Professional Documents

Culture Documents

Hyundai Getz Body Electric

Uploaded by

StuGnuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hyundai Getz Body Electric

Uploaded by

StuGnuCopyright:

Available Formats

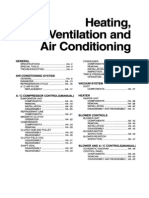

Body Electrical

System

GENERAL FUSES AND RELAYS

SPECIFICATIONS ............................................. BE -3 COMPONENTS ................................................. BE -62

SPECIAL TOOLS ............................................... BE -6 RELAY BOX (ENGINE COMPARTMENT)

TROUBLESHOOTING ....................................... BE -7 COMPONENTS .......................................... BE -64

INSPECTION .............................................. BE -65

AUDIO SYSTEM RELAY BOX (PASSENGER COMPARTMENT)

COMPONENTS ................................................. BE -29 COMPONENTS .......................................... BE -67

AUDIO UNIT INSPECTION .............................................. BE -69

COMPONENTS .......................................... BE -30

REMOVAL AND INSTALLATION ................ BE -33 INDICATORS AND GAUGES

INSPECTION .............................................. BE -34 COMPONENTS ................................................. BE -71

SPEAKERS INSTRUMENT CLUSTER

REMOVAL AND INSTALLATION ................ BE -35 COMPONENTS .......................................... BE -72

INSPECTION .............................................. BE -36 CIRCUIT DIAGRAM .................................... BE -74

ANTENNA REMOVAL AND INSTALLATION ................ BE -76

COMPONENTS .......................................... BE -37 INSPECTION .............................................. BE -77

REMOVAL AND INSTALLATION ................ BE -38

POWER DOOR LOCKS

MULTI FUNCTION SWITCH COMPONENTS ................................................. BE -81

COMPONENTS ................................................. BE -39 POWER DOOR LOCK ACTUATORS

MULTI FUNCTION SWITCH INSPECTION .............................................. BE -82

REMOVAL AND INSTALLATION ................ BE -40 POWER DOOR LOCK RELAY

INSPECTION .............................................. BE -42 INSPECTION .............................................. BE -84

HORNS POWER DOOR MIRRORS

COMPONENTS ................................................. BE -44 COMPONENTS ................................................. BE -85

HORN POWER DOOR MIRROR SWITCH

REMOVAL AND INSTALLATION ................ BE -45 CIRCUIT DIAGRAM .................................... BE -86

INSPECTION .............................................. BE -45 INSPECTION .............................................. BE -87

POWER DOOR MIRROR ACTUATOR

KEYLESS ENTRY AND BURGLAR ALARM INSPECTION .............................................. BE -88

COMPONENTS ................................................. BE -46

INSPECTION ..................................................... BE -47

POWER WINDOWS

ETACS MODULE COMPONENTS ................................................. BE -89

ANTI-THEFT FUNCTION ........................... BE -52 POWER WINDOW MOTOR

TRANSMITTER INSPECTION .............................................. BE -90

INSPECTION .............................................. BE -55 POWER WINDOW SWITCH

TRANSMITTER CODE REGISTRATION ... BE -55 CIRCUIT DIAGRAM .................................... BE -91

INSPECTION .............................................. BE -92

ETACS (ELECTRONIC TIME AND ALARM

CONTROL SYSTEM)

REAR WINDOW DEFOGGER

DESCRIPTION .................................................. BE -57

COMPONENTS ................................................. BE -94

SPECIFICATIONS ............................................. BE -57

REAR WINDOW DEFOGGER PRINTED HEATER

ELECTRONIC TIME AND ALARM CONTROL MODULE

INSPECTION .............................................. BE -95

CIRCUIT DIAGRAM .................................... BE -58

REAR WINDOW DEFOGGER SWITCH

REMOVAL AND INSTALLATION ................ BE -59

INSPECTION .............................................. BE -97

INSPECTION .............................................. BE -59

WINDSHIELD WIPER /WASHER

COMPONENTS ................................................. BE -98

WINDSHIELD WIPER I WASHER SWITCH

REMOVAL AND INSTALLATION ................ BE -99

INSPECTION .............................................. BE -100

FRONT WIPER MOTOR

COMPONENTS .......................................... BE -101

REMOVAL ................................................... BE -102

INSPECTION .............................................. BE -102

INSTALLATION ........................................... BE -103

FRONT WASHER MOTOR

REMOVAL AND INSTALLATION ................ BE -104

INSPECTION .............................................. BE -104

REAR WIPER /WASHER

REAR WIPER MOTOR

COMPONENTS .......................................... BE -105

REMOVAL ................................................... BE -106

INSPECTION .............................................. BE -107

INSTALLATION ........................................... BE -107

REAR WAHSER SWITCH

INSPECTION .............................................. BE -108

REAR WAHSER MOTOR

INSPECTION .............................................. BE -109

SEAT WARMER

COMPONENTS ................................................. BE -110

SEAT WARMER SWITCH

INSPECTION .............................................. BE -110

SUNROOF

COMPONENTS ................................................. BE -111

SUNROOF SWITCH

INSPECTION .............................................. BE -112

SUNROOF RELAY

INSPECTION .............................................. BE -113

SUNROOF MOTOR

INSPECTION .............................................. BE -114

LIGHTING SYSTEM

COMPONENTS ................................................. BE -115

HEAD LAMPS

REMOVAL AND INSTALLATION ................ BE -116

AIMING INSTRUCTIONS ........................... BE -116

TURN SIGNAL LAMP

REMOVAL AND INSTALLATION ................ BE -119

ROOM LAMP

INSPECTION .............................................. BE -120

OVERHEAD CONSOLE LAMP

REMOVAL AND INSTALLATION ................ BE -121

INSPECTION .............................................. BE -121

TURN I HAZARD LAMPS

INSPECTION .............................................. BE -122

FLASHER UNIT

INSPECTION .............................................. BE -123

RHEOSTAT

INSPECTION .............................................. BE -124

FRONT FOG LAMPS

REMOVAL AND INSTALLATION ................ BE -125

INSPECTION .............................................. BE -125

REAR FOG LAMPS

INSPECTION .............................................. BE -126

TAIL, PARKING AND LICENSE LAMPS

REMOVAL AND INSTALLATION ................ BE -127

STOP LAMPS

REMOVAL AND INSTALLATION ................ BE -128

COURTESY AND TRUNK LAMPS

REMOVAL AND INSTALLATION ................ BE -129

HEAD LAMP LEVELLING DEVICE

COMPONENTS ................................................. BE -130

HEAD LAMP LEVELLING SWITCH

CIRCUIT DIAGRAM .................................... BE -131

INSPECTION .............................................. BE -131

IMMOBILIZER CONTROL SYSTEM

DESCRIPTION .................................................. BE -133

BLOCK DIAGRAM ............................................. BE -135

COMPONENTS ................................................. BE -136

LIMP HOME FUNCTION ................................... BE -138

DIAGNOSIS OF IMMOBILIZER FAULTS .......... BE -139

IGNITION SYSTEM

IGNITION SWITCH

REMOVAL AND INSTALLATION ................ BE -141

INSPECTION .............................................. BE -143

GENERAL

GENERAL

SPECIFICATIONS E45BACD64

MULTIFUNCTION SWITCH

Items

Rated voltage

Operating temperature range

Rated load

Dimmer & passing switch

Lighting switch

Turn signal & lane change switch

Wiper switch

Washer switch

Rear wiper & washer switch

INSTRUMENTS AND WARNING SYSTEM

Warning lamps

Illumination

High beam

Low fuel

Turn signal (LH, RH)

Battery (charge)

Oil pressure

Air bag

Parking brake

Seat belt

Check engine

ABS

Door ajar

Tailgate open

Immobilizer

EPS

OD OFF

BE -3

Specifications

DC 12 V

-30C - +80C ( -22 - + 176F)

High : 230W (Lamp load)

Low : 11 OW (Lamp load)

Tail : 66W (Lamp load)

Lighting : 21 W (Lamp load)

69W (Lamp load)

Low, High : SA (Motor load)

Intermittent : 7mA (Relay load)

Lock : Max. 2SA (Motor load)

SA (Motor load)

Rear wiper : 3.SA (Motor load)

Rear washer : SA (Motor load)

Bulb wattage (W) Color

GLS-L : 3.4W (4EA), 1.4W (1 EA)

GL : 3.4W (3EA), 1.4W (1 EA) Green

GLS-H : 3.4W (4EA), LED (3EA)

1.4 Blue

1.4 Amber

1.4 Green

1.4 Red

1.4 Red

1.4 Red

1.4 Red

1.4 Red

1.4 Amber

1.4 Amber

1.4 Red

1.4 Amber

1.4 Amber

1.4 Red

1.4 Amber

BE -4 BODY ELECTRICAL SYSTEM

INDICATORS AND GAUGE

Items Specifications

Speedometer

Type

0 Cross-coil type

Input spec.

