Professional Documents

Culture Documents

TALAT Lecture 2301: Design of Members Example 5.4: Axial Force Resistance of Channel Cross Section

Uploaded by

CORE MaterialsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TALAT Lecture 2301: Design of Members Example 5.4: Axial Force Resistance of Channel Cross Section

Uploaded by

CORE MaterialsCopyright:

Available Formats

TALAT Lecture 2301

Design of Members

Axial Force

Example 5.4 : Axial force resistance of channel cross

section

7 pages

Advanced Level

prepared by Torsten Höglund, Royal Institute of Technology, Stockholm

Date of Issue: 1999

EAA - European Aluminium Association

TALAT 2301 – Example 5.4 1

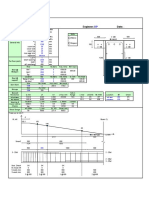

Example 5.4. Axial force resistance of channel cross section

Width/depth b 80 . mm h 100 . mm fo 300 . MPa kN 1000 . newton

E

8 . mm 25 . mm 70000 . MPa MPa 10 . Pa

6

Inner thickness/outstand ti c E G

2.6

Outer/bottom thickness to 3.5 . mm tu 4 . mm γ M1 1.0

Length L 1200 . mm

i 0 .. 8 k 1 .. 3

Nodes no., tli to th i to yk 0.5 . h zi b

co-ordinates,

thickness th 1 ti tl8 ti yk 4 0.5 . h zk 2 0 . mm

y4 0 . mm z2 0.5 . z1

th 4 tu tl4 tu

y0 0.5 . h c z6 0.5 . z1

th 5 th 4 tl5 tl4

y8 y0 z1 z1 0.5 . ( ti to )

yi zi tli th i z7 z1

= = = =

i = mm mm mm mm

0 25 80 3.5 3.5

1 50 77.75 3.5 8

2 50 40 3.5 3.5

3 50 0 3.5 3.5

4 0 0 4 4

5 -50 0 4 4

6 -50 40 3.5 3.5

7 -50 77.75 3.5 3.5

90

8 -25 80 8 3.5

65

40

Nodes i 1 .. rows ( y ) 1 15

Cross-section constants, varying thickness 10

60 30 0 30 60

0 . mm

2

Sectorial ω0

co-ordinates

ω 0 yi .z yi . zi 1 ωi ω ω 0

i 1 i i 1 i

Thicknesses Dti tli Dti tli Dti

to simplify Dti th i tli t1 i tli t2 i t3 i

expressions 2 2 3 3 4

Length of 2 2

elements li yi yi 1 zi zi 1

rows ( y ) 1

tli th i

Area A .l A = 1.233 . 10 mm

3 2

i

2

i =1

rows ( y ) 1

yi 1 . t1 i yi 1 . t2 i . li S z = 8.47 . 10

13 3

First moments Sz yi mm

of area

i =1

TALAT 2301 – Example 5.4 2

TALAT 2301 – Example 5.4 3

rows ( y ) 1

zi 1 . t1 i zi 1 . t2 i . li S y = 4.388 . 10 mm

4 3

Sy zi

i =1

rows ( y ) 1

Sω ω . t1 ω ω . t2 . l S ω = 7.328 . 10 mm

6 4

i 1 i i i 1 i i

i =1

rows ( y ) 1

yi 1 . t1 i 2 . yi 1 . yi yi 1 . t2 i yi 1 . t3 i . li

2 2

Second Iz yi

moments

of area i =1

rows ( y ) 1

zi 1 . t1 i 2 . zi 1 . zi zi 1 . t2 i zi 1 . t3 i . li

2 2

Iy zi

i =1

rows ( y ) 1

2.

2 . ω i 1. ω i . t2 2.

