Professional Documents

Culture Documents

Seminar Report On Reactive Powder Concrete (Civil Engineering)

Uploaded by

Siddhartha SiddhuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seminar Report On Reactive Powder Concrete (Civil Engineering)

Uploaded by

Siddhartha SiddhuCopyright:

Available Formats

Reactive powder concrete

A Seminar Report

Submitted in partial fulfillment of the requirements of the degree of

BACHELOR OF TECHNOLOGY

IN

CIVIL ENGINEERING

By

D. Siddhartha(UG101218)

DEPARTMENT OF CIVIL ENGINEERING

NATIONAL INSTITUTE OF TECHNOLOGY, WARANGAL

2013-2014

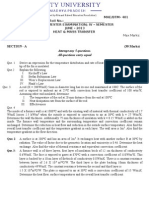

Table of Contents

Abstract................................................................................................................................. 4

1. Introduction ....................................................................................................................... 5

1.1 Defining Reactive powder concrete ............................................................................. 5

1.2 History and development of RPC ................................................................................. 5

1.3 Scope of RPC .............................................................................................................. 5

2. Composition of RPC .......................................................................................................... 6

2.1 Introduction .................................................................................................................. 6

2.2 RPC components ........................................................................................................ 6

2.2.1 Cement ................................................................................................................. 6

2.2.2 Sand ..................................................................................................................... 6

2.2.3 Quartz powder ...................................................................................................... 7

2.2.4 Silica fume ............................................................................................................ 7

2.2.5 Steel fibers ............................................................................................................ 7

2.2.6 Super plasticizer.................................................................................................... 7

2.2.7 Table showing components of RPC ...................................................................... 7

2.3 Mix proportion of RPC ................................................................................................. 8

3. Properties of RPC ............................................................................................................. 9

3.1 Introduction .................................................................................................................. 9

3.2 Typical properties of RPC 200 ................................................................................... 10

3.3 Typical properties of RPC 800 ................................................................................... 10

3.4 Comparison of RPC and HPC ................................................................................... 11

3.5 Fresh concrete properties .......................................................................................... 11

3.6 Compressive strength ................................................................................................ 12

3.7 Flexural strength ........................................................................................................ 12

3.8 Water absorption ....................................................................................................... 13

3.9 Water permeability ..................................................................................................... 13

3.10 Resistance to chloride ion penetration ..................................................................... 14

4. Factors effecting strength of RPC ................................................................................... 15

4.1 Silica Fume Percentage ............................................................................................. 15

4.2 Quartz Powder........................................................................................................... 15

4.3 Curing Regime........................................................................................................... 15

4.4 Compressive and tensile properties of RPC at elevated temperatures ...................... 15

4.5 Effect of pre-setting pressure ..................................................................................... 15

5. Advantages ..................................................................................................................... 16

6. Limitations ....................................................................................................................... 16

7. Structures built using RPC .............................................................................................. 17

8. Case study ...................................................................................................................... 17

8.1 THE SIDEWALK SYSTEM OF THE QINGHAI-TIBET RAILWAY BRIDGE ................ 17

8.2 Pedestrian bridge in Sherbrooke ............................................................................... 18

9. References ..................................................................................................................... 19

Abstract

Reactive Powder Concrete (RPC) is catching more attention now days because of its high

mechanical and durability characteristics. RPC mainly comprises of cement, silica fume,

silica sand, quartz powder and steel fibers. RPC has been able to produce with compressive

strength ranging from 200 MPa to 800 MPa with flexural strength up to 50 MPa and in some

cases can replace traditional steel reinforcement. RPC will allow the concrete industry to

optimize material use, generates economic benefits, and build structures that are strong and

durable. Present seminar mainly discusses on composition and Mix proportion of RPC,

properties and factors effecting RPC and comparison between High performance concrete

(HPC) and RPC and limitations of RPC and few case studies.

1. Introduction

1.1 Defining Reactive powder concrete

Reactive powder concrete (RPC) is ultra high strength and high ductile composite material

with advanced mechanical properties. Reactive powder concrete is a concrete without

coarse aggregate, but contains cement, silica fume, sand, quartz powder, super plasticizer

and steel fiber with very low water binder ratio. The absence of coarse aggregate was

considered by inventors to be key aspect for the microstructure and performance of RPC in

order to reduce the heterogeneity between cement matrix and aggregate.

1.2 History and development of RPC

The concept of reactive powder concrete was first developed by P. Richard and M. Cheyrezy

and RPC was first produced in the early 1990s by researchers at Bouygues laboratory in

France. The worlds first Reactive Powder Concrete structure, the Sherbrooke Bridge in

Canada, was erected in July 1997. The addition of supplementary material, elimination of

coarse aggregates, very low water/binder ratio, additional fine steel fibers, heat curing and

application of pressure before and during setting were the basic concepts on which it was

developed. Compressive strength of RPC ranges from 200 to 800 MPa, flexural strength

between 30-50 MPa and Youngs modulus up to 50-60 GPa. There is a growing use of RPC

owing to the outstanding mechanical properties and durability. RPC structural elements can

resist chemical attack, impact loading from vehicles and vessels, and sudden kinetic loading

due to earthquakes. Ultra high performance is the most important characteristic of RPC.

