Professional Documents

Culture Documents

Investigation of Foaming Capacity of Different Washing Soap

Uploaded by

Ashwin BrahmaneCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Investigation of Foaming Capacity of Different Washing Soap

Uploaded by

Ashwin BrahmaneCopyright:

Available Formats

Investigation Of Foaming Capacity Of Different Washing Soap

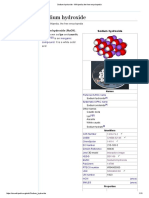

Aim is To investigate foaming capacity of different washing soap and effect of addition of sodium carbonate on them. Soaps and detergents are cleaning ingredients that are able to remove oil particles from surfaces because of their unique chemical properties. Soaps are created by the chemical reaction of a jetty acid with on alkali metal hydroxide. In a chemical sense soap is a salt made up of a corboxylix acid and an alkali like sodium of potassium. The cleaning action of soap and detergents is a result of thrill, ability to surround oil particles on a surface and disperse it in water. Bar soap has been used for centuries and continues to be an important product for batching and cleaning. It is also a mild antiseptic and ingestible antidote for certain poisons. SOAP Soap is a common term for a number of related compounds used as of washing clothes or bathing. Soaps are sodium or potassium salts of higher fatty acids such as stearic acid (C17 H35 COOH), palmittic acid (C15 H31 COOH) and oleic acid (C17H35 COOH) they have the general formula RCOONa and R COONa. Soap is produced by a saponification or basic hydrolysis reaction of a fat or oil. Currently sodium carbonate or sodium hydroxide is used to neutralize the fatty acid and convert it to the salt..

General Overall Hydrolysis Reaction

Although the reaction is shown as one step reaction, it is in fact two steps. The net effect as that the ester bonds all broken. The glycerol turns back into an alcohol. The fatty acid is turned into a salt due to the presence of abasic solution of NaoH. In the carboxyl group, one oxygen now has a negative charge that attacts the positive sodium ion. A molecule of soap consists of two parts. a) Alkyl group it is oil soluble b) Corboxyl group It is water soluble

Types of soaps The type of fatty acid and length of the carbon chain determines the unique properties of various soaps. Tallow or animal fats give plimarily sodium stearate (18 carbons) a very hard, insoluble soap. Fatty acids with longer chains are even more insoluble. As a matter of fact, 3inc stearate is used in talcum powders because it is water repellent. Coconut oil is a source of lauric acid (12 carbons) which can be made into sodium lourate. This soap is very soluble and will lather easily even in sea water. Fatty acids with only 10 or fewer carbons are not used in soaps because they irritate the skin and have objectionable odors Materials Required: (a) Apparatus Five 100ml conical flasks, five 20ml test tubes, 100ml measuring cylinder, test tube stand, weight box and stop watch. (b) Chemicals Five different samples of soap and distilled water. Theory There is no quantitative method for the determination of foaming capacity of a soap. The foaming capacity of soap depends upon concentration of soap in the sample. Solution of different soap are prepared by dissolving their equal weights in equal volumes of distilled water. These solutions are shaken vigorously to produce foam and then they are allowed to stand. Time taken for the disappearance of foam are measured for different samples. Longer the time taken for the disappearance of foam in a given sample of soap, greater is its foaming capacity Procedure Take five 100ml conical flasks and lobel them as A,B,C,D,E. Take 50ml of water in each conical flask and then add 2g of different samples of soap to each flask. Warm to dissolve and get a clear solution. Arrange five test tubes on a test tube stand labelled as A,B,C,Dand E. Take ICC of the soap solution from each conicol flask ad to the corresponding test tube. Shake the test tube for 1 minute by covering its mouth by the thumb.

Foam will be formed in the test tube. Start the stop watch and note the time taken for the disappearance of foam. Repeat the same procedure for the test tubes B, C,D and E. Shaking each tube with the same force and noting the time taken for disappearance of the foam Observation Table

Conclusion Foaming capacity of soap is maximum in distilled water as compared to that in tap water.