Iω ω i 1

t1 i ω i 1 i

ω i

ω i 1

t3 i . li

Mixed i =1

rows ( y ) 1

I yz yi 1 . zi 1 . t1 i yi 1 . zi zi 1 zi 1 . yi yi 1 . t2 i yi yi 1 . zi zi 1 . t3 i . li

i =1

rows ( y ) 1

I yω yi 1 . ω i 1 . t1 i yi 1 . ω i ω i 1

ω i 1

. y

i

yi 1 . t2 i yi yi 1 . ω i ω i 1

. t3 . l

i i

i =1

rows ( y ) 1

I zω zi 1 . ω i 1 . t1 i zi 1 . ω i ω i 1

ω i 1

. z

i

zi 1 . t2 i zi zi 1 . ω i ω i 1

. t3 . l

i i

i =1

rows ( y ) 1

l Iai . yi yi 1 . zi zi 1

th i . tli . i

2 2

Iai tli th i I yz I yz

Influence of 48 2

thickness li

i =1

rows ( y ) 1 rows ( y ) 1

Iai . zi Iai . yi

2 2

zi 1 yi 1

Iz Iz Iy Iy

2 2

li li

i =1 i =1

rows ( y ) 1

l

th i . tli . i . 1.05 I t = 8.425 . 10 mm

2 2 3 4

It tli th i

12

i =1

Sy

A . z gc I y = 1.325 . 10 mm

2 6 4

z gc z gc = 35.593 mm Iy Iy

A

Sz

A . y gc I z = 2.151 . 10 mm

2 6 4

y gc y gc = 0 mm Iz Iz

A

S y .S z S z.S ω

I yz = 1.816 . 10 I yω = 1.057 . 10 mm

10 4 8 5

I yz I yz mm I yω I yω

A A y

S y .S ω

2

Sω

I ω = 9.438 . 10 mm I zω = 5.294 . 10

9 6 8 5

Iω Iω I zω I zω mm

A A

TALAT 2301 – Example 5.4 4

I zω . I z I yω . I yz I yω . I y I zω . I yz

y sc = 4.668 . 10

14

Shear y sc z sc mm

I y .I z I y .I z

centre 2 2

I yz I yz

z sc = 49.159 mm

z sc . I yω y sc . I zω I w = 4.24 . 10 mm

9 6

Warping Iw Iω

constant

Polar radius

gyration

0

50

Iy Iz 2 2

ip y sc y gc z sc z gc

A

i p = 100 mm 0

0

50

50 0 50

Buckling of stiffened flanges

5.4.5 Local buckling, internal elements i 3 , 5 .. 7

250 . MPa 2

zi 2 .

2 2

ε ε = 0.913 βi yi yi 2 zi

fo tli 1 th i

β 32 220

ρ c. tli ρ c. th i

i

5.4.5 (3) c) ρ c if 22 , 1.0 , t efl t efh

heat-treated i ε β i β

2 i i i i

i

unwelded

ε t efl ρ c. tli t efh ρ c. th i

ε i 1 i i 1 i t efl t efh

i i

ρ c= = =

βi = i mm mm

22.214 0.943 3.302 3.302

25 0.875 3.501 3.501

22.214 0.943 3.302 3.302

5.4.5 Local buckling, outstand elements i 1 , 8 .. 8

1 1

4 4 2 1

tli . th i th i . tli zi 1 .

3 3 2

t fic if tli > th i , , βi yi yi 1 zi

i t fic

i

TALAT 2301 – Example 5.4 5

β 10 24

ρ c. tli ρ c. th i

i

5.4.5 (3) c) ρ c if 6 , 1.0 , t efl t efh

heat-treated i ε β i β

2 i i i i t fic t efl t efh

i i i i

unwelded

ε ρ c= = = =

ε βi = i mm mm mm

3.858 1 6.506 3.5 8

3.858 1 6.506 8 3.5

Reference: Pekoz, T., Flanges of nonuniform thickness.