RPC is composed of more compact and arranged hydrates. The microstructure is optimized

by precise gradation of all particles in the mix to yield maximum density. It uses extensively

the pozzolonic properties of highly refined silica fume and optimization of the Portland

cement chemistry to produce highest strength hydrates.

1.3 Scope of RPC

RPC will be suitable for pre-stressed application and for structures acquiring light and thin

components such as roofs of stadiums, long span bridges, space structures, high pressure

pipes, blast resistance structures and the isolation and containment of nuclear wastes. In

India the work on RPC has started from last few years. The utility of RPC in actual

construction is minimal or nil in India, it is because of non-availability of sufficient

experimental data regarding production and performance of RPC.

2. Composition of RPC

2.1 Introduction

RPC is composed of very fine powders (cement, sand, quartz powder and silica fume), steel

fibers and super plasticizer. The super plasticizer, used at its optimal dosage, decreases the

water to cement ratio (w/c) while improving the workability of the concrete. A very dense

matrix is achieved by optimizing the granular packing of the dry fine powders. This

compactness gives RPC ultra-high strength and durability. Reactive Powder Concretes have

compressive strengths ranging from 200 MPa to 800 MPa.

Richard and Cheyrezy indicate the following principles for developing RPC:

1. Elimination of coarse aggregates for enhancement of homogeneity

2. Utilization of the pozzolonic properties of silica fume

3. Optimization of the granular mixture for the enhancement of compacted density

4. The optimal usage of super plasticizer to reduce w/c and improve workability

5. Application of pressure (before and during setting) to improve compaction

6. Post-set heat-treatment for the enhancement of the microstructure

7. Addition of small-sized steel fibers to improve ductility

Application of these principles without steel fibers produces a matrix with very high

compressive strength, but with ductility no better than that of conventional mortar. The

inclusion of fibers improves tensile strength, and also makes it possible to obtain the

required level of ductility.

2.2 RPC components

2.2.1 Cement

Cement is binding material for production of primary hydrates. Its particle size ranges from

1m to 100m. Optimum cement properties are C

3

S: 60% C

2

S: 22% C

3

A: 3.8% C

4

AF: 7.4%

2.2.2 Sand

Coarse aggregates are replaced by fine sand. It gives strength to the concrete. Maximum

size of sand is 600m. Size ranges from 150m to 600m. It eliminates mechanical

chemical and thermo mechanical failures.

2.2.3 Quartz powder

Its particle size ranges from 5m to 25m. It must be in crystalline form.

2.2.4 Silica fume

Silica fume is used for filling voids and enhance rheology and for production of secondary

hydrates. Its particle size ranges from 0.1m to 1m .

2.2.5 Steel fibers

It should have good aspect ratio and should be able to improve ductility. Its length ranges

from 13mm to 25mm. It should be straight.

2.2.6 Super plasticizer

A copolymer of acrylic ester (CAE), a polynaphtalene Sulfonate (PNS) and a polymelamine

sulfonate (PMS) are normally employed for the purpose. These admixtures are synthetic

polymers.

2.2.7 Table showing components of RPC

Component

Selection parameter

Function

Particle size

Sand Good hardness

Readily available and

low cost.

Gives strength 150 m to 600 m

Cement C

3

S: 60% C

2

S: 22%

C

3

A: 3.8% C

4

AF: 7.4%

Binding material,

Production of

primary hydrates

1 m to 100 m

Quartz powder Fineness Max. reactivity

during heat-treating

5m to 25m

Silica fume Very less quantity of

impurities

Filling the voids,

Enhance rheology,

Production of

secondary hydrates

0.1m to 1m

Steel fibers Good aspect ratio Improve ductility Length 13mm to 25mm

Dia. 0.15 0.2 mm

Super plasticizer Less retarding

characteristic

Reduce w/c Polyacrylate based

Table 1 Components of RPC

2.3 Mix proportion of RPC

The RPC family includes two types of concrete, designated RPC 200 and RPC 800.

Mix proportion (by weight) given by P. Richard and and M. Cheyrezy.

