarse Aggregates, (ASTMC 136 – 96a)

or (BS 812-103.1).

2-Resistance to degradation of coarse aggregate

Hardness is the resistance of an aggregate to wear and is normally determined by an abrasion

test, while the toughness of an aggregate is defined as its resistance to failure by impact.

Hardness and toughness are particularly important when aggregates are to be used in a

concrete road pavement or heavy duty wearing surfaces.

A test used as a measure of degradation of mineral aggregates of standard grading resulting

from a combination of actions including abrasion or attrition, impact, and grinding is

"Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the

Los Angeles Machine" ASTM C 131 – 96). Another test used for the determination of the

aggregate crushing value (ACV) which gives a relative measure of the resistance of an

aggregate to crushing under a gradually applied compressive load is

"Methods for determination of aggregate crushing value (ACV)" (BS 812-110)

3&4-Presence of Clay lumps and materials finer than 75µm

Clay may be present in aggregate in the form of surface coatings which interfere with the

bond between the aggregate and the cement paste. In addition, silt and crusher dust may be

present either as surface coatings or as loose material. Even in the latter form. Silt and free

dust should not be present in large quantities because, owing to their fineness and therefore

large surface area, they increase the amount of water necessary to wet all the particles in the

mix.

Material finer than the 75-μm (No. 200) sieve can be separated from larger particles much

more efficiently and completely by wet sieving than through the use of dry sieving.

Therefore, accurate determinations of material finer than 75 μm in fine or coarse aggregate

are desired. Materials Finer than 75-μm (No. 200) Sieve in Mineral Aggregates by Washing

(ASTM C 117 – 95) and for clay lumps, the test is "Clay Lumps and Friable Particles in

Aggregates" (ASTM C 142 – 97)

Prepared by Balsam J. Farid 8

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

5-Soundness.

The soundness of an aggregate is a measure of its durability. which is defined as:

“The ability of individual particles to retain their integrity and not suffer physical. mechanical

or chemical changes to extents which could adversely affect the properties of the concrete in

either engineering or aesthetic respects.”

The physical causes of large or permanent volume changes of aggregate are freezing and

thawing, thermal changes at temperatures above freezing, and alternating wetting and drying.

If the aggregate is unsound such changes in physical conditions result in a deterioration of

the concrete in the form of local scaling, so called pop-outs, and even extensive surface

cracking. Unsoundness is exhibited by porous flints and cherts, especially lightweight ones

with a fine-textured pore structured pore structure, by some shales, and by other particles

containing clay minerals. The degree of unsoundness is expressed by the reduction in particle

size after a specified number of cycles.

A test method covers the testing of aggregates to estimate their soundness when subjected

to weathering action in concrete or other applications. This is accomplished repeated

immersion in saturated solutions of sodium or magnesium sulfate followed by oven drying to

partially or completely dehydrate the salt precipitated in permeable pore spaces. The internal

expansive force, derived from the rehydration of the salt upon re-immersion, simulates the

expansion of water on freezing. "Soundness of Aggregates by Use of Sodium Sulfate or

Magnesium Sulfate"(ASTM C 88 – 99a)

6-Presence of sulfate or chloride ions in aggregates.

Because of the danger of chloride- induced corrosion of steel reinforcement, the BS

specifications specifies the maximum total chloride content in the mix. The chlorides may

arise from all ingredient of the mix. Apart of the danger of corrosion of steel reinforcement,

if salt is not removed, it will absorb moisture from the air and cause efflorescence- unsightly

white deposits on the surface of the concrete.

The presence of Sulphates will cause low ultimate strength and disintegration due to

expansion. "Methods for determination of sulphate content"(BS 812-118)

For chloride ions: "Method for determination of water-soluble chloride salts"

(BS 812-117)

7- Flakiness or Elongation of the aggregate particles.

The particle shape is of importance with regard to the properties of fresh and hardened

concrete. Particles with high ratio of surface area to volume are of particular interest as they

lower the workability of the mix. Elongated and flaky particles are of this type. The latter can

also adversely affect the durability of concrete as they tend to oriented in one plane, with

water and air voids forming underneath. The presence of elongated or flaky particles in

excess of 10 to per cent of the mass of coarse aggregate is generally considered undesirable,

although no recognized limits are laid down.

Methods for determination of particle shape (BS 812-105.1) for Flakiness index and (BS 812-

105.2) for Elongation index of coarse Aggregate.

8- Presence of Organic Impurities in Fine Aggregates.

Natural aggregates may be sufficiently strong and resistant to wear and yet may not be

satisfactory for concrete-making if they contain organic impurities which interfere with the

hydration process. The organic matter consists of products of decay of vegetable matter in the

form of human or organic loam, which is usually present in sand rather than in coarse

aggregate, and is easily removed by washing. A test method used for that is "Organic

Impurities in Fine Aggregates for Concrete" (ASTM C 40 – 99)

Prepared by Balsam J. Farid 9

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

B- Properties required for choosing mix proportions

1- Absorption and Specific gravity.

The following definitions can be useful:

Absorption—the increase in the weight of aggregate due to water in the pores of the material,

but not including water adhering to the outside surface of the particles, expressed as a

percentage of the dry weight. The aggregate is considered “dry” when it has been maintained

at a temperature of 110 + 5°C for sufficient time to remove all uncombined water

Specific Gravity—the ratio of the mass (or weight in air) of a unit volume of a material to the

mass of the same volume of water at stated temperatures. Values are dimensionless.

Apparent Specific Gravity—the ratio of the weight in air of a unit volume of the

impermeable portion of aggregate at a stated temperature to the weight in air of an equal

volume of gas-free distilled water at a stated temperature.

Bulk Specific Gravity—the ratio of the weight in air of a unit volume of aggregate (including

the permeable and impermeable voids in the particles, but not including the voids between

particles) at a stated temperature to the weight in air of an equal volume of gas-free distilled

water at a stated temperature.

Bulk Specific Gravity (SSD)—the ratio of the weight in air of a unit volume of aggregate,

including the weight of water within the voids filled to the extent achieved by submerging in

water for approximately 24 h (but not including the voids between particles) at a stated

temperature, compared to the weight in air of an equal volume of gas-free distilled water at a

stated temperature.

Significance and Use

1 Bulk specific gravity is the characteristic generally used for calculation of the volume

occupied by the aggregate in various mixtures containing aggregate, including Portland

cement concrete, bituminous concrete, and other mixtures that are proportioned or analyzed

on an absolute volume basis. Bulk specific gravity is also used in the computation of voids in

aggregate in the unit weight test.

2 Bulk specific gravity (SSD) is used if the aggregate is wet, that is, if its absorption has

been satisfied. Conversely, the bulk specific gravity (oven-dry) is used for computations

when the aggregate is dry or assumed to be dry.

3 Apparent specific gravity pertains to the relative density of the solid material making up

the constituent particles not including the pore space within the particles which is accessible

to water.

