Professional Documents

Culture Documents

D155 Engine

Uploaded by

Ahmad FaoziOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D155 Engine

Uploaded by

Ahmad FaoziCopyright:

Available Formats

Mechanic Development.

PT Pamapersada Nusantara

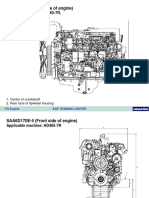

D 155 A - 2 ENGINE SYSTEM TRAINING

GENERAL STRUCTURE

II - 01 - 14

1. Fan

2. V belt

3. Thermostat

4. Cylinder head

5. Injection nozzle

6. Cylinder head cover

7. Breather

8. Piston pin

9. Intake valve

10. Exhaust valve

11. Rocker arm shaft

12. Camshaft

13. Tappet

14. Push rod

15. Rocker arm housing

16. Cylinder block

17. Rear seal

18. Vibration damper

19. Front seal

20. Oil strainer

Mechanic Development.

PT Pamapersada Nusantara

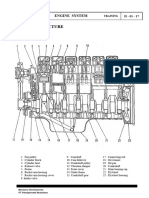

D 155 A - 2 ENGINE SYSTEM TRAINING

21. Oil pump

22. Connecting rod cap

23. Oil pan

24. Main metal cap

25. Crankshaft

26. Ring gear

27. Flywheel

28. Air cleaner

29. Cylinder liner

30. Piston

II - 02 - 14

31. Oil cooler

32. Starting motor

33. Oil level gauge

34. Fuel injection pump

35. Oil filler

36. Piston cooling nozzle

37. Connecting rod

Mechanic Development.

PT Pamapersada Nusantara

D 155 A - 2 ENGINE SYSTEM TRAINING

INTAKE DAN EXHAUST SYSTEM

II - 03 - 14

1. Turbocharger

2. Air cleaner

3. Intake manifold

Air cleaner

Centrifugal type

with paper element

Dust indicator

Perceive vacuum: 635mmAq

1. Exhaust pipe

2. Muffler

3. Turbocharger

4. Exhaust manifold

Mechanic Development.

PT Pamapersada Nusantara

D 155 A - 2 ENGINE SYSTEM TRAINING

VALVE MECHANISME

II - 04 - 14

1. Push rod

2. Valve spring

3. Compression release shaft

4. Adjusting screw

5. Lock nut

6. Rocker arm shaft

7. Cam shaft gear

8. Camshaft

9. Intake valve

10. Exhaust valve

11. Tappet

12. Rocker arm lever

13. Cross head

14. Valve spring

15. Valve spring seat

Mechanic Development.

PT Pamapersada Nusantara

D 155 A - 2 ENGINE SYSTEM TRAINING

II - 05 - 14

VALVE TIMING

VALVE CLEARANCE

Mechanic Development.

PT Pamapersada Nusantara

D 155 A - 2 ENGINE SYSTEM TRAINING

MAIN REVOLVING

II - 06 - 14

1. Piston

2. Piston pin

3. Connecting rod

4. Bushing

5. Top ring

6. 2nd ring

7. Oil ring

8. Upper metal

9. Nylock bolt

10. Vibration damper

11. Flange

12. Crankshaft gear (number of teeth: 36)

13. Lower metal

14. Connecting rod cap

15. Connecting rod cap mount bolt

16. Crankshaft

17. Flywheel

18. PTO drive gear (number of teeth: 44)

19. Ring gear (number of teeth: 140)

Mechanic Development.

PT Pamapersada Nusantara

D 155 A - 2 ENGINE SYSTEM TRAINING

II - 07 - 14

Crankshaft

Stamp forging

Induction hardening journal portion

Front seal

Double lip oil seal

Rear seal

Double lip oil seal (for bulldozer)

Single lip oil seal Ifor generators)

PISTON RING

Mechanic Development.

PT Pamapersada Nusantara

D 155 A - 2 ENGINE SYSTEM TRAINING

TIMING GEAR

II - 08 - 14

1. Main idler gear (big) (number of teeth 84)

2. Main idler gear (small) (number of teeth 63)

3. Camshaft drive gear (number of teeth 54)

4. Fuel injection pump drive gear (number of teeth 54)

5. Crankshaft drive gear (number of teeth 36)

6. Idler gear (number of teeth 37)

7. Oil pump drive gear (number of teeth 27)

8. Water pump drive gear (number of teeth 23)

9. Accessory drive gear (number of teeth 43)

10. Alternator drive gear (number of teeth 22)

Mechanic Development.