RPC 200 RPC 800

Non fibered Fibered Silica

aggregates

Steel

aggregates

Portland cement 1 1 1 1 1 1

Silica fume 0.25 0.23 0.25 0.23 0.23 0.23

Sand 1.1 1.1 1.1 1.1 0.5 -

Quartz powder - 0.39 - 0.39 0.39 0.39

Super plasticizer 0.016 0.019 0.016 0.019 0.019 0.019

Steel fibre L=12 mm - - 0.175 0.175 - -

Steel fibre

L=3 mm

- - - - 0.63 0.63

Steel

aggregates<800m

- - - - - 1.49

Water 0.15 0.17 0.17 0.19 0.19 0.19

Compaction pressure - - - - 50 MPa 50 MPa

Heat treatment

pressure (in C)

20 90 20 90 250-400 250-400

Table 2 Mix proportion of RPC

3. Properties of RPC

3.1 Introduction

Comparison of the physical, mechanical, and durability properties of RPC and HPC (High

Performance Concrete) shows that RPC possesses better strength (both compressive and

flexural) and lower permeability compared to HPC.

High-Performance Concrete (HPC) is not just a simple mixture of cement, water, and

aggregates. It contains mineral components and chemical admixtures having very specific

characteristics, which give specific properties to the concrete. The development of HPC

results from the materialization of a new science of concrete, a new science of admixtures

and the use of advanced scientific equipments to monitor concrete microstructure.

HPC has achieved the maximum compressive strength in its existing form of microstructure.

However, at such a level of strength, the coarse aggregate becomes the weakest link in

concrete. In order to increase the compressive strength of concrete even further, the only

way is to remove the coarse aggregate. This philosophy has been employed in Reactive

Powder Concrete (RPC).

Microstructure enhancement of RPC is done by heat curing. Heat curing is performed by

simply heating (normally at 90C) the concrete at normal pressure after it has set properly.

This considerably accelerates the pozzolanic reaction, while modifying the microstructure of

the hydrates that have formed. Pre-setting pressurization has also been suggested as a

means of achieving high strength.

The high strength of RPC makes it highly brittle. Steel fibers are generally added to RPC to

enhance its ductility. Straight steel fibers used typically are about 13 mm long, with a

diameter of 0.15 mm. The fibers are introduced into the mixture at a ratio of between 1.5 and

3% by volume. The cost-effective optimal dosage is equivalent to a ratio of 2% by volume, or

about 155 kg/m

3

.

Mechanical properties for the two types of RPC are given below

3.2 Typical properties of RPC 200

Portland cement 955 kg/m3

Fine Sand (150-400 micron) 1051 kg/m3

Silica fume (18m2/gram) 229 kg/m3

Precipitated silica(35 m2/g) 10 kg/m3

Super plasticizer (polyacrylate) 13 kg/m3

Steel fibers 191 kg/m3

Total water 153 kg/m3

Compressive strength(cylinder) 170-230 MPa

Flexural strength 25-60 MPa

Youngs modulus 50-60 GPa

3.3 Typical properties of RPC 800

Portland cement 1000 kg/m3

Fine Sand (150-400 micron) 500 kg/m3

Ground Quartz (4 microns) 390 kg/m3

Silica fume (18m2/gram) 230 kg/m3

Super plasticizer (polyacrylate) 18 kg/m3

Steel fibers 630 kg/m3

Total water 180 kg/m3

Compressive strength(cylinder) 490-680 MPa

Flexural strength 45-102 MPa

Youngs modulus 65-75 GPa

3.4 Comparison of RPC and HPC

Table 3 shows typical mechanical properties of RPC compared to a conventional HPC of

compressive strength 80 MPa. As fracture toughness, which is a measure of energy

absorbed per unit volume of material to fracture, is higher for RPC, it exhibits high ductility.

Apart from their exceptional mechanical properties, RPCs have an ultra-dense

microstructure, giving advantageous waterproofing and durability characteristics. These

materials can therefore be used for industrial and nuclear waste storage facilities.

Property HPC(80 MPa) RPC 200

Compressive strength 80 MPa 200 MPa

Flexure strength 7 MPa 40 MPa

Modulus of elasticity 40 GPa 60 GPa

Fracture toughness <10 J/m 30*10 J/m

Table 3 comparison of HPC and RPC

RPC has ultra-high durability characteristics resulting from its extremely low porosity, low

permeability, limited shrinkage and increased corrosion resistance. In comparison to HPC,

there is no penetration of liquid and/or gas through RPC. The characteristics of RPC given in

Table 4 enable its use in chemically aggressive environments and where physical wear

greatly limits the life of other concretes.

Abrasive Wear 2.5 times lower

Water Absorption 7 times lower

Rate of Corrosion 8 times lower

Chloride ions diffusion 25 times lower

Table 4 durability of RPC compared with HPC

3.5 Fresh concrete properties

The workability of RPC mixtures (with and without fibers), measured using the mortar flow

table test will be in the range of 120 140%. On the other hand, the workability of HPC

mixtures (with and without fibres), measured using the slump test will be in the range of 120

150 mm. The density of fresh RPC and HPC mixtures was found to be in the range of

2500 2650 kg/m

3

.