4 Absorption values are used to calculate the change in the weight of an aggregate due to

water absorbed in the pore spaces within the constituent particles, compared to the dry

condition, when it is deemed that the aggregate has been in contact with water long enough to

satisfy most of the absorption potential. The laboratory standard for absorption is that

obtained after submerging dry aggregate for approximately 24h in water. Aggregates mined

from below the water table may have a higher absorption, when used, if not allowed to dry.

Conversely, some aggregates when used may contain an amount of absorbed moisture less

than the 24-h soaked condition. For an aggregate that has been in contact with water and that

has free moisture on the particle surfaces, the percentage of free moisture can be determined

Prepared by Balsam J. Farid 10

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

by deducting the absorption from the total moisture content determined The test method used

for calculating the specific gravities and absorption is (ASTM C127&128-88)

2-Moisture content.

One of the properties of the aggregates which should be known to design a concrete mix is

its moisture content. It is necessary in order to determine the net water -cement ratio in a

batch of concrete and to adjust batch quantities of ingredients for concrete. The test method

used for that is “Moisture Content of Concrete Aggregate” (ASTM C-566- 84)

3-Loose or rodded unit weight of aggregates

The following definitions can be useful:

Bulk density, of aggregate, the mass of a unit volume of bulk aggregate material, in which

the volume includes the volume of the individual particles and the volume of the voids

between the particles. Expressed in [kg/m3].

Unit weight, weight (mass) per unit volume. (Deprecated term–used preferred term bulk

density.)

Voids, in unit volume of aggregate, the space between particles in an aggregate mass not

occupied by solid mineral matter.

Note: Voids within particles, either permeable or impermeable, are not included.

Bulk density values are necessary for use for many methods of selecting proportions for

concrete mixtures.

The test method : “Unit Weight and Voids in Aggregate in its compacted or loose condition”

(ASTM C 29 – 89) is used to determine bulk density values that are necessary for use for

many methods of selecting proportions for concrete mixtures.

4-Nominal maximum size of aggregate and fineness modulus

Nominal Maximum Size (of aggregate), in specifications for, or description of aggregate,

the smallest sieve opening through which the entire amount of the aggregate is permitted to

pass.

Specifications on aggregates usually stipulate a sieve opening through which all of the

aggregate may, but need not, pass so that a stated maximum proportion of the aggregate may

be retained on that sieve. A sieve opening so designated is the nominal maximum size of the

aggregate.

The larger the aggregate particle the smaller the surface area to be wetted per unit mass(

specific surface). Thus, extending the grading of aggregate to a larger maximum size lowers

the water requirement of the mix so that, for specified workability and richness of the mix,

the water/cement ratio can be reduced a consequent increase in strength. However, there is a

limit of maximum size of aggregate.

Fineness Modulus, a factor obtained by adding the percentages of material in the sample

that is coarser than each of the following sieves (cumulative percentages retained), and

dividing the sum by 100: 150-μm (No. 100), 300-μm (No. 50), 600-μm (No. 30), 1.18-mm

(No. 16), 2.36-mm (No. 8), 4.75-mm (No. 4), 9.5-mm (3⁄8-in.), 19.0-mm (3⁄4-in.), 37.5-mm

(11⁄2-in.), 75-mm (3-in.), 150-mm (6-in.).

Usually, the fineness modulus is calculated for the fine aggregate rather than for coarse

aggregate. Typical values range from 2.3 and 3.0, a higher value indicating a coarser grading.

The usefulness of the fineness modulus lies in detecting slight variations in the aggregate

from the same source, which could affect the workability of the fresh concrete.

Prepared by Balsam J. Farid 11

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Moisture Conditions of aggregate

The porosity, permeability and absorption of aggregate influence the bond between it and

the cement paste, the resistance of concrete to freezing and thawing, as well as chemical

stability, resistance to abrasion, and specific gravity.

When all the pores in the aggregate are full, it is said to be saturated and surface-dry.

If this aggregate is allowed to stand free in dry air, some water will evaporate so that the

aggregate is air-dry. Drying in an oven will remove the moisture; the aggregate is now oven

dry. The aggregate can be also moist or wet when all voids are full of water and the surface is

wet also.

Moisture conditions of aggregate.

Deleterious Materials

These are materials that can prove harmful to the concrete if present in sufficient quantity.

Some impurities can be removed by careful washing and screening at the aggregate

production plant.

Prepared by Balsam J. Farid 12

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Sampling and testing

Two things to remember when performing a test on any material are:

1. The test must be performed in exactly the same way each time so that any change in the

result is only indicative of a change in the property being measured.

2. The sample being tested must be truly representative of the total quantity.

When testing aggregates the total weight of the sample being tested is no more than a few

kilogram's yet it has to be representative of a stockpile of several tonnes.

Sampling aggregates for concrete is usually based on random selection with each part of the

stock pile having an equal chance of being sampled.

The first requirement is to define the batch or stockpile quantity to be sampled, then to take a

number of scoopfuls which are then combined into a representative sample to be reduced into

one or more laboratory samples.

At the laboratory, the sample is reduced to an appropriate size using a riffle box or a

quartering board.

Details of tests are shown in the laboratory manual ( see Appendix )

Prepared by Balsam J. Farid 13

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

The cement

When all the ingredients are mixed, the cement and water react together and the resulting

reaction products bind the sand and coarse aggregate together to form concrete.

This reaction process is known as hydration and it continues throughout the life of the

concrete, providing the temperature is high enough and moisture is present.

It is important to realize that the reaction is a chemical one and not a drying out process as is

commonly thought.

The manufacturing process can be summarized in the following figure:

Manufacture steps of cement

INGREDIENTS

The essential ingredients of cement are lime and silica. Limestone has a high lime content,

while the clay contains the silica.

CRUSHING and MILLING

The raw materials are crushed and reduced to a size or less (0.075 mm).

of approximately 75 microns

BLENDING

There are two alternative ways of blending the materials together. In the wet process the

ingredients are mixed in a slurry, while in the dry process the particles are transported in an

air stream to the kiln. The dry process being the least energy intensive is now the preferred

method.

Prepared by Balsam J. Farid 14

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

HEAT EXCHANGE - Stage I

The blend is fed into a slightly inclined rotary kiln where the initial temperature is sufficient

to drive off any water. The dimensions of the kiln can be up to 230m long, land 7m diameter

and the temperature gradually increases along its length.

HEAT EXCHANGE - Stage 2

The second stage heats the mix to approximately 600 °C, when the calcium carbonate and

chalk decompose to produce quicklime.

HEAT EXCHANGE - Stage 3

The temperature in this zone is approximately 1500 °C and 20-30% of the material becomes a

liquid flux. The mass of lime, silica and alumina then fuse into balls of hard clinker.

DUST EXTRACTION

This is necessary to prevent harmful particles being discharged into the atmosphere.

CLI NKER

The clinker drops into coolers, and the heat that is exchanged is used to raise the temperature

of the air going into the kiln. At this stage, the size of the clinker particles is in the order of 2-

25 mm.