PT Pamapersada Nusantara

D 155 A - 2 ENGINE SYSTEM TRAINING

DATA SPESIFIKASI ENGINE

II - 09 - 14

S 6 D 155 - 4

D 155 A - 2

( Eng. S / N. 52707 and Up )

(mm) 6 - 155 x 170

(cc) 19.260

1-5-3-6-2-4

Overall length (mm) 1.880

Overall width (mm) 1.190

Overall height (Excluding exhaust pipe) (mm) 1.931

Overall height (Including exhaust pipe) (mm) 2.914

Flywheel horsepower (HP/rpm) 320/2.000

Maximum torque (kgm/rpm) 144/1.400

No-load maximum engine speed (rpm) 2.240 40

No-load minimum engine speed (rpm) 600 50

Minimum fuel consumption ratio (g/HPh) 180

(kg) 2.580

BOSCH PES - PD type

BOSCH RSUV

centrifugal all speed

liter

75

(55)

liter 160

24V, 35A

24V, 11 kW

12V 200Ah x 2

KTR130

-

-

Battery

Turbocharger

Air compressor

After cooler

Lubricating oil amount

( refill capacity )

coolant amount

Alternator

Starting motor

Firing order

Dry weight

Fuel pump

Governor

Number of cylinders - Bore x Stroke

Total piston displacement

Engine model

Machine

D

i

m

e

n

s

i

o

n

P

e

r

f

o

r

m

a

n

c

e

Mechanic Development.

PT Pamapersada Nusantara

D 155 A - 2 ENGINE SYSTEM TRAINING

ENGINE PERFORMANCE CURVE

II - 10 - 14

Mechanic Development.

PT Pamapersada Nusantara

D 155 A - 2 ENGINE SYSTEM TRAINING

LUBRICATION SYSTEM

II - 11 - 14

1. Oil pan

2. Scavenging pump

( Excluding generator )

3. Oil pump

4. Main relief valve

5. Oil cooler by-pass valve

6. By-pass filter

7. Oil cooler

8. Regulator valve

9. Full flow filter

10. Safety valve

11. Piston cooling valve

12. Fuel injection pipe

13. Main gallery

14. Crankshaft

15. Piston cooling nozzle

16. Timing gear

17. Gear lubrication nozzle

18. Rocker arm

19. Camshaft

20. Turbocharger

21. Oil pressure gauge

W. Cooling water

Mechanic Development.

PT Pamapersada Nusantara

D 155 A - 2 ENGINE SYSTEM TRAINING

REGULATOR VALVE

II - 12 - 14

SAFETY VALVE

PISTON COOLING VALVE

1. Plug

2. Valve spring

3. Regulator valve

4. Filter bracket

A. From filter

B. To main gallery

C. To oil pen

Operating pressure

4,05 0,25 kg/cm

1. Plug

2. Valve spring

3. Safety valve

4. Filter bracket

5. Caution terminal

A. From oil cooler

B. To il filter

C. To main gallery

Operating pressure (Balance pressure):

2 0.2 kg/cm

1. Plug

2. Valve spring

3. Piston cooling valve

A. To piston cooling gallery

B. From oil filter

Operating pressure

2.75 0.25kg/cm

S6D155-4 No.20000-22650

1.6 0.2 kg/cm

S6D155 -4 No. 22651 and up

Mechanic Development.

PT Pamapersada Nusantara

D 155 A - 2 ENGINE SYSTEM TRAINING

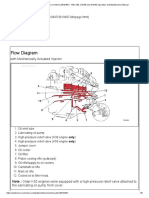

FUEL SYSTEM

II - 13 - 14

1. Fuel tank

2. Strainer

3. Fuel filter

4. Fuel injection pump

5. Feed pump

6. Nozzle

Mechanic Development.