Soap is an anionic surfactant used in conjunction with water for washing and cleaning, which historically comes either in solid bars or in the form of a viscous liquid. Soap consists of sodium or potassium salts of fatty acids and is obtained by reacting common oils or fats with a strong alkaline in a process known as saponification. The fats are hydrolyzed by the base, yielding alkali salts of fatty acids (crude soap) and glycerol. The general formula of soap is Fatty end water soluble end CH3-(CH2) n COONa Soaps are useful for cleaning because soap molecules have both a hydrophilic end, which dissolves in water, as well as a hydrophobic end, which is able to dissolve non polar grease molecules. Applied to a soiled surface, soapy water effectively holds particles in colloidal suspension so it can be rinsed off with clean water. The hydrophobic portion (made up of a

long hydrocarbon chain) dissolves dirt and oils, while the ionic end dissolves in water. The resultant forms a round structure called micelle. Therefore, it allows water to remove normally-insoluble matter by emulsification. Commercial production of soap The most popular soap making process today is the cold process method, where fats such as olive oil react with strong alkaline solution, while some soapers use the historical hot process. Handmade soap differs from industrial soap in that, usually, an excess of fat is sometimes used to consume the alkali (super fatting), and in that the glycerin is not removed, leaving a naturally moisturizing soap and not pure detergent. Often, emollients such as jojoba oil or Shea butter are added at trace (the point at which the saponification process is sufficiently advanced that the soap has begun to thicken), after most of the oils have saponified, so that they remain unreacted in the finished soap. Fat in soap Soap is derived from either vegetable or animal fats. Sodium Tallowate, a common ingredient in much soap, is derived from rendered beef fat. Soap can also be made of vegetable oils, such as palm oil, and the product is typically softer. An array of saponifiable oils and fats are used in the process such as olive, coconut, palm, cocoa butter to provide different qualities. For example, olive oil provides mildness in soap; coconut oil provides lots of lather; while coconut and palm oils provide hardness. Sometimes castor oil can also be used as an ebullient. Smaller amounts of unsaponifable oils and fats that do not yield soap are sometimes added for further benefits. Preparation of soap In cold-process and hot-process soap making, heat may be required for saponification. Cold-process soap making takes place at a sufficient temperature to ensure the liquification of the fat being used. Unlike coldprocessed soap, hot-processed soap can be used right away because the alkali and fat saponify more quickly at the higher temperatures used in hot-process soap making. Hot-process soap making was used when the purity of alkali was unreliable. Cold-process soap making requires exact measurements of alkali and fat amounts and computing their ratio, using saponification charts to ensure that the finished product is mild and skin-friendly. Hot process In the hot-process method, alkali and fat are boiled together at 80100 C until saponification occurs, which the soap maker can determine by taste or by eye. After saponification has occurred, the soap is sometimes precipitated from the solution by adding salt, and the excess liquid drained off. The hot, soft soap is then spooned into a mold. Cold process A cold-process soap maker first looks up the saponification value of the fats being used on a saponification chart, which is then used to calculate the appropriate amount of alkali. Excess unreacted alkali in the soap will result in a very high pH and can burn or irritate skin. Not enough alkali and the soap are greasy. The alkali is dissolved in water. Then oils are heated, or melted if they are solid at room temperature. Once both substances have cooled to approximately 100-110F (3743C), and are no more than 10F (~5.5C) apart, they may be combined. This alkali-fat mixture is stirred until trace. There are varying levels of trace. After much stirring, the mixture turns to the consistency of a thin pudding. Trace