Aluminium Design Workshop, Cornell University Oct. 1997

Buckling of edge stiffener i 1 .. 2 z2 = 40 mm

t efh t efl t efl t efh t efl

Effective i i i i i

t1 i t efl t2 i

area i 2 2 3

Length of 2 2

elements li yi yi 1 zi zi 1

2 t efl t efh

i i. 2

Area Ar li A r = 269 mm

2

i =1

2

Centre of 1

gravity zr zi 1 . t1 i zi zi 1 . t2 i . li . z r = 69.528 mm

Ar

i =1

Second moment

i 1 .. 2 z2 z1 15 . tl2 th 2 . 0.5 z6 z2 z2 = 25.25 mm

of area

Dti tli Dti tli Dti

Dti th i tli t1 i tli t2 i t3 i

2 2 3 3 4

Length of 2 2

elements li yi yi 1 zi zi 1

2

tli th i

Area A r1 .l A r1 = 328.1 mm

2

i

2

i =1

2

Centre of 1

gravity yr yi 1 . t1 i yi yi 1 . t2 i . li . y r = 45.218 mm

A r1

i =1

TALAT 2301 – Example 5.4 6

Second 2

yi 1 . t1 i 2 . yi 1 . yi yi 1 . t2 i yi 1 . t3 i . li y r . A r1

moments 2 2 2

Ir yi

of area

i =1

z2 z1 . 0.5

I r = 1.668 . 10 mm

4 4

k 6 .. 8 i 0 .. 2 j 0 .. 8

z6 z2

yr zr

mm mm

Left: Cross section for

second moment of areaIr

based on t

Right: Effective cross section areaAr

based on t ef

s1 y3 y5 b1 zr

b 1 = 69.528 mm

I r . th 3

3

s 1 = 100 mm

N r.cr 1.05 . E .

1.5 . s 1 . th 4

3

N r.cr = 52.195 kN

b1 . 1

3

b 1 . th 3

3

f o .A r

Table 5.5 α 0.2 λ 1 0.6 λ c λ c= 1.243

and 5.8 N r.cr

1

0.5 . 1 α . λ c

2

(5.37) φ λ 1 λ c χ r χ r if χ r > 1 , 1 , χ r

2 2

φ φ λ c φ = 1.337

χ r= 0.547

i 1 .. 2 t efl χ .rt efl t efh χ .rt efh

i i i i

i 7 .. 8 t efl χ .rt efl t efh χ .rt efh

i i i i

i 1 .. 8

t efl t efh li

Length of 2 2 i i

elements li yi yi 1 zi zi 1 = = =

mm mm mm

8 t efl t efh 1.913 4.372 25.101

i i. 2

Area A eff li A eff = 904.9 mm 1.805 1.805 38.875

2 3.302 3.302 38.875

i =1

3.501 3.501 50

3.501 3.501 50

Axial force resistance, flexural-torsional buckling 3.302 3.302 38.875

1.805 1.805 38.875

Buckling length l L l = 1200 mm 4.372 1.913 25.101

TALAT 2301 – Example 5.4 7

π .E .I y π .E .I z π .E .I ω

Reference 2 2 2

buckling N Ey N Ez NT G .I t . 1

loads 2 2 2 2

l l l ip

N Ez = 1.03 . 10 kN 0.2 . N Ez

3

N Ey = 635.91 kN N T = 475.37 kN Guess: N

N . N Ez N . NT N .i p z gc . N . N Ey y gc . N . N Ez

2 2 2 2 2

Given N Ey z sc N y sc N 0

Solution N cr minerr( N ) N cr = 348.11 kN

General cross-section

Table 5.5 α 0.35 λ 1 0.4 k2 1

and 5.8

f o . A eff

λ c λ bar λ c λ c= 0.883

N cr

1

0.5 . 1 α . λ c

2

(5.37) φ λ 1 λ c χ φ = 0.974 χ = 0.721

2 2

φ φ λ c

min z z gc max z z gc

Table 5.5 ψ min z z gc = 35.6 mm ψ = 0.11

min z z gc max z z gc

max z z gc = 44.4 mm

2

λ c

2.4 . ψ .

2

Table 5.5 k1 1 k 1 = 0.996

λ c . 1

2 2

1 λ c

fo

5.8.3 (1) N b.Rd χ .k 1 .k 2 . .A N b.Rd = 265.8 kN

γ M1

TALAT 2301 – Example 5.4 8

You might also like

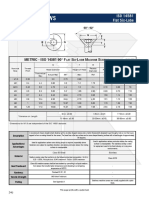

- Ejot Data Sheet jt2 5.50x 25Document2 pagesEjot Data Sheet jt2 5.50x 25Vengatesh HariNo ratings yet