PT Pamapersada Nusantara

D 155 A - 2 ENGINE SYSTEM TRAINING

COOLING SYSTEM

II - 14 - 14

1. Water manifold

2. Thermostat.

3. Radiator

4. Fan

5. Water pump

6. Engine oil cooler

7. Torque converter oil cooler

B. Corrosion resistor

9. Cylinder block

10. Cylinder liner

A. From oil pump (oil)

B. To each part of engine (oil)

C. From pump of chassis side ( oil )

D. To torque converter (oil)

You might also like

- Saa6d170 5 EngDocument46 pagesSaa6d170 5 EngAhmad Mubarok75% (4)

- Bomag bw212 Full-Product-Guide - PRE101334 - 1803 PDFDocument364 pagesBomag bw212 Full-Product-Guide - PRE101334 - 1803 PDFmartin marsayNo ratings yet

- Ajustes Trans 140GDocument13 pagesAjustes Trans 140GDomingo Cruz Garcia100% (3)

- Material Caterpillar d8r Bulldozer Transmission Power Train Hydraulic System Components DiagramsDocument50 pagesMaterial Caterpillar d8r Bulldozer Transmission Power Train Hydraulic System Components DiagramsAhmed92% (24)

- d8r Hydraulic SystemDocument2 pagesd8r Hydraulic Systemwtn201392% (12)

- D155A-2 Engine Parts Manual S/N 50001-UPDocument354 pagesD155A-2 Engine Parts Manual S/N 50001-UPOecox Cah Djadoel100% (5)

- Manual de Sistema Hidraulico D9R 2 PDFDocument96 pagesManual de Sistema Hidraulico D9R 2 PDFgodavicho100% (2)

- GD510R-1 S/N 15001-UP Transmission Parts ReferenceDocument7 pagesGD510R-1 S/N 15001-UP Transmission Parts ReferenceShop ManualNo ratings yet

- Power Train D65P-12Document28 pagesPower Train D65P-12Muhammad Hafiz Ismail100% (1)

- Connecting Rod Bearings - Install: Table 1Document3 pagesConnecting Rod Bearings - Install: Table 1David Apaza HurtadoNo ratings yet

- Parts KCG 950GDocument4 pagesParts KCG 950GJanina Cseko100% (1)

- SM Komatsu GD705A-5 - SEN06489-03Document1,451 pagesSM Komatsu GD705A-5 - SEN06489-03Dewa PurnamaNo ratings yet

- Maintenance Interval Schedule: Operation and Maintenance ManualDocument11 pagesMaintenance Interval Schedule: Operation and Maintenance ManualAHMED2ALI100% (1)

- CRANKSHAFT GP FOR 320D2 EXCAVATORDocument4 pagesCRANKSHAFT GP FOR 320D2 EXCAVATORfebruNo ratings yet

- Part Number Part Name Part Number Part Name: Weichai Power WD10 Engine Spare Parts For EngineeringDocument3 pagesPart Number Part Name Part Number Part Name: Weichai Power WD10 Engine Spare Parts For EngineeringMd. Arefin Shawon100% (1)

- 3054C Industrial Engine - Maintenance IntervalsDocument34 pages3054C Industrial Engine - Maintenance IntervalsAlberto Migraña80% (5)

- Manual Completo d8rDocument151 pagesManual Completo d8redgardo-ehq91% (54)

- BD D8R Catalog PDFDocument958 pagesBD D8R Catalog PDFKadir Koray Bozyel100% (3)

- 3306 TORQUE: 1. 115 Ibft 2. 185 Ibft 3.185 IbftDocument7 pages3306 TORQUE: 1. 115 Ibft 2. 185 Ibft 3.185 IbfthamadaabdelgawadNo ratings yet

- Catalog Caterpillar 740b Articulated Truck SpecificationsDocument20 pagesCatalog Caterpillar 740b Articulated Truck Specificationssuwarjitechnic0% (1)

- Cat 12H Motor Grader: Standard TypeDocument22 pagesCat 12H Motor Grader: Standard Typestopaferreira80% (5)

- Specalog CS533EDocument16 pagesSpecalog CS533Earfa ujianto100% (1)

- Backhoe Loader B877Document4 pagesBackhoe Loader B877MS Buk3100% (1)

- Ytozl50f Catalog Weichai EngineDocument97 pagesYtozl50f Catalog Weichai EngineHongwei Zhang50% (2)

- Cat 936eDocument5 pagesCat 936eAlberto Ferradás100% (1)

- Brosure d6d DKP PDFDocument2 pagesBrosure d6d DKP PDFXitoAntho100% (1)

- Spect Torque Cat 320DDocument8 pagesSpect Torque Cat 320Dlilik100% (1)

- Electric 120H 5FM PDFDocument2 pagesElectric 120H 5FM PDFrprim100% (2)

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler Dozerthirsheel balaji100% (1)

- D6G2 XL Product PresentationDocument51 pagesD6G2 XL Product Presentationfirman manalu100% (1)