corresponds roughly to viscosity. Essential and fragrance oils are added at light trace. Introduction to the experiment Soap samples of various brands are taken and their foaming capacity is noticed. Various soap samples are taken separately and their foaming capacity is observed. The soap with the maximum foaming capacity is thus, said to be having the best cleaning capacity. The test requires to be done with distilled water as well as with tap water. The test of soap on distilled water gives the actual strength of the soaps cleaning capacity. The second test with tap water tests the effect of Ca2+ and Mg2+ salts on their foaming capacities. Objective: To compare the foaming capacity of various soaps. Theory: The foaming capacity of soap depends upon the nature of the soap and its concentration. This may be compared by shaking equal volumes of solutions of different samples having the same concentration with same force for the same amount of time. The solutions are then allowed to stand when the foam produced during shaking disappears gradually. The time taken for the foam to disappear in each sample is determined. The longer the time taken for the disappearance of the foam for the given sample of soap, greater is its foaming capacity or cleansing action. Requirements: Five 100ml conical flasks, five test tubes, 100ml measuring cylinder, test tube stand, weighing machine, stop watch.

You might also like

- Investigation of The Foaming Capacity of Different Washing Soaps and The Effect of Addition of Sodium Carbonate On ItDocument10 pagesInvestigation of The Foaming Capacity of Different Washing Soaps and The Effect of Addition of Sodium Carbonate On ItPrasanna kudale100% (1)

- Class 12th Chemistry Project On Cleaning Action of Soaps 1Document17 pagesClass 12th Chemistry Project On Cleaning Action of Soaps 1ankur bharali60% (5)

- Chemistry - Investigation of Foaming Capacity of Different Washing SoapDocument8 pagesChemistry - Investigation of Foaming Capacity of Different Washing SoapSanjeeth SNo ratings yet

- Soaps and DetergentsDocument11 pagesSoaps and DetergentsNeetika Mishra100% (1)

- Chemistry Project Class 12th - Foaming Capacity of Soaps and Effect of Addition in It.Document16 pagesChemistry Project Class 12th - Foaming Capacity of Soaps and Effect of Addition in It.nitin sankhla100% (3)

- Investigatory Project On Foaming Capacity of SoapsDocument5 pagesInvestigatory Project On Foaming Capacity of SoapsMuthu ManickamNo ratings yet

- Foaming Capacity of SoapDocument11 pagesFoaming Capacity of SoapAditya Sethi100% (1)

- Chemistry Project On Foaming Capacity of SoapsDocument4 pagesChemistry Project On Foaming Capacity of SoapsSri50% (2)

- Foaming Capacity of Soaps: Chemistry Project OnDocument12 pagesFoaming Capacity of Soaps: Chemistry Project OnNilabha Das100% (2)

- Foaming Ability of Soaps and DetergentsDocument13 pagesFoaming Ability of Soaps and DetergentsSanjukta Cyrus60% (5)

- Preparation of SoapDocument9 pagesPreparation of SoapAkarshan KumarNo ratings yet

- Preparation of SoapDocument12 pagesPreparation of Soapsureshkumar Chem100% (1)

- Chemistry Project Class 11 Topic: Foaming Capacity of SoapDocument10 pagesChemistry Project Class 11 Topic: Foaming Capacity of Soapabhishek singhNo ratings yet

- Foaming Capacity of Soaps Investigatory Projects Chemistry Class 12 CbseDocument17 pagesFoaming Capacity of Soaps Investigatory Projects Chemistry Class 12 CbseChandan Kumar SharmaNo ratings yet

- Chemistry Project: Divyansh DubeyDocument14 pagesChemistry Project: Divyansh DubeyYogita DubeyNo ratings yet

- Foaming Capacity of SoapsDocument4 pagesFoaming Capacity of SoapsAvinash Dwivedi60% (5)

- Chemistry Investigatory ProjectDocument24 pagesChemistry Investigatory ProjectYakshithChinnappa100% (2)

- Soap Making Project For Cbse Class 12 - Soap - Detergent - FilesDocument27 pagesSoap Making Project For Cbse Class 12 - Soap - Detergent - FilesFarhan Shekh0% (2)

- Investigatory File On Foaming Capacity of SoapsDocument16 pagesInvestigatory File On Foaming Capacity of SoapsAditya Pratap Singh Sengar86% (7)