- TALAT Lecture 2301: Design of Members Example 4.1: Bending Moment Resistance of Open Cross Section With Closed PartDocument7 pagesTALAT Lecture 2301: Design of Members Example 4.1: Bending Moment Resistance of Open Cross Section With Closed PartCORE MaterialsNo ratings yet

- Figure UG-34 Forged HeadDocument8 pagesFigure UG-34 Forged Headmiteshpatel191No ratings yet

- HSS Taps PDFDocument26 pagesHSS Taps PDFRavipawarNo ratings yet

- Standard Holes and Tapping ChartDocument1 pageStandard Holes and Tapping ChartajaykrishnaaNo ratings yet

- Shear Deflection Shear Shear Deflection Shear: M/BD M/BDDocument11 pagesShear Deflection Shear Shear Deflection Shear: M/BD M/BDHafeel Ahamed Ashraf AliNo ratings yet

- Bs 3692 2001 Hex NutsDocument4 pagesBs 3692 2001 Hex NutsLuke HathawayNo ratings yet

- Design Test Setup Arrangement For Initial Vertical Pile Load Test A Design of Main Beam Condition 1 - After Loading ConditionDocument33 pagesDesign Test Setup Arrangement For Initial Vertical Pile Load Test A Design of Main Beam Condition 1 - After Loading ConditionSantosh ZunjarNo ratings yet

- Roof Sheeting Technical Data SheetDocument1 pageRoof Sheeting Technical Data SheetSyed AbuthahirNo ratings yet

- Section Properties Comp Beam 12mDocument6 pagesSection Properties Comp Beam 12mSuhas MangaloreNo ratings yet

- Example - Transformed Sections Fig. 1: A y A yDocument1 pageExample - Transformed Sections Fig. 1: A y A yThabiso MotalingoaneNo ratings yet

- NYR (F) GbY 4 Core 0.6-1kV SPDocument1 pageNYR (F) GbY 4 Core 0.6-1kV SPEco'o SetiawanNo ratings yet

- Catalog Kabel Power SupremeDocument1 pageCatalog Kabel Power SupremeEnlynNo ratings yet

- STD-ENGPROC-OTH-039 App.6 - Acceptance Crireria For WeldsDocument2 pagesSTD-ENGPROC-OTH-039 App.6 - Acceptance Crireria For WeldsMichael CovillNo ratings yet

- TALAT Lecture 2301: Design of Members Example 5.3: Resistance of Cross Section With Radiating OutstandsDocument6 pagesTALAT Lecture 2301: Design of Members Example 5.3: Resistance of Cross Section With Radiating OutstandsCORE MaterialsNo ratings yet

- C1 CalcDocument1 pageC1 CalcJayar Valloyas MendietaNo ratings yet

- TALAT Lecture 2301: Design of Members Example 8.1: Torsion Constants For Open Cross SectionDocument6 pagesTALAT Lecture 2301: Design of Members Example 8.1: Torsion Constants For Open Cross SectionCORE MaterialsNo ratings yet

- Broaching Unit enDocument4 pagesBroaching Unit enSiddharth RaviNo ratings yet

- Catalogo Honnen FundicionDocument131 pagesCatalogo Honnen FundicionFEDERICONo ratings yet

- Steel Connection DesignDocument81 pagesSteel Connection DesignAnkan SarkarNo ratings yet

- Liquid Chromatography Separation Mechanisms Zhang SlidesDocument22 pagesLiquid Chromatography Separation Mechanisms Zhang SlidesMandu ManNo ratings yet

- SCRM BrochureDocument6 pagesSCRM BrochureRizwan TonoyNo ratings yet

- Portable X-Ray Flaw DetectorDocument16 pagesPortable X-Ray Flaw Detectorhunggul amelNo ratings yet

- TIG Welding Amp ChartsDocument3 pagesTIG Welding Amp ChartsHikmet ParakNo ratings yet

- Builtup SectionDocument4 pagesBuiltup SectionSuhas MangaloreNo ratings yet

- Leichtmetall Data Sheet EN AW 6082T6Document1 pageLeichtmetall Data Sheet EN AW 6082T6Satendra ThakurNo ratings yet

- General Information: 2.1. ConcreteDocument4 pagesGeneral Information: 2.1. ConcreteWilliam ProvidoNo ratings yet

