Professional Documents

Culture Documents

Electromagnetic Pulse (Emp) Gun

Uploaded by

rajmudgalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electromagnetic Pulse (Emp) Gun

Uploaded by

rajmudgalCopyright:

Available Formats

1

EMPGUN1 Electromagnetic Pulse (EMP) Gun

Figure 12-1 shows the construction of a low power pulse gun that will

provide kilowatts of peak power at frequencies up to 100 MHz with

harmonics. The unit is shown battery powered and uses the NEON21 high

voltage plasma generator plans included in this data. A higher powered

more functional device is being developed in our labs and will be ready by

mid 2006. This is an advanced level project requiring basic high frequency

electronic skills. A spectrum analyzer can be a very valuable tool in set up

Fig 12-1 but is not necessary. Expect to spend $50 to $100. All parts are readily

available with specialized parts through Information Unlimited

(www.amazing1.com) and are listed in Table 12-1.

Basic Theory Simplified

The ability of a signal to disrupt sensitive circuitry requires several properties. Most micro processors

consist of field effect transistors (FET) operating at very low voltages. Once these voltages are

exceeded, catastrophic failure becomes imminent. Forgiveness to an over voltage fault is practically

non-existence due to a micro thin metal oxide between controlling elements. Any over voltage

generated across these elements consequently produces permanent damage or in some less severe

cases cause de-programming. To generate these damaging voltages from an external source requires

a wave that can produce a standing wave of energy across circuit board traces, components and other

key points. The external signal energy therefore must be high enough for the circuitry geometry to be a

significant part of energy at the wavelength. Therefore microwave having fast rise times (high Fourier

equivalents) and burst duration are all figures of merit for maximizing the effect. The energy required

also must be sufficient to enhance damage. A good figure of merit would be the quotient of

energy/wavelength.

A high power pulse of microwaves can be generated in several ways:

Explosive flux compression driven virtual cathode oscillators and their generics relatives can produce

giga-watts of peak power from hundreds of kilojoules. This is where a seed current is pulsed into an

inductor and at its peak being compressed by a shaped explosive charge trapping the flux creating a

source of high energy. The coil must be compressed both axially and along its radius using high

detonation velocity explosive such as the cyclo-trimethyltrinitramine or its derivatives PETN, or other

equivalent energetic explosive. This trapped flux now produces an energy gain that is conditioned into

the final peak powered pulse of microwave power (HEPM) Flux compression like that of a nuclear

initiation requires precise timing of the explosive chargers. Krytron switches or similar can be used for

©2005 Information Unlimited, PO Box 716, Amherst, NH 03031 603-673-4730

2

flux compression instead of the more radiation hardened Sprytrons used in nuclear initiations where

ionizing radiation is produced from the inherent fissionable materials.

A virtual cathode oscillator can also easily be energized form a small Marx impulse generator

generating 200 to 400 kilo-volts. The fast current rise and high peak power can produce a powerful

burst of microwaves.

Other methods are exploding wires where energy is allowed to flow into a LCR circuit and then rapidly

disrupted by the explosion of the feed wire as it vaporizes at near the peak injection current. A very fast

and energetic pulse is produced capable of generating an EMP pulse.

Micro wave pulses are excellent candidates for damaging sensitive electronic circuitry, but much lower

frequencies are better to disrupt power grids and other similar sized systems as now the lengths of the

conductive elements are more conducive to generate the high standing voltage waves. Obviously more

energy is now required as breakers, switches, transformers require more energetic pulses

Circuit Description

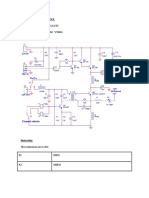

Our circuit as shown in Figure 12 -2 provides a simple demonstration showing a method of obtaining a

high power pulse with Fourier equivalents above 100 MHz. Even though the power and frequency are

relatively low, close range effects are possible on many target circuits.

The project utilizes a high frequency plasma source that is converted to a direct current charging

source that is short circuit functional by use of lossless reactive ballasting. This means that the

capacitor can be charged without the use of an energy robbing resistor as only the real part of the

complex current is seen by the battery supply.