3.6 Compressive strength

RPC has higher compressive strength than HPC, as shown in Fig. 1. Compressive strength

at early ages is also very high for RPC. Compressive strength is one of the factors linked

with the durability of a material. In the context of nuclear waste containment materials, the

compressive strength of RPC is higher than required.

Fig 1: Compressive strength of RPC and HPC

(http://www.theconcreteportal.com/reac_pow.html)

The incorporation of fibers and use of heat curing was seen to enhance the compressive

strength of RPC by 30 50%. The incorporation of fibers did not affect the compressive

strength of HPC significantly.

3.7 Flexural strength

Plain RPC was found to possess marginally higher flexural strength than HPC. Here the

increase of flexural strength of RPC with the addition of fibres is higher than that of HPC.

RPC 200 should have an approximate flexural strength of 40 MPa. Fibre reinforced RPC

(with appropriate fibres) has the potential to be used in structures without any additional

steel reinforcement. This cost reduction in reinforcement can compensate the increase in the

cost by the elimination of coarse aggregates in RPC to a little extent.

3.8 Water absorption

Fig. 2 presents a comparison of water absorption of RPC and HPC. A common trend of

decrease in the water absorption with age is seen here both for RPC and HPC. The

percentage of water absorption of RPC, however, is very low compared to that of HPC. This

quality of RPC is one among the desired properties of nuclear waste containment materials.

Fig. 2: Water absorption of RPC and HPC

(http://www.theconcreteportal.com/reac_pow.html)

The incorporation of fibers and the use of heat curing is seen to marginally increase the

water absorption. The presence of fibers possibly leads to the creation of channels at the

interface between the fiber and paste that promote the uptake of water. Heat curing, on the

other hand, leads to the development of a more open microstructure (compared to normal

curing) that could result in an increased absorption.

3.9 Water permeability

A comparison of the surface water permeability of RPC and HPC is shown in Fig. 3.

It can be seen from the data that water permeability decreases with age for all mixtures.

28

th

day water permeability of RPC is negligible when compared to that of HPC (almost 7

times lower). As in the case of water absorption, the use of fibers increases the surface

permeability of both types of concrete.

Fig. 3: Surface Water Permeability of RPC and HPC

(http://www.theconcreteportal.com/reac_pow.html)

3.10 Resistance to chloride ion penetration

Penetration of chloride increases when heat curing is done in concrete. Total charge passed

for normal-cured RPC is negligible compared to the other mixtures. Even though heat-cured

RPC shows a higher value than normal-cured RPC, in absolute terms, it is still extremely low

or even negligible (<100 Coulombs). This property of RPC enhances its suitability for use in

nuclear waste containment structures.

Addition of steel fibres leads to an increase in the permeability, possibly due to increase in

conductance of the concrete. The HPC mixtures also showed very low permeability,

although higher compared to RPC.

4. Factors effecting strength of RPC

4.1 Silica Fume Percentage

It is observed that the compressive strength tends to decrease as the silica fume dosage

increases. The compressive strength is seen to fluctuate in the range of 15 % to 25% of

silica fume regardless of water/binder ratio. As silica fume content increases, mix requires

more super plasticizer to disperse in fresh concrete.

4.2 Quartz Powder

Hydrated cement alone cannot help to elevate the strength of RPC, but other finer materials

also contribute marginally. Quartz powder improves the filler effect in RPC mix. Addition of

quartz powder produce the better result under accelerated curing condition than that of

normal curing condition. The results show that the addition of quartz powder increases the

compressive strength by 20% under the accelerated curing condition.

4.3 Curing Regime

An adequate supply of moisture is necessary to ensure that hydration is sufficient to reduce

the porosity to a level such that the desired strength can be attained. The compressive

strength increased by 10% when cured in hot water as compared to normal curing. This

indicates that curing temperature has a significant effect on the early strength development

of RPC. The increased strength is due to the rapid hydration of cement at higher curing

temperatures of 90C compared to that of 27C. Moreover, the pozzolonic reactions are also

accelerated by the higher curing temperatures.

4.4 Compressive and tensile properties of RPC at elevated temperatures

Cube compressive strength decreases at 100 C, increases at temperatures from 200 to 500

C, and decreases at temperatures above 600 C. Below 300 C, the cube compressive

strength of RPC increases as the fibre content increases, but decreases above 300 C as

the fibre content increases. The tensile strength of RPC with steel fibres decreases at

temperatures below 200 C, increases at temperatures ranging from 200 to 300 C, and

decreases at temperatures above 300 C. 2% steel fibres prevent spalling and significantly

increase mechanical properties.

4.5 Effect of pre-setting pressure

It is observed that application of pre-setting pressure increased compressive strength of the

RPC about twice.

5. Advantages

As fracture toughness is higher, RPC exhibits high ductility.

