Professional Documents

Culture Documents

Water and Slurry Hammer

Uploaded by

alvarezjgoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water and Slurry Hammer

Uploaded by

alvarezjgoCopyright:

Available Formats

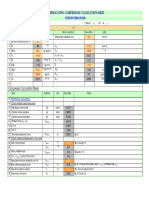

Water hammer

1.- Input data Speed of sound in water

Operating pressure and flowrate

p

op

= 13.8 bar

Q = 108.0 m

3

/h c: speed of sound (m/s)

Pipe data K: water bulk modulus (Pa)

Material: Carbon Steel : water density (kg/m)

d

n

= 8 in c

(K / )^0.5

sch = 40 - K = 2.1E+09 Pa

L = 1524.0 m = 1000 kg/m

Steel pipe elasticity module c = 1438.2 m/s

E

t

= 2,059,397 bar

s 3.- Celerity

Bulk modulus and density of water

K = 20,684 bar

= 1,000 kg/m

2.- Auxiliary variables

Pipe dimensions a : celerity (wave velocity) (m/s)

d

i

= Pipe_Imp_CS_Dint_dn_sch c: speed of sound (m/s)

d

i

= 202.74 mm d: inside pipe diameter (mm)

s = Pipe_Imp_CS_Thickness_dn_sch s: minimum wall thickness (mm)

s = 8.18 mm K: water bulk modulus (bar)

a = c / (1 + (K/E

t

) * (d/s) )^(0.5)

Pipe section area c = 1438.2 m/s

A = (pi()/4)*d^2 K = 2.1E+09 Pa

d = 0.2027 m E

t

= 2.1E+11 Pa

A = 0.0323

m

2

d = 202.74 mm

s = 8.18 mm

Fluid velocity a = 1286.9 m/s

v = Q / A

Q= 0.0300

m

3

/s

A = 0.0323 m

2

v = 0.93 m/s

Bulk modulus of water Steel elasticity modulus

K = 2.1E+09 Pa E

t

= 2.10E+06 kp/cm

K = 20,684 bar E

t

= 2.06E+11 Pa

E

t

= 2.1E+06 bar

|

|

.

|

\

|

+

=

s

d

E

K

c

a

t

1

K

c =

4.- Velocity change 7. Critical time 8.- Pressure increment due to water

hammer produced by a Not Sudden

Initial velocity Maximum over- pressure or under- Shutoff "NSS"

v

i

= 0.93 m/s pressure are obtained when the

Final velocity shutoff time "At", is less or equal to For a shutoff time greater than the

v

f

= 0.00 m/s the critical time "t

c

", critical time, the Michaud relation can

Velocity change be used.

Av = vf - vi m/s

Av =

-0.93 m/s

t

c

= 2 * L / a h

NSS

: presure increment in a Non

5.- Pressure increment due to water L = 1,524 m Sudden Shutoff

hammer produced by a sudden shutoff.

a = 1286.9 m/s h

SS

: Pressure increment in a Sudden

t

c

= 2.4 s Shutoff (Joukovsky)

The pressure increment can be t

c

: Critical time

calculated with Joukovsky elasticity Michaud At : Valver closing time

theory, by a Sudden Shutoff "SS"

Valve closing time

h

SS

=

(- a * Av ) / g At =

a = 1286.9 m/s

Av = -0.93 m/s Pressure ncrement (NSS)

h = 122 m h

NSS

=

h

SS

= 12.0 bar h

SS

=

t

c

=

6.- Total pressure developed by a At =

sudden shutoff h

NSS

=

p

tot_SS

= p

op

+ h

SS

p

op

= 13.8 bar 9. Pressure developed due to valve

h

SS

= 12.0 bar shutoff in the time interval At > t

c

p

tot_SS

= 25.8 bar

p

tot_NSS

=

p

op

=

h

NSS

=

p

tot_NSS

=

a

L

c

=

2

t

t

t

t

t

t

t

t

t

t

t

A

=

A

=

=

A

=

A

=

=

A

A

A

=

A

A

=

A

A

=

c

SS NSS

c SS NSS

c

SS NSS

SS NSS

SS

NSS

NSS

NSS

h h

h h

a

L

with

a

L

h h

a

L

h h

h

g

v a

a

L

g

v a

h

L

g

v

h

g

v L

h

1

2

1 2

2

2

2

2

t

t

A

=

c

SS NSS

h h

Rev. cjc 30.01.2014

8.- Pressure increment due to water

hammer produced by a Not Sudden

Shutoff "NSS"

Michad

For a shutoff time greater than the

critical time, the Michaud relation can

h

NSS

: presure increment in a Non Joujovsky

Sudden Shutoff

h

SS

: Pressure increment in a Sudden

Shutoff (Joukovsky)

t

c

: Critical time

At : Valver closing time

Valve closing time

5.0 s E

t

= 2,059,397 bar

s

Pressure ncrement (NSS) Bulk modulus and density of water

h

SS

*( t

c

/ At ) K = 20,684 bar

12.0 bar

2.4 s

5.0 s

5.7 bar

9. Pressure developed due to valve

shutoff in the time interval At > t

c

p

op

+ h

NSS

13.8 bar

5.7 bar

19.5 bar

g

v a

h

SS

A

=

a

L

c

=

2

t

t A

A

=

g

v L

h

NSS

2

t

t

A

=

c

SS NSS

h h

t

t

A

=

c

SS NSS

h h

Water hammer [2] Tyler, page 228

Maximum pressure developed in a water pipeline with a pressure "p", if a valve is closed nearly instantly or pumps discharging into the line are

all stoped at the same instant. Pipe data is: "steel", "dn", "sch", "L". The water flow rate is "Q". What is the maximum pressure developed if

the valve closes in a time "At"?