The modified source now supplies a current charge to the reservoir capacitor (C1) to a value where

spark gaps (SG1). Current through (L1) rapidly rises to a value and rings along with the circuit and

lumped capacitance (C2). Spark gap SG1 must turn off and allow energy to circulate in the discharge

in order to generate a resonant peak of power that is now coupled into the system emitter.

Experimentation of the gap settings and pulse damping is necessary to obtain optimum effect.

Circuit Assembly

1. Fabricate a piece of lexan plastic or G10 circuit board as shown in figure 12-3 to a 7 x 2” for

(PL1) plate.

Locate the two ¼” spark gap holder (SGH1, 2) screws holes and locate as shown. Holes are spaced 2

¾” from one another.

©2005 Information Unlimited, PO Box 716, Amherst, NH 03031 603-673-4730

3

2. Form a 3 turn 1” diameter coil (L1) from ½” sheet copper or #14 solid copper wire as shown in

figure 12-4. Note the leads as attached to the capacitor (C1) and end gap holder.

3. Connect an output port at the junction of C1 and L1 as shown. This point is now considered the

output and can be connected to the radiating emitter.

4. Connect the generator to the NEON21 plasma driver as shown in figure 12-2 schematic. Note

the added diodes D1, 2 for converting the output to direct current.

5. You will note a coil (L2) connected in series with the output lead. This inductor tunes out the

capacitive reactance of the lead and the end capacitance. Experiment using a radio or absorption

wave meter to determine the resonant frequency of L1/C1. Select a value for L2 to provide maximum

radiation from a distance.

6. Experiment on various electronic devices and observe the effects at various distances.

7. Install in a gun like enclosure using your own ingenuity

Notes:

A low cost spectrum analyzer would be a great aid in setting up this system for wave damping etc

Please note this is a low power device intended as an introductory project for those desiring in

experimenting with shock pulse and EMP research. Several more functional and sophisticated devices

will be featured in the next book in this series.

©2005 Information Unlimited, PO Box 716, Amherst, NH 03031 603-673-4730

4

Table 12-1 EMP Gun Parts List

Ref# Qty Description DB#

R1 3 47K 1 watt resistor (yel-pur-or) connected in series

D1,2 2 16 KV 10 ma fast recovery high voltage rectifiers #VG16

C1 .05 mfd 5 KV strip line capacitor #.05M/5KV

L1 Inductor 3 turns 1” diameter use #12 copper wire

L2 Inductor wind as directed in text

ELECTTRODES 2 ½ X 1” pure tungsten electrodes #TUNG141B

PL1 7 x 2” x .063 Lexan or G10 plastic

TYE1 10” nylon tie wraps

SW1/NU1 2 ¼ X 1” brass screw and nuts

NEON21K Plasma driver kit #NEON21K

NEON2100 Plasma driver assembly #NEON2100

©2005 Information Unlimited, PO Box 716, Amherst, NH 03031 603-673-4730

Figure 12-2 Circuit Schematic 5

L1/3.6

T1

C4

1M/250V

METPOL Y

From output

R2 transformer T1 L2

1.8K

C1 C2 D1

1000/25 .1/50 TP1 R1 C1

HV

Q1 AN T

R1 C6

220/1 50P/6KV

R3

27/.25 D2 L1

SG1 Cint L1

FB C5

8T C3/.068/ .047/100

100

HV C OM

NEON21 Power Module

The ideal peak power of this circuit can be approximated by evaluating the product of the charge voltage across C1

x the peak current as determined by Ipk = Epk x the square root of the capacitance of C1/the total inductance of

the discharge circuit. This expression implies no resistance (R) in the discharge circuit that now is only in an ideal

situation. In all actuality the resistance in the real world will now be a factor in where e to the -(pi/square root of L/

C) / R must be a factor in the above ideal condition. This now implies a damped waveform.

Diodes D1,2 are 10 kv 10 ma fast recovery

Resistor R1 is three 47k 1 watt resistors in series and isolate the diodes from the dv/dt of the discharge.