- Tutorial 2 Bending Stress With SolutionsDocument11 pagesTutorial 2 Bending Stress With SolutionsAbelBayartNo ratings yet

- NOZZLEDocument4 pagesNOZZLEHarshil TejaniNo ratings yet

- Test Coupon SizeDocument1 pageTest Coupon SizeSARSAN NDTNo ratings yet

- Proforma Rock InternationalDocument3 pagesProforma Rock Internationalmamadou varoreNo ratings yet

- Thread Turning ToolsDocument22 pagesThread Turning ToolsАндрейNo ratings yet

- Worktable-Super StructureDocument1 pageWorktable-Super StructureSourcePune MidcNo ratings yet

- Mathcad - LGS Channel - StudDocument13 pagesMathcad - LGS Channel - StudtonyNo ratings yet

- M48D965Document1 pageM48D965Gulfstream Data, IncNo ratings yet

- AJIYA-Structural Product Purlin PDFDocument4 pagesAJIYA-Structural Product Purlin PDFKartegan ElavarasuNo ratings yet

- Klemco MPS Featuring Chemical FixingsDocument3 pagesKlemco MPS Featuring Chemical FixingsMahajan VickyNo ratings yet

- TalaveraDocument16 pagesTalaveraLavern JohnzenNo ratings yet

- Sinhoo-SMTSO2530MTJ C2916380Document3 pagesSinhoo-SMTSO2530MTJ C2916380Mirosław MirekNo ratings yet

- 1.7 - Is 12779Document6 pages1.7 - Is 12779vrgohilNo ratings yet

- Concrete Beam DesignDocument4 pagesConcrete Beam DesignpetersiglosNo ratings yet

- RollDocument20 pagesRollVicente GarcíaNo ratings yet

- Iso 14581 CSK ScrewDocument1 pageIso 14581 CSK ScrewMitesh MakvanaNo ratings yet

- Multi-Position Cylinders TOC Bookmark Multi-Position CylindersDocument23 pagesMulti-Position Cylinders TOC Bookmark Multi-Position CylindersLogesh LoguNo ratings yet

- Ammz) 4oawea (: Verify Steel YieldingDocument2 pagesAmmz) 4oawea (: Verify Steel YieldingBenjaminNo ratings yet

- Design Manual Is-800 Chapter 3Document38 pagesDesign Manual Is-800 Chapter 3Vivek Kumar GopeNo ratings yet

- Spun Pile DetailsDocument1 pageSpun Pile DetailsMarvin VelasquezNo ratings yet

- TMT401 EyhDocument28 pagesTMT401 EyhAlfredo UriarteNo ratings yet

- Member Code: Dyntek Pte. LTDDocument1 pageMember Code: Dyntek Pte. LTDHerbert BishopNo ratings yet

- Prestressing Thread Steel BarDocument3 pagesPrestressing Thread Steel BarIsmantoTaufikNo ratings yet

- Developing and Testing Phased Array Ultrasonic TransducersDocument27 pagesDeveloping and Testing Phased Array Ultrasonic TransducersscribdmustaphaNo ratings yet

- Profile: Master 3144782 NPDocument3 pagesProfile: Master 3144782 NPfabioNo ratings yet

- Screw, DIN 7500TX 7500CE DIN 7500-1, Thread Forming Screw, Metric, TorxDocument1 pageScrew, DIN 7500TX 7500CE DIN 7500-1, Thread Forming Screw, Metric, TorxDerekNo ratings yet

- Safety Fences: Arc Welding Fixed Alignment Before Welding TypDocument1 pageSafety Fences: Arc Welding Fixed Alignment Before Welding Typphong viNo ratings yet

- TIG Welding Amp Charts PDFDocument2 pagesTIG Welding Amp Charts PDFEnrico959No ratings yet

- Metric DIN 609 SpecDocument4 pagesMetric DIN 609 SpecCAT MINING SHOVELNo ratings yet

- IS 12779.1989 Steel - Tollerences Hot Rolled Parallel Flange Sections PDFDocument9 pagesIS 12779.1989 Steel - Tollerences Hot Rolled Parallel Flange Sections PDFJostin P JoseNo ratings yet