CLINKER GRINDING

The clinker/gypsum mix is ground to produce the cement The grinding continues until the

particle sizes are between 2 to 80 microns (0.002 to 0.080 mm).

GYPSUM

Gypsum (calcium sulphate), is added to the clinker to prevent rapid setting of the cement

when water is added.

Properties of Portland Cement

There are many different types of cement available, the most common of which is Portland

cement (PC). The properties of PC will now be discussed in detail and reference will be made

later to the other types of cements.

Portland cement is a fine powder that when mixed

with water becomes the glue that holds aggregates together in concrete.

Prepared by Balsam J. Farid 15

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Cement Composition.

In the kiln the raw materials fuse together to form the cement clinker. This clinker is

composed of four primary compounds - each playing a different part in the hydration

reaction.

Tricalcium Dicalcium Tricalcium Tetracalcium

Silicate Silicate Aluminate Alumino-ferrite

C3S C2S C3A C4AF

The properties of the cement depend upon the proportions in which these compounds exist

Variations in compound composition can lead to significant variations in the properties of the

cement.

Hydration - The Chemical Reactions

When the water and cement are mixed a number of chemical reactions begin involving the

silicates and aluminates in the cement. These combine with the water producing the hydration

products which in time form the hardened cement paste (HCP).

The first reaction between C3A and the water is the most rapid of all. It needs to be controlled

to avoid “flash-setting”, this is achieved by the addition of gypsum

The formation of ettringite slows down the hydration of C3A by creating a barrier around the

cement grains.

This dormant period is extremely important since it allows time for the cement to be

transported to site and compacted

After a certain proportion of the sulphate has been consumed, the ettringite coating becomes

broken and a second reaction begins to take place

It is not until this second reaction occurs that the paste begins to stiffen significantly and

workability begins to drop. Shortly we can say:

Tricalcium Silicate, C3S, hydrates and hardens rapidly and is largely responsible for initial

set and early strength. In general, the early strength of Portland cement concrete is higher

with increased percentages of C3S.

Dicalcium Silicate, C2S, hydrates and hardens slowly and contributes largely to strength

increase at ages beyond one week.

Tricalcium Aluminate, C3A, liberates a large amount of heat during the first few days of

hydration and hardening. It also contributes slightly to early strength development. Cements

with low percentages of C3A are more resistant to soils and waters containing sulfates.

Tetracalcium Aluminoferrite, C4AF, is the product resulting from the use of iron and

aluminum raw materials to reduce the clinkering temperature during cement manufacture.

It contributes little to strength. Most color effects that make cement gray are due to C4AF and

its hydrates.

Calcium Sulfate, as anhydrite (anhydrous calcium sulfate), gypsum (calcium sulfate

dihydrate), or hemihydrate, often called plaster of paris or bassanite (calcium sulfate

hemihydrate) is added to cement during final grinding to provide sulfate to react with C3Ato

form ettringite (calcium trisulfoaluminate). This controls the hydration of C3A. Without

sulfate, a cement would set rapidly. In addition to controlling setting and early strength gain,

the sulfate also helps control drying shrinkage and can influence strength through 28 days.

Prepared by Balsam J. Farid 16

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Strength Contribution

Providing moisture is present, the cement can continue to hydrate for many years. However,

after about one year the rate of hydration is so slow that it is assumed to be fully hydrated and

therefore at full strength.

During this period each compound contributes a different amount to the strength of the

cement. This is best described by the diagram on the left.

Heat Evolution

During hydration the four main compounds generate different amounts of heat as shown in

the graph on the right.

TYPES OF PORTLAND CEMENT

Different types of Portland cement are manufactured to meet various normal physical and

chemical requirements for specific purposes. Portland cements are manufactured to meet the

specifications of ASTM C 150, AASHTO M 85, or ASTM C 1157.

ASTM C 150, Standard Specification for Portland Cement, provides for eight types of

Portland cement using Roman numeral designations as follows:

Type I Normal

Type IA Normal, air-entraining

Type II Moderate sulfate resistance

Type IIA Moderate sulfate resistance, air-entraining

Type III High early strength

Type IIIA High early strength, air-entraining

Type IV Low heat of hydration

Type V High sulfate resistance

Type I Portland cement is a general-purpose cement suitable for all uses where the special

properties of other types are not required. Its uses in concrete include pavements, floors,

reinforced concrete buildings, bridges, tanks, reservoirs, pipe, masonry units, and precast

concrete products

Prepared by Balsam J. Farid 17

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Type II Portland cement is used where precaution against moderate sulfate attack is

important. It is used in normal structures or elements exposed to soil or ground waters where

sulfate concentrations are higher than normal but not unusually severe. Type II cement has

moderate sulfate resistant properties because it contains no more than 8% tricalcium

aluminate (C3A).

Type III portland cement provides strength at an early period, usually a week or less. It is

chemically and physically similar to Type I cement, except that its particles have been ground

finer. It is used when forms need to be removed as soon as possible or when the structure

must be put into service quickly. In cold weather its use permits a reduction in the length of

the curing period. Although higher-cement content mixes of Type I cement can be used to

gain high early strength, Type III may provide it easier and more economically.

Type IV Portland cement is used where the rate and amount of heat generated from hydration

must be minimized. It develops strength at a slower rate than other cement types. Type IV

cement is intended for use in massive concrete structures, such as large gravity dams, where

the temperature rise resulting from heat generated during hardening must be minimized. Type

IV cement is rarely available.

Type V Portland cement is used in concrete exposed to severe sulfate action—principally

where soils or ground waters have a high sulfate content. It gains strength more slowly than

Type I cement. The high sulfate resistance of Type V cement is attributed to a low tricalcium

aluminate content, not more than 5%. Use of a low water to cementitious materials ratio and

low permeability are critical to the performance of any concrete exposed to sulfates. Even

Type V cement concrete cannot withstand a severe sulfate exposure if the concrete has a high

water to cementitious materials ratio. Type V cement, like other Portland cements, is not

resistant to acids and other highly corrosive substances.

Air-Entraining Portland Cements

Specifications for three types of air-entraining Portland cement (Types IA, IIA, and IIIA) are

given in ASTM C 150 and AASHTO M 85. They correspond in composition to ASTM Types

I, II, and III, respectively, except that small quantities of air-entraining material are

interground with the clinker during manufacture. These cements produce concrete with

improved resistance to freezing and thawing. Such concrete contains minute, well-distributed,

and completely separated air bubbles. Air entrainment for most concretes is achieved through

the use of an air-entraining admixture, rather than through the use of air-entraining cements.

Air-entraining cements are available only in certain areas.