0 Hall IC type : 4 pulses/rev.

Indication

0 Km/h : 637rpm x 4 pulses/rev. indicates 60Km/h

0 MPH: 1024 rpm x 4 pulses/rev. indicates 60MPH

Standard values

Velocity (km/h) 20 40 60 80 100

Tolerance (km/h) 20-24.6 40-44 60.8-65.4 81.4-86.8 102.5-1 08.2

Velocity (km/h) 120 140 160 180 200

Tolerance (km/h) 123.5-129.6 144.4-151 165.4-172.4 186.3-193.8 207.2-215.2

Velocity (MPH) 10 20 40 60 80 100 120

Tolerance (MPH) 10-12.5 20-22.5 40-42.6 60-63.4 80.3-84.1 100.3-104.7 120.3-125.3

0 Tap the speedometer to prevent hysterisis effects during inspection.

Tachometer

Type 0 Cross-coil type (4cyl: 2pulses/rev, 4cyl: 4pulses/rev)

Standard values

Revolution (RPM) 1,000 2,000 3,000 4,000 5,000 6,000 7,000

Tolerance (RPM) 100 125 150 150 150 180 210

0 Tap the tachometer to prevent hysterisis effects during inspection.

Fuel gauge

Type 0 Cross - coil type (Fixed point type : Pointer should not fall into the "E" point but indicate remaining

fuel level when the ignition is off)

Standard values

Level

Gauge

Resistance (n) Gauge angle (')

E (Empty) 95 -40 2.5

1/2 32.5 04.0

F (Full) 7.0 40 2.5

0 Inspection order : E-+F-+E

The level must be reached within 7 minutes after the resistance is set for Full or Empty.

0 Point stability tolerance : Within 6.

Apply power for 1 0 minutes. Then turn off the power for an hour and read the position of the pointer.

ETPD001A

GENERAL BE -5

Items Specifications

Temperature gauge

Type

0 Cross - coil type

Indication standard

Temperature Angle C) Assembled tolerance C)

60"C -40 -

85"C- 110"C -7

+3

-2

Red zone (over 125"C) 355

+7

-4

0 Inspection order : OFF-+C-+H

Resistance of

Temperature ("C) 60 85 110 125 Remark

temperature sender

118 49 25 14.6 Without trip computer

(NTC) Resistance (n)

143.1 58.1 27.1 17.6 With trip computer

ETPD001B

LIGHTING SYSTEM

Items Bulb wattage (W)

Head lamp 60W /55W (High I Low beam)

Front turn signal lamp 21W

Front position lamp 5W

Front fog lamp 27W

Rear combination lamps

Tail/stop lamp 5W I 21W

Back up lamp 21W

Turn signal lamp 21W

Luggage lamp 5W

Room lamp 10W

Center high mounted stop lamp 16W

Overhead console lamp 10W X 2

License plate lamp 5W X 2

AUDIO

Items K210, K220 K240, H280

Rated output Max. 20W x 2 Max. 20W x 4

Load impedance 4n x 4 4n x 4

Band AM/FM, LW/MW/FM AM/FM, LW/MW/FM

Tuning type PLL Synthesized type PLL Synthesized type

Dark current Max. 2m A Max. 2mA

BE -6

Items

Frequency range I Channel

WINDSHIELD WIPER AND WASHER

Items

Windshield wiper motor

Rated voltage

Operating voltage range

Insulation resistance

Speed/current at 1 Nm load test

Speed/current at 4Nm load test

Torque/current when parking

Windshield & rear washer

Motor type

Pump type

Rated voltage

Discharge pressure

Flow rate

Current

BODY ELECTRICAL SYSTEM

K210, K220 K240, H280

AM : 531 - 1602KHZ/9 KHZ AM: 531 - 1602KHZ/9KHZ

FM : 87.5 - 1 08MHZ/1 00 KHZ FM: 87.5- 108 MHZ/100KHZ

LW : 153 - 279KHZ/1 KHZ LW : 153 - 279 KHZ/1KHZ

MW : 522 - 1620KHZ/9KHZ MW : 522 - 1620KHZ/9KHZ

FM : 87.5-108 MHZ/50KHZ FM: 87.5-108 MHZ/50KHZ

Specifications

DC 12V

DC 10-15V

Min. 1Mn

Low : 44-52 rpm/3.5A or less

High : 64-78 rpm/4.5A or less

Low : 39-47 rpm/5.5A or less

High : 56-68 rpm/?.OA or less

Low : 28Nm/24A or less

High : 23Nm/28A or less

DC ferrite magnet

Centrifugal

12V

1 .8kg/cm

2

or more

1 ,500cc/min. or more

5.0A or less

Overload capacity (Continuous operation)

With water 60 sec. or less

20 sec. or less Without water (Racing)

Rear wiper motor

Speed/current at no load test

Speed/current at 1 Nm load test

Torque/current when parking

Wiping angle at no load

SPECIAL TOOLS E449ASD6F

Tool (Number and Name)

09900-21300

Keyless adapter

Illustration

38-50 rpm/2.0A or less

35-45 rpm/3.5A or less

8Nm/14A or less

173 3

10021300

Use

Store transmitter code connecting the DLC

(Data Link Connector) cable of Hi-scan to

the multi purpose check connector.

GENERAL BE-7

TROUBLESHOOTING E43047A23

INSTRUMENTS AND WARNING SYSTEM

Symptom Possible cause Remedy

Tachometer does not operate No.7 fuse (10A) blown Check for short and replace fuse

Tachometer faulty Check tachometer

Wiring faulty Repair if necessary

Fuel gauge does not operate No.7 fuse (10A) blown Check for short and replace fuse

Fuel gauge faulty Check gauge

Fuel sender faulty Check fuel sender

Wiring faulty Repair if necessary

Low fuel warning lamp does not light No.7 fuse (10A) blown Check for short and replace fuse

Bulb burned out Replace bulb

Fuel level sensor faulty Check sensor

Wiring or ground faulty Repair if necessary

Water temperature gauge does No.7 fuse (10A) blown Check for short and replace fuse

not operate Water temperature gauge faulty Check gauge

Water temperature sender faulty Check sender

Wiring or ground faulty Repair if necessary

Oil pressure warning lamp does No.7 fuse (10A) blown Check for short and replace fuse

not light Bulb burned out Replace bulb

Oil pressure switch faulty Check switch

Wiring or ground faulty Repair if necessary

Low brake fluid warning lamp No.7 fuse (10A) blown Check for short and replace fuse

does not light Bulb burned out Replace bulb

Brake fluid level warning switch faulty Check switch

Parking brake switch faulty Check switch

Wiring or ground faulty Repair if necessary

Open door warning lamp does not light No.29 fuse (15A) blown Check for short and replace fuse

Bulb burned out Replace bulb

Door switch faulty Check switch

Wiring or ground faulty Repair if necessary

Seat belt warning lamp does not light No.7 fuse (10A) blown Check for short and replace fuse

Bulb burned out Replace bulb

Buckle switch faulty Check switch

Wiring or gound faulty Repair if necessary

BE -8 BODY ELECTRICAL SYSTEM

LIGHTING SYSTEM

Symptom Possible cause Remedy

One lamp does not light Bulb burned out Replace bulb

(all exterior) Socket, wiring or ground faulty Repair if necessary

Head lamps do not light Bulb burned out Replace bulb

No.26, No.28 fuse (10A) blown Check for short and replace fuse

Lighting switch faulty Check switch

Wiring or ground faulty Repair if necessary

Tail lamps and license plate No.2, No.6 fuse (1 OA) blown Replace fuse and check for short

lamps do not light Battery fusible link (50A) blown Replace the fusible link

Tail lamp relay faulty Check relay

Lighting switch faulty Check switch

Wiring or ground faulty Repair if necessary

Stop lamps do not light No.19 fuse (15A) blown Replace fuse and check for short

Stop lamp switch faulty Adjust or replace switch

Wiring or ground faulty Repair if necessary

Stop lamps stay on Stop lamp switch faulty Adjust or replace switch

Instrument lamps do not light Rheostat faulty Check rheostat

(Tail lamps light) Wiring or ground faulty Repair if necessary

Turn signal lamp does not flash Bulb burned out Replace bulb

on one side Turn signal switch faulty Check switch

Wiring or ground faulty Repair if necessary

Turn signal lamps do not operate No.5 fuse (1 OA) blown Replace fuse and check for short

Flasher unit faulty Check flasher unit

Turn signal switch faulty Check switch

Wiring or ground faulty Repair if necessary

Hazard warning lamps do not operate No.20 fuse (15A) blown Replace fuse and check for short

Flasher unit faulty Check flasher unit

Hazard switch faulty Check switch

Hazard relay faulty Replace relay

Wiring or ground faulty Repair if necessary

Flasher rate too slow or too fast Lamps' wattages are smaller or Replace lamps

larger than specified

Defective flasher unit Check flasher unit

Back up lamps do not light up No.5 fuse (1 OA) blown Replace fuse and check for short

Back up lamp switch faulty Check switch

Wiring or ground faulty Repair if necessary

Overhead console lamp does No.29 fuse (15A) blown Replace fuse and check for short

not light up Wiring or ground faulty Repair if necessary

GENERAL

AUDIO

There are six areas where a problem can occur: w1rmg

harness, the radio, the cassette tape deck, the CD player,

the speaker, and antenna. Troubleshooting enables you to

confine the problem to a particular area.