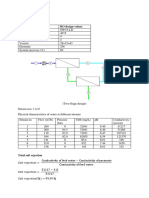

1. Data, SI Pipe section 3.-Speed of sound in water

Tyler data in Anex A (This page, below) A = (pi()/4)*d^2

d = 0.2027 m

Operating pressure and flowrate A = 0.0323 m

2

p = 15.6 bar Material data c: speed of sound (m/s)

Q = 0.0300 m

3

/s Bulk modulus and density of water K: water bulk modulus (Pa)

Pipe data K = 20,684 bar : water density (kg/m)

Material: PEAD = 1,000 kg/m c

d

n

= 8 in Steel pipe elasticity module K =

sch = 40 - E

t

= 2,068,428 bar

=

L = 3000.0 m c =

Valve closing time 2. Fluid velocity

At = 2.8 s v = Q / A

Pipe dimensions Q= 0.0300 m

3

/s

d

i

= Pipe_Imp_CS_Dint_dn_sch A = 0.0323

m

2

d

i

= 202.74 mm v = 0.93 m/s

s = Pipe_Imp_CS_Thickness_dn_sch

s = 8.18 mm

5.- Pressure increment due to water 6.- Maximum pressure developed due to 8.- Pressure increment due to water

hammer produced by a sudden shutoff. a sudden shutoff hammer produced by a Not sudden

shutoff.

The pressure increment can be calculated p

max

= p

op

+ h For a shutoff time greater than the

with Joukovsky elasticity theory p

op

= 15.6 bar critical time, the Michaud relation can

h = 12.0 bar be used.

p

max

= 27.5 bar

h : pressure increment [mwc] p

max

= 399.2 psi

a : wave velocity [m/s]

Av : speed variation [m/s] 7. Critical time AP: presure increment (mwc)

Av =

v

final

- v

initial

L : pipe length (m)

g : acceleration of gravity m/s Maximum over- pressure or under-

Av :speed change

The pressure change "h" is pressure are obtained when the g : acceleration of gravity m/s

h =

(- a * Av ) / g shutoff time "At", is less or equal to At: shutoff time interval (s)

a = 1287.5 m/s the critical time "t

c

",

Av = vf - vi m/s AP =

vf = 0 m/s h =

vi = 0.93 m/s L =

Av =

-0.93 m/s t

c

= 2 * L / a a =

g = 9.81 m/s L = 3,000 m

At =

g

v a

h

A

=

K

c =

a

L

c

=

2

t

h = 122 mwc a = 1287.5 m/s AP =

h = 12.0 bar

t

c

=

4.7 s

Anex A

Anex A. Tyler data Data, SI Tyler results

p = 200 psi p = 13.8 bar

d

n

= 8 in d

n

= 8 in 5.- Celerity

sch = 40 sch = 40 a =

L = 5,000 ft L = 1,524 m Calculated value

Q = 2,800 gpm Q = 0.177

m

3

/s

a =

t = 5 s t = 5 s 6.- Pressure increment due to water

Bulk modulus of water hammer produced by a sudden shutoff.

k = 300,000 psi k = 20,684 bar h =

= 1000 kg/m k = 2,068 Mpa Calculated value

Pipe elasticity module h =

E = 30,000,000 psi E = 2,068,428 bar 8. Pressure developed due to valve

E = 206,843 Mpa shutoff in the time interval At > t

c

p

max

=

d

i

= 202.74 mm Calculated value

s = 8.18 mm

p

max

=

g = 9.80665 m/s

Water hammer [2] Tyler, page 228

Maximum pressure developed in a water pipeline with a pressure "p", if a valve is closed nearly instantly or pumps discharging into the line are

all stoped at the same instant. Pipe data is: "steel", "dn", "sch", "L". The water flow rate is "Q". What is the maximum pressure developed if

the valve closes in a time "Dt"?

1. Data, SI Pipe section 3.-Water speed of sound

Tyler data in Anex A (This page, below) A = (pi()/4)*d^2

d = 0.20274 m

Operating pressure and flowrate A = 0.03228262 m2

p = 13.78952 bar Material data c: speed of sound (m/s)

Q = 0.17665256 m3/s Bulk modulus and density of water K: water bulk modulus (Pa)

Pipe data K = 20684.28 bar r: water density (kg/m)

Material: Carbon steel r = 1000 kg/m c

dn = 8 in Steel pipe elasticity module K =

sch = 40 - Et = 2068428 bar r =

L = 1524 m c =

Valve closing time 2. Fluid velocity

Dt = 5 s v = Q / A

Pipe dimensions Q= 0.17665256 m3/s

di = Pipe_Imp_CS_Dint_dn_sch A = 0.03228262 m2

di = 202.74 mm v = 5.47206402 m/s

s = Pipe_Imp_CS_Thickness_dn_sch

s = 8.18 mm

5.- Pressure increment due to water 6.- Maximum pressure developed due to 8.- Pressure increment due to water

hammer produced by a sudden shutoff. a sudden shutoff hammer produced by a Not sudden

shutoff.