L2 inductor tunes out the capacitive reactance of the antenna at the desired resonant frequency

Capacitor C1 is a “slapper” capacitor. These are used to produce a very fast rise time necessary to detonate

initiators necessary for initiating high explosive. Its claim to fame is the high peak current discharge current. The

capacitor is constructed as strip lines with the connection leads exiting a common end.

©2005 Information Unlimited, PO Box 716, Amherst, NH 03031 603-673-4730

6

Fig 12-3 Generator Board Bottom Gap View

Spark gap uses 1 4" x 1 pieces of pure

tungsten rod. These are secured in the

electrode holders via the set screws.

Preset the gap to .003" using a feeler as

voltage must not go above the rating of

C1. Increase a few thousandths of an

inch always checking the maximum

charge voltage before self breakdown

occurs

Resistor R1 is made from three 47k connected in series.

It is a good idea to sleeve these inside a flexible piece of

plastic tubing

Connection points These leads are connected to

to NEON21 diodes D1,2

©2005 Information Unlimited, PO Box 716, Amherst, NH 03031 603-673-4730

Fig 12-4 Generator Board Top View

7

Capacitive emitter

L2

PL1

L1 SW1/NU1

Output connection point

C1

TY1

Contact electrode

Insulator

Contact electrode

Side view of C1 showing copper strip electrodes seperated by a dielectric

insulating piece. Very carefully solder to the foil electrodes of C1 being

careful not to burn the insulating foil

©2005 Information Unlimited, PO Box 716, Amherst, NH 03031 603-673-4730

1

NEON21 Universal Low Power Plasma Supply

Useful modular circuit can be used for a low power source of high frequency for energizing gas

discharge displays by contact or proximity. High frequency arc can be used for etching, precision

burning, chemical excitation, wart removal, Kirlian photography, wireless energy transmission and

more. Power supply is easily retrofitted to our multiplier modules for DC voltages up to 100 kv. The unit

is open and short circuit protected and can be operated fro 12 vdc or 115 vac via a wall adapter.

This is an intermediate level project requiring basic electronic skills. Expect to spend $25 to $35. All

parts are readily available with specialized parts through Information Unlimited (www.amazing1.com)

and are listed on the parts list at the end of these plans.

Driver Circuit Description Reference Figure 10-2

The circuit is a frequency, high voltage oscillator that consists of transistor (Q1) connected as a simple

oscillator where its collector drives the primary winding (PR1) of resonant transformer (T1). Feedback

is obtained via a second winding (FB) and fed to the base of Q1 thru current limiting resistor (R1).

Resistor (R2) biases Q1 into conduction and initiates oscillation.

Capacitor (C3) speeds up the “turn off” time of Q1 while resistor (R3) capacitor and (C4) provide a filter

to prevent oscillation at the self resonant frequency of T1. Resonating capacitor (C5) resonate the

transformer to around 35 kHz. Current limiting inductor (L1) limits the short circuit current to a non

catastrophic value. Capacitor (C1) and (C2) bypass any signal to ground

Figure 10-3 Board Assembly

1. Layout and identify all parts and pieces. Verify with parts list, separate resistors as they have a color

code to determine their value. Colors are noted on parts list.

2. Obtain the available printed circuit board as shown figure 10-3 or fabricate a piece of perforated

circuit board to the PC as laid out. Note size of the printed circuit board is 3 1/2" X 1-3/8" and contains

the silk screening that shows the positioning of the mounted parts.

3. If you are building from a perforated circuit board it is suggested to Insert the components starting in

the lower left hand corner. Pay attention to polarity of capacitors with polarity signs, and all

semiconductors. Route leads of components as shown and solder as you go cutting away unused

©2005 Information Unlimited, PO Box 716, Amherst, NH 03031 603-673-4730

2

wires. Attempt to use certain leads as the wire runs. Follow foil traces on drawing as these indicate

connection runs on underside of assembly board.

4. Insert the components as indicated by the silk screened identification numbers. Compare with the

bill of materials to identify. Attach three 6” #22 -20 leads as shown for input power (P1,2) and external

high voltage return. Attach a high voltage lead to the output as shown. Note this lead must be selected

for required length. Use silicon 20 kv dc wire or equivalent. Note the ground lead that connects to the

metal frame under the screw head. as shown.