Turn Ignition key to

ACC position

Turn on the radio or the

tape player

I

I

Verify customer com-

BE-9

1 ) Place balance and fader control

to center position.

2) Set volume control to proper

position.

plaint or identify symptom

I I I

I

Sound

I I

Radio

I

I Cassette player I

I

Noise

I I

CD player

I

I Miscellaneous I

See CHART 1 See CHART2 See CHART3 SeeCHART4 See CHARTS

I

I I I I

I

Faint reception I Poor volume

I I

Seek/scan

I I

"Eating" tape

I

problem

See CHARTS SeeCHART7 See CHARTS SeeCHART9

ETPD001C

BE -10

CHART 1

Sound

1. Radio and tape player

have no sound at all.

Are all connectors behind

radio and tape player prop-

erly connected ?

Yes

Is there voltage (12V) be-

tween terminal 16 of the

M16 and body ground?

Yes

Are radio and player prop-

erly connected ?

Yes

Check connection between

output connector of radio

and car.

O.K.

Replace radio unit

Connect

properly

Reinstall

properly

BODY ELECTRICAL SYSTEM

Check speaker

connector

O.K.

Temporarily install

another speaker.

N.G.

Replace radio unit

ETNC015A

GENERAL

I 2. Tape player OK but no sound from radio I

I

I

Check that the antenna isi--I___;Y:..::e:.:::s:._...--1

pluged into the radio. 1 1 Reinsert plug, O.K. ? 1 1 Inspect antenna plug

No I Not O.K. I

I

Insert properly

I

CHART 2

I Does radio alone work ? Replace radio

No I

I

Temporarily install 11--_o;:;.:.:...K::.... ---1

another antenna. O.K.? I

NotO.K.I

I

Replace radio

I

Inspect antenna and

antenna cable, and

replace if necessary

I

Radio problem

I

I I

Weak Poor tone

I

I

Check antenna Tune correctly. Still poor?

(extend antenna fully)

Yes I

I

Check for shorts in speaker Not O.K. 1 .

Check connection of harness

1

Repair harness

antenna plug

oKI

I Not O.K. r . Check for object lying on

Temporarily install another

speaker and rattling

1 Remove obJect

antenna. O.K. ?

OK'

I Not O.K.

Extend antenna. Still poor ?

O.K. I Replace radio

Yes I

Check antenna and lead-in

Replace antenna

for broken connectors. Yes

: Replace antenna

Does the tester indicate an

open circuit ?

No I

Is the broadcast quality the

Yes

: Replace radio unit

cause of poor tone quality ?

BE -11

ETA9010C

I

I

I

J

ETA9010D

~

0

I

r

I

Cassette player

I

Dead

o t ~ Check inside tape O.K.

door for obstruction

Remove obstruction

I

Play test tape

I O.K. I

Play test tape

I I I

Not O.K. Not O.K.

INFORM CUSTOMER

1. To use good quality tape.

2. Don't put anything inside

tape door except tape

3. Don't use C-120 type tape

I

Remove unit I

I

Replace radio unit

I

for repair

l

Low sound or poor Will not accept

sound quality or eject tape

Clean tape head

and capstan (page BE-34)

L Use a cotton swab dipped

in isopropyl alcohol (refer

to owner's manual)

Play test tape

I O.K.

1

Inspect by using test tape I

I

Not O.K. Not O.K.

INFORM CUSTOMER

1. To use good quality tape.

2. To clean tape head and

capstan at intervals of no

more than 1 00 hours

Replace radio unit Replace radio unit

0

:::1:

>

~

w

m

m

I

......

N

m

0

~

m

r

m

0

.....

l:J

0

)>

r

en

-<

en

.....

m

s:::

GENERAL BE -13

CHART 4

1. RADIO

I

Noise

I

I

I

Start the engine

I

I

I

Tune correctly, still noise ? I

Yes I

I

Check connectors

I Not O.K. I

Fully insert connector

I I I

O.K.I

I

Check mounting screws

I Not O.K. I

Tighten the screws

I I

O.K.I

lis the antenna lead-in routed I

Yes

Reroute the antenna lead-in I

too close to a harness ? I

No I

ON

I

Engine

I

OFF

I I

I

When disconnecting the ant- I No "i When disconnecting the ant-r

Yes

I enna lead, is there a noise ? I I enna lead, is there a noise ? 1 I

Replace radio unit

Yes I Yes I

No

If noise still occurs after checking

I

Is wiring correct ?

I

Noise from outside source

I

----1

(No fault in radio unit)

the above points, check for outside

No I

noise sources (various accesso-

ries, i.e. horn, wipers, etc.)

I

Repair harness

I

ETA9010F

BE -14 BODY ELECTRICAL SYSTEM

2. TAPE

Noise

Start the engine

Not O.K.

Check ground Ground completely

O.K.

Not O.K.

Check mounting screws Tighten the screws

O.K.

O.K.

Check with another tape Tape is defective

Not O.K.

Is wiring correct ?

Yes

Replace radio unit

No

Repair harness

ETA9010G

CHART 5

1. CD WILL NOT BE ACCEPTED

Can you insert a CD ?

No

I

A CD is already in the unit.

I

I

I Yes

Is CD rejected from approx. 15mm

depth of the insertion panel even

No _j

O.K.

I I

though CD can be inserted ?

I Yes

Though CD is completely inserted

once, "error" is displayed and the CD

No _I

O.K.

I

I

is rejected ?

I Yes

Check CD.

o Is the labeled side faced downward ?

Yes

I Insert the CD correctly or check to I

o Is the recorded face of the CD dirty ?

o Does dew exist on the recorded

I see if the CD is defective.

face of the CD ?

I No

I

Replace CD player

l

I\9010H

GENERAL

2. NO SOUND

H

Does it play if a good quality CD

Replace defective CD.

is inserted ?

I No

Return it to normal temperature,

Does the "WAIT" indicator flicker? and recheck operation. O.K.

I No

Does it operate properly ?

No

Are the radio and CD player

No

Securely connect the

t---

connected securely ? radio and CD player.

Jves

Repair or replace CD player if the

combined radio cassette operates

properly.

3. CD SOUND SKIPS

1) Sound sometimes skips when parking.

Is CD face scratched or dirty ? CD is defective, or clean CD. I

Does it play properly if CD is replaced

Repair or replace CD player. I

with an existing proper CD ?

lves

Replace CD.

2) Sound sometimes skips when driving.

(Stop vehicle, and check it.)

(Check by using a CD which is free of scratches, dirt or other damage.)

Does sound skip when the side of No Check for skipping while driving

the CD player is tapped ? and contact a service shop.

lves

Securely mount the CD player.

BE -15

I

ETA90100

ETA90101

BE -16

4. SOUND QUALITY IS POOR

Does it play properly if another good-

quality CD is loaded ?

Repair or replace CD player.

5. CD WILL NOT EJECT

Is the ignition key at ACC or ON ?

I Yes

Is the combined amplifier or radio

connected securely ?

I Yes

If CD does not eject, don't try

removing it.

The player may be damaged.

Therfore, contact a service shop for

repairs.

6. NO SOUND FROM ONE SPEAKER

Is CD player securely connected to

the combined radio ?

I Yes

Does it play properly if another CD

player is connected ?

I No

Repair or replace the combined radio.

BODY ELECTRICAL SYSTEM

Yes 1 I

1--------1

1

Replace CD

~ ~

I

No

~ Turn the key to ON.

I I

No

~ Securely connect.

I

No

: Securely connect them.

I

Yes

~ Repair or replace CD player.

I

ETA9010J

GENERAL

CHART 6

Faint reception

Are both reception and static faint

even when antenna is fully length-

Temporarily install another

speaker. O.K. ?

ened?

No

Inspect antenna

Temporarily install another

antenna. O.K. ?

Replace radio

CHART 7

Poor Volume

Does the problem disappear

No

when switching from the cas-

sette to the radio ?

Yes

Is the tape player head O.K. ? 1

No

Yes

No

Inspect antenna and cable and

repair if necessary.

Improperly connected harness

or connector.

Dirty, worn or damaged tape

player head, improperly installed

tape player head.

Check for an improperly connected

I Correct the connection or re- I

tape player head wire or a malfunc-

l

place the malfunctioning parts.

tion in the tape player itself.

The tape being tested must be of

I Use tapes which have been

I

good stereo quality.

I

recorded in stereo.

BE -17

Replace speaker

Replace radio unit

ETA9010K

I Correct the connection of the

I I

harness or the connector.

i Clean or replace the tape

player head.