White Portland Cements

White Portland cement is a true Portland cement that differs from gray cement chiefly in

color. It is made to conform to the specifications of ASTM C 150, usually Type I or Type III;

the manufacturing process is controlled so that the finished product will be white. White

Portland cement is made of selected raw materials containing negligible amounts of iron and

magnesium oxides—the substances that give cement its gray color. White Portland cement is

used primarily for architectural purposes in structural walls, precast and glass fiber reinforced

concrete (GFRC) facing panels, terrazzo surfaces, stucco, cement paint, tile grout, and

decorative concrete. Its use is recommended wherever white or colored concrete, grout, or

mortar is desired. White Portland cement should be specified as: white Portland cement

meeting the specifications of ASTM C 150, Type [I, II, III, or V]. White cement is also used

Prepared by Balsam J. Farid 18

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

to manufacture white masonry cement meeting ASTM C 91 and white plastic cement

meeting ASTM C 1328. White cement was first manufactured in the United States in York,

Pennsylvania in 1907.

Physical Properties of Cement

Specifications for cement place limits on both its physical properties and often chemical

composition. An understanding of the significance of some of the physical properties is

helpful in interpreting results of cement tests. Tests of the physical properties of the cements

should be used to evaluate the properties of the cement, rather than the concrete. Cement

specifications limit the properties with respect to the type of cement. Cement should be

sampled in accordance with ASTM C 183 (AASHTO T 127). During manufacture, cement is

continuously monitored for its chemistry and the following properties:

The fineness of cement affects heat released and the rate of hydration. Greater cement

fineness (smaller particle size) increases the rate at which cement hydrates and thus

accelerates strength development. The effects of greater fineness on paste strength are

manifested principally during the first seven days In the early 1900s, cement fineness was

expressed as

The Wagner turbidimeter test (ASTM C 115 or AASHTO T 98—Fig. 2-32), the 45

micrometer (No. 325) sieve (ASTM C 430 or AASHTO T 192—Fig. 2-33) or the

150-μm (No. 100) and 75-μm (No. 200) sieve (ASTM C 184 or AASHTO T 128), and the

electronic (x-ray or laser) particle size analyzer can also be used to test fineness.

Soundness

Soundness refers to the ability of a hardened paste to retain its volume. Lack of soundness or

delayed destructive expansion can be caused by excessive amounts of hard burned free lime

or magnesia. Most specifications for Portland cement limit the magnesia (periclase) content

and the maximum expansion as measured by the autoclave-expansion test. Since adoption of

the autoclave-expansion test (ASTM C 151 or AASHTO T 107) in 1943, there have been

exceedingly few cases of abnormal expansion attributed to unsound cement.

Consistency

Consistency refers to the relative mobility of a freshly mixed cement paste or mortar or to its

ability to flow. During cement testing, pastes are mixed to normal consistency as defined by a

penetration of 10 ± 1 mm of the Vicat plunger (see ASTM C 187 or AASHTO T 129)

Setting Time

The object of the setting time test is to determine (1) the time that elapses from the moment

water is added until the paste ceases to be fluid and plastic (called initial set) and (2) the time

required for the paste to acquire a certain degree of hardness (called final set). To determine

if a cement sets according to the time limits specified in cement specifications, tests are

performed using either the Vicat apparatus (ASTM C 191 or AASHTO T 131) or the

Gillmore needle (ASTM C 266 or AASHTO T 154 ).

The Vicat test governs if no test method is specified by the purchaser. Initial set of cement

paste must not occur too early and final set must not occur too late. The setting times indicate

that a paste is or is not undergoing normal hydra-

Compressive Strength

Compressive strength as specified by ASTM cement standards is that obtained from tests of

50-mm (2-in.) mortar cubes tested in accordance with ASTM C 109 (AASHTO T 106)

Prepared by Balsam J. Farid 19

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

These cubes are made and cured in a prescribed manner using a standard sand. Compressive

strength is influenced by the cement

Density and Relative Density (Specific Gravity)

The density of cement is defined as the mass of a unit volume of the solids or particles,

excluding air between particles. It is reported as mega grams per cubic meter or grams per

cubic centimeter (the numeric value is the same for both units). The particle density of

Portland cement ranges from 3.10 to 3.25, averaging 3.15 Mg/

Mixing Water for Concrete

Water that is safe to drink is safe to use in concrete.

Water is mixed with the cement powder to form a paste which holds the aggregates

together like glue.

Almost any natural water that is drinkable and has no pronounced taste or odor can be used as

mixing water for making concrete. However, some waters that are not fit for drinking may be

suitable for use in concrete. Water of questionable suitability can be used for making concrete

if mortar cubes (ASTM C 109 or AASHTO T 106) made with it have 7-day strengths equal

to at least 90% of companion specimens made with drinkable or distilled water. In addition,

ASTM C 191 (AASHTO T 131) tests should be made to ensure that impurities in the mixing

water do not adversely shorten or extend the setting time of the cement. Acceptable criteria

for water to be used in concrete are given in ASTM C 94 (AASHTO M 157) and AASHTO

T 26. Excessive impurities in mixing water not only may affect setting time and concrete

strength, but also may cause efflorescence, staining, corrosion of reinforcement, volume

instability, and reduced durability. Therefore, certain optional limits may be set on chlorides,

sulfates, acid alkalies, and solids in the mixing water or appropriate tests can be performed to

determine the effect the impurity has on various properties. Some impurities may have little

effect on strength and setting time, yet they can adversely affect durability and other

properties. Water containing less than 2000 parts per million (ppm) of total dissolved solids

can generally be used satisfactorily for making concrete. Water containing more than 2000

ppm of dissolved solids should be tested for its effect on strength and time of set.

Prepared by Balsam J. Farid 20

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Acceptance Criteria for Questionable Water Supplies (ASTM C 94 or AASHTO M 157)

Limits Test method

Compressive strength, minimum

percentage of 90 C 109* or T 106 90

control at 7 days C 109* or T 106

Time of set, deviation from control, hr:

from 1:00 earlier to 1:30 later C 191* or T 131

min

Curing water for concrete

Lawn sprinklers saturating burlap with water keep

the concrete continuously moist.

Generally, water satisfactory for mixing is also suitable for curing purpose. However, iron

or organic matter may cause staining, particularly if water flows slowly over concrete and

evaporates rapidly. In some cases, discolorationis of no significance, and any water suitable

for mixing, or even slightly inferior in quality, is aacceptable for curing. However, it is

essential that curing water be free from substances that attack hardened concrete. For

example, concrete is attacked by water containing free CO2. Flowing pure water, formed by

melting ice or by condensation, and containing little CO2, dissolves (CaOH)2 and causes

surface erosion. Curing with sea water may lead to attack of reinforcment.

Prepared by Balsam J. Farid 21

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Appendix

Building Materials Laboratory Manual

A- The aggregate tests:

1- Reducing Field Sample of Aggregate to Test Sample

2- Moisture Content of Concrete Aggregate.

3- Specific Gravity and Absorption of Coarse Aggregate.

4- Specific Gravity and Absorption of fine Aggregate.

5- Resistance to Degradation of Small-size coarse Aggregate by Abrasion in the Los

Angeles Machine.

6- Sieve Analysis of fine and coarse aggregates.

7- Unit Weight and Voids in Aggregate.