Since RPC is an Ultra dense micro structure, porosity and permeability is less and

therefore can be used for waste storage holding facility.

RPC has limited shrinkage, increased corrosion resistance and so can be used in

aggressive chemical environments.

Its superior strength combined with higher shear capacity results in significant dead

load reduction and limitless structural member shape.

Its superior strength combined with higher shear capacity results in significant dead

load reduction and limitless structural member shape.

With its ductile tension failure mechanism, RPC can be used to resist all stresses

except direct primary tensile stresses. This eliminates the need for supplemental

shear and other auxiliary reinforcing steel.

RPC improve seismic performance reduces inertia loads with lighter members.

reduced cross sections of members provides higher energy absorption.

Low and non-interconnected porosity reduces mass transfer, making penetration of

liquid/gas or radioactive elements nearly non-existent.

6. Limitations

The least costly components of conventional concrete are basically eliminated or

replaced by more expensive elements.

The fine sand used in RPC becomes equivalent to the coarse aggregate of

conventional concrete

The Portland cement plays the role of the fine aggregate and the silica fume that of

the cement of conventional concrete.

The mineral component optimization alone results in a substantial increase in cost

over and above that of conventional concrete (5 to 10 times higher than HPC)

Applying pressure to mix and applying heat treatment in the field has got

technological difficulties and cost.

RPC should be used in areas where weight savings can be realized

Since RPC is in its infancy, the long-term properties are not yet known.

7. Structures built using RPC

First bridge that used RPC-pedestrian bridge in Sherbrooke, Quebec, Canada.

(230MPa) It was used during the early days of RPC production.

Portugal has used it for seawall anchors

Australia has used it in a vehicular bridge

France has used it in building power plants

Side walk of Qinghai-Tibet Railway Bridge.

8. Case study

8.1 THE SIDEWALK SYSTEM OF THE QINGHAI-TIBET RAILWAY BRIDGE

Fig.4 Qinghai-Tibet Railway Bridge

(http://english.people.com.cn/200607/01/images/railway.jpg)

The Qinghai-Tibet railway lies in the west area of China at an altitude of more than 4,000

meters. The 576-km railway is being built on frozen earth. The bad climate and sandstorms

of the tundra require the concrete of the bridge to have superior mechanical properties and

high durability. By adding portland cement, silica fume, superfine fly ash, and

superplasticizers, reactive powder concrete (RPC) is used in the sidewalk systems of

bridges with compressive strength of 160 MPa.

There are a lot of different problems with conventional concrete sidewalks such as corrosion,

rust of reinforcing steel bars, and breakability of concrete slab. The steel brackets rust in a

conventional concrete sidewalk. As a result, a conventional concrete sidewalk system

requires maintenance every year. Dead weight of the traditional sidewalk system is greater

than that of the RPC sidewalk system, which makes bridges have a bad dynamic

performance.

The sidewalk system made of RPC has such merits as small deadweight, excellent

durability, low cost, and minimum maintenance. Thus, RPC is more suitable for the sidewalk

system of Qinghai-Tibet Railway than conventional concrete.

8.2 Pedestrian bridge in Sherbrooke

Spanning 197 ft ( 60 m), this precast, pre stressed pedestrian/bikeway bridge in Sherbrooke,

Quebec, is a post-tensioned open-web space truss containing no conventional steel

reinforcement. Made up of six prefabricated match-cast segments, it was manufactured

using RPC.

An extensive program monitoring bridge deflections and forces in the pre stressing tendons

has been implemented to Provide information on long-term performance of RPC.

Fig.5 sherbrooke pedestrian bridge

9. References

1. Composition of reactive powder concretes Pierre Richard and Marcel Cheyrezy Cement

and Concrete Research, Vol. 25. No. 7, pp. 1501-1511.1995.

(http://www.sciencedirect.com/science/article/pii/0008884695001442)

2. MICROSTRUCTURAL ANALYSIS OF RPC Pierre Richard and Marcel Cheyrezy Cement

and Concrete Research, Vol. 25, No. 7. pp. 1491-1500.1995.

(http://www.sciencedirect.com/science/article/pii/000888469500143Z)

3. The effect of autoclave pressure, temperature and duration time on mechanical properties

of reactive powder concrete by Halit Yazc, Engin Deniz, Blent Baradan. Construction and

Building Materials, Volume 42, May 2013, Pages 53-63

(http://www.sciencedirect.com/science/article/pii/S0950061813000299)

4. Compressive and tensile properties of reactive powder concrete with steel fibres at

elevated temperatures by Wenzhong Zheng, Baifu Luo, Ying Wang.