The pressure increment can be calculated pmax = pop + h For a shutoff time greater than the

with Joukovsky elasticity theory pop = 13.8 bar critical time, the Michaud relation can

h = 70.5 bar be used.

pmax = 84.2 bar

h : pressure increment [mwc] pmax = 1221.8 psi

a : wave velocity [m/s]

Dv : speed variation [m/s] 7. Critical time DP: presure increment (mwc)

Dv = vfinal - vinitial L : pipe length (m)

g : acceleration of gravity m/s Maximum over- pressure or under- Dv :speed change

The pressure change "h" is pressure are obtained when the g : acceleration of gravity m/s

h = (- a * Dv ) / g shutoff time "Dt", is less or equal to Dt: shutoff time interval (s)

a = 1287.476435 m/s the critical time "tc",

Dv = vf - vi m/s DP =

vf = 0 m/s h =

vi = 5.47 m/s L =

Dv = -5.47 m/s tc = 2 * L / a a =

g = 9.80665 m/s L = 1524 m Dt =

h = 718.4 mwc a = 1287.5 m/s DP =

h = 70.45 bar tc = 2.4 s

Anex A

Anex A. Tyler data Data, SI Tyler results

p = 200 psi p = 13.78952 bar

dn = 8 in dn = 8 in 5.- Celerity

sch = 40 sch = 40 a =

L = 5000 ft L = 1524 m Calculated value

Q = 2800 gpm Q = 0.17665256 m3/s a =

t = 5 s t = 5 s 6.- Pressure increment due to water

Bulk modulus of water hammer produced by a sudden shutoff.

k = 300000 psi k = 20684.28 bar h =

r = 1000 kg/m k = 2068.428 Mpa Calculated value

Pipe elasticity module h =

E = 30000000 psi E = 2068428 bar 8. Pressure developed due to valve

E = 206842.8 Mpa shutoff in the time interval Dt > tc

pmax =

di = 202.74 mm Calculated value

s = 8.18 mm pmax =

g = 9.80665 m/s

Rev. cjc 30.01.2014

Maximum pressure developed in a water pipeline with a pressure "p", if a valve is closed nearly instantly or pumps discharging into the line are

all stoped at the same instant. Pipe data is: "steel", "dn", "sch", "L". The water flow rate is "Q". What is the maximum pressure developed if

3.-Speed of sound in water 4.- Celerity

c: speed of sound (m/s)

K: water bulk modulus (Pa)

: water density (kg/m) a : celerity (wave velocity) (m/s)

(K / )^0.5 c: speed of sound (m/s)

2.1E+09 Pa d: inside pipe diameter (mm)

1000 kg/m s: minimum wall thickness (mm)

1438.2 m/s K: water bulk modulus (bar)

a = c / (1 + (K/E

t

) * (d/s) )^(0.5)

c = 1438.2 m/s

K = 2.1E+09 Pa

E

t

= 2.1E+11 Pa

d = 202.74 mm

s = 8.18 mm

a = 1287.5 m/s

8.- Pressure increment due to water

AP =

h *( t

c

/ At )

hammer produced by a Not sudden h = 12.0 bar

t

c

= 4.7 s

For a shutoff time greater than the

At =

2.8 s

critical time, the Michaud relation can

AP =

19.91 bar

9. Pressure developed due to valve

shutoff in the time interval At > t

c

At =

2.8 s

AP: presure increment (mwc)

L : pipe length (m) p

max

= p

op

+ h

Av :speed change

p

op

= 15.6 bar

g : acceleration of gravity m/s h = 19.9 bar

At: shutoff time interval (s)

p

max

= 35.5 bar

p

max

= 514.5 psi

AP =

2 * h * L / (a * At) L =

12.0 bar Av =

3000.0 m At =

1287.5 m/s

AP =

2.8 s

AP =

|

|

.

|

\

|

+

=

s

d

E

K

c

a

t

1

K

c =

|

|

.

|

\

|

+

=

s

d

E

K

a

t

1

2 . 1483

t

t

t

t

A

A

= A

A

A

= A

A

A

= A

A

=

A

= A

g

v L

P

L

g

v

P

a

L

g

v a

P

g

v a

h

a

L

h P

2

2

2

2

19.9 bar

1287.9 m/s

Calculated value

1287.5 m/s

6.- Pressure increment due to water

hammer produced by a sudden shutoff. Bulk modulus of water

70.5 bar k = 22000 bar

Calculated value

12.0 bar Pipe elasticity module

8. Pressure developed due to valve E = 2068428 bar

shutoff in the time interval At > t

c

44.7 bar Note 1.

Calculated value Tyler error

35.5 bar 484 + 200 = 684 (psi) = 47.16 (bar)

Carlos J. Cruz. Rev.15.01.2012

Maximum pressure developed in a water pipeline with a pressure "p", if a valve is closed nearly instantly or pumps discharging into the line are

all stoped at the same instant. Pipe data is: "steel", "dn", "sch", "L". The water flow rate is "Q". What is the maximum pressure developed if

3.-Water speed of sound 4.- Celerity

c: speed of sound (m/s)

K: water bulk modulus (Pa)

r: water density (kg/m) a : celerity (wave velocity) (m/s)

(K / r )^0.5 c: speed of sound (m/s)

2.068E+09 Pa d: inside pipe diameter (mm)

1000 kg/m s: minimum wall thickness (mm)

1438.203 m/s K: water bulk modulus (bar)

a = c / (1 + (K/Et) * (d/s) )^(0.5)

c = 1438.203045 m/s

K = 2068428000 Pa

Et = 2.06843E+11 Pa

Note 1

d = 202.74 mm

s = 8.18 mm

a = 1287.5 m/s

8.- Pressure increment due to water DP = h *( tc / Dt )

hammer produced by a Not sudden h = 70.4515348 bar

tc = 2.367421971 s

For a shutoff time greater than the Dt = 5 s

critical time, the Michaud relation can DP = 33.35770227 bar

9. Pressure developed due to valve

shutoff in the time interval Dt > tc

Dt = 5 s

DP: presure increment (mwc)