- Project On Foaming Capacity of Soaps XiiDocument16 pagesProject On Foaming Capacity of Soaps XiiDeepanshu RajputNo ratings yet

- Foaming CapacityDocument13 pagesFoaming CapacitySagar91% (11)

- Foaming Capacity of SoapDocument18 pagesFoaming Capacity of SoapShashankNo ratings yet

- Preparation of Toilet SoapDocument24 pagesPreparation of Toilet SoapIshaan Sharma92% (12)

- Foaming Capacity of SoapDocument16 pagesFoaming Capacity of SoapAnonymous D5g37JjpGB100% (1)

- Chemistry ProjectDocument20 pagesChemistry Projectbineeshbgopal71% (24)

- Preparation of InkDocument14 pagesPreparation of InkDaily Meme DOSENo ratings yet

- Soap Making ProjectDocument21 pagesSoap Making ProjectPranay Dodiya100% (1)

- Chemistry Investigatory ProjectDocument23 pagesChemistry Investigatory Projectsunidhi dewangan100% (4)

- Formation of Soap Foaming Capacity of SoapDocument17 pagesFormation of Soap Foaming Capacity of SoapRay KumarNo ratings yet

- Chem Investigatory Project On Soap Class 12Document23 pagesChem Investigatory Project On Soap Class 12Phuķhaz MP86% (7)

- HardnessDocument25 pagesHardnessChirag Kesar100% (1)

- Chemistry Investigatory ProjectDocument9 pagesChemistry Investigatory Projectanon_32709488156% (16)

- Chemistry Investigatory Report On "Adulteration of Food-Stuffs"Document16 pagesChemistry Investigatory Report On "Adulteration of Food-Stuffs"Samyak Sau78% (40)

- A Study of The Preparation of Soap Using Coconut Oil or Any Vegetable OilDocument20 pagesA Study of The Preparation of Soap Using Coconut Oil or Any Vegetable OilAPK Khan100% (3)

- Chemistry ProjectDocument20 pagesChemistry ProjectHino Kahoko56% (9)

- Project ChemistryDocument23 pagesProject Chemistryrit100% (1)

- Delhi Public School Indirapuram Investigatory Project ON Preparation of Soap For The Academic Session 2013-2014Document19 pagesDelhi Public School Indirapuram Investigatory Project ON Preparation of Soap For The Academic Session 2013-2014IshAn Bhatnagar80% (15)

- Chemistry Investigatory Project 2023-2024Document9 pagesChemistry Investigatory Project 2023-2024Om Rane0% (1)

- Chemistry Investigatory Project 2020-2021Document23 pagesChemistry Investigatory Project 2020-2021S100% (1)

- Chemistry Investigatory ProjectDocument17 pagesChemistry Investigatory ProjectAprameya C M100% (1)

- Chemistry-Project PDFDocument19 pagesChemistry-Project PDFVeerNo ratings yet

- Adulterants in LipsticksDocument17 pagesAdulterants in LipsticksJainam Shah50% (2)

- Sterilization of Water Using Bleaching PowderDocument16 pagesSterilization of Water Using Bleaching PowderShubham Gupta100% (1)

- Chemistry Investigatory ProjectDocument14 pagesChemistry Investigatory ProjectKumar Ratikant77% (13)

- Biodiesel ProjectDocument18 pagesBiodiesel ProjectpavithraNo ratings yet

- Chemistry Investigatory Project: Acidity in Tea LeavesDocument9 pagesChemistry Investigatory Project: Acidity in Tea LeavesLOVKUSH PANDEYNo ratings yet

- Chemistry Investigatory ProjectDocument16 pagesChemistry Investigatory ProjecthgvgNo ratings yet

- Chemistry ProjectsDocument16 pagesChemistry Projectsanilk5265100% (1)

- Chemistry Project Class 12Document13 pagesChemistry Project Class 12chemistry projectNo ratings yet