- Cat Transmission 950F PDF - PDFDocument43 pagesCat Transmission 950F PDF - PDFMehdi Chakroune100% (1)

- Valvula de Control Trans. 140HDocument13 pagesValvula de Control Trans. 140HRCA09100% (6)

- CAT MOTOR 3306 PressDocument39 pagesCAT MOTOR 3306 PressIsmael De Jesus Andrade100% (7)

- Shop Manual: D85EX D85PXDocument1,180 pagesShop Manual: D85EX D85PXGabriely Murilo75% (8)

- Operação Dos Sistemas 12G, 120G, 130G & 140G MOTOR GRADERS POWER TRAINDocument37 pagesOperação Dos Sistemas 12G, 120G, 130G & 140G MOTOR GRADERS POWER TRAINLeandro SalNo ratings yet

- Scematic 777E PDFDocument31 pagesScematic 777E PDFAdi HindartoNo ratings yet

- Specifications Systems Operation Testing and Adjusting - CS-531D, CP-533D and CS-533D Vibratory Compactors Vibratory SystemDocument64 pagesSpecifications Systems Operation Testing and Adjusting - CS-531D, CP-533D and CS-533D Vibratory Compactors Vibratory SystemTony Melendez50% (2)

- 966h Main Control System OperationDocument17 pages966h Main Control System Operationesternocleido24100% (3)

- Light Tower PartsDocument2 pagesLight Tower PartsghghNo ratings yet

- D155A-2 # 57001 Up SEBM018602 PDFDocument462 pagesD155A-2 # 57001 Up SEBM018602 PDFJoko Sukariono100% (6)

- Engine Cat 3116: Head InstallationDocument8 pagesEngine Cat 3116: Head InstallationYeremiaNo ratings yet

- Cat 950 Loader Service Manual: Read/DownloadDocument2 pagesCat 950 Loader Service Manual: Read/Downloadargya Awang27% (11)

- m0072944-07 (En-Us) - 00 - Manuals-Service-Modules - TroubleshootingDocument204 pagesm0072944-07 (En-Us) - 00 - Manuals-Service-Modules - Troubleshootingmostafa ali100% (1)

- D7RDocument20 pagesD7ROmar Zelada100% (1)

- Manuelle D'atelier KOMATSU D275A-5RDocument1,411 pagesManuelle D'atelier KOMATSU D275A-5RNacer Nacer100% (3)

- Vdocuments - MX Caterpillar 926e Manuals Volu Caterpillar Wheel Loader Powershift ManualDocument7 pagesVdocuments - MX Caterpillar 926e Manuals Volu Caterpillar Wheel Loader Powershift ManualAbdelbagi100% (1)

- Tractores d9r D10r-HeuiDocument49 pagesTractores d9r D10r-HeuiRodrigo Chacca100% (1)

- Transmission Pressures - Test and Adjust: Shutdown SISDocument7 pagesTransmission Pressures - Test and Adjust: Shutdown SIScreator ideaNo ratings yet

- 02 EngineDocument14 pages02 EngineIdha AprianNo ratings yet

- 02 EngineDocument17 pages02 EngineSantosa NagoyaNo ratings yet

- Engine jt8d Boeing 737 200Document160 pagesEngine jt8d Boeing 737 200Cristian Gutierrez100% (1)

- Engine Guideline Engine Guideline: Engine Mechanical F8B EngineDocument42 pagesEngine Guideline Engine Guideline: Engine Mechanical F8B EnginePraveen KumarNo ratings yet

- Flow Diagram: With Mechanically Actuated InjectorDocument8 pagesFlow Diagram: With Mechanically Actuated InjectorAHMAD100% (1)

- SN 1230084-1 Raja L100-Mv150ic X c2.2t - PT Trakindo UtamaDocument100 pagesSN 1230084-1 Raja L100-Mv150ic X c2.2t - PT Trakindo UtamaSupriyo AdiNo ratings yet

- Gmax Service ManualDocument157 pagesGmax Service ManualBenny Kaysen SørensenNo ratings yet

- VOLVO G710B MOTOR GRADER Service Repair Manual PDFDocument19 pagesVOLVO G710B MOTOR GRADER Service Repair Manual PDFsekfsekmddde63% (8)

- Spare Parts ListDocument1 pageSpare Parts ListPower MuruganNo ratings yet

- Bab III Power LineDocument54 pagesBab III Power Linenauza getstar100% (1)