Construction and Building Materials, Volume 41, April 2013, Pages 844-851

(http://www.sciencedirect.com/science/article/pii/S0950061813000226)

5. Mechanical performance of low cement reactive powder concrete (LCRPC) by Hseyin

Yiiter, Serdar Aydn, Halit Yazc, Mert Ycel Yardmc. Composites Part B:

Engineering, Volume 43, Issue 8, December 2012, Pages 2907-2914

(http://www.sciencedirect.com/science/article/pii/S1359836812004969)

6. Compressive behaviour of hybrid fiber-reinforced reactive powder concrete after high

temperature by Wenzhong Zheng, Haiyan Li, Ying Wang.

Materials & Design, Volume 41, October 2012, Pages 403-409

(http://www.sciencedirect.com/science/article/pii/S0261306912003275)

7. Compressive stressstrain relationship of steel fiber-reinforced reactive powder

concrete after exposure to elevated temperatures by Wenzhong Zheng, Haiyan Li, Ying

Wang .Construction and Building Materials, Volume 35, October 2012, Pages 931-940

(http://www.sciencedirect.com/science/article/pii/S095006181200387X)

8. Reactive powder concrete change in compressive strength and modulus of elasticity at

high temperature by Tomasz Zdeb, Izabela Hager, Jacek liwiski. Brittle Matrix Composites

10, 2012, Pages 135-143

(http://www.sciencedirect.com/science/article/pii/B978085709988450013X)

9. Assessing drying shrinkage and water permeability of reactive powder concrete produced

in Hong Kong by C.M. Tam, Vivian W.Y. Tam, K.M. Ng. Construction and Building

Materials, Volume 26, Issue 1, January 2012, Pages 79-89

(http://www.sciencedirect.com/science/article/pii/S0950061811002443)

10. Effect of pre-setting pressure applied to mechanical behaviours of reactive powder

concrete during setting phase by Metin Ipek, Kemalettin Yilmaz, Mansur Smer, Mehmet

Saribiyik .Construction and Building Materials, Volume 25, Issue 1, January 2011, Pages 61-

68

(http://www.sciencedirect.com/science/article/pii/S0950061810003053)

You might also like

- Seminar Presentation PPT On Reactive Powder Concrete (Civil Engineering)Document39 pagesSeminar Presentation PPT On Reactive Powder Concrete (Civil Engineering)Siddhartha Siddhu100% (19)

- Seminar Reactive Powder ConcreteDocument16 pagesSeminar Reactive Powder ConcreteBharath MuraliNo ratings yet

- A Mini Project Report On CONCRETEDocument9 pagesA Mini Project Report On CONCRETEsuresh nenavathNo ratings yet

- Transparent ConcreteDocument26 pagesTransparent Concretekapil more67% (3)

- MINI PROJECT REPORT. (Original)Document19 pagesMINI PROJECT REPORT. (Original)Yashaswi M Gowda100% (1)

- A Study On Water AbsorbingDocument2 pagesA Study On Water AbsorbingInternational Journal of Innovative Science and Research Technology100% (1)

- Water Absorbing Raod PPT 2k23Document20 pagesWater Absorbing Raod PPT 2k23Video Cloud100% (3)

- Reactive Powder ConcreteDocument25 pagesReactive Powder ConcreteAbhiram Ravipati100% (1)

- Government Engineering College Patan: Manufacturing of Concrete Block Using Pervious ConcreteDocument31 pagesGovernment Engineering College Patan: Manufacturing of Concrete Block Using Pervious ConcreteRaval BhaveshNo ratings yet

- Seminar Report On Analysis of Cable Stayed BridgeDocument31 pagesSeminar Report On Analysis of Cable Stayed BridgeSijan Shrestha100% (1)

- Seminar Report On Fiber Rainforced ConcreteDocument48 pagesSeminar Report On Fiber Rainforced ConcreteAbd Al HAmid90% (10)

- PMC-18CV733 Notes Module-2Document8 pagesPMC-18CV733 Notes Module-2Girish Haragon100% (1)

- Civilcprojectbook PDFDocument89 pagesCivilcprojectbook PDFAnonymous ueXqEGHkxNo ratings yet

- 1.1 Concrete: Partial Replacement of Coarse Aggregate With Ceramic Tile 2019-2020Document25 pages1.1 Concrete: Partial Replacement of Coarse Aggregate With Ceramic Tile 2019-2020Naveen S100% (2)

- Underwater ConcretingDocument31 pagesUnderwater Concretingshivakumar83% (12)

- Fibre Reinforced ConcreteDocument19 pagesFibre Reinforced ConcreteJethalal Champaklal Gada67% (3)

- Final Project ReportDocument39 pagesFinal Project Reportmeenu67% (3)

- Transparent Concrete SeminarDocument17 pagesTransparent Concrete Seminarimul100% (2)

- Project ReportDocument61 pagesProject ReportSandeep SainiNo ratings yet

- Major Project Report PDFDocument74 pagesMajor Project Report PDFGaddam Sudheer100% (1)

- Major Project PPT GGBSDocument20 pagesMajor Project PPT GGBSNaReN KumarNo ratings yet