8- Materials Finer than 75µm (No. 200) Sieve in Mineral aggregate.

9- Method of determination of particle shape " Flakiness index"

10- Method of determination of particle shape " Elongation index"

11- Method for determination of water-soluble chloride salts

12- Methods for determination of sulphate content

13- Organic Impurities in Fine Aggregates for Concrete

14- Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate

B- The cement tests:

1- Fineness of cement.

2- Normal consistency.

3- Initial and final time of setting.

4- Density and specific gravity.

5- Compressive strength of cement mortar.

6- Tensile strength of cement mortar.

Prepared by Balsam J. Farid 22

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Reducing Field Sample of Aggregate to Test Sample

ASTM C 702, D75

Purpose: To obtain laboratory samples of aggregates from stockpiles.

Equipment: Shovel, scoop , boom.

Procedure:

1-Obtain a sample of aggregate (about 50 kg) from three places in the

stockpile: from the top third, at the midpoint, and from the bottom third

of the volume of the pile.

2- Place the field sample on a hard, clean level surface.

3- Mix the material thoroughly by turning the entire sample three times.

4- Shovel the entire sample into a conical pile.

5- Carefully flatten the conical to a uniform thickness and diameter by

pressing down the apex with a shovel. ( The diameter should be

approximately four to eight times the thickness).

6- Divide the flattened mass into four equal quarters with a shovel.

7- Remove two diagonally opposite quarters. Brush the cleared spaces

clean.

8-Mix and quarter the remaining materials until the sample is reduced to

the desired size.

Note

The sample splitters can be used instead of flattening the mass on a level

surface.

Prepared by Balsam J. Farid 23

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Fig. (1) The sample splitters for fine &coarse aggregates

Fig.(2) Reducing Field Sample of Aggregate to Test Sample

Prepared by Balsam J. Farid 24

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Aggregate Tests

Test No.1:

“Moisture Content of Concrete Aggregate”

( ASTM C-566- 84)

Scope of test:

One of the properties of the aggregates which should be known to design a concrete

mix is its moisture content. It is necessary in order to determine the net water -cement ratio in

a batch of concrete made with job aggregate.

Materials:

The amount of materials depends on the nominal maximum size of aggregate as follows:

N.M.S Weight of Sample

(mm) (kg)

4.75 0.5

9.5 1.5

12.5 2

19 3

25 4

37.5 6

Apparatus:

1. A balance sensitive to 0.5gm.

2. Electrical oven at temperature 105 °C.

3. Container with a cover.

4. Sample splitter.

Procedure:

1- Prepare the container clean, record its empty weight (A).

2- Weigh the suitable sample of aggregate and keep it in a container, put the cover on.

3-The weight of the container with the cover and the gravel is (B).

4-Remove the cover, then put the sample in the oven at 105 °C for 24 hours.

5-Remove the sample forms the oven and put the cover on it, then leaves it for half

an hour, and then weigh it (D).

6- Repeat the same steps for the sand sample.

Prepared by Balsam J. Farid 25

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Calculations and Results:

Moisture Content % = [ ( B – D ) / ( D – A )] x 100

Discussion:

1- Comment on the results you get.

2- Do you think that your results are affected by the weather conditions?

Prepared by Balsam J. Farid 26

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

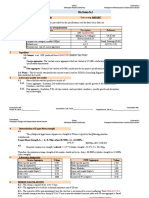

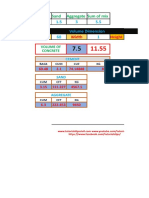

Test 2:

“Specific Gravity and Absorption of Coarse Aggregate”

(ASTM C 127 – 88)

Scope:

This test method covers the determination of Specific Gravity and Absorption of

coarse aggregate. The specific gravity may be expressed as bulk specific gravity, bulk

specific gravity SSD or apparent specific gravity. The bulk specific gravity and absorption

are based on aggregate after 24hour soaking in water.

Materials:

1- Coarse aggregate , must be sampled using sample splitter.

2- The weight of the sample depends on nominal maximum size (NMS) of the

aggregate as follows.

N.M.S Minimum Weight of Sample

(mm) (kg)

12.5 or less 2

19 3

25 4

37.5 5

50 8

Apparatus:

1-A weighing balance sensitive, readable and accurate to 0.5gm.

2-The balance shall be equipped with suitable apparatus for suspending the

sample container in water.

3.Sample container (A wire basket) [20cm diameter& 20cm in height].

4.Water tank; a watertight tank into which the sample container may be placed

while suspended below the balance.

5-Sieves; 4.75mm (No.4) or other sizes as needed

Procedure:

1- Take the sample of coarse aggregate using the sample splitter.

2-Sieve the sample with 4.75mm sieves and ignore the materials passing through

No.4.75 sieve. -

3- Wash the sample to remove dust..

4- Put the sample in the oven at 105°C for 24hours.

5- Get the sample out of the oven, leave it to cool then determine its weight.

6- Submerge the sample in water for 24hours.

7- Remove the sample from the water and roll it in a large absorbent cloth until all

Prepared by Balsam J. Farid 27

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

visible films of water are removed .Wipe the larger particles individually. Take

care to avoid evaporation of water from aggregate pores during the operation of

surface- drying.

8- Take the required weight of the sample in its (S.S.D) (saturated surface dry)

condition.

9-After weighing, immediately place the S.S.D sample in the sample container and

determine its weight in water at 23±1°C.Take care to remove all entrapped air

before weighing by shaking the container while immersed.

10-Dry the test sample to constant weight at a temperature of 110±5°C, Cool in air at

room temperature 1 to 3 hours, or until the aggregate has cooled to a temperature that is

comfortable to handle, and weigh.

Calculations :-

1-Specific Gravity:-

a. Bulk specific gravity: - Calculate the bulk specific gravity as follow :

Bulk Specific Gravity = A /(B-C)

Where:

A=Weight of oven-dry test sample in air,(gm).

B= Weight of S.S.D. sample in air,(gm).

C=Weight of saturated sample in water,(gm).

b- Bulk Specific Gravity (SSD) = B / (B-C)

c-Apparent Specific gravity: - Calculate the apparent sp. gr. As follows:

Apparent Specific Gravity = A / (A - C)

2- Absorption:-

Calculate the percentage of absorption as follows:

Absorption% = [(B – A) / A ]x100

Prepared by Balsam J. Farid 28

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Discussion:

1-Comment on the results.

2- Compare the results with the typical values.

3- How can the percentage of absorption affect on a concrete mix?

Fig.(3) A balance with suitable apparatus for suspending the sample

container in water.

Prepared by Balsam J. Farid 29

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

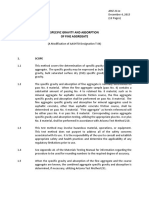

Test No.3

“Specific Gravity and Absorption of fine Aggregate”

(ASTM C 128 – 88)

Scope:. This test method covers the determination of Bulk and Apparent Specific

Gravity and Absorption of fine aggregate.

Materials:- l kg of sand is used using sample splitter.