5. Double check accuracy of wiring and quality of solder joints. Avoid wire bridges, shorts and close

proximity to other circuit components. If a wire bridge is necessary, sleeve some insulation onto the

lead to avoid any potential shorts.

6. Fabricate the metal bracket (BRKT1) from a piece of .062 sheet aluminum and final assemble as

shown figure 10-4. Note that the metal tab of Q1 must be insulated from the bracket as shown on the

mounting scheme. This piece is also the heat sink for Q1.

Driver Board Testing

7. Obtain a 12 volt DC source preferably with a volt and ammeter. Leave out put leads open circuit

and apply power. Note a current draw of less than than 250 milliamps. If you have a scope, observe

the wave shape at the collector of Q1 as shown figure 10-2.

8. Contact the high voltage output lead to the bracket and note that you can draw a ½ inch arc with the

input current going to 1 amp.

This completes this module.

©2005 Information Unlimited, PO Box 716, Amherst, NH 03031 603-673-4730

3

Table 10-1 Parts List

Ref# Qty Description DB#

R1 220 OHMS 1W (red-red-br)

R2 1.8K 1/4 W (br-gray-red)

R3 27 OHMS 1/4 W (red-pur-blk)

C1 1000 mfd/ 25 volts vertical electrolytic capacitor

C2 .1mfd/50 volts plastic (small blue capacitor)

C3 .068mfd/ 50 volts plastic capacitor (683)

C4 1mfd/ 250 volts (mf) larger blue plastic capacitor

C5 .047mfd/ 100 volts plastic capacitor (473)

C6,7 2 25 pfd at 6Kv ceramic capacitor or single 50 pfd 6 Kv.

Q1 MJE3055T to220 power tab NPN transistor

T1 Special high frequency transformer #28K089

WR20 24" #22-20 Vinyl stranded hook up wire

PCMTC MTC3 printed circuit board #PCMTC

Or use a piece of 3 1/2 x 1 1/2" .1 grid perf board

BRKT1 Fabricate as shown figure 10-4

WR20 4” 20 KV silicon high voltage wire

Assembled high voltage module figure 10-4 #MINIMAX7

14V/1G 14 volt 1 amp grounded adapter #14V/1G

©2005 Information Unlimited, PO Box 716, Amherst, NH 03031 603-673-4730

4

Figure 10-2 Circuit Schematic

Output

L1/3.6

T1

C4

1M/250V

METPOLY

R2

1.8K

C1 C2

1000/25 .1/50 TP1

R1 Q1

220/1

R3

27/.25 C6

50P/6KV

FB C5

8T C3/.068/ .047/100

100

WAVESHAPE AT TP1

24-30 volts

20-30 usec

©2005 Information Unlimited, PO Box 716, Amherst, NH 03031 603-673-4730

5

Figure 10-3 Views of the printed circuit board

High voltage return

C7

-12 vdc

+12 vdc

Frame ground lead HVoutput

©2005 Information Unlimited, PO Box 716, Amherst, NH 03031 603-673-4730

6

Figure 10-4 Iso view of driver module

HV output

T1

C4

C1 Ground lead to frame

C8

C3

Q1

+ lead

-lead

SW1 Nylon screw HV ground return

MICA Washer between Q1 and panel

Q1

NU1

Q1 mounting scheme

for insulating from BRK1 bracket

©2005 Information Unlimited, PO Box 716, Amherst, NH 03031 603-673-4730

You might also like

- Stun GunDocument13 pagesStun GunRICHIHOTS2No ratings yet

- Ebook Emp Herf Shock Pulse Generators Empplans 400j 1.8gw Plan Gun WeaponDocument22 pagesEbook Emp Herf Shock Pulse Generators Empplans 400j 1.8gw Plan Gun Weaponarmandoaltomare100% (2)

- EMP Generator SchematicDocument6 pagesEMP Generator SchematicTC Serhan Uçar0% (1)

- Electromagnetic EMP Pulse Gun, Gen II InstructionsDocument32 pagesElectromagnetic EMP Pulse Gun, Gen II InstructionsAntny Pepin100% (1)

