Professional Documents

Culture Documents

CC

Uploaded by

TungstenCarbideOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CC

Uploaded by

TungstenCarbideCopyright:

Available Formats

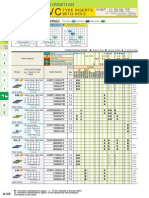

A100

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

H

6

4

0

0

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

V

P

4

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

MW

CCMT 060204-MW 0.4 [ [ a a a

C022

D008

E030

E034

060208-MW 0.8 a [ [ a a a

09T304-MW 0.4 a [ [ a a a

09T308-MW 0.8 a [ [ a a a

120404-MW 0.4 a [ [ a a a

120408-MW 0.8 a [ [ a a a

R/L-SR

CCET 0602V3R-SR 0.03 a a a

C022

D008

E030

E034

0602V3L-SR 0.03 a a a

060201R-SR 0.1 a a a

060201L-SR 0.1 a a a

060202R-SR 0.2 a a a

060202L-SR 0.2 a a a

060204R-SR 0.4 a a a

060204L-SR 0.4 a a a

09T3V3R-SR 0.03 a a a

09T3V3L-SR 0.03 a a a

09T301R-SR 0.1 a a a

09T301L-SR 0.1 a a a

09T302R-SR 0.2 a a a

09T302L-SR 0.2 a a a

09T304R-SR 0.4 a a a

09T304L-SR 0.4 a a a

R/L-SN

CCET 060200R-SN 0 a a a

C022

D008

E030

E034

060200L-SN 0 a a a

0602V3R-SN 0.03 a a a

0602V3L-SN 0.03 a a a

060201R-SN 0.1 a a a

060201L-SN 0.1 a a a

060202R-SN 0.2 a a a

060202L-SN 0.2 a a a

060204R-SN 0.4 a a a

060204L-SN 0.4 a a a

09T300R-SN 0 a a a

09T300L-SN 0 a a a

09T3V3R-SN 0.03 a a a

CCMT 06 02 04 MW

CC

80

N

E

W

N

E

W

N

E

W

N

E

W

P P M

3

2

1

0

0.1 0.2 0.3 0.4

6

4

2

0

0.1 0.3

3

2

1

0

0.1 0.2 0.3 0.4

4

3

2

1

0

4

3

2

1

0

4

3

2

1

0

0.1 0.2 0.3 0.4 0.1 0.2 0.3 0.4 0.1 0.2 0.3 0.4

MM MP MP

LM LP LP

FM FP FP

TURNI NG I NSERTS

[

POSI TI VE

]

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Size Thickness Corner Radius

*

Please refer to page A002.

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

POSI

7

WITH

HOLE

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Medium Cutting

(Wiper)

Medium Cutting

Medium Cutting

Chip Breaker

TYPE I NSERTS

WI TH HOLE

CHIP CONTROL RANGE FOR WORK MATERIALS

Finish Cutting Light Cutting MediumCutting

Carbon Steel Alloy Steel

Carbon Steel Alloy Steel

a

p

(

m

m

)

a

p

(

m

m

)

f (mm/rev)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

a : Inventory maintained in Japan.

[ : Inventory maintained in Japan. To be replaced by new products.

(10 inserts in one case)

*

*

Please refer to A028 before using the MW breaker (wiper insert).

Mild Steel Carbon Steel Alloy Steel (180280HB) Stainless Steel (<200HB)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

A101

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

H

6

4

0

0

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

V

P

4

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

R/L-SN

CCET 09T3V3L-SN 0.03 a a a

C022

D008

E030

E034

09T301R-SN 0.1 a a a

09T301L-SN 0.1 a a a

09T302R-SN 0.2 a a a

09T302L-SN 0.2 a a a

09T304R-SN 0.4 a a a

09T304L-SN 0.4 a a a

R/L-SN

CCGT 0602V3R-SN 0.03 a

C022

D008

E030

E034

060201R-SN 0.1 a

060201L-SN 0.1 a

060202R-SN 0.2 a

060202L-SN 0.2 a

09T3V3R-SN 0.03 a

09T3V3L-SN 0.03 a

09T301R-SN 0.1 a

09T301L-SN 0.1 a

09T302R-SN 0.2 a

09T302L-SN 0.2 a

09T304R-SN 0.4 a

09T304L-SN 0.4 a

R/LW-SN

CCET 0602V3RW-SN 0.03 a

C022

D008

E030

E034

0602V3LW-SN 0.03 a

09T3V3RW-SN 0.03 a

09T3V3LW-SN 0.03 a

SMG

CCGT 060202M-SMG 0.2 a

C022

D008

E030

E034

060204M-SMG 0.4 a

CCMW 060202 0.2 a

C022

D008

E030

E034

060204 0.4 a a a a

09T304 0.4 a a a

09T308 0.8 a a a a

120404 0.4 a a a

120408 0.8 a a a

120412 1.2 a

CCGW 060200 0 a

C022

D008

E030

E034

0602V5 0.05 a

09T300 0 a

09T3V5 0.05 a

N

E

W

N

E

W

N

E

W

N

E

W

6

4

2

0

0.1 0.3

6

4

2

0

0.1 0.3

6

4

2

0

0.1 0.3

3

2

1

0

0.1 0.2 0.3 0.4

3

2

1

0

0.1 0.2 0.3 0.4

3

2

1

0

0.1 0.2 0.3 0.4

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

POSI

7

WITH

HOLE

*

Please refer to A028 before using the R/LW-SN breaker (wiper insert).