I

ETA9010L

BE -18 BODY ELECTRICAL SYSTEM

CHART 8

Seek/scan problem

I

Is antenna lead-in properly in- No

1

Install antenna properly

I

stalled?

Yes!

Check that the antenna is

Not O.K. 1

I

inserted completely into the

1

Fully insert antenna

antenna receptacle.

O.K.,

Check antenna and lead-in for

Yes

: Replace antenna

I

broken connectors. Tester indi-

cates open circuit ?

No I

Replace radio unit

CHART 9

"Eating" tape

Check capstan and pinch roller Clean head, capstan, and pinch roller.

Use head cleaner or isopropyl alcohol for oxide and dirt build-up

O.K.

O.K.

O.K.

Use C-30, 60, 90 tapes (C-120 tape is

very thin and delicate)

Check with another tape t-----t Tape is defective. Change tape

Not O.K.

Replace tape player

ETA9010M

ETA9010N

GENERAL BE -19

WINDSHIELD WIPER

1. Wiper low and wiper high does not work.

Check No.21 fuse(20A) for short

NG

Replace the fuse

I

OK

Inspect the battery supply voltage of

wiper switch between connector(M01-2)

NG

Repair the wire harness and poor

terminals 11 and 9. ground (G01)

OK: Battery voltage (12V)

OK

Wiper switch inspection

NG

(See the workshop manual page BE-1 00) I

Replace the wiper switch

OK

Windshield wiper motor inspection

NG

Replace the wiper motor

(See the workshop manual page BE-1 02)

I

ETPD001E

2. When washer switch is on, wiper does not work.

Check No.21 fuse(20A) for short

NG

I

Replace the fuse

I

OK

Inspect the input voltage of washer

NG

Repair the wire harness or

switch between connector (M01-2)

terminal 15 and ground

the washer switch

OK

Refer to the above "1. Wiper does not work"

I

ETPD001F

BE -20 BODY ELECTRICAL SYSTEM

POWER WINDOW

1. No windows operate from the main switch on the

driver's door.

NG

Replace fuse or fusible link No.19,23 fuse and fusible link short

I

check

OK

Power window relay inspection

NG

(See the workshop manual page BE-66)

Replace the relay

OK

Poor ground (G01) and the wire

NG

Repair the wire harness and poor

harness inspection ground (G01)

2. Driver's side window does not operate.

Inspect the battery supply voltage of

power window main switch between

NG

Repair the wire harness and

connector (005) terminals 1 0 and 11. poor ground (GOB)

OK : Battery voltage (12V)

OK

Power window main switch inspection

(See the workshop manual page BE-92}

NG

Replace the power window main switch

OK

Driver's side power window

NG

I

Replace the power window motor

motor inspection

(See the workshop manual page BE-90)

ETPD001G

I

ETPD001H

GENERAL BE-21

3. Passenger's side window does not operate.

Inspect the battery supply voltage of

passenger's side power window switch

NG

Repair the wire harness and

between connector (015) terminal 6 poor ground (G08)

and ground.

OK : Battery voltage (12V)

OK

Passenger's side power window

NG

I

Replace the power window switch

I switch inspection

(See the workshop manual page BE-93)

OK

Passenger's side power window

NG

I

Replace the power window motor

I motor inspection

(See the workshop manual page BE-90)

ETPD0011

BE -22 BODY ELECTRICAL SYSTEM

POWER DOOR LOCK ~ i n c e door lock relay is fail, replace the door lock

relay.

1. Lock function works but unlock function does not in-

terlock.

~ Since door unlock relay is fail, replace the door

unlock relay.

3. When passenger side knob is controlled, all doors

interlocks, but when driver side knob is controlled, all

doors do not interlock.

2. Unlock function works but lock function does not in-

terlock.

I

Passenger's side actuator

NG

Connection rod defective of

operation passenger's side door lock actuator

OK

1. Input wiring short of driver's

side door lock switch

I

Driver's side door lock switch

NG

inspection

2. Internal switch contact failure

of driver's side door lock

actuator

OK

1. Output wiring short of all

doors' lock actuator

2. All doors' lock actuator failure

1. Check the wiring between connectors

M25-2 and 009@.

2. Check the wiring between connector

009@ and ground (G08).

Measure resistance of actuator by

handling it by the hand after connecting

an ohmmeter to the both ends of actuator

unit.

Locked condition : oo

Unlocked condition : Normal if it is below 1 n

[009]

@

(Connector terminal of driver's

side door lock actuator)

Check the output wiring between door

lock relay and all doors' actuator

Apply 12V to the both ends under

uninstalled condition, and it's normal if

it operates.

[019/029/039]

g (Connector terminal of

ttfj all doors' lock actuator)

ETPD001J

GENERAL

4. When passenger side knob is controlled. All doors

interlocks. But when the driver side knob is controlled,

all doors do not interlock.

NG

I Driver's side actuator operation :

Connection rod defective of

driver's side door lock actuator

OK

1 . Input wiring short of passenger's

side door lock switch

I

I

NG

Passenger's side door lock

I

switch inspection

2. Internal switch contact failure

of passenger's side door lock

actuator

OK 1. Output wiring short of all

doors' lock actuator

2. All doors' lock actuator failure

BE -23

1. Check the wiring between connectors

M25-20and 0190.

2. Check the wiring between connector

019 and ground (GO?).

Measure resistance of actuator by

handling it by the hand after connecting

an ohmmeter to the both ends of actuator

unit.

Locked condition : oo

Unlocked condition : Normal if it is below 1 n

[019]

@

(Connector terminal of

passenger's side door

lock actuator)

Check the output wiring between door

lock relay and all doors' actuator.

Apply 12V to the both ends under

uninstalled condition, and it's normal if

it operates.

[009/029/039]

Q (Connector terminal of

C::=fj all doors' lock actuator)

ETPD001K

BE -24 BODY ELECTRICAL SYSTEM

5. Both sides do not interlock either.

NG

I

I

No.11 fuse(20A) short check

I

Replace the fuse

OK

Door lock/unlock relay inspection

NG

I I (See the workshop manual page BE-84)

Replace the relay

OK

Driver's side door lock switch input

signal inspection

NG

I

Check for an open in the wire

I

(ET ACS module connector M25-2

I

terminal@)

OK

Passenger's side door lock switch input

signal inspection

NG

I I

(ETACS module connector M25-2

Check for an open in the wire

terminal@)

OK

Replace the ET ACS module

ETPD001L

GENERAL

KEYLESS ENTRY & BURGLAR ALARM SYSTEM

1. Alarm does not work. (Hazard lamp works)

NG

I

No.20 fuse(15A) short check Replace the fuse

OK

Output wiring inspection of

NG

Repair the wire harness and

burglar alarm horn poor ground (G12)

OK

Burglar alarm horn inspection

NG

I

Replace the burglar alarm horn

(See the workshop manual page BE-51)

OK

Replace the ET ACS module

2. When hood is opened inside the car like alarm test,

horn does not work.

Check input wiring short of hood switch

1

NG

Repair an open in the wire between

connector (M25-2) terminal 8 and

OK

the hood switch (E38).

NG

Hood switch inspection

I

(See the workshop manual page BE-50)

Replace the hood switch

OK

Replace the ET ACS module

BE -25

I

I

ETPD001M

I

ETPD001N

BE -26 BODY ELECTRICAL SYSTEM

3. When door is opened inside the car like alarm test,

horn does not work (If tailgate and hood is opened,

alarm works)

Check input wiring short of all door switch

1

NG

Repair an open in the wire between

connector (M25-2) terminal 10, 11, 12

OK

and the door switch.

NG

All door switch inspection

I (See the workshop manual page BE-49)

Replace the door switch

OK

Replace the ET ACS module

4. When tailgate is opened inside the car like alarm test,

horn does not work.

Check input wiring short of tailgate switch

1

NG

Repair an open in the wire between

connector (M25-2) terminal 14

OK

and the tailgate switch.

NG

Tail gate switch inspection

I

(See the workshop manual page BE-50)

Replace the tailgate switch

OK

Replace the ET ACS module

I

ETPD0010

ETPD001P

GENERAL

5. When the vehicle is locked by the transmitter, cen-

tral door lock function works but hazard lamp doesn't

blink.

NG

Check input wiring short of all door switch

1

Repair an open in the wire between

connector (M25-2) and the door switch

OK

NG

Repair an open in the wire between

Check input wiring short of tailgate switch

connector (M25-2) and the tailgate

switch

OK

Display

When checking hood switch under

open condition

Rubber at the above hood is not

closed condition pressing enough the hood switch.

OK

Replace the ET ACS module

6. Engine does not start, when the alarm released con-

dition.

YES

Does the start motor move? Check the starting circuit

NO

Change In

Turn the key into start position as

on state

ET ACS module is currently alarm

monitoring the start inhibit output

condition mode

Remain off

Check the starting circuit

BE -27

ETPD001Q

ETPD001R

BE -28

7. Central door lock function works, but keyless entry

system does not work.