- EMP GeneratorDocument30 pagesEMP GeneratorRed100% (2)

- EMP GeneratorDocument22 pagesEMP GeneratorMark Reichfeld100% (1)

- Emp 400Document5 pagesEmp 400Ishwar SharmaNo ratings yet

- What Is An Electro Magnetic Rail GunDocument13 pagesWhat Is An Electro Magnetic Rail Gunsudeeplko100% (1)

- JammerDocument95 pagesJammerctenar2No ratings yet

- Coil GunDocument20 pagesCoil GunSimi Simon100% (1)

- FM JammerDocument13 pagesFM JammerJay Shree Patel100% (1)

- How To Kill A UAVDocument16 pagesHow To Kill A UAVNate Robertson100% (1)

- #Operation #DROPtheDRONEDocument11 pages#Operation #DROPtheDRONEtwittersub100% (1)

- High Energy Pulser: System DescriptionDocument14 pagesHigh Energy Pulser: System DescriptionBirdy MadNo ratings yet

- Anarchist Cookbook 2004 (Part-2)Document4 pagesAnarchist Cookbook 2004 (Part-2)Jagmohan JagguNo ratings yet

- JammerDocument21 pagesJammeraritra singh100% (5)

- Emp Generator Circuit Diagram: GrandcaretDocument7 pagesEmp Generator Circuit Diagram: GrandcaretMarckos FrancoNo ratings yet

- Mobile JammerDocument30 pagesMobile JammerFranklin-Noble Akwa-deltan UmohNo ratings yet

- How To Make Cell Phone Signal JammerDocument12 pagesHow To Make Cell Phone Signal JammerMoata Haile50% (2)

- Kurt Saxon - The Poor Mans James Bond - Vol5-28Document13 pagesKurt Saxon - The Poor Mans James Bond - Vol5-28Kenneth ConnerNo ratings yet

- Signal JammerDocument8 pagesSignal JammerEmAySiOhNo ratings yet

- The Poor Man's Armorer Magazine Volume 2 Number 1 - Kurt SaxonDocument161 pagesThe Poor Man's Armorer Magazine Volume 2 Number 1 - Kurt Saxonsniper_spotter100% (6)

- Cell Phone Controlled Remote Airsoft Grenade DetonDocument8 pagesCell Phone Controlled Remote Airsoft Grenade DetonKo Pyae SoneNo ratings yet

- GBPPR Electromagnetic Pulse Experiments - Part 1Document19 pagesGBPPR Electromagnetic Pulse Experiments - Part 1tutankamon20010No ratings yet

- Flame Thrower Rifle Complete Plans Paul RainwaterDocument19 pagesFlame Thrower Rifle Complete Plans Paul Rainwaterdownload1414No ratings yet

- Building A DIY Faraday-CageDocument7 pagesBuilding A DIY Faraday-CageAll News Pipeline100% (2)

- Stunguns Comprehensive Stungun InfoDocument15 pagesStunguns Comprehensive Stungun InfockkimbleNo ratings yet

- Eml 30Document13 pagesEml 30deborah8888100% (1)

- How To Make A Powerful RF Signal Jammer Circuit - Homemade Circuit ProjectsDocument15 pagesHow To Make A Powerful RF Signal Jammer Circuit - Homemade Circuit ProjectsShawn CarswellNo ratings yet

- Magnetic High Impact Cannon Coil Gun HTTPDocument27 pagesMagnetic High Impact Cannon Coil Gun HTTPjcarnley2005100% (1)

- FM JammerDocument21 pagesFM JammerKumar R Ranjan100% (3)

- MultiBand Jammer Final ReportDocument65 pagesMultiBand Jammer Final Reportusman ali100% (1)

- Mobile JammerDocument25 pagesMobile JammerRohit NarainNo ratings yet

- Paladin Press - Expedient B&e - Tactics and Techniques For Bypassing Alarms and Defeating Locks (HDocument6 pagesPaladin Press - Expedient B&e - Tactics and Techniques For Bypassing Alarms and Defeating Locks (Hanon-948045100% (3)

- TM 31-210 Improvised Munitions Handbook v3Document273 pagesTM 31-210 Improvised Munitions Handbook v3poisonknives100% (8)