- BEINEI Spare Parts ManualDocument156 pagesBEINEI Spare Parts ManualRomanhnapNo ratings yet

- KV38,50Document46 pagesKV38,50Mohammed Elbadri100% (1)

- Lexus Engine 1UZ FE Service and Repair ManualDocument80 pagesLexus Engine 1UZ FE Service and Repair Manualeamon100% (2)

- C75 C85 C90 & O-200 Parts ManualDocument56 pagesC75 C85 C90 & O-200 Parts ManualMichaelSawyer100% (2)

- Catálogo de Peças: Trator 7210JDocument664 pagesCatálogo de Peças: Trator 7210Jalisson mateus oliveira pereiraNo ratings yet

- Finding Top Center Position For No. 1 Piston: Testing and AdjustingDocument3 pagesFinding Top Center Position For No. 1 Piston: Testing and AdjustingMbahdiro KolenxNo ratings yet

- Piaggio Runner 125 - 200 Scooter Shop ManualDocument327 pagesPiaggio Runner 125 - 200 Scooter Shop Manualmylitter5391100% (1)

- Manual Motor WC30D Tier-3 SM PDFDocument105 pagesManual Motor WC30D Tier-3 SM PDFAndres Abril100% (1)

- Valve and Injector Adjustment With VEBDocument9 pagesValve and Injector Adjustment With VEBFranky Fernandez100% (1)

- Bombe 4Document154 pagesBombe 4Adith K PNo ratings yet

- ME sFIDocument10 pagesME sFIMai văn NhớNo ratings yet

- VLCC TDC501 319 DocDocument377 pagesVLCC TDC501 319 DocMinh Trí100% (1)

- fz750 Workshop Man Searchable PDFDocument270 pagesfz750 Workshop Man Searchable PDFSergei BaikovNo ratings yet

- Greaves Cotton LTD: 4G11TAG23 Diesel Engine CPCB IIDocument55 pagesGreaves Cotton LTD: 4G11TAG23 Diesel Engine CPCB IIteja sri rama murthyNo ratings yet

- GM Performance - View Topic - L31 Cam SpecsDocument4 pagesGM Performance - View Topic - L31 Cam Specsjimbeamjohn88888No ratings yet

- CASE-84496807-preview MOTOR LFPDocument31 pagesCASE-84496807-preview MOTOR LFPjerryoz100% (1)

- Engine Czca Czda CZDB Djka CZDC Repair Manual EngDocument592 pagesEngine Czca Czda CZDB Djka CZDC Repair Manual EngasliberkaydereliNo ratings yet

- 245 DI Orchard Part Catalogue103 PDFDocument93 pages245 DI Orchard Part Catalogue103 PDFSamsher Ali100% (1)

- LCT Engines Service Man 208ccDocument23 pagesLCT Engines Service Man 208ccmowerman33No ratings yet

- Suzuki FL125 cylinder head and engine partsDocument65 pagesSuzuki FL125 cylinder head and engine partsRendiNo ratings yet

- Usp BookletDocument77 pagesUsp BookletJamie Gwen StewertNo ratings yet

- Mitsubishi Galant 4g63 Engine Repair ManualDocument29 pagesMitsubishi Galant 4g63 Engine Repair ManualMoaed Kanbar100% (1)

- PropellerDocument25 pagesPropellerNima ConquistadorNo ratings yet

- SL3640 SL3840 SL4240 Skid Loader Yanmar 3TNV88 4TNV88 Engine Parts Manual 917329Document47 pagesSL3640 SL3840 SL4240 Skid Loader Yanmar 3TNV88 4TNV88 Engine Parts Manual 917329monza1989100% (3)

- RIENG1Document158 pagesRIENG1Petrus Kanisius WiratnoNo ratings yet

- ExhibitorList 2018Document68 pagesExhibitorList 2018Charles JacobNo ratings yet

- 14450589-Repair Manual Mercury 40 50 60 HP Outboard 2002-2007Document590 pages14450589-Repair Manual Mercury 40 50 60 HP Outboard 2002-2007Adrian Radoi100% (7)

- How to Maintain Your VehicleDocument288 pagesHow to Maintain Your Vehiclenick_millar_150% (6)

- Bobcat s185 PDFDocument440 pagesBobcat s185 PDFkarol1177No ratings yet

- 1P51 FiDocument125 pages1P51 FiAlex KuNo ratings yet

- Yangdong Not EnabledDocument4 pagesYangdong Not EnabledalawiNo ratings yet