L : pipe length (m) pmax = pop + h

Dv :speed change pop = 13.78952 bar

g : acceleration of gravity m/s h = 33.35770227 bar

Dt: shutoff time interval (s) pmax = 47.14722227 bar

pmax = 683.8123774 psi

2 * h * L / (a * Dt)

70.45 bar

1524.00 m

1287.48 m/s

5.00 s

33.4 bar

1287.9 m/s

Calculated value

1287.4764 m/s

6.- Pressure increment due to water

hammer produced by a sudden shutoff. Bulk modulus of water

70.5 bar k = 22000 bar

Calculated value

70.451535 bar Pipe elasticity module

8. Pressure developed due to valve E = 2068428 bar

shutoff in the time interval Dt > tc

44.67 bar Note 1.

Calculated value Tyler error

47.147222 bar 484 + 200 = 684 (psi) = 47.16 (bar)

Carlos J. Cruz. Rev.15.01.2012

AP = h * 2 * L / (a * At)

h = 122.0 m

L = 3000.0 m

a = 1287.5 m/s

At =

2.8 s

AP =

203.1 m

AP =

19.9 bar

2 * L * Av / (g * At)

3000.0 m/s

0.93 s

2.8 s

203.1 m

19.9 bar

|

|

.

|

\

|

+

=

s

d

E

K

c

a

t

1

t A

A

= A

g

v L

P

2

t

t

t

t

A

A

= A

A

A

= A

A

A

= A

A

=

A

= A

g

v L

P

L

g

v

P

a

L

g

v a

P

g

v a

h

a

L

h P

2

2

2

2

|

|

.

|

\

|

+

=

s

d

E

K

c

a

t

1

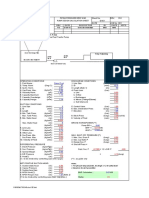

Pehmco water-hammer [3], page 7.21

1. Data Pipe section

Operating pressure and flowrate A = (pi()/4)*d^2

p

op

= 158.63 mwc d = #VALUE! m

p

op

= 15.56 bar A = #VALUE!

m

2

Q = 30 l/s

Q = 0.030

m

3

/s

3. Material data

Pipe data Bulk modulus and density of water

Material: HDPE PE80 k = 22,000 bar

d

n

= 8 in

=

1000 kg/m

PN 17 bar Pipe elasticity module

L = 3000 m E

p

= 7,845 bar

Valve closing time 784.532 MPa

At = < Tc 4. Fluid velocity

2. Pipe dimensions and section v = Q / A

d

e

= Pipe_Imp_HDPE_PE80_Dext_Dn Q= 0.0300

m

3

/s

d

e

= N/A mm A = #VALUE!

m

2

s = Pipe_Imp_HDPE_PE80_Thickness_Dn_PN v = #VALUE! m/s

s = N/A mm

d

i

=

d

i

=

N/A mm

7.- Pressure increment due to water 8.- Maximum pressure developed due to

hammer produced by a sudden shutoff. a sudden shutoff (Joukovsky)

For this case, the pressure increment can be P

max_Jouk

= p

op

+ h

Jouk

calculated with Joukovsky elasticity theory p

op

= 15.6 bar

h

Jouk

= #VALUE! bar

P

max_Jouk

= #VALUE! bar

h

Jouk

: pressure increment, Joukovsky #VALUE!

a : wave velocity [m/s]

Av : speed variation [m/s] 9. Critical time

Av =

v

final

- v

initial

g : acceleration of gravity m/s Maximum over- pressure or under-

The pressure change "h" is pressures are obtained when the

h

Jouk

=

(- a * Av ) / g

m

shutoff time "At", is less or equal to

a = #VALUE! m/s the critical time "t

c

",

Av = vf - vi m/s

vf = 0 m/s

vi = #VALUE! m/s

Av =

#VALUE! m/s t

c

= 2 * L / a

g = 9.81 m/s L = 3,000 m

h

Jouk

= #VALUE! mwc a = #VALUE! m/s

h

Jouk

=

#VALUE! bar

t

c

=

#VALUE! s

a

L

c

=

2

t

g

v a

h

Jouk

A

=

Approximate bulk modulus Steel elasticity modulus

E = 2.95E+07

Water 2.2109Pa (value increases at higher pressures) E = 2.03E+11

K = 2.20E+09 Pa E = 2.03E+06

K = 22,000 bar

Water bulh modulus

Air 1.42105Pa (adiabatic bulk modulus) Water

Air 1.01105Pa (constant temperature bulk modulus) K = 2.06E+04

K = 2.2E+09

K = 22,000

g = 9.80665 m/s

Rev. cjc 30.01.2014

5.-Speed of sound in water a : celerity (wave velocity) (m/s)

c: speed of sound (m/s)

d: inside pipe diameter (mm)

s: minimum wall thickness (mm)

c: speed of sound (m/s) K: water bulk modulus (bar)

K: water bulk modulus (Pa) a = c / (1 + (K/E

p

) * (d/s) )^(0.5)

: water density (kg/m) c = 1483.2 m/s

c (K / )^0.5 K = 2.20E+09 Pa

K = 2.2E+09 Pa E

p

= 7.8E+08 Pa

= 1000 kg/m d = N/A mm

c = 1483.2 m/s s = N/A mm

6.- Celerity a = #VALUE! m/s

K

c =

|

|

.