Apparatus:

1-A balance having capacity of 1kg or more sensitive to 0.1gm

2- Pycnometer: A flask or other suitable container into which the fine aggregate

sample can be introduced .It is usually of 500cm3 capacity.

3-Mold: a metal mold in the form of a frustum of a cone with dimensions as follows:

37mm inside diameter at the top, 90mm inside diameter at the bottom and 75mm in

height.

4-Tamper: A metal tamper weighing 340±15gm and having a flat circular tamping face

25mm in diameter.

5- Electrical Oven.

6- A container suitable to submerge the sample with water.

Preparation of the test Specimen:-

1-Obtain approximately 1kg of the fine aggregate using sample splitter.

2- Dry it in a suitable pan or vessel to constant weight at 110°C. Allow it to cool to a

comfortable handling temperature, cover with water by immersion and permit to stand

for 24 hours.

3- Decant excess water with care to avoid loss of fines, spread the sample on a flat

nonabsorbent surface exposed to a gently moving current of warm air.

4- Stir frequently to get homogeneous drying until achieving the saturated surface dry

condition. Use cone test for surface moisture. 5-

Hold the mold firmly on a smooth nonabsorbent surface with the large diameter down.

Place a portion of partially dried fine aggregate loosely in the mold by filling it to

over following and heaping additional materials above the top of the mold.

6- Lightly tamp the sand into the mold with 25 light drops of the tamper. Each drop

should start about 5mm above the top surface of the sand. Permit the tamper to fall freely

under gravitational attraction on each drop.

7- Adjust the surface, remove loose sand from the base and lift the mold vertically. If

surface moisture is still present the sand will retain the molded shape. When the sand

slumps slightly, it indicates that it has reached S.S.D condition.

Prepared by Balsam J. Farid 30

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Procedure:-

1 -Weigh 500gm of the S.S.D sample.

2- Partially fill the pycnometer with water. Immediately put into the pycnometer

500gm saturated surface dry aggregate.

3- Then fill with additional water to approximately 90%of capacity.

4- Roll; invert the pycnometer to eliminate all air bubbles.

5-Adjust its temperature to 23±1.7 °C by putting the pycnometer in a water bath for an

hour.

6-Bring the water level in the pycuometer to its calibrated capacity.

7- Determine the total weight of the pycnometer, specimen and water.

8- Remove the fine aggregate from the pycnometer, dry to constant weight at temp.

110±5 oC, cool in air at room temperature for one hour, and weigh.

9- Determine the weight of the pycnometer filled to its capacity with water at 23 oC

Calculations:

1-Calculat the bulk specific gravity as follows:-

Bulk sp. gr. = A / ( B + S – C )

Where: A: Weight of oven —dry specimen in air, (gm).

B: Weight of pycnometer filled with water, (gm)

S: Weight of the saturated surface-dry specimen. (500 gm)

C: Weight of pycnometer with specimen and water to calibration

mark, (gm).

1-Calculat the bulk specific gravity (SSD) as follows:

Bulk sp. gr.(SSD) = S / ( B + S – C )

3- Calculate the apparent Specific Gravity as follows:-

Apparent sp. gr=. A / ( B + A - C )

3-Calculate the percentage of absorption as follows:-

Absorption = [ ( S – A) / A x] 100

Discussion:

1- Comment on the results.

2- Compare the results with the typical values.

3- How can the percentage of absorption affect on a concrete mix?

Prepared by Balsam J. Farid 31

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Fig.(4) Exposing the fine

aggregate to a gently

moving current of warm

air.

Fig.(5) The fine aggregate is still damp. Fig.(6) The fine aggregate is

in SSD condition.

Prepared by Balsam J. Farid 32

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Test No.4

“Resistance to Degradation of Small-size coarse Aggregate

by Abrasion in the Los Angeles Machine.”

ASTM C 131-81(1987)

Scope of test: This test method cover testing sizes of coarse of (12.5mm) for

resistance to degradation using the Los Angeles testing machine.

Summary of test:

The Los Angeles test is a measure of degradation of mineral aggregates of standard

grading resulting form a combination of actions including abrasion or attrition, impact, and

grinding in a rotating steel drum containing a specified number of steel spheres, the number

depending upon the grading of the test sample. As the drum rotates a shelf plate picks up the

sample and the steel spheres, carrying them around until they are dropped to the opposite side

of the drum, creating an impact- crushing effect. The contents then roll within the drum with

an abrading and grinding action until the shelf plate impacts and the cycle is repeated. After

the prescribed number of revolutions, the content is removed from the drum and the

aggregate portion is sieved to measure the degradation as percent loss.

Materials:

The test sample shall be washed and oven-dried at (105-110) CO and separated

into individual size fractions and recombined to the grading of table (1) most nearly

corresponding to the range of sizes in the aggregate as furnished for the work.

Apparatus:-

1. Los Angeles Machine.

2. Sieves.

3. Balance accurate to 0.5 gm.

4. Oven. and containers.

5. Charge – The Charge must consist of steel spheres averaging (46.8mm) in diameter and

each weighing between 390 to 445gm. The charge, depending upon the

grading of the test sample as follows:

Prepared by Balsam J. Farid 33

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Grading No: of spheres Wt of charge (gm)

A 12 5000+25

B 11 4584+25

C 8 3330+20

D 6 2500+15

Procedure:

1. Put the sample of coarse aggregate in an oven at 105°C to get oven-dry sample.

2. Prepare the sample, then Weigh and record its weight to the nearest 1gm.

3.Placc the test sample and charge in the Los Angeles testing

machine and rotate the machine at 30to33 round/min for 500

revolutions.

4. Discharge the material from the machine and make preliminary separation of the

sample a sieve coarser then (1.7mm).The finer portion shall then be sieved on a 1.7mm

sieve.

5. The material coarser then the 1.7mm sieve shall be washed, oven dried at 105 oC to

substantially constant weight, and weighed to

the nearest 5gm.

Calculations:

%Abrasion = (wt of the initial sample- wt of retained of 1.7mm sieve) x 100

Wt of initial sample

or = wt of passing sieve (1.7mm) x 100

Wt. of initial sample

Note:

ASTM Specifications C33-86 requires that the abrasion percent should not exceed 50%

for coarse aggregate used in concrete mixes.

Prepared by Balsam J. Farid 34

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Table (1): Grading of test samples:

Sieve size (mm) Weight of indicated sizes (gm)

Grading

Passing Retained

A B C D

on

37.5 25 1250+25 - - -

25 19 1250+25 - - -

19 12.5 1250+10 2500+10 - -

12.5 9.5 1250+10 2500+10 - -

9.5 6.3 - - 2500+10 -

6.3 4.75 - - 2500+10 -

4.75 2.36 - - - 5000+10

Total 5000+10 5000+10 5000+10 5000+10

Fig. (7) The Los

Angeles Machine.