YES

Does the transmitter lamp work

when its button is depressed?

OK

Does the door lock or unlock when

the transmitter button is depressed?

I

Normal

I

BODY ELECTRICAL SYSTEM

NO

Transmitter battery replacement

NG

After replacing transmitter, register

the transmitter code using Hi-scan

(See the workshop manual page BE-55)

OK

Does the keyless entry operation

work after removing the key?

NO

Since ET ACS module is defective,

replace ET ACS module and register

transmitter code

ETPD001S

AUDIO SYSTEM BE -29

AUDIO SYSTEM

COMPONENTS E410C937E

Roof antenna

Rear door speaker

Front door speaker

Antenna feeder cable

Rear door speaker

Front door speaker

Audio unit

ETPD060A

BE -30 BODY ELECTRICAL SYSTEM

AUDIO UNIT

COMPONENTS E4085F1

[ 1<210 1

Connector [M16) Antenna jack

==u=======

==n======

<=I 1:=1 <=I

.

,\. ,\. ,\. lFoll lFoll

Connector [M16) Terminal Description

1 Antenna

2 Rear left speaker()

3 Front left speaker(-)

4 Front right speaker()

5 Rear right speaker(-)

[M16]

6 Illumination(-)

7 ACC(+)

8 Ground

9 Rear left speaker(+)

10 Front left speaker(+)

ETJA001C

11 N.C.

12 N.C.

13 Front right speaker(+)

14 Rear right speaker(+)

15 Illumination(+)

16 Battery(+)

ETPD061A

AUDIO SYSTEM BE -31

[ K220]

Connector [M16] Antenna jack

Connector [M16] Terminal Description

1 Antenna

2 Rear left speaker(-)

3 Front left speaker(-)

4 Front right speaker(-)

[M16]

5 Rear right speaker(-)

GJ@XjJ J

6 Illumination(-)

7 ACC(+)

8 Ground

9 Rear left speaker(+)

10 Front left speaker(+)

ETJA001C

11 N.C.

12 N.C.

13 Front right speaker(+)

14 Rear right speaker(+)

15 Illumination(+)

16 Battery(+)

ETPD061B

BE -32

[ H280]

Connector [CD changer]

Connector [3 pin]

-

0

@

Connector(M16]

[M16)

= J

ETJA001C

Terminal

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Description

Antenna

Rear left speaker(-)

Front left speaker(-)

Front right speaker(-)

Rear right speaker(-)

Illumination(-)

ACC(+)

Ground

Rear left speaker(+)

Front left speaker(+)

Voice ON

N.C.

Front right speaker(+)

Rear right speaker(+)

Illumination(+)

Battery(+)

BODY ELECTRICAL SYSTEM

KTMB001M

Antenna jack

KTMB001L

Connector [3pin] Terminal Description

w

1

Ground

2

Signal

'

3

Ground

ETHA005F

Connector Terminal Description

(CD Changer)

1

R

2

COON

3

BUS

4 B+

5

M. Ground

6

N.C.

7

L

ETJA001G 8 A. Ground

ETPD061C

AUDIO SYSTEM BE -33

REMOVAL AND INSTALLATION E4F8868AO

1. Disconnect the negative (-) battery terminal.

2. Remove the 2 screws and 2 bolts holding the driver's

crash pad lower panel.

ETPD062E

3. Disconnect the hood release cable and the data link

connector from the beneath driver's crash pad lower

panel.

ETPD062B

4. Remove the glove box.

5. Disconnect the intake control mode, mode control and

air mix control cable.

6. Detach the clips and disconnect the wire connectors

then carefully remove the center facia panel with a

flat-tip screwdriver.

Front fog lamp

switch

Air mix control

cable

ETPD062D

7. Remove the 4 screws holding the audio unit and dis-

connect the wire connector then remove the audio

unit.

KTPC062A

8. Installation is the reverse of removal.

BE -34 BODY ELECTRICAL SYSTEM

INSPECTION E4DE3449F

TAPE HEAD AND CAPSTAN CLEANING

1. To obtain optimum performance, clean the head, and

capstan as often as necessary, depending on fre-

quency of use and tape cleanness.

2. To clean the tape head and capstan, use a cotton

swab dipped in ordinary rubbing alcohol. Wipe the

head and capstan.

~

/

Head

Capstan

ETA9035A

AUDIO SYSTEM

SPEAKERS

REMOVAL AND INSTALLATION E48B5588C

FRONT SPEAKER

1. Remove the screw holding the inner handle and dis-

connect the inner handle rod and lock rod, then re-

move the inner handle.

2. Remove the screws holding the front door trim panel

then carefully remove it with a flat-tip screwdriver.

~ N O T

When prying with a flat-tip screwdriver, wrap it with a

shop towel to protect the painting surface.

ETPD063C

BE -35

3. Remove the 4 screws and disconnect the wire con-

nector, then remove the front speaker.

KTPC063A

4. Installation is the reverse of removal.

BE -36

REAR SPEAKER

1. Remove the screw holding the inner handle and dis-

connect the inner handle rod and lock rod, then r e ~

move the inner handle.

2. Remove the screws holding the rear door trim panel

then carefully remove it with a flat-tip screwdriver.

~ N O T

When prying with a flat-tip screwdriver, wrap it with a

shop towel to protect the painting surface.

ETPD063D

BODY ELECTRICAL SYSTEM

3. Remove the 4 screws and disconnect the wire con-

nector, then remove the rear speaker.

KTPC063B

4. Installation is the reverse of removal.

INSPECTION E447EADEA

1 . Check the speaker with an ohmmeter. If an ohmmeter

indicates the correct impedanceof the speaker when

checking between the speaker(+) and speaker(-) of

thesame channel, the speaker is ok.

2. If a clicking sound is emitted from the speaker when

the ohmmeter is connectedto the speaker terminals,

the speaker is ok.

ETA9040A

AUDIO SYSTEM BE -37

ANTENNA

COMPONENTS E496E56B6

Roof antenna pole

Antenna feeder cable

Front pillar (RH)

Antenna feeder cable

KSNB002A

TB32

Clip

Roof antenna

Roof panel

Antenna feeder cable

Nut

Headliner

[Section A-A] [Section B-8]

KSNB002B KSNB002C

ETPD064A

BE -38

REMOVAL AND INSTALLATION E42DOE918

1. Detach the lens from the overhead console lamp with

a flat-tip screwdriver.

(-)screwdriver

ESPD170P

2. Remove the 2 screws and the roof wire connector

then remove the overhead console assembly.

\UJl II 1/U/

AWl

I

ETPD065D

3. Remove the roof antenna after removing a nut.

Roof antenna

Roof panel

ETPD065A

BODY ELECTRICAL SYSTEM

4. Remove the sun visor and the assist grip handle then

pull the headliner down and remove the roof antenna

cable.

ETPD065B

5. Installation is the reverse of removal.

MULTI FUNCTION SWITCH BE -39

MULTI FUNCTION SWITCH

COMPONENTS E429E70F

[Turn signal switch]

[Wiper switch]

--LO

--HI

T81

[Lighting switch]

[Intermittent wiper volume] FAST

[Rear wiper switch] R ~ V ~ o w 1b

OFF /

ON

/' /'

/ "''FF

[Washer switch]

[Dimmer & Passing switch]

[M01-1] TB2

(M01-1] [M01-2] [M01-3]

I11IWI411

CR208001

ETJAOOSI

Circuit connection

Connector Terminal

Description

Connector Terminal

Description

No. No. No. No.

10 Head lamp switch power 9 Wiper ground

11 Rear fog lamp 10 Wiper high speed

12 Head lamp switch ground 11 Wiper/Washer & mist power

M01-1

13 Tail lamp switch

M01-2

12 Wiper low speed

14 Head lamp high beam power 13 Wiper parking

15 Head lamp low beam power 14 Rear wiper & washerpower

16 Tum signal lamp (RH) switch 15 Front washer switch

17 Flasher unit power 16 Rear wioer oarkina

18 Tum signal lamp (LH) switch 17 Rear washer

1 - 18 Rear wiper

M01-3

2 Horn relay

3 -

4 -

ETPD066A

BE -40

MULTI FUNCTION SWITCH

REMOVAL AND INSTALLATION E42FD74C3

Prior to removing of the multi function switch assembly in

vehicles equippedwith air bags, be careful to follow the

following:

ffi CAUTION

Never attempt to disassemble or repair the air

bag module or clock spring.lf faulty, replace

it.

Do not drop the air bag module or clock

spring or allow contact with water,grease or

oil. Replace if a dent, crack, deformation or

rust is detected.

The air bag module should be stored on a flat

surface and placed so that thepad surface is

facing upward. Do not place anything on top

of it.

Do not expose the air bag module to temper-

atures over 9:1' C (20d' F).

After deployment of an air bag, replace the

clock spring with a new one.

Wear gloves and safety glasses when hand-

ing an air bag that has been deployed.

An undeployed air bag module should only

be disposed of in accordance withthe proce-

dures mentioned in the restraints section.