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Carbon Steel Alloy Steel

Carbon Steel Alloy Steel

a

p

(

m

m

)

a

p

(

m

m

)

f (mm/rev)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Cast Iron

a

p

(

m

m

)

f (mm/rev)

Cast Iron

a

p

(

m

m

)

f (mm/rev)

Medium Cutting

Medium Cutting

Medium Cutting

(Wiper)

Medium Cutting

Flat Top

Flat Top

*

CHIP BREAKERS A052

GRADES A030

IDENTIFICATION A002

You might also like

- TraceDocument106 pagesTracemanu choudharyNo ratings yet

- CT StructureDocument8 pagesCT StructureMaria ClaraNo ratings yet

- ADocument2 pagesAMahdy MohamedNo ratings yet

- Death Mom Dad SSN 136125787Document629 pagesDeath Mom Dad SSN 136125787Joseph Matthias ZaoNo ratings yet

- ADDDocument109 pagesADDMiguel ChavezNo ratings yet

- LogDocument135 pagesLogДаня БорковскийNo ratings yet

- You Can Hate Me As Much As You Want But - Google SearchDocument1 pageYou Can Hate Me As Much As You Want But - Google Searchpurvak agrawalNo ratings yet

- Wanda Greene County Credit Card RecordsDocument48 pagesWanda Greene County Credit Card RecordsAaron Adelson WlosNo ratings yet

- Office Monang Sianipar Abadi PT Jog Agent Monang Sianipar Abadi PT Jog Currency IDRDocument32 pagesOffice Monang Sianipar Abadi PT Jog Agent Monang Sianipar Abadi PT Jog Currency IDRFredhi Sumardhi100% (1)

- DocumentDocument9 pagesDocumentCharlie MorgulisNo ratings yet

- KMMMDocument270 pagesKMMMBENITEX SASNo ratings yet

- Most Important ThingDocument1 pageMost Important ThingzazaazNo ratings yet

- NytstrfrtddyeemoegbhDocument109 pagesNytstrfrtddyeemoegbhdownloader20No ratings yet

- GN 03325 Verification of SSNDocument8 pagesGN 03325 Verification of SSNTheplaymaker508No ratings yet

- NiggoDocument49 pagesNiggojosephNo ratings yet

- MinidumpDocument2 pagesMinidumpMilanisti22No ratings yet

- Nuevo Documento de TextoDocument1 pageNuevo Documento de TextoBrandy Hummer100% (1)

- TransferConfirmation 20230110 102051Document2 pagesTransferConfirmation 20230110 102051Bobur BokijonovNo ratings yet

- License Key HMA ProVPNDocument2 pagesLicense Key HMA ProVPNAkshay SinghNo ratings yet

- ARC - Architect - All StatusesDocument909 pagesARC - Architect - All Statusesgnarly tiredNo ratings yet

- Bianca Fax Confirmation Combined SSA - RedactedDocument14 pagesBianca Fax Confirmation Combined SSA - RedactedNeg Blanche Boukman LouvertureNo ratings yet

- Amazon inDocument3 pagesAmazon inBruce StebbinsNo ratings yet

- Retailer Ranking - SalesDocument47 pagesRetailer Ranking - SalesC.J. GardnerNo ratings yet

- SSN DeductionDocument5 pagesSSN DeductionMarwan SNo ratings yet

- Us Work Excel Mini Work SheetDocument116 pagesUs Work Excel Mini Work SheetMaksNo ratings yet

- Credit Cards D8Document5 pagesCredit Cards D8Isaac GonzalezNo ratings yet

- Store Transactions List: A B C D E F G H 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26Document8 pagesStore Transactions List: A B C D E F G H 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26Shaan RoyNo ratings yet

- ChatDocument2 pagesChatJack0% (1)

- Roadrunner Password RecoveryDocument7 pagesRoadrunner Password RecoverySteve SmithNo ratings yet

- I36457422100002RPOSDocument2 pagesI36457422100002RPOSAbhishek Nayak0% (1)

- TAF DocumentsDocument80 pagesTAF DocumentsreutersdotcomNo ratings yet

- SSNDocument9 pagesSSNFaouzi BoualiNo ratings yet

- Arrest Disposition Rpts. 12-2014 To 5-2017Document2,430 pagesArrest Disposition Rpts. 12-2014 To 5-2017ol_49er100% (1)