- AC Current Monitor by LM358Document14 pagesAC Current Monitor by LM358wlen2012No ratings yet

- Experiment 1: Linear Power SuppliesDocument9 pagesExperiment 1: Linear Power SuppliesŞems TanriverdiNo ratings yet

- Transformer Isolated Gate DriveDocument9 pagesTransformer Isolated Gate DriverobertdenchNo ratings yet

- HAM RF Research 5 MergedDocument219 pagesHAM RF Research 5 MergedpowerinfiniteNo ratings yet

- RF - PA - 250 - 3 - HV - V300 180W PA KIT CONSTRUCTION (English)Document15 pagesRF - PA - 250 - 3 - HV - V300 180W PA KIT CONSTRUCTION (English)Luiz Luiz100% (1)

- VIPower 18 - 23W Electronic Ballast For Removable Tubes-CD00042539Document11 pagesVIPower 18 - 23W Electronic Ballast For Removable Tubes-CD00042539Dan EsentherNo ratings yet

- Rangkaian RangkaianDocument30 pagesRangkaian RangkaianAhmad JuheriNo ratings yet

- 07 k275 VaristorDocument27 pages07 k275 VaristorJorge Ugaz La RosaNo ratings yet

- All About Op Amplifier-CollectionDocument105 pagesAll About Op Amplifier-CollectionAnonymous DjWqKpZ1No ratings yet

- Semiconductor AN758: Motorola Application NoteDocument16 pagesSemiconductor AN758: Motorola Application NoteYovani GuirolaNo ratings yet

- 1.5v Battery ChargerDocument25 pages1.5v Battery ChargerJOHN BRICCO A. MATACSILNo ratings yet

- Switch Mode Supplies - Elegant Designs From ChinaDocument6 pagesSwitch Mode Supplies - Elegant Designs From Chinasafet100% (2)

- 4029INSTRUMENTTRANSFORMERSDocument95 pages4029INSTRUMENTTRANSFORMERSmuaz_aminu1422100% (2)

- Linear Technology Magazine Circuit Collection1 PDFDocument16 pagesLinear Technology Magazine Circuit Collection1 PDFArun GuptaNo ratings yet

- Project of Electronics SubjectDocument14 pagesProject of Electronics SubjectDarren Troy Lingao MayorNo ratings yet

- Experiment No: DateDocument24 pagesExperiment No: DateChaitanya ShahNo ratings yet

- 2 CT Notes - Steady State NotesDocument17 pages2 CT Notes - Steady State NotesmubarakkirkoNo ratings yet

- Technical Characteristics BoosterDocument4 pagesTechnical Characteristics BoosterVany BraunNo ratings yet

- PDFDocument15 pagesPDFNilesh KhareNo ratings yet

- An-995a 103Document10 pagesAn-995a 103Kendert BarrientosNo ratings yet

- 100 Watt InverterDocument11 pages100 Watt InverterscribdexpressNo ratings yet

- Circuit DiagramDocument3 pagesCircuit DiagramEarl Jhoy EstreraNo ratings yet

- INSTRUMENTTRANSFORMERSDocument95 pagesINSTRUMENTTRANSFORMERSmuaz_aminu1422No ratings yet

- This Is 20 Watt Power Audio Amplifier Which Use IC LM1875 As Main ComponentDocument14 pagesThis Is 20 Watt Power Audio Amplifier Which Use IC LM1875 As Main ComponentJc LastaNo ratings yet

- PowlVac 5-15kV Metal-Clad Switchgear Guide Specification v7Document8 pagesPowlVac 5-15kV Metal-Clad Switchgear Guide Specification v7ahmadgce04No ratings yet

- Kenwood Stereo Cassette Tape Deck Kx-w791Document25 pagesKenwood Stereo Cassette Tape Deck Kx-w791lunwenNo ratings yet

- Digital Multimeter Selection GuideDocument3 pagesDigital Multimeter Selection GuideThomas VargheseNo ratings yet

- SANYO - Cg21ys2s PDFDocument38 pagesSANYO - Cg21ys2s PDFAsallimitNo ratings yet