When you disconnect the air bag mod-

ule-clock spring connector, take care notto

apply excessive force.

The removed air bag module should be stored

in a clean, dry place.

Prior to installing the clock spring, align the

mating mark and "NEUTRAL" position indica-

tor of the clock spring, and after turning the

front wheelsto the straight-ahead position, in-

stall the clock spring to the column switch.lf

the mating mark of the clock spring Is not

properly aligned, the steeringwheel may not

completely rotate during a turn, or the flat

cable within theclock spring may be broken

obstructing normal operation of the SRS and

possiblyleading to serious Injury to the vehi-

cle's driver. To inspect the clock sprlng,refer

to the restraints section.

BODY ELECTRICAL SYSTEM

1. Disconnect the negative(-) battery terminal.

KPPD004A

2. Remove the 3 bolts and disconnect the air bag con-

nector and the horn connector, then remove the air

bag module.

& CAUTION

Remove the horn pad only for vehicle without air

bag.

KPPD005A

3. Remove the steering wheel lock nut.

KPPD006A

MULTI FUNCTION SWITCH

4. Remove the steering wheel with special tool (09561-

11002).

& CAUTION

Do not hammer on the steering wheel to remove it.

Doing so may damage the collapsible mechanism.

KPPD007A

5. Remove the steering column shroud after removing 3

screws.

KPPD008A

6. Remove the clock spring.

KPPD010A

BE -41

7. Disconnect the wire connectors and remove the

multi-function switch after pressing down the indi-

cated parts as shown in the illustration.

KPPD011A

8. Installation is the reverse of removal.

BE -42

INSPECTION E41E634F6

LIGHTING SWITCH INSPECTION

Check for continuity between the terminals while operating

the lighting switch.

LIGHTING SWITCH [M01-1]

~

10 11 12

n

OFF

I

0

II

0

......, ......,

DIMMER AND PASSING SWITCH [M01-1]

~ 10

n

HU 0

HL

0

p

HU : Head lamp high beam

HL : Head lamp low beam

12

0

P : Head lamp passing switch

14

D

0

KTPC075G

13

D

0

ETPD075A

15

D

ETPD075B

BODY ELECTRICAL SYSTEM

TURN SIGNAL AND LANE CHANGE SWITCH

[M01-1]

~

Hazard Turn signal

16 17 18

switch switch

L

OFF N

R 0 D

ETPD075C

WIPER AND WASHER SWITCH INSPECTION

Check for continuity between the terminals while operating

the wiper and washer switch.

KTPC075H

WIPER SWITCH [M01-2]

~

10 11 12 13

n

MIST 0 D

OFF

0 0

INT 0 0

LOW

0 D

HI 0 0

ETPD075D

MULTI FUNCTION SWITCH BE -43

WASHER SWITCH [M01-2]

~ 11 15

n

OFF

ON

0 0

ETPD075E

REAR WIPER AND WASHER SWITCH [M01-2]

~

14 16 17 18

n

OFF 0

{)

Rear wiper

Rear wiper &

washer

ETP0075F

BE -44

HORNS

COMPONENTS E4D838A20

Horn

BODY ELECTRICAL SYSTEM

Horn switch

Clock spring

ETPD090A

HORNS

HORN

REMOVAL AND INSTALLATION E4s1sso?o

1 . Open the hood and remove the hood latch cover after

removing 2 screws.

KTPC091A

2. Remove the bolt and disconnect the horn connector,

then remove the horn.

KTPC091B

KTPC091C

3. Installation is the reverse of removal.

BE -45

INSPECTION E43F8F65F

1. Test the horn by connecting battery voltage to the 1

terminal and ground the 2 terminal.

2. The horn should make a sound. If the horn fails to

make a sound, replace it.

ADJUSTMENT

Operate the horn, and adjust the tone to a suitable level

by turning the adjustingscrew.

~ N O T

After adjustment, apply a small amount of paint

around the screw head to keepit from loosening.

ETDA050A

BE -46

KEYLESS ENTRY AND

BURGLAR ALARM

COMPONENTS E40CFB225

BODY ELECTRICAL SYSTEM

Transmitter

Front door switch

Hood switch

Burglar alarm horn

ET ACS module

Door warning switch

Front door lock

actuator & switch

Rear door lock

actuator & switch

Front door lock

actuator & switch

Rear door lock

actuator & switch

Rear door switch

.,.- ~ . c . . . . - . t - - - - Tailgate lock

actuator & switch

Tailgate switch

Rear door switch

ETPD125A

KEYLESS ENTRY AND BURGLAR ALARM

INSPECTION E4A4A4D96

FRONT DOOR LOCK ACTUATOR INSPECTION

1. Remove the front door trim panel. (Refer to BD group-

Front door)

2. Disconnect the 6P connector from the actuator.

~

~

KTPC270A

3. Check actuator operation by connecting power and

ground according to the table. To prevent damage to

the actuator, apply battery voltage only momentarily.

~

p

1 3

Lock e EB

Front left

Unlock

EB e

Lock EB e

Front right

Unlock

e EB

ETPD270B

BE-47

REAR DOOR LOCK ACTUATOR INSPECTION

1. Remove the rear door trim panel. (Refer to BD group-

Rear door)

2. Disconnect the 6P connector from the actuator.

~

~

KTPC275A

3. Check actuator operation by connecting power and

ground according to the table. To prevent damage to

the actuator, apply battery voltage only momentarily.

~

p

1 3

Lock e EB

Rear left

EB e

Unlock

Lock EB e

Rear right

Unlock

e EB

ETPD275B

BE -48

FRONT DOOR LOCK SWITCH INSPECTION

1. Remove the front door trim panel. (Refer to BD group-

Front door)

2. Disconnect the 6P connector from the actuator.

~

~

KTPC270A

3. Check for continuity between the terminals in each

switch position according to the table.

~

p

4 5 6

Lock 0 0

Front left

0

-() Unlock

Lock 0 -0

Front right

Unlock

0 -o

ETPD2BOB

BODY ELECTRICAL SYSTEM

REAR DOOR LOCK SWITCH INSPECTION

1. Remove the rear door trim panel. (Refer to BD group-

Rear door)

2. Disconnect the 6P connector from the actuator.

tS\

~

KTPC275A

3. Check for continuity between the terminals in each

switch position according to the table.

~

p

4 5 6

Lock 0 0

Rear left

Unlock

0 -o

Lock 0 -o

Rear right

Unlock

0

-()

ETP0285B

KEYLESS ENTRY AND BURGLAR ALARM

DOOR SWITCH INSPECTION

Remove the door switch and check for continuity between

the terminals.

V5BE060P

~

n

Ground(Body) 1 2

Free(Door open)

Push(Door close)

ETPD305C

TAILGATE LOCK ACTUATOR INSPECTION

1. Remove the tailgate trim panel. (Refer to BD group-

Tailgate)

2. Disconnect the 6P connector from the actuator.

KTPC165A

BE -49

3. Check actuator operation by connecting power and

ground according to the table. To prevent damage to

the actuator, apply battery voltage only momentarily.

~

2 3

n

L O K ~ U N L O K 8 0

U N L O K ~ L O K 0 8

ETPD165B

TAILGATE LOCK SWITCH INSPECTION

1. Remove the tailgate trim panel. (Refer to BD group-

Tailgate)

2. Disconnect the 6P connector from the actuator.

KTPC165A

3. Check for continuity between the terminals in each

switch position according to the table.

~

4 5 6

n

UNLOCK 0 0

LOCK 0

ETPD170A

BE -50

TAILGATE SWITCH INSPECTION

1. Remove the tailgate trim panel. (Refer to BD group -

Tailgate)

2. Remove the tailgate latch after removing 3 bolts and

disconnect the 1 P connector from the tailgate switch.

KTPC175A

3. Check for continuity between the terminal and ground

according to the table.

~

Ground (Body) 1

n

Tailgate open

Tailgate close

ETPD175B

BODY ELECTRICAL SYSTEM

HOOD SWITCH INSPECTION

1. Remove the air duct after removing 2 bolts.

2. Disconnect the 1 P connector from the hood switch.

KTPC180A

3. Check for continuity between the terminal and ground

according to the table.

~

n

Ground (Body) 1

Hood open (Free)

Hood close (Push)

ETPD180B

KEYLESS ENTRY AND BURGLAR ALARM

DOOR WARNING SWITCH INSPECTION

1. Remove the driver's crash pad lower panel. (Refer to

BD group-Crash pad)

2. Disconnect the 4P connector from the door warning

switch.

KTPC185A

3. Check for continuity between the terminals in each

position according to the table.

3 4

n

Insert 0

Removal

ETPD185B

BE -51

BURGLAR ALARM HORN INSPECTION

1. Remove the horn after removing a bolt and disconnect

the 2P connector from the horn.

KTPC190A

2. Test the horn by connecting battery power to the ter-

minal 1 and ground the terminal 2.

The horn should make a sound. If the horn fails to

make a sound replace it.