|

\

|

+

=

s

d

E

K

c

a

p

1

HDPE elasticity modulus

psi PEEC

Pa E

p

= 8,000 kp/cm

bar

E

p

=

7.8E+08 Pa

E

p

=

7,845 bar

kp/cm

Pa

bar

Slurry hammer [8]

Data

Operating pressure and flowrate Water

p

op

=

158.63 mwc E

L

: 2.2E+09

p

op

=

15.56 bar

L

= 1000

Q = 30 l/s

Q = 0.030 m

3

/s Valve closing time

At =

0.0

Pipe data

Material: HDPE PE80

d

n

= 8 in

PN 10 bar

L = 3000 m

E

P

: 7.8E+08 Pa

Slurry

C

v

= 0.4 -

s

= 1800 kg/m

L

= 1000 kg/m

E

S

: 1.17E+11 Pa

(Copper)

Celerity of slurries Slurry celerity calculation

a = ( ( ( (C

v

/

s

) + ((1-C

v

) / (

L

)) )*E

L

) / (1 - C

v

+ E

L

/E

s

* C

v

+ E

L

* D / (E

P

* e)) )^0.5

Eq. 20, [8], page 340 C

v

= 0.4

s

= 1800

L

= 1000

E

P

: 7.85E+08

E

L

: 2.2E+09

a

m2

: Celerity of an heterog. E

S

: 1.2E+11

C

v

: Solids concentration vol. D : N/A

s

: Solids density e : N/A

L

: Water density a = #VALUE!

E

P

: Elastic modulus pipe mat.

E

L

: Elastic modulus of liquid

E

S

: Elastic modulus of solids

D : Pipe diameter

e : Pipe wall thickness

e E

D E

C

E

E

C

E

C C

a

P

L

v

S

L

v

L

L

v

s

v

m

+ +

|

|

.

|

\

|

+

=

1

1

2

Pressure increment for heterogeneous sluryy, due to suddenly valve shut-off

In engineering practice the initial hammer pressure can usually be used to substitute

the slurry hammer pressure Eq. 33, page 344

P : slurry hammer pressure [Pa]

a

m

: celerity of mixture (slurry) [m/s]

u

m0

: velocity ofmixture (slurrry) before valve closure [m/s]

L

: liquid density [kg/m]

S

: solids density [kg/m]

C

V

: Volume concentration [ - ]

P = a

m

* u

m0

*

L

*

S

/ ( (1 - C

V

) *

S

+ C

V

*

L

)

a

m

= #VALUE! m/s

u

m0

= #VALUE! m/s

L

= 1000

S

= 1800

C

V

= 0.4

P = #VALUE! Pa

P = #VALUE! bar

Maximum pressure developed due to a sudden shutoff

P

max_Jouk

= p

op

+ P

P

op

= 15.56 bar

P = #VALUE! bar

P

max_Jouk

= #VALUE! bar

( )

L V S V

S L m m

C C

u a

P

+

=

1

0

Rev. cjc 30.01.2014

Pipe dimensions and section

Pa

d

e

=

Pipe_Imp_HDPE_PE80_Dext_Dn

kg/m

d

e

=

N/A mm

s = Pipe_Imp_HDPE_PE80_Thickness_Dn_PN

s = N/A mm

s d

i

= Pipe_Imp_HDPE_PE80_Dint_Dn_PN

d

i

= N/A mm

A = (pi()/4)*d^2

d = #VALUE! m

A = #VALUE! m

2

Fluid velocity

v = Q / A

Q= 0.0300 m

3

/s

A = #VALUE!

m

2

v = #VALUE! m/s

( ( ( (C

v

/

s

) + ((1-C

v

) / (

L

)) )*E

L

) / (1 - C

v

+ E

L

/E

s

* C

v

+ E

L

* D / (E

P

* e)) )^0.5

-

kg/m

kg/m

Pa Pipe : HDPE

Pa Liquid: Water

Pa Solids: copper

mm

mm

m/s

[9]

a =

a: wave velocity

C: speed of sound

k: water bulk modulus

E:pipe elasticity modulus

DR: dimension Ratio

c =

k =

E

PVC 12454

=

E

PE 3408

=

a)

Av =

Material

DR =

Celerity

a =

c =

K =

E =

DR =

a =

Surge pressure

Ps =

a =

Av =

g =

Ps =

b)

Av =

Material

DR =

Celerity

a =

c =

K =

E =

DR =

a =

Surge pressure

Ps =

a =

Av =

g =

Ps =

a = c / ( 1 + (k/E) * (DR-2) )^0.5

a: wave velocity

C: speed of sound

k: water bulk modulus

E:pipe elasticity modulus

DR: dimension Ratio

c = 4,660 fps

k = 300,000 psi

E

PVC 12454

= 400,000 psi

E

PE 3408

= 115,000 psi

a)

Av = 2 fps

Material PVC 12454

DR = 25

Celerity

a = c / ( 1 + (k/E) * (DR-2) )^0.5

c = 4,660 fps

K = 300,000 psi

E = 400,000 psi

DR = 25

a = 1,091 fps

Surge pressure

Ps = a * AV / (2.31*g)

a = 1,091 fps

Av = 2 fps

g = 32.2 ft/s

Ps = 29.3 psi

( ) 2 1 +

=

DR

E

k

c

a

b)