- Reactive Powder ConcreteDocument15 pagesReactive Powder ConcreterishinathnehruNo ratings yet

- Civil Seminar TopicsDocument13 pagesCivil Seminar TopicsKaran AvadNo ratings yet

- Study of Partial Replacement of Fine Aggregate by Oyster Shell and Partial Replacement of Cement by Rice Husk AshDocument53 pagesStudy of Partial Replacement of Fine Aggregate by Oyster Shell and Partial Replacement of Cement by Rice Husk AshRadix Citizen100% (1)

- Alternatives of Sand PDFDocument27 pagesAlternatives of Sand PDFRaviteja100% (1)

- Internship ReportDocument30 pagesInternship ReportAbhishek SengarNo ratings yet

- Seminar On GeopolymerDocument18 pagesSeminar On GeopolymerKritika100% (2)

- Partial Replacement of Glass Pieces With Fine AggregateDocument44 pagesPartial Replacement of Glass Pieces With Fine AggregateBharath Kumar H RNo ratings yet

- Major Project ReportDocument49 pagesMajor Project ReportMohini BhartiNo ratings yet

- Geopolymer Concrete REPORTDocument15 pagesGeopolymer Concrete REPORTharsha33367% (3)

- Water Soaking RoadDocument50 pagesWater Soaking RoadTanvi100% (5)

- 3D Printed Houses List of Tables: Table Number Title Page NumberDocument22 pages3D Printed Houses List of Tables: Table Number Title Page NumberShain100% (2)

- Project Report On Self Compacting ConcreteDocument89 pagesProject Report On Self Compacting ConcretePirpasha Ujede0% (1)

- Glass Poweder PPT - 2Document38 pagesGlass Poweder PPT - 2siddham shroff100% (2)

- M60 Self Compacting ConcreteDocument42 pagesM60 Self Compacting ConcreteAsif HussainNo ratings yet

- A Mini Project ReportDocument37 pagesA Mini Project ReportChintuu Sai100% (2)

- Partial Replacement of Cement by GgbsDocument25 pagesPartial Replacement of Cement by GgbsSai Ram100% (1)

- Ultra High Performance ConcreteDocument20 pagesUltra High Performance ConcretePavan Kumar63% (8)

- Plastic Roads Seminar ReportDocument8 pagesPlastic Roads Seminar ReportShahid Bhat0% (1)

- DE Sem 5Document24 pagesDE Sem 5Yamin Devgadhwala100% (1)

- Sagar PPT On Plastic As Soil StabilizerDocument20 pagesSagar PPT On Plastic As Soil StabilizerSagar78% (9)

- Seminar Final ReportDocument22 pagesSeminar Final ReportVasu Dev Vkm67% (6)

- Civil Engineering Mini Project-Flexible PavemetDocument31 pagesCivil Engineering Mini Project-Flexible PavemetG J R Ravikiran67% (9)

- Project Report (Phase 1) PDFDocument38 pagesProject Report (Phase 1) PDFvikki100% (3)

- Report On Building Construction Summer TrainingDocument64 pagesReport On Building Construction Summer TrainingVkram Joshi100% (2)

- Replacement of Natural Sand With Robosand in Making Concrete PDFDocument55 pagesReplacement of Natural Sand With Robosand in Making Concrete PDFsumankanthnelluri773% (30)

- Civil-Engineering Summer Training ReportDocument48 pagesCivil-Engineering Summer Training ReportLakshit Joshi82% (22)

- Reactive Powder Concrete PresentationDocument18 pagesReactive Powder Concrete PresentationSibabrata Choudhury67% (3)

- AAC Blocks Seminar PresentationDocument26 pagesAAC Blocks Seminar PresentationMahaManthra67% (3)

- Geopolymer Concrete PPT-KVRDocument24 pagesGeopolymer Concrete PPT-KVRBindu Srirangam100% (2)

- Major Project GGBS-1Document49 pagesMajor Project GGBS-1NaReN Kumar0% (1)

- Porous ConcreteDocument22 pagesPorous ConcreteROSHAN OJHA100% (8)

- Light Weight ConcreteDocument23 pagesLight Weight ConcretePavan EkboteNo ratings yet

- Project Report On GLASS FIBER REINFORCED CONCRETEDocument61 pagesProject Report On GLASS FIBER REINFORCED CONCRETEFazal Ahmad71% (7)

- Partially Replacing of Aggregate by Wall and Floor Tile in ConcreteDocument69 pagesPartially Replacing of Aggregate by Wall and Floor Tile in ConcreteprotenelllyNo ratings yet

- Project FINAAL 11Document16 pagesProject FINAAL 11vaibhavmnprNo ratings yet

- "Pervious Concrete": Gujarat Technological UniversityDocument26 pages"Pervious Concrete": Gujarat Technological UniversityRutvikNo ratings yet