BE -52

ETACS MODULE

ANTI-THEFT FUNCTION E48455FE5

1. ARM FUNCTION

Pressing the remote key lock button will result in a

0.5-second pulse issued to lock all doors.

Pressing the remote keypad unlock button once will

result in a 0.5-second unlock pulse issued to unlock

all doors.

As part of the arming sequence the alarm first en-

ters a pre-armed state before falling into the armed

state. During this pre-armed state alarm triggers are

ignored. Pre-armed state can be reached from the

alarmed state, the start inhibit state or the disarmed

state. Pre-Arming of the alarm can be achieved by a

press of the lock button on the remote key.

In the pre-armed state the visible and audible warn-

ings are disabled.

This system enters the armed state if it is in the pre-

armed state and, after 0.6 sec, check actuator lock

and each door, hood and tail gate close, and no door

warning switch (no key in ignition).

On entering the arm state, a single flash of the hazard

lamps is given, period of cycle 2 second, duty rate

50%.

If TX lock signal is received when a door, tail gate or

hood is open, then lock output is given and a flash of

hazard is not given.

After the armed state is entered, if a lock signal is

received then a single flash of the hazard lamps is

given, period of cycle 2 second, duty rate 50%.

The armed state cannot be reached by locking the car

with the keys.

DOOR, HOOD OPEN

__f[___

TAILGATE

CLOSE

TX LOCK _fl

UNLOCK ~

T1

DOOR LOCK ON ___fL____

OUTPUT OFF

ARM STATE

ARM:-

DISARM

T3

HAZARD

O ~

LAMP OFF

Time specification

T1 : 0.5 sec.

T2 : Max. 2 sec.

T3: 1.0 0.2 sec.

~

T21--oi

~

ETHA115Q

BODY ELECTRICAL SYSTEM

2. DISARM FUNCTION

TX

Disarming can be performed while the alarm is

armed, or alarming, or after alarming. The alarm can

be disarmed by the following methods :

Pressing the unlock button on the TX key. The

hazard lamps shall be flashed twice for 1 sec pe-

riod (of cycle), 50% duty rate.

If door warning switch is on, IGN1 and IGN2 are

on in arm state, then arm state should be imme-

diately cancelled. This means that the driver is

inside the vehicle before pushing TX lock, so sys-

tem should not arm.

In the disarm state the visible and audible warnings

are disabled and start is enabled.

In the disarm state, if TX key unlock command is re-

ceived, then the hazard lamps shall be flashed twice

for period of cycle 1 sec, 50% duty rate.

Disarm state cannot be reached using the door locks

by key.

LOCK

UNLOCK

UNLOCK ON

OUTPUT OFF

ARM STATE ARM

DISARM

HAZARD

ON

nl IT21J

LAMP

OFF

ETHA115R

Time specification

T1, T2: 0.5 0.1 sec.

3. ALARM FUNCTION

1) European countries

Once armed, should any door, hood or the tail-

gate be opened, then :

Start relay drive output is disabled, so start-

ing is inhibited.

Audible (horn) and visual (hazard lamp)

warnings are issued, for 27seconds du-

ration. The horn warning is continuously

occurring in this period. The hazard lamps

operate with 1 sec period, 50 % duty rate.

The alarm is given in the case where a door is

opened with a key.

KEYLESS ENTRY AND BURGLAR ALARM

Time specification

T1 : 27 2 sec.

T2 : 0.4-0.5 sec.

ETOC100C

2) Non European countries

Once armed, should any door, hood or the tail-

gate be opened, then.

Start relay drive output is disabled, so start-

ing is inhibited.

Audible (horn) and visual (hazard lamp)

warnings are issued, for three cycles, each

cycle 272 sec. duration on, 10±1

sec. off. The horn warning is continuously

occurring during the on period. The hazard

lamps operate with 1 sec period, 50 % duty

rate during the on period.

The alarm is given in the case where a door is

opened with a key.

After this time, the system maintains the start in-

hibit state, where no audible and visual warnings

are issued but engine starting is not possible.

ARM STATE

ARM DISARM

ALL

DOORS

HORN

HAZARD

LAMP

OPEN

CLOSE

ON

OFF

ON

OFF

Time specification

T1 : 27 2 sec.

T2: 10 1sec.

T3 : 0.4-0.5 sec.

ETOC100D

4. OPERATION DURING ALARM CONDITIONS

1) Cancelling audible alarm with the remote trans-

mitter

CASE 1 : Door closed

DOOR

TX

LOCK

OUTPUT

BE -53

During or after alarming and then closing all

doors and a TX lock signal is received Then

The lock command is executed with 0.5 sec.

ON

Horn and start inhibition are OFF

Hazard lamp is flashed one time (period : 2

sec., duty: 50%, within 2 sec.)

The state goes to arming mode (after a lock

state check)

The start is enabled

OPEN

CLOSE

LOCK

UNLOCK

ON

OFF

ACTUATOR

UNLOCK

START

INHIBIT

HAZARD

LAMP

LOCK

ON

OFF

ON

OFF

Time specification

T1 : 0.5 sec.

T2: 1.0 0.2 sec.

CASE 2 : Door Open

ETHA115V

During or after alarming, with a door open and a

TX lock signal is received Then

The lock command is executed with 0.5 sec.

ON

Horn is disabled and start is enabled after

confirmation of actuator lock

At this time, when the door is closed,

Hazard lamp is flashed one time (period : 2

sec., duty 50%)

The state goes to arming mode

DOOR OPEN

CLOSE

TX

LOCK

OUTPUT

LOCK _n

UNL::K ~ - - - - - : - - T -

1

----------

OFF _j I

ACTUATOR UNLOCK

LOCK

START ON

INHIBIT OFF

HAZARD ON

LAMP OFF

Time specification

T1 : 0.5 sec.

T2 : 1.0 0.2 sec.

T2 1----J

ETHA115W

BE -54

2) New alarm conditions

Second alarm condition during alarming.

When another alarm occurs during alarming, the

starting is disabled, and the alarm continues to

sound for the remained time of warning signal.

The alarm continues to sound after the second

alarm condition is removed.

New alarm condition occurs after alarming (with

all entrances closed)

If any entrance is opened again then

The horn is ON 3 times (EC area : one time

for 27sec.)

Start is disabled

Hazard lamps flash during the ON time of

horn

New alarm condition occur after alarming (with

any entrance open).

If another entrance is opened, the ETACS mod-

ule keeps start disabled and there is no horn out-

put.

ALL OPEN

DOORS CLOSE

START

INHIBIT

HORN

HAZARD

LAMP

ON r----,u

OFF

ON

OFF

u

ETOC100N

3) Key operation during alarm

4)

After the alarm state or start inhibit state are en-

tered, if door warning switch on (key in ignition)

& IGN 2 ON, if IGN 2 state is changed to OFF

within 30sec, remain in alarm state.

Disarming using the key

During alarming, in case that door warning switch

(key in) is ON and then IGN1 and IGN2 are both

ON for 30 sec continuously, the alarm is can-

celled, and the system enters the disarm state.

After alarming, in case that door warning switch

(key in) is ON and then IGN1 and IGN2 are both

ON for 30 sec continuously, the alarm is can-

celled, and the system enters the disarm state.

BODY ELECTRICAL SYSTEM

DOOR

WARN"G

SWITCH

IGN.

SWITCH

KEY IN

KEY OUT

ON

HORN

OFF

1

30sec .,

LJI L I- -------

ARM

STATE

ARM-------,

DISARM

5. ALARM STATE IN POWER DOWN

ETOC1000

If the battery is disconnected to the ETACS module in

the following states:

Alarm

After alarming

Upon restoring the battery, the alarm state shall be

entered and the alarm cycle shall restarted (timer re-

set to 0).

Upon restoring the battery, the alarm state shall be

entered and the alarm cycle shall restarted (timer re-

set to 0).

ARM

STATE

ARM

HOOD

ON

SWITCH OFF

BATTERY

REMOVAL n

INSTALLATION

START

I

INHIBIT

I

L

HORN ON

OFF

ETHA115Z

KEYLESS ENTRY AND BURGLAR ALARM

TRANSMITTER

INSPECTION E49CC6DCD

1. Check that the red light flickers when the door lock or

unlock button is pressed on the transmitter.

2. Remove the battery and check voltage if the red light

doesn't flicker.

Standard voltage : 3V

KTPC195A

3. Replace the transmitter battery with a new one, if volt-

age is below 3V then try to lock and unlock the doors

with the transmitter by pressing the lock or unlock but-

ton five or six times.

4. If the doors lock and unlock, the transmitter is O.K,

but if the doors don't lock and unlock, register the

transmitter code, then try to lock and unlock the doors

(See the workshop manual page BE-28)

5. If the doors lock and unlock, the transmitter is O.K, but

if the doors don't lock and unlock, replace the trans-

mitter.