- Is 12779 1989 PDFDocument9 pagesIs 12779 1989 PDFravi kiranNo ratings yet

- The Scanning Electron MicroscopeDocument65 pagesThe Scanning Electron MicroscopeCORE Materials67% (3)

- Durability of MaterialsDocument72 pagesDurability of MaterialsCORE Materials100% (2)

- Electron DiffractionDocument45 pagesElectron DiffractionCORE Materials100% (1)

- Equations in Materials ScienceDocument25 pagesEquations in Materials ScienceCORE Materials86% (7)

- The Transmission Electron MicroscopeDocument73 pagesThe Transmission Electron MicroscopeCORE MaterialsNo ratings yet

- Microscopy With Light and ElectronsDocument36 pagesMicroscopy With Light and ElectronsCORE Materials100% (1)

- TALAT Lecture 5301: The Surface Treatment and Coil Coating of AluminiumDocument26 pagesTALAT Lecture 5301: The Surface Treatment and Coil Coating of AluminiumCORE Materials100% (1)

- TALAT Lecture 5205: Plating On AluminiumDocument19 pagesTALAT Lecture 5205: Plating On AluminiumCORE Materials100% (1)

- TALAT Lecture 1100.01: Introduction: Aluminium, A Light MetalDocument10 pagesTALAT Lecture 1100.01: Introduction: Aluminium, A Light MetalCORE MaterialsNo ratings yet

- TALAT Lecture 5204: Organic Coating of AluminiumDocument17 pagesTALAT Lecture 5204: Organic Coating of AluminiumCORE MaterialsNo ratings yet

- TALAT Lecture 5201: Aluminium Surface PretreatmentDocument12 pagesTALAT Lecture 5201: Aluminium Surface PretreatmentCORE Materials100% (1)

- TALAT Lecture 4701: Terms and Definitions For Adhesive BondingDocument20 pagesTALAT Lecture 4701: Terms and Definitions For Adhesive BondingCORE MaterialsNo ratings yet

- TALAT Lecture 5105: Surface Treatment of AluminiumDocument15 pagesTALAT Lecture 5105: Surface Treatment of AluminiumCORE MaterialsNo ratings yet

- TALAT Lecture 5103: Corrosion Control of Aluminium - Forms of Corrosion and PreventionDocument20 pagesTALAT Lecture 5103: Corrosion Control of Aluminium - Forms of Corrosion and PreventionCORE MaterialsNo ratings yet

- TALAT Lecture 4703: Design and Calculation of Adhesive JointsDocument9 pagesTALAT Lecture 4703: Design and Calculation of Adhesive JointsCORE MaterialsNo ratings yet

- TALAT Lecture 5203: Anodizing of AluminiumDocument27 pagesTALAT Lecture 5203: Anodizing of AluminiumCORE Materials100% (2)

- TALAT Lecture 4702: Factors Influencing The Strength of Adhesive JointsDocument13 pagesTALAT Lecture 4702: Factors Influencing The Strength of Adhesive JointsCORE MaterialsNo ratings yet

- TALAT Lecture 4500: Resistance WeldingDocument23 pagesTALAT Lecture 4500: Resistance WeldingCORE MaterialsNo ratings yet

- Introduction To Brazing of Aluminium Alloys: TALAT Lecture 4601Document24 pagesIntroduction To Brazing of Aluminium Alloys: TALAT Lecture 4601fedeloquiNo ratings yet

- 4102Document14 pages4102henrychtNo ratings yet

- TALAT Lecture 4400: Introduction To Friction, Explosive and Ultrasonic Welding Processes of AluminiumDocument11 pagesTALAT Lecture 4400: Introduction To Friction, Explosive and Ultrasonic Welding Processes of AluminiumCORE MaterialsNo ratings yet

- TALAT Lecture 4101: Definition and Classification of Mechanical Fastening MethodsDocument19 pagesTALAT Lecture 4101: Definition and Classification of Mechanical Fastening MethodsCORE MaterialsNo ratings yet

- MP65557-1 Manual Técnico - 4900Document371 pagesMP65557-1 Manual Técnico - 4900Tecnico IncoderNo ratings yet