- Foaming Capacity of Soaps Investigatory Projects Chemistry Class 12 CbseDocument19 pagesFoaming Capacity of Soaps Investigatory Projects Chemistry Class 12 CbseGaurav Kumar71% (160)

- Chemistry Project 12Document19 pagesChemistry Project 12NANDA KISHOREMNo ratings yet

- Chemistry Project On Foaming Capacity of SoapsDocument13 pagesChemistry Project On Foaming Capacity of SoapsAditya Kumar67% (3)

- Foaming Capacity of SoapDocument6 pagesFoaming Capacity of Soapabhishek singh100% (1)

- Content: The Determination of The Amount of Phosphate in A DetergentDocument20 pagesContent: The Determination of The Amount of Phosphate in A DetergentAditya jain100% (10)

- Chemistry Class 12 Project (Acetic Acid)Document23 pagesChemistry Class 12 Project (Acetic Acid)Anand Baburajan92% (12)

- Chemistry Investigatory ProjectDocument15 pagesChemistry Investigatory ProjectSuchitra Balaji67% (3)

- Investigatory Project On ChemistryDocument12 pagesInvestigatory Project On ChemistryIresh Agrawal100% (1)

- Chemistry Investigatory Project On Study of Rate of FermentationDocument14 pagesChemistry Investigatory Project On Study of Rate of FermentationRohan KannaNo ratings yet

- Project SoapsDocument14 pagesProject Soapskeru9718No ratings yet

- Tanu Chem ProjectDocument3 pagesTanu Chem ProjectTanu TomarNo ratings yet

- Complementary AngleDocument2 pagesComplementary AngleAshwin BrahmaneNo ratings yet

- Sachin Tendulkar: Early YearsDocument1 pageSachin Tendulkar: Early YearsAshwin BrahmaneNo ratings yet

- Electronic MediaDocument2 pagesElectronic MediaAshwin BrahmaneNo ratings yet

- Indira Gandhi: Early Life and CareerDocument1 pageIndira Gandhi: Early Life and CareerAshwin BrahmaneNo ratings yet

- Advantages of DiwaliDocument1 pageAdvantages of DiwaliAshwin Brahmane100% (2)

- Micromax: Micromax Is An IndianDocument8 pagesMicromax: Micromax Is An IndianAshwin BrahmaneNo ratings yet

- ChandrayaanDocument10 pagesChandrayaanAshwin BrahmaneNo ratings yet

- Project Axis Bank: Human Resource ManagementDocument2 pagesProject Axis Bank: Human Resource ManagementAshwin BrahmaneNo ratings yet

- Biography of Sarojini Naid1Document1 pageBiography of Sarojini Naid1Ashwin BrahmaneNo ratings yet

- PR 50 Years of LG Electronics PDFDocument112 pagesPR 50 Years of LG Electronics PDFAshwin BrahmaneNo ratings yet

- Cadbury Dairy MilkDocument10 pagesCadbury Dairy MilkAshwin BrahmaneNo ratings yet

- Microbiology and Parasitology: Exercise No. 6Document6 pagesMicrobiology and Parasitology: Exercise No. 6Joshua MendezNo ratings yet

- PRELIM-COMPILATION (Che Calc 2)Document58 pagesPRELIM-COMPILATION (Che Calc 2)Jerico Hercules MutiaNo ratings yet

- Everything You Need To Know About AlkanesDocument2 pagesEverything You Need To Know About AlkanesJohnNo ratings yet

- Volume I (01-20)Document410 pagesVolume I (01-20)Xuan ManhNo ratings yet

- 60 Cycle HumDocument4 pages60 Cycle HumDivna CvetkovićNo ratings yet

- Corrosion & Non-Ferrous MetalDocument21 pagesCorrosion & Non-Ferrous Metalsiraphat.bmNo ratings yet