- Ultra High Strength ConcreteDocument29 pagesUltra High Strength ConcreteShahab Sadqpur88% (8)

- Reactive Powder Concrete: A Seminar ReportDocument20 pagesReactive Powder Concrete: A Seminar ReportRama Chaithanya SingareddyNo ratings yet

- Seminar On Reactive Powder Concrete: Submitted byDocument21 pagesSeminar On Reactive Powder Concrete: Submitted byVîkÅš VìČkýNo ratings yet

- Stress Analysis - Creo-Simulate-220813Document35 pagesStress Analysis - Creo-Simulate-220813saad HussainNo ratings yet

- Me 1303 Gas Dynamics and Jet Propulsion: Presented byDocument24 pagesMe 1303 Gas Dynamics and Jet Propulsion: Presented byArul SankaranNo ratings yet

- Final SolutionDocument6 pagesFinal SolutionIR Ika EtyEtyka DoraNo ratings yet

- AB Die Casting EngDocument24 pagesAB Die Casting Engkaniappan sakthivelNo ratings yet

- BPSC AE Paper 5 (Civil) 2022 (English)Document9 pagesBPSC AE Paper 5 (Civil) 2022 (English)धीरज कुमारNo ratings yet

- ASTM Designation: C 1305 - 08Document3 pagesASTM Designation: C 1305 - 08Lupita RamirezNo ratings yet

- Comparison Carrier vs. McQuayDocument2 pagesComparison Carrier vs. McQuayPradeep SukumaranNo ratings yet

- Instruction Manual: Kosangas LPG Sdn. BHDDocument10 pagesInstruction Manual: Kosangas LPG Sdn. BHDahmad hafizNo ratings yet

- Flare KOD SizingDocument4 pagesFlare KOD SizingSaid Ahmed Salem100% (1)

- ASME IX QW (Welding General Requirements)Document12 pagesASME IX QW (Welding General Requirements)Ariq Fauzan100% (1)

- HMT Question PaperDocument1 pageHMT Question PaperSanjay GomastaNo ratings yet

- Prusa BOM.2Document3 pagesPrusa BOM.2Willow PrusaNo ratings yet

- 1.chapter 2: Lateral Earth Pressures and Retaining WallsDocument20 pages1.chapter 2: Lateral Earth Pressures and Retaining Wallssalt2009No ratings yet

- 4351 Steel Door FramesDocument11 pages4351 Steel Door Framesladharsunil100% (2)

- Column Design BS 8110.1985Document114 pagesColumn Design BS 8110.1985aries pambudiNo ratings yet

- 15B21H, 15B21RHDocument4 pages15B21H, 15B21RHGil CabreraNo ratings yet

- eRep-Performance Standards For Walk-In Refrigerator and Freezer Systems, AHRI 2012Document216 pageseRep-Performance Standards For Walk-In Refrigerator and Freezer Systems, AHRI 2012Moly69xNo ratings yet

- Tower A DesignDocument254 pagesTower A DesignAnderson Quispe VilcaNo ratings yet

- Modine - Comuserdata RACIWIDesktopepcasebolt Desktopdiscontinued 6-551Document28 pagesModine - Comuserdata RACIWIDesktopepcasebolt Desktopdiscontinued 6-551Bashar DaoudNo ratings yet

- Quiz 1 PrestressDocument4 pagesQuiz 1 PrestressHeiro KeystrifeNo ratings yet

- RCC54 Circular Column ChartingDocument13 pagesRCC54 Circular Column ChartingvaideehNo ratings yet

- Engine Cooling System: SectionDocument48 pagesEngine Cooling System: SectionLuis Alfonso Ortiz ESpinosaNo ratings yet

- Pitot TubeDocument8 pagesPitot TubeFarhad MalikNo ratings yet

- PDF - DownloadDocument3 pagesPDF - DownloadRohit PanditNo ratings yet

- Cec 110p PDFDocument20 pagesCec 110p PDFJoifry DonnaNo ratings yet

- طريقة 1Data14-01-2013Document1,100 pagesطريقة 1Data14-01-2013Alsaboha Engineering0% (1)

- 11 3082 01 Dowsil TC 5080 Thermal GreaseDocument2 pages11 3082 01 Dowsil TC 5080 Thermal GreasePRATHAMESH CHAUDHARINo ratings yet

- Wattle and Daub: Craft, Conservation and Wiltshire Case StudyDocument112 pagesWattle and Daub: Craft, Conservation and Wiltshire Case StudyPriyanka SuteNo ratings yet

- Ceilcote SF Corocrete: Description Mixing Ratio by VolumeDocument3 pagesCeilcote SF Corocrete: Description Mixing Ratio by VolumeRiian ApriansyahNo ratings yet

- Alucobond ProductDocument27 pagesAlucobond ProductYus wantoNo ratings yet