Av = 2 fps

Material PE 3408

DR = 11

Celerity

a = c / ( 1 + (k/E) * (DR-2) )^0.5

c = 4,660 fps

K = 300,000 psi

E = 115,000 psi

DR = 11

a = 942 fps

Surge pressure

Ps = a * AV / (2.31*g)

a = 942 fps

Av = 2 fps

g = 32.2 ft/s

Ps = 25.3 psi

Tehmco

a

m2

: Celerity of an heterogeneous fluid

C

v

: Solids concentration by volume

s

: Solids density

L

: Water density

E

P

: Elastic moduli of pipe material

E

L

: Elastic modulus of liquid

E

S

: Elastic modulus of solids

T

: tension stress on the pipe wall

D : Pipe diameter

e : Pipe wall thickness

Eq. 20, [8], page 340

[8] http://tech.scichina.com:8082/sciEe/fileup/PDF/98ye0337.pdf

e E

D E

C

E

E

C

E

C C

a

P

L

v

S

L

v

L

L

v

s

v

m

+ +

|

|

.

|

\

|

+

=

1

1

2

Pressure increment for heterogeneous sluryy, due to suddenly valve shut-off

( )

L V S V

S L m m

C C

u a

P

+

=

1

0

( )

w v s v

s w

C C

v a

P

+

=

1

[10]

http://www.plasticpipe.org/pdf/chapter06.pdf

Design of PE Piping Systems

Chapter 6, page 161

PE pipes can safely tolerate the commonly observed maximum peak

temporary surge pressure of twice the steady state condition.

Repetead cyclel loads

Long-term strength of PE pipes is not adversely affected by repeated

cyclic load. Thus, PE pipes are very fatigue resistant.

Recurring surge pressures

Negative pressures

Design principles

Recurring surge pressures

Temporary surge pressures

PE pipes can safely tolerate the commonly observed maximum peak

temporary surge pressure of twice the steady state condition.

Repetead cyclel loads

Long-term strength of PE pipes is not adversely affected by repeated

cyclic load. Thus, PE pipes are very fatigue resistant.

Occasional surge pressures

Recurring surge pressures

Negative pressures

Design principles

Occasional surge pressures

Recurring surge pressures

ed _compensat temerature tot

surge sustained tot

2 PR P

P P P

s

+

=

ed _compensat temerature tot

5 . 1 PR P s

[2] Tyler

Power generation calculations reference

Tyler G. Hicks., P.E., Editor

The McGraw-Hill Engineering reference guide series

1985

Water-hammer in liquid pipelines. Page 228

[3] Productos PECC http://issuu.com/rockoicm/docs/catalogo_final_tehmco

Tehmco S.A.

Example page 7.21

[4] Heat ans mass transfer

Anthony F. Mills

Irwin, 1995

[5] Heat transfer

J. P. Holman

McGraw-Hill, 1989

[6] Water Hammer

by Robert Pelikan

April 1, 2005

[7]

[8] http://tech.scichina.com:8082/sciEe/fileup/PDF/98ye0337.pdf

[9]

http://www.plasticengineeredproducts.com/manufacturers/unibell/pubs/uni-tr-7.pdf

[10] http://www.plasticpipe.org/pdf/chapter06.pdf

Design of PE Piping Systems

http://issuu.com/rockoicm/docs/catalogo_final_tehmco

Mendiluce

Altura piezomtrica 158.67 m

Velocidad de rgimen del agua 0.93 m/s

Aceleracion de la gravedad 9.81 m/s2

Longitud de la conduccin 3000 m

Coeficiente C 1 adim

Coeficiente K 1 adim

Altura manomtrica 158.714083 m

Tiempo 2.79192461 seg

You might also like

- Water Hammer: Design CriteriaDocument3 pagesWater Hammer: Design CriteriamazharimechNo ratings yet

- PENSTOCK Optimization ResearchDocument3 pagesPENSTOCK Optimization ResearchAnjan SigdelNo ratings yet

- Calculation of Ejector Jet Engine: Thrust 119.8 NDocument2 pagesCalculation of Ejector Jet Engine: Thrust 119.8 Njbrferracin782No ratings yet

- Agitator CalDocument2 pagesAgitator Calvazzoleralex6884No ratings yet

- Oily Water SeparatorDocument2 pagesOily Water SeparatorTun Naing WinNo ratings yet

- Purpose: The Purpose of This Document Is To Carry Out Hydraulic CalculationDocument14 pagesPurpose: The Purpose of This Document Is To Carry Out Hydraulic CalculationEkundayo John100% (1)

- Control Valve Sizing - EnggcyclopediaDocument4 pagesControl Valve Sizing - EnggcyclopediaazitaggNo ratings yet

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocument5 pagesGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- Water HammerDocument3 pagesWater HammerSrinivas ReddyNo ratings yet

- Nss CalculatorDocument4 pagesNss CalculatorZoebair100% (1)

- Pump (English) TemplateDocument1 pagePump (English) TemplateMichael HaiseNo ratings yet

- 04-04-2019 Surge Tank Design Calculation ReportDocument16 pages04-04-2019 Surge Tank Design Calculation ReportCloradoJuniorNo ratings yet

- PumpDocument3 pagesPumpfazila fauziNo ratings yet

- Design of AgitatorDocument3 pagesDesign of Agitatorkaps12No ratings yet

- Design of AgitatorDocument3 pagesDesign of AgitatorManish PatelNo ratings yet

- Water HammerDocument3 pagesWater HammerSrinivas ReddyNo ratings yet

- Valve Sizing CalculationDocument7 pagesValve Sizing CalculationSteve Wan100% (1)

- Filter Separator SizingDocument3 pagesFilter Separator SizingChem.EnggNo ratings yet