Prepared by Balsam J. Farid 35

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Test No.5

“Unit Weight and Voids in Aggregate in its Compacted

or Loose condition”

(ASTM C 29 – 89)

Scope: This test method covers the determination of unit weight in a compacted or loose

condition and calculation of voids in fine and coarse aggregates. This test method is

applicable to aggregates not exceeding (100mm) in N.M.S.

Materials:

Sample of, preferably, oven dry fine aggregate and an other of oven-dry coarse aggregate.

Apparatus:-

1. A balance accurate to 0.5gm.

2. Measure: A cylindrical metal measure preferably provided with handles. Its

capacity shall conform to the limits below:

N.M.S (mm) Capacity of measure (m3)

12.5 0.0028

25 0.0093

37.5 0.014

100 0.028

Note: - The indicated size measure may be used to test aggregate of

N.M.S equal to or smaller than that listed.

3. Tamping Rod (A round, straight steel rod (l6mm) in diameter and

approximately 600mm in length with a rounded to a hemispherical tip.

4. Containers and shovel or scoop.

Prepared by Balsam J. Farid 36

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Procedure:

A- Calibration of the measure:

1- Fill the measure with water at room temperature and cover with a

piece of plate glass in such away as to eliminate bubbles and excess water.

2- Determine the weight of the water in the measure.

3-Measure the temperature of water and determine its density from table below:-

Density of water

Temperature (0C) Density (kg/m3)

15.6 999.01

18.3 998.54

21.1 997.97

23 997.54

23.9 997.32

26.7 996.59

29.4 995.83

Note: Use interpolating if necessary.

4- Calculate the volume, V of the measure by dividing the weight of water required to

fill the measure by its density.

B- Procedure of the test:-

1. Weigh the cylinder (empty).

2. Fill the cylinder to overflowing by means of a shovel or scoop, discharging the

aggregate from a height not to exceed 50mm above the top the cylinder edge.

Exercise care to prevent, so far as possible, segregation of the particle sizes of which

the sample in composed. Level the surface of the aggregate with the fingers or straight

edge in such way that any slight projections of the larger pieces of the coarse

aggregate approximately balance the larger voids in the surface below the top of the

cylinder

3. Determine the weight of the measure plus its contents, and calculate the weight of the

aggregate by subtracting the empty weight of the cylinder.

4. Empty the cylinder and refill it again to one third of its height and rod the layer of

aggregate with (25) strokes of the tamping rod evenly distributed over the surface. Fill

Prepared by Balsam J. Farid 37

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

the cylinder two-thirds full and again level and rod as previous. Finally, of the

cylinder to overflowing and rod again in the manner previously mentioned. Level the

surface of the aggregate with the fingers or a straight edge in such away as that

mentioned in (step 3).

5. In Roding the first layer, do not allow the rod to strike the bottom of the measure

forcibly. In Roding the second layer and third layer, use only enough force to cause

the tamping rod to penetrate the previous layer of aggregate.

6. Determine the weight of the measure plus its contents and calculate the wt. Of

aggregate.

7. Repeat the same procedure for the fine aggregate sample.

Calculations:

1-Unit weight: calculate the unit weight for the rodding or shoveling procedure

follows:- M = ( G-T )/ V

Where :-

M= unit weight of the aggregate (kg/m3)

G= Weight of the aggregate plus the cylinder (kg)

T= Weight of the empty cylinder (kg)

V= Volume of the cylinder (m3)

Note: The unit weight determined by this test method is for aggregate in an oven- dry

condition.

2-Void content:- Calculate the void content in the aggregate using the unit weight

determined by either the rodding or shoveling procedure as follows:

%void= (S )(W) – (M) x100

( S) (W)

Where S= bulk specific gravity (from tests 2+3)

W= density of water (1000kg/m3 )

Prepared by Balsam J. Farid 38

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

3-Put your results in a table like that shown below.

Coarse Aggregate Fine Aggregate

Loose Compacted Loose Compacted

Unit weight

kg/m3

%Voids

Note:

Normal-Weight aggregate density: (1280-1920) kg/m3

Fig.(8) The cylindrical metal measures for the fine and coarse aggregates

Prepared by Balsam J. Farid 39

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Test No.6

“Sieve Analysis of fine and coarse aggregates"

(ASTM C136 – 84a)

Scope: This method covers the determination of the particle size distribution the fine and

coarse aggregate by sieving.

Materials:

1. The weight of test sample of fine aggregate shall be, after drying, approximately (500

gm).

2. The weight of test sample of coarse aggregate shall conform with the following:

N.M.S (mm) Minimum Weight (kg)

9.5 1

12.5 2

19 5

25 10

37.5 15

Apparatus:

1. Balance: For fine aggregate accurate for 0.5gm.

For coarse aggregate accurate for 0.5gm.

2. Containers to carry the sample.

3. Oven.

4. Mechanical Sieve shaker.

5. Two sets of sieve:-For fine aggregate [ No.4 , No.8, No.16 , No.30 , No.50,

No.100]

For coarse aggregate [37.5mm , 19mm ,9.5mm, No.4 , No.8]

In addition to a pan and a cover for each set.

Procedure:

1- Put the sample in the oven at 110°C.

2-Determine the empty weight for each sieve and record.

3-Nest the sieve in order of decreasing size of opening from top to bottom place the

sample on the top sieve.

4- Agitate (shake) the sieve by placing the set on the mechanical shaker for 10min.

Prepared by Balsam J. Farid 40

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

5- Open the set of sieve carefully so that no loosing of materials is expected.

6-Weigh each sieve with the residue record its weight.

7- Tabulate your data in a suitable shape.

8. Make sure that the summation of the residue weights equals to the original sample

weight with a difference not more than 1% of the original weight.

9-The table should contain:-

No. of Sieve Sieve Residue Residue % Cum %

sieve empty Wt +residue Wt Wt % Residue Passing

10-Fineness Modulus for fine aggregate can be determined as: -

F.M. = Σ cumulative residue percentage

100

It must be within-(2.6 - 3.1) for sand.

Notes:

1-The sieves dimensions are:

No. of sieve 100 50 30 16 8 4 3/8'' 1/2'' 3/4'' 1'' 1.5''

Size of

0.150 0.3 0.6 1.18 2.36 4.75 9.5 12.5 19 25.4 37.5

opening (mm)

2- The results must be compared with ASTM Specification [C33-99a]

a- For Fine aggregate:

Sieve No. Sieve size % Passing

mm

3/8'' 9.5 100

No.4 4.75 95-100

No.8 2.36 80-100

No.16 1.18 50-85

No.30 0.600 25-60

No.50 0.300 5-30

No.100 0.150 0-10

b- For Coarse aggregate: See table (1).

Prepared by Balsam J. Farid 41

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Prepared by Balsam J. Farid 42

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Fig. (9) The Mechanical Sieve Shaker.

Prepared by Balsam J. Farid 43

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Test No.7

“Materials Finer than 75µm (No. 200) Sieve in Mineral

Aggregate by Washing ”

(ASTM C117-87)

Scope: This test method covers determination of the amount of materials finer than a 75µm

(N0.200) sieve in aggregate by washing. Clay particles and other aggregate particles that are

dispersed by the wash water, as well as water –soluble materials, will be removed from the

aggregate during the test.