TRANSMITTER CODE

REGISTRATION E466BF2B6

BE -55

1. To register transmitter code, first connect keyless

adapter (09900-21300) to DLC(Data Link Connector)

cable of hi-scan as shown in the illustration.

Keyless adapter

(09900-21300)

ETAC065J

2. After connecting keyless adapter to the multi purpose

check connector (1 Opins) beside data link connector

in driver side crash pad lower panel, turn the power

on hi-scan.

KTPC200A

3. Select the vehicle model and then do "CODE SAV-

ING".

1. HYUNDAI VEHICLE DIAGNOSIS

MODEL ALL

02. ENGINE

03. AUTOMATIC TRANSAXLE

04. ANTI-LOCK BRAKE SYSTEM

07 CODE SAVING

ETPD7001

BE -56

4. After selecting "CODE SAVING" menu, button "EN-

TER" key, then the screen will be shown as below.

KEYLESS ENTRY CODE SAVING

1. REMOVE THE IG.KEY FROM KEY CYLINDER.

2. CONNECT THE DLC CABLE AND 16 PIN

CONNECTOR OF THE KEYLESS ADAPTER.

3. CONNECT THE 10 PIN CONNECTOR OF THE

KEYLESS ADAPER INTO THE MULTIPURPOSE

CHECK CONNECTOR.

4. AFTER PRESSING [ENTER], FINISH CODE SAVING

WITHIN 10 SECONDS.

5. PRESS [ENTER], IF YOU ARE READY!

ETAC065M

5. After removing the ignition key from key cylinder, push

"ENTER" key to proceed to the next mode for code

saving.

KEYLESS ENTRY CODE SAVING

1. PRESS THE TRANSMITTER [LOCK] BUTTON

FOR 1 SECOND.

2. IF SAVE ONE MORE PRESS OTHER

TRANSMITTER [LOCK] BUTTON FOR 1 SECOND.

3. PRESS [ESC] AND DISCONNECT KEYLESS

ADAPTER FROM VEHICLE AND CHECK

THE KEYLESS ENTRY SYSTEM.

ETAC065N

6. Follow steps 1 to 3 and then code saving is completed.

7. Disconnect keyless adapter (09900-21300) from DLC

cable and then proceed toself-diagnosis with DLC ca-

ble connected.

BODY ELECTRICAL SYSTEM

ETACS (ELECTRONIC TIME AND ALARM CONTROL SYSTEM)

ETACS (ELECTRONIC TIME

AND ALARM CONTROL

SYSTEM)

DESCRIPTION E437F3C68

ETACS module receives various input switch signals, and

controls time and alarm such as rear defogger timer,

seat belts warning, decayed out room lamp, central

door lock, ignition key reminder, power window timer,

door warning, tail lamp auto cut, crash door unlock and

keyless entry & burglar alarm automatically.

SPECIFICATIONS E43F328CF

Items

Rated voltage

Operating voltage

Operating temperature

Insulation resistance

Rated load

Horn relay

Chime bell

Rear defogger relay

Hazard lamp relay

Tail lamp relay

Seat belt warning indicator

Room lamp

Door lock relay

Door unlock relay

Burglar alarm relay

Specifications

DC 12V

DC 9- 16V

-30C - 80C

1 OOMn or more

DC 12V, 200mA (Inductance load)

DC 12V, 350mA (Inductance load)

DC 12V, 200mA (Inductance load)

DC 12V, 200mA (Inductance load)

DC 12V, 200mA (Inductance load)

DC 12V, 1 .2W (Lamp load)

DC 12V, 10W (Lamp load)

DC 12V, 200mA (Inductance load)

DC 12V, 200mA (Inductance load)

DC 12V, 200mA (Inductance load)

BE -57

ETPD115A

BE -58

ELECTRONIC TIME AND ALARM

CONTROL MODULE

CIRCUIT DIAGRAM E042851BD1

IG1 IG2 B+ ALT"L'

Door switch x 4

Driver door switch

Assist door switch

Rear defogger switch

Tailgate switch

Rear & tailgate lock switch

[M25-1]

BODY ELECTRICAL SYSTEM

B+

Burglar alarm relay

[M25-2]

IG1 B+ B+ ST

B+

Power window

relay

Power window

main switch

B+

B+

ETPD110A

ETACS (ELECTRONIC TIME AND ALARM CONTROL SYSTEM) BE-59

REMOVAL AND INSTALLATION E4B9A734B

1. Disconnect the negative(-) battery terminal.

2. Remove the 2 screws and 2 bolts holding the driver's

crash pad lower panel.

ETPD062E

3. Disconnect the hood release cable and the data link

connector from the beneath driver's crash pad lower

panel.

ETPD062B

4. Remove the ETACS module from the bracket after re-

moving nuts.

ETPD115A

5. Installation is the reverse of removal.

INSPECTION E4F5AEB40

While operating the components, check whether the oper-

ations are normal as shown in the timing chart.

1. DEFOGGER TIMER (Including Outside Mirror Demis-

ter)

1) After ALT "L" ON, if the defogger is switched ON,

the defogger output is ON for 20 minutes dura-

tion.

2) If the defogger switch is pressed again, or if the

ignition is switched OFF during this time, the de-

fogger output is OFF.

Alternator ON _j

OFF

Defogger ON

switch OFF

Defogger ON

output OFF

T1 : 20 1min.

2. SEAT BELT WARNING TIMER

L

ETMB180C

1) Since the ignition is switched ON, the seat belt

warning indicator is illuminated (with period :

0.6 sec., duty rate : 50%) and the chime bell is

sounded (with period : 0.9 sec., duty rate : 50%)

for total time 6 seconds.

2) If the ignition is swithced off during the indicator

and the chime bell output, the indicator and the

chime bell are switched OFF.

If the seat belt is sensed as fastened during the

indicator and the chime bell output, the chime bell

is switched OFF immediately and the seat belt

warning indicator is illuminated for the remained

seconds.

3) When the ignition is already switched ON, if the

seat belt is removed, the warning indicator and

the chime bell are output for total time 6 seconds.

BE -60 BODY ELECTRICAL SYSTEM

IGNSWITCH

ON

OFF

SEAT BELT

SWITCH

CHIME

ON

BELL

OFF

SEAT BELT

ON

WARN'GIND.

OFF

ETMB902B

T1 : 61 sec., T2 : 0.45 0.1 sec., T3 : 0.3 0.1

sec.

3. DECAYED ROOM LAMP & KEYLESS UNLOCK

TIMER

1) When the first door (driver's or assist) is opened,

the room lamp shall brighten. When the last door

is closed, the room lamp will drop to 75% inten-

sity, then fade out over 5-6 seconds.

2) If the door switch is ON for less than 0.1 sec.,

then no illumination occurs.

3) The fade resolution is over 32 steps.

4) The room lamp must not flicker during fade oper-

ation, if the ignition is switched ON.

5) With keyless UNLOCK, when the door is closed,

the room lamp is turned ON, then OFF after about

30 seconds. While the room lamp is ON due

to keyless UNLOCK, if another UNLOCK is re-

ceived, the room lamp is again ON for 30 sec-

onds.

While the room lamp is ON, If the door is opened,

the lamp is continued to ON. If the door is closed,

the lamp follows as the above step 1 .

If keyless LOCK (ARM state) is received during

fade out, the room lamp is switched off immedi-

ately.

DOOR OPEN

SWITCH CLOSE

IGN2

UNLOCK

TRANSMITTER

(TX)

ROOM ON

LAMP OFF

ETMB003K

T1 : 5.5 0.5 sec., T2 : 30 3 sec.

4. CENTRAL DOOR LOCK/UNLOCK

1) The driver's door lock, assist door lock, or the

inside door lock knob is switched LOCK to UN-

LOCK or UNLOCK to LOCK, the all doors lock

and unlock outputs will follow.

2) Battery connecting would not change the

LOCK/UNLOCK states.

DRIVER'S DOOR UNLOCK------, r---

LOCK SWITCH LOCK L__j

ASSIST DOOR

LOCK SWITCH LOCK

DOOR LOCK

OUTPUT

ON

OFF

oN n n DOOR UNLOCK

OUTPUT

OFF ____j L___j L__

ETNB110A

T1 : 0.5 0.1 sec.

5. IGNITION KEY REMINDER

If the key is in the ignition and the driver's door or as-

sist door is opened and the vehicle is locked using

driver's knob or assist knob, then the central locking

system will issue an unlock pulse of 1 second duration

to the all doors thus preventing locking of the vehicle.

(With a knob remains locked, if the switch in the actu-

ator is not changed, the central locking shall issue 1

pulse of 1 seconds duration and 3 pulses of 0.5 sec-

ond duration to unlock the vehicle.)

DOOR WARN'G ON

SWITCH OFF

DRIVER/ASSIST ON

DOOR SWITCH OFF

DRIVER/ASSIST ON

DOOR LOCK OFF

SWITCH ON

DOOR UNLOCK OFF

OUTPUT

ETPD120A

T1 ,T3: 0.5 sec., T2: 1 sec., T4: Max.0.5 sec.