- Manual de Partes Gen Dqdac 300 Kw-1Document184 pagesManual de Partes Gen Dqdac 300 Kw-1Daniel Lopez100% (2)

- EET301 2013 Chapter 5Document84 pagesEET301 2013 Chapter 5Lee Boon HongNo ratings yet

- 45586301TH - R1 - Es9465 - Es9475 MFPDocument1,558 pages45586301TH - R1 - Es9465 - Es9475 MFPsmrizalNo ratings yet

- SF6 Circuit Breakers For Out D 040126.HTML AvsDocument4 pagesSF6 Circuit Breakers For Out D 040126.HTML AvsLinh VănNo ratings yet

- The Hourmeter Range - 3ppDocument3 pagesThe Hourmeter Range - 3ppN.I.C.E spares & serviceNo ratings yet

- Sony Ha 21p52Document27 pagesSony Ha 21p52Cao AnhNo ratings yet

- Tda 8425Document24 pagesTda 8425Ariel NavarreteNo ratings yet

- Isc 2SC3280: Silicon NPN Power TransistorDocument2 pagesIsc 2SC3280: Silicon NPN Power Transistorklaus allowsNo ratings yet

- 7KM31200BA011DA0 Datasheet en PDFDocument8 pages7KM31200BA011DA0 Datasheet en PDFPeter UhuleNo ratings yet

- Sony Klv-22ex300 Klv-26ex300 Klv-32ex300 Klv-32ex400 Klv-40ex400 Klv-46ex400 B L RDocument67 pagesSony Klv-22ex300 Klv-26ex300 Klv-32ex300 Klv-32ex400 Klv-40ex400 Klv-46ex400 B L RDinuka MalinthaNo ratings yet

- Boss GE-10 Service NotesDocument5 pagesBoss GE-10 Service NotesIncubusKissNo ratings yet

- Using GigaProbes Agilent TDR D5Document12 pagesUsing GigaProbes Agilent TDR D5yadamyugandharNo ratings yet

- 15A04802-Low Power VLSI Circuits & Systems - Two Marks Q&A-5 UnitsDocument31 pages15A04802-Low Power VLSI Circuits & Systems - Two Marks Q&A-5 UnitsPallavi Ch71% (7)

- Intelligent Power Module and Gate Drive Interface OptocouplersDocument21 pagesIntelligent Power Module and Gate Drive Interface Optocouplersshafiqul islamNo ratings yet

- Photoelectric LabDocument5 pagesPhotoelectric LabNajma BelvanaNo ratings yet

- Lecture - 1 - Introduction To Sensors and TransducersDocument35 pagesLecture - 1 - Introduction To Sensors and TransducersgumarangchieannNo ratings yet

- PT SUPREME CABLE Company Profile 2022Document16 pagesPT SUPREME CABLE Company Profile 2022Mhuez Anhek GheloNo ratings yet

- Problems in DecibelsDocument6 pagesProblems in DecibelsLara Jane ReyesNo ratings yet

- ksp90 Charching SystemDocument17 pagesksp90 Charching SystemKevin HamiltonNo ratings yet

- PRO1 10E IntroductionMicromasterDocument22 pagesPRO1 10E IntroductionMicromasterSeVictor Rudas CajaNo ratings yet

- Chapter 9Document24 pagesChapter 9Deivasigamani SubramaniyanNo ratings yet

- Automatic Dipper Light Control For VehiclesDocument5 pagesAutomatic Dipper Light Control For VehiclesesatjournalsNo ratings yet

- Cable Capacity TablesDocument2 pagesCable Capacity TablesEJBSE100% (5)

- TIME - TABLE - July - DEC - 2021 - ECE - BTech - Mtech - PhD-27.07.2021Document12 pagesTIME - TABLE - July - DEC - 2021 - ECE - BTech - Mtech - PhD-27.07.2021HarshNo ratings yet

- CO2 Laser - OrganizedDocument4 pagesCO2 Laser - OrganizedEE Sachin18No ratings yet

- Magnetic HysteresisDocument10 pagesMagnetic HysteresisHarsh PurwarNo ratings yet