- Hydrodynamic Calculation Needle ValveDocument23 pagesHydrodynamic Calculation Needle Valvemet-calcNo ratings yet

- Type k1 (Re 1) NP (Re 10 5) : Anchor 0.7 LaminarDocument3 pagesType k1 (Re 1) NP (Re 10 5) : Anchor 0.7 LaminarRobinNo ratings yet

- Restriction Orifice Final CalculationDocument1 pageRestriction Orifice Final CalculationJasperTanNo ratings yet

- Pipe SizingDocument2 pagesPipe Sizinggroup2sd1314No ratings yet

- Compressor Settle Out PressureDocument1 pageCompressor Settle Out PressureAhmed GattoufiNo ratings yet

- DesignDocument2 pagesDesignhmxNo ratings yet

- Process Calculation For FREYLIT CPI Oil SeparatorDocument4 pagesProcess Calculation For FREYLIT CPI Oil SeparatorRajdeepsinhNo ratings yet

- Vacum Calculation ExampleDocument18 pagesVacum Calculation ExampleAgung SiswahyuNo ratings yet

- Me 2204 Fluid Mechanics and Machinery LiDocument8 pagesMe 2204 Fluid Mechanics and Machinery LiSheryll de GuzmanNo ratings yet

- GEMI Equations ToolDocument10 pagesGEMI Equations TooljnmanivannanNo ratings yet

- Restriction Orifice Sizing Calculation: P (kg/ms2)Document2 pagesRestriction Orifice Sizing Calculation: P (kg/ms2)SiLan Subramaniam100% (1)

- Total Length Calcs For Pipes Valves and FittingsDocument6 pagesTotal Length Calcs For Pipes Valves and FittingsImtinan MohsinNo ratings yet

- Water Hammer: Values For CalculationDocument3 pagesWater Hammer: Values For CalculationEng-CalculationsNo ratings yet

- Power CalculationDocument4 pagesPower CalculationGunasekaranNo ratings yet

- Fire Relief Dynamic StudyDocument2 pagesFire Relief Dynamic StudyImtinan MohsinNo ratings yet

- Tank SizingDocument2 pagesTank SizingsamehNo ratings yet

- Fuel Oil Unloading, Storage and Transfer System Storage Volume Calculation of Dyke AreaDocument2 pagesFuel Oil Unloading, Storage and Transfer System Storage Volume Calculation of Dyke Areaananyo_senguptaNo ratings yet

- Expansion Tank Capacity Calculation SheetDocument5 pagesExpansion Tank Capacity Calculation SheetDEX TERRNo ratings yet

- 3.4.B.07.03 Static MixerDocument1 page3.4.B.07.03 Static Mixerwado11100% (1)

- Data Solution: C F L DDocument27 pagesData Solution: C F L DJMVNo ratings yet

- CO2 Condenser 02-03-2023-15 PMDocument37 pagesCO2 Condenser 02-03-2023-15 PMahmad santosoNo ratings yet

- Water Pressure Loss Calculator Colebrook WhiteDocument5 pagesWater Pressure Loss Calculator Colebrook Whitebahus911No ratings yet

- Channel. 4. - Circular Channel With. Constant Manning Friction CoefficientDocument15 pagesChannel. 4. - Circular Channel With. Constant Manning Friction CoefficientJuan Pablo ApazaNo ratings yet

- Surge TankDocument26 pagesSurge TankAmar WadoodNo ratings yet

- Bahan Tugas 3 Buat EXCEL Perhitungan PompaDocument37 pagesBahan Tugas 3 Buat EXCEL Perhitungan PompaIhsan Wiratama100% (1)

- Existing:-Pitch Blade Turbine AgitatorDocument5 pagesExisting:-Pitch Blade Turbine AgitatorPrathmesh Gujarati100% (1)

- Piping Pressure Drop and Pump Design Calculation Sheet: R-0 07-06-18 Issued For Information MRB MRBDocument2 pagesPiping Pressure Drop and Pump Design Calculation Sheet: R-0 07-06-18 Issued For Information MRB MRBmoh. rusli bahtiarNo ratings yet

- Pressure Drop Calc - STDDocument25 pagesPressure Drop Calc - STDhardik5818No ratings yet

- Equipment Name Sheet No. 1 of 3 Tag No.: Hydraulic Power CalcDocument2 pagesEquipment Name Sheet No. 1 of 3 Tag No.: Hydraulic Power Calcbagus handoko0% (1)

- FLB Tank Pump Calculation 7/28/1998 P1: Document No.: Title: Sign Date Made by Rev: Checked by Contract No.: QX0032Document3 pagesFLB Tank Pump Calculation 7/28/1998 P1: Document No.: Title: Sign Date Made by Rev: Checked by Contract No.: QX0032Ekundayo JohnNo ratings yet

- (Centrifugal Pump Calculation For DM PW Water To R-401Document20 pages(Centrifugal Pump Calculation For DM PW Water To R-401Ashish PawarNo ratings yet

- Hydraulic Calculation For Pipeline PumpsDocument12 pagesHydraulic Calculation For Pipeline PumpsDEEPAK PAL100% (1)

- Water Hammer. Examples Tyler - PehmcoDocument12 pagesWater Hammer. Examples Tyler - PehmcoZwingerfeltNo ratings yet

- Formulas and Calculations For Drilling, Production and Work-Over - Norton J. LapeyrouseDocument6 pagesFormulas and Calculations For Drilling, Production and Work-Over - Norton J. LapeyrouseElias GonzalezNo ratings yet