Materials :

the mass of the test sample, after drying , shall conform with the following:

Nominal Max. Size Minimum Mass (gm)

4.5mm or smaller 300

9.5mm 1000

19mm 2500

37.5mm or larger 5000

Apparatus :

1- Balance accurate to 0.1g or 0.1% of the test mass , whichever greater.

2- Sieves: 75µm (No.200) sieve + 1.18mm (No.16) sieve .

3- Container.

4- Oven.

Procedure:

1- Dry the test sample to constant mass at a temperature of 110 CO ± 5 Co

Determine the mass to the nearest 0.1gm of the test sample.

2- Place the test sample in the container and add sufficient water to cover it. Agitate the

sample to result in complete separation of all particles finer than the 75µm

(No.200) sieve from the coarser particles, and to bring the fine materials into

suspension. immediately pour the wash water containing the suspended and

dissolved solids over the nested sieves, arranged with the coarser sieve on top .

3- Add a second charge of water to the sample in the container, agitate , and decant as

before. Repeat this operation until the wash water is clear.

Prepared by Balsam J. Farid 44

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

4- Return all materials retained on the nested sieve by flushing to the washed sample .

Dry the washed sample to constant mass at a temp. of 110 + 5 Co and determine the

mass to the nearest 0.1% of the original mass of the sample .

5- Calculate the amount of materials passing 75µm (No.200) sieve by washing as

follows:

B-C

A= × 100

B

Where :

A = percentage of material finer than 75µm sieve by washing .

B = Original dry mass of sample .(gm)

C = Dry mass of sample after washing.(gm)

Note:

According to [C33-99a] ASTM.

[A] must be not more than (3%), in fine aggregate for concrete, and not more than (1%), in

coarse aggregate.

Prepared by Balsam J. Farid 45

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Test No.8

Method of determination of particle shape "Flakiness index"

BS 812-105.1:1989

Scope:

The test describes the method for determining the flakiness index of coarse aggregate.

Principle

Aggregate particles are classified as flaky when they have a thickness (smallest

dimension) of less than 0.6 of their mean sieve size. The flakiness index of an aggregate

sample is found by separating the flaky particles and expressing their mass as a percentage of

the mass tested. The test is not applicable to material passing a 6.30mm BS test sieve or

retained on a 63.0 mm BS test sieve.

Apparatus

1- A sample divider

2- A ventilated oven.

3- A balance accurate to 0.1% of the mass of the test portion.

4- Test sieves.

5- A mechanical sieve shaker.

6- Trays of suitable size.

7- A metal thickness gauge ( see figure).

Preparation of test sample

1- Reduce the sample using sample splitter to produce a test portion that complies with

table 2 with due allowance fo the later rejection of particles retained on a 63.0 mm

test sieve and passing a 6.30 mm test sieve.

2- Dry the test portion by heating at temperature of 105+5 oC .

Table 2

Minimum mass of test portion

Nominal size of

after rejection of oversize and

material

undersize particles

mm

kg

50 35

40 15

28 5

20 2

14 1

10 0.5

Prepared by Balsam J. Farid 46

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Procedure

1- Carry out a sieve analysis in accordance with 7.3 of BS 812-103.1:1989 using the

standard sieves.

2- Discard all aggregates retained on the 63.0 mm test sieve and aggregates passing the

6.3 mm test sieve.

3- Weigh each of the individual size-fractions retained on the sieves, and store them in

separate trays with their size marked on the tray.

4- From the sums of the masses of the fractions in the trays(M1), calculate the individual

percentage retained on each of the various sieves. Discard any fraction whose mass is

5% or less of mass M1.Record the mass remaining (M2).

5- Gauge each fraction by using the thickness gauge : select the thickness gauge

appropriate to the size-fraction under testand gauge each particle of that size-fraction

separately by hand.

6- Combine and weigh all the particles passing each of the gauges (M3)

Calculation and expression of the results

The value of the flakiness index is calculated from the expression:

Flakiness index = M3/M2 x 100

Fig.10 Thickness gauge

( Dimensions are in millimeters )

Prepared by Balsam J. Farid 47

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Test No.9

Method of determination of particle shape "Elongation index"

BS 812-105.2:1989

Scope:

The test describes the method for determining the elongation index of coarse aggregate.

Principle

Aggregate particles are classified as elongated when they have a length (greatest

dimension) of more than 1.8 of their mean sieve size. The flakiness index of an aggregate

sample is found by separating the flaky particles and expressing their mass as a percentage of

the mass tested. The test is not applicable to material passing a 6.30mm BS test sieve or

retained on a 50.0 mm BS test sieve.

.

Apparatus

1- A sample divider

2- A ventilated oven.

3- A balance accurate to 0.1% of the mass of the test portion.

4- Test sieves.

5- A mechanical sieve shaker.

6- Trays of suitable size.

7- A metal length gauge ( see figure).

Preparation of test sample

1- Reduce the sample using sample splitter to produce a test portion that complies with

table 2 with due allowance for the later rejection of particles retained on a 50.0 mm

test sieve and passing a 6.30 mm test sieve.

2- Dry the test portion by heating at temperature of 105+5 oC .

Table 2

Minimum mass of test portion

Nominal size of

after rejection of oversize and

material

undersize particles

mm

kg

40 15

28 5

20 2

14 1

10 0.5

Prepared by Balsam J. Farid 48

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Procedure

1- Carry out a sieve analysis in accordance with 7.3 of BS 812-103.1:1989 using the

standard sieves.

2- Discard all aggregates retained on the 50.0 mm test sieve and aggregates passing the

6.3 mm test sieve.

3- Weigh each of the individual size-fractions retained on the sieves, and store them in

separate trays with their size marked on the tray.

4- From the sums of the masses of the fractions in the trays(M1), calculate the individual

percentage retained on each of the various sieves. Discard any fraction whose mass is

5% or less of mass M1.Record the mass remaining (M2).

5- Gauge each fraction as follows. Select the length gauge appropriate to the

size fraction under test (see Table 3) and gauge each particle separately by

hand. Elongated particles are those whose greatest dimension prevents them

from passing through the gauge, and these are placed to one side.

6- Combine and weigh all the elongated particles (M3)

Calculation and expression of the results

The value of the Elongation index is calculated from the expression:

Elongation index = M3/M2 x 100

where

M2 is the sum of the masses of fractions that have a mass greater than 5 % of the

total mass.

M3 is the mass of all the elongated particles.

Express the elongation index to the nearest whole number

Figure 11 — Metal length gauge

Prepared by Balsam J. Farid 49

Properties and Testing of Concrete Materials 6/7/2008 - 17/7/2008

Test No.10

Method for determination of water-soluble chloride salts

BS 812-117:1988

1 Scope

This Part of BS 812 describes the method for determination of the water-soluble chloride