- Term Paper On Strategic ManagementDocument8 pagesTerm Paper On Strategic Managementea7j5ys3100% (1)

- BS9266 2013 Adaptable HousingDocument46 pagesBS9266 2013 Adaptable HousingGrant MastersonNo ratings yet

- Financial Accounting Report (Partnership - Group 2)Document20 pagesFinancial Accounting Report (Partnership - Group 2)syednaim0300No ratings yet

- Position, Velocity and AccelerationDocument12 pagesPosition, Velocity and Accelerationpeter vuNo ratings yet

- Development of Mmlps in India: Western DFC Eastern DFCDocument2 pagesDevelopment of Mmlps in India: Western DFC Eastern DFCsdfg100% (2)

- SRMDocument4 pagesSRMinocente333No ratings yet

- Press Releases Are Not A PR Strategy An Executive Annas ArchiveDocument200 pagesPress Releases Are Not A PR Strategy An Executive Annas Archivehelenajosemacuacua31No ratings yet

- Introduction To Game Theory: Analysis of GamesDocument13 pagesIntroduction To Game Theory: Analysis of GamesAoiNo ratings yet

- ABAP On HANA TopicsDocument23 pagesABAP On HANA Topicsrupesh kumarNo ratings yet

- Exercicios de PhonicsDocument51 pagesExercicios de Phonicsms. TeixeiraNo ratings yet

- Assignment-2: 1) Explain Classification With Logistic Regression and Sigmoid FunctionDocument6 pagesAssignment-2: 1) Explain Classification With Logistic Regression and Sigmoid FunctionpraneshNo ratings yet

- Filled System Temperature Recorders & Recorder Controllers: SpecificationDocument2 pagesFilled System Temperature Recorders & Recorder Controllers: SpecificationdencryNo ratings yet

- Community Policing EssaysDocument7 pagesCommunity Policing Essaysgqdknjnbf100% (2)

- BF V CatalogDocument56 pagesBF V CatalogmaciasrobNo ratings yet

- Acr On Clean-Up DriveDocument7 pagesAcr On Clean-Up DriveRichard ToliaoNo ratings yet

- Pilot Implementation of The Limited Face-to-Face Class Program at Librada Avelino Elementary SchoolDocument10 pagesPilot Implementation of The Limited Face-to-Face Class Program at Librada Avelino Elementary SchoolCher GeriNo ratings yet

- Merged DocumentDocument28 pagesMerged DocumentJamirah Maha ShahinurNo ratings yet

- Dubai Holding FactsheetDocument2 pagesDubai Holding FactsheetHarley soulNo ratings yet

- A Guide To Become A Succesful Marine EngineerDocument99 pagesA Guide To Become A Succesful Marine EngineerTammam Hassan100% (1)

- Saudi Arabia Companies Contact DetailsDocument64 pagesSaudi Arabia Companies Contact DetailsYAGHMOURE ABDALRAHMAN86% (69)

- Apple Witness ListDocument30 pagesApple Witness ListMikey CampbellNo ratings yet

- List Katalog Fire Hydrant (Box)Document3 pagesList Katalog Fire Hydrant (Box)Sales1 mpicaNo ratings yet

- Time Series Data Analysis For Forecasting - A Literature ReviewDocument5 pagesTime Series Data Analysis For Forecasting - A Literature ReviewIJMERNo ratings yet

- P16mba7 1Document4 pagesP16mba7 1Vishalatchi MNo ratings yet

- PSCADDocument10 pagesPSCADkaran976No ratings yet

- Megger-Mjolner-600 Ds enDocument5 pagesMegger-Mjolner-600 Ds enAmit Kumar KandiNo ratings yet

- Sherman Notes PDFDocument213 pagesSherman Notes PDFAbdul Hamid Bhatti100% (1)

- Ai R16 - Unit-6Document36 pagesAi R16 - Unit-6RakeshNo ratings yet

- Operator'S Manual AND Set-Up Instructions For The: WDL-2070-FADocument49 pagesOperator'S Manual AND Set-Up Instructions For The: WDL-2070-FAМаксим ЛитвинNo ratings yet