- 5 - Hydro Power PlantsDocument73 pages5 - Hydro Power Plants2003_335100% (1)

- Pump. Slurry Selection Typical WarmanDocument44 pagesPump. Slurry Selection Typical WarmanJuan Pablo Apaza100% (1)

- Penstock Thickness CalculationDocument2 pagesPenstock Thickness Calculationrakesh1987_careers100% (6)

- Blower Air LineDocument52 pagesBlower Air LineJuan Pablo ApazaNo ratings yet

- Feuille Calcul Gas Pipeline Blowdown TimeDocument6 pagesFeuille Calcul Gas Pipeline Blowdown TimeNic RicNo ratings yet

- Drilling Hydraulics ADocument63 pagesDrilling Hydraulics Asryn89100% (3)

- Water Hammer Analysis: Sample ProblemsDocument15 pagesWater Hammer Analysis: Sample ProblemsZedrickTrinidad0% (1)

- Problem Set 1.1Document8 pagesProblem Set 1.1meenuraj979100% (3)

- Design of Various Components of An Open Circuit Blower Tunnel Without Exit DiffuserDocument6 pagesDesign of Various Components of An Open Circuit Blower Tunnel Without Exit DiffuserprashasscribdNo ratings yet

- Total Compressed Air Solution 1 PDFDocument12 pagesTotal Compressed Air Solution 1 PDFAsep Ahmad ToniNo ratings yet

- FME 002 Fluid Mechanics TrainerDocument1 pageFME 002 Fluid Mechanics TrainerInquiry XEEPLNo ratings yet

- Ostwald Viscometer STUDYDocument3 pagesOstwald Viscometer STUDYAravind PVNo ratings yet

- Installation: Pressure Reducing Valves EuropressDocument2 pagesInstallation: Pressure Reducing Valves EuropressTahir SaeedNo ratings yet

- PICV-Fig1932 IOM-Hatts PDFDocument4 pagesPICV-Fig1932 IOM-Hatts PDFSujit RajanNo ratings yet

- Biogas Dehumidification System - ENDocument4 pagesBiogas Dehumidification System - ENkiller120No ratings yet

- HHI - 1918 - FWG - Final - 0311 ADocument84 pagesHHI - 1918 - FWG - Final - 0311 ANazar MonshukNo ratings yet

- Centrifugal Pump Problems PDFDocument18 pagesCentrifugal Pump Problems PDFAleidinNo ratings yet

- Chapter 2 Pure SubstanceDocument52 pagesChapter 2 Pure SubstanceSyafiq AimanNo ratings yet

- Three Phase SeparatorsDocument44 pagesThree Phase SeparatorsAtif100% (2)

- Manometers DiscussionDocument3 pagesManometers DiscussionIshan Madhusanka82% (33)

- Week 3: Ideal Gases and Ideal Gas Laws: ObjectivesDocument9 pagesWeek 3: Ideal Gases and Ideal Gas Laws: ObjectivesMarc Jairro GajudoNo ratings yet

- Layers of The AtmosphereDocument25 pagesLayers of The AtmosphereandreasNo ratings yet

- Datasheet HRE E R01 040831Document3 pagesDatasheet HRE E R01 040831Vladimir KirovNo ratings yet

- W20Y 11X BrochureDocument16 pagesW20Y 11X Brochurefd27No ratings yet

- Fluent-Adv Turbulence 15.0 L05 Case StudiesDocument51 pagesFluent-Adv Turbulence 15.0 L05 Case StudiesEnrique FloresNo ratings yet

- Manual de Instrucciones - Milroyal BDocument31 pagesManual de Instrucciones - Milroyal BHendrifel ValbuenaNo ratings yet

- Hydrogen Generator Booster PDFDocument61 pagesHydrogen Generator Booster PDFbabu100% (2)

- Oil TankerDocument11 pagesOil TankerPrabodh GautamNo ratings yet

- Problem 1Document3 pagesProblem 1DANIEL DAVID VALENCIA HARRISNo ratings yet

- Thermofluids Lab Report Centrifugal PumpDocument3 pagesThermofluids Lab Report Centrifugal PumpMohamedNo ratings yet

- Total PVV ListDocument2 pagesTotal PVV Listmohamadsadegh kamali100% (3)

- Fundamentals of The Anaesthetic Machine Final PDFDocument19 pagesFundamentals of The Anaesthetic Machine Final PDFNilam PatelNo ratings yet

- Lubricate and BleedDocument18 pagesLubricate and BleedRoby Rido100% (1)

- Developed Laminar Flow in Pipe Using Computational Fluid DynamicsDocument10 pagesDeveloped Laminar Flow in Pipe Using Computational Fluid Dynamicsyashsaini020No ratings yet

- A15 Cengel - Gráfica de TermodinámicaDocument1 pageA15 Cengel - Gráfica de Termodinámicalolololprogamer0263No ratings yet

- Booklet Ninnelt EnglishDocument16 pagesBooklet Ninnelt EnglishharoonshaikhNo ratings yet

- Selecting Amines For Sweetening Units PDFDocument9 pagesSelecting Amines For Sweetening Units PDFGui Do EspNo ratings yet

- 2007 Vilter VSG Single Screw Compressor - 450 HP MFG: Vilter Model: VSG1801 Stock No: NTSD02 Serial No: 4103Document5 pages2007 Vilter VSG Single Screw Compressor - 450 HP MFG: Vilter Model: VSG1801 Stock No: NTSD02 Serial No: 4103hanner90No ratings yet