- (VCE Chemistry) 2008 TSSM Unit 2 Sample ExamDocument5 pages(VCE Chemistry) 2008 TSSM Unit 2 Sample ExamJustine LyNo ratings yet

- Heat Transfer PDFDocument1 pageHeat Transfer PDFPiyush MahajanNo ratings yet

- Chap 7 Ultra Low Power BioelectronicsDocument3 pagesChap 7 Ultra Low Power BioelectronicsVarun GuptaNo ratings yet

- Taller Aspen TermodinámicaDocument3 pagesTaller Aspen TermodinámicaJuanda BarbosaNo ratings yet

- BS en 12671-2009Document26 pagesBS en 12671-2009Ramakrishnan Hari50% (2)

- Worksheet 2 - Circular Motion: Department of Science PhysicsDocument2 pagesWorksheet 2 - Circular Motion: Department of Science PhysicsDhanBahadurNo ratings yet

- Def Stan IndexDocument160 pagesDef Stan Indexdipak.medhaneNo ratings yet

- Lista Mestra - DE 08 - 2013 A 07-2014Document9 pagesLista Mestra - DE 08 - 2013 A 07-2014aldairlopesNo ratings yet

- Model Question Paper-CBCS Scheme: 18ME15/25 15ME751Document2 pagesModel Question Paper-CBCS Scheme: 18ME15/25 15ME751channabasavanna S GNo ratings yet

- Kuliah SpektrofotometriDocument25 pagesKuliah SpektrofotometriAufa Rahmatika MuswarNo ratings yet

- CHM13P Exit Exam ReviewerDocument9 pagesCHM13P Exit Exam ReviewerPaolo GochingcoNo ratings yet

- ELIMINATOR® Liquid Line Filter Drier Types DCL and DML: Data SheetDocument16 pagesELIMINATOR® Liquid Line Filter Drier Types DCL and DML: Data SheetSouljah KhifferNo ratings yet

- Chapter4 Enrichment (Answer)Document5 pagesChapter4 Enrichment (Answer)Siti Arbaiyah AhmadNo ratings yet

- Test Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)Document1 pageTest Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)yskushwah16No ratings yet

- 08aug18 - Batch2 - B Ed ScienceDocument13 pages08aug18 - Batch2 - B Ed ScienceTapaswinee SamalNo ratings yet

- The Physics of Fluids-2 PDFDocument20 pagesThe Physics of Fluids-2 PDFMellissa MungureNo ratings yet

- SolutionsDocument51 pagesSolutionsSaad MazharNo ratings yet

- Delhi Public School Bangalore North ACADEMIC SESSION 2021-2022 Ut2 Revision Work Sheet TOPIC: Sorting Materials Into Group Answer KeyDocument6 pagesDelhi Public School Bangalore North ACADEMIC SESSION 2021-2022 Ut2 Revision Work Sheet TOPIC: Sorting Materials Into Group Answer KeySumukh MullangiNo ratings yet

- Sodium HydroxideDocument11 pagesSodium HydroxideSrinivasan RajenderanNo ratings yet

- Jyothikiran TotalRecallDocument11 pagesJyothikiran TotalRecallHARITHA H.PNo ratings yet

- Formula Sheet (10 Pages) : CHE 314 - Heat Transfer Midterm Exam (Fall 2018), October 22, Lecture Time and PlaceDocument10 pagesFormula Sheet (10 Pages) : CHE 314 - Heat Transfer Midterm Exam (Fall 2018), October 22, Lecture Time and PlaceAkib ImtihanNo ratings yet

- 2017 - Using Fusel Oil As A Blend in Gasoline To Improve SI EngineDocument11 pages2017 - Using Fusel Oil As A Blend in Gasoline To Improve SI Enginevalzapt8411No ratings yet

- Chapter 1Document6 pagesChapter 1AhmadNo ratings yet

- Deutz Lubricating Oil Quality ClassesDocument18 pagesDeutz Lubricating Oil Quality ClassesDavid PomaNo ratings yet