- 2011 PaypalDocument28 pages2011 PaypalTechCrunch100% (1)

- Jumpstart Credit Card Processing (Version 1)Document15 pagesJumpstart Credit Card Processing (Version 1)Oleksiy KovyrinNo ratings yet

- James Stagnitta QuoteDocument49 pagesJames Stagnitta Quotejessica messicaNo ratings yet

- American ExpDocument12 pagesAmerican Expkuljeet_gujral89No ratings yet

- Paypal IstragaDocument19 pagesPaypal IstragaCvijetin MitrovicNo ratings yet

- Bank Accouunts DetailsDocument3 pagesBank Accouunts DetailsFarooq MaqboolNo ratings yet

- ReadmeDocument1 pageReadmeposa akhilNo ratings yet

- Netflix Chrome Cookie 32asasasDocument18 pagesNetflix Chrome Cookie 32asasasGlory SiahaanNo ratings yet

- Visa StatementsDocument1 pageVisa Statementsdchristensen5No ratings yet

- Minority Depository Institutions (Mdis) December 31, 2020Document3 pagesMinority Depository Institutions (Mdis) December 31, 2020Mark LeeNo ratings yet

- CRA RosterDocument56 pagesCRA Rosterlotuseater23No ratings yet

- Credit CardDocument6 pagesCredit CardAnup SrivastavaNo ratings yet

- All 11A - January 31, 2012 (2011 Year End) FEC ReportDocument52 pagesAll 11A - January 31, 2012 (2011 Year End) FEC ReportProgressivesUnitedNo ratings yet

- Direct Deposit FormDocument2 pagesDirect Deposit FormDaeveon MitchellNo ratings yet

- Credit Card ClientsDocument943 pagesCredit Card ClientsMamadou SowNo ratings yet

- Martview Guide-MarketingDocument4 pagesMartview Guide-MarketingIsabel GarciaNo ratings yet

- Gmail - Booking Confirmation On IRCTC, Train - 12192, 10-Jul-2019, 3A, BPL - GWLDocument1 pageGmail - Booking Confirmation On IRCTC, Train - 12192, 10-Jul-2019, 3A, BPL - GWLmanish sharmaNo ratings yet

- CCDocument95 pagesCCframana01No ratings yet

- Part B - Case Tools-Uml - Lab: Usecase DiagramDocument60 pagesPart B - Case Tools-Uml - Lab: Usecase DiagramStevohNo ratings yet

- Return Predictability and Market-Timing: A One-Month Model: Blair Hull Xiao Qiao Petra BakosovaDocument30 pagesReturn Predictability and Market-Timing: A One-Month Model: Blair Hull Xiao Qiao Petra BakosovaRonitSingNo ratings yet

- Passwords FilesDocument2 pagesPasswords FilesAnsu NjieNo ratings yet

- Methods to Overcome the Financial and Money Transfer Blockade against Palestine and any Country Suffering from Financial BlockadeFrom EverandMethods to Overcome the Financial and Money Transfer Blockade against Palestine and any Country Suffering from Financial BlockadeNo ratings yet

- You’Re a Business Owner, Not a Dummy!: Understand Your Merchant AccountFrom EverandYou’Re a Business Owner, Not a Dummy!: Understand Your Merchant AccountRating: 2 out of 5 stars2/5 (1)

- Gy2g0200d020n-Mf VP10RTDocument6 pagesGy2g0200d020n-Mf VP10RTTungstenCarbideNo ratings yet

- Aemw150304er Up20mDocument1 pageAemw150304er Up20mTungstenCarbideNo ratings yet

- CBN InsertsDocument27 pagesCBN InsertsTungstenCarbideNo ratings yet

- Through Holes Steam Oxide External Cooling: Series 4402Document8 pagesThrough Holes Steam Oxide External Cooling: Series 4402TungstenCarbideNo ratings yet

- CC CC: Type Inserts With HoleDocument4 pagesCC CC: Type Inserts With HoleTungstenCarbideNo ratings yet

- Any Size Kits Are All $400.00: Steel ApplicationsDocument2 pagesAny Size Kits Are All $400.00: Steel ApplicationsTungstenCarbideNo ratings yet

- CCMXDocument1 pageCCMXTungstenCarbideNo ratings yet

- AOMT 123602 PEER-M VP15TF Mitsubishi CarbideDocument2 pagesAOMT 123602 PEER-M VP15TF Mitsubishi CarbideTungstenCarbideNo ratings yet

- Aemw150304er Up20mDocument1 pageAemw150304er Up20mTungstenCarbideNo ratings yet

- Cpmt1205zpen-M2 VP15TFDocument1 pageCpmt1205zpen-M2 VP15TFTungstenCarbideNo ratings yet

- Type Inserts With Hole: WNMG 08 04 04-FHDocument4 pagesType Inserts With Hole: WNMG 08 04 04-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: VBMT 11 03 04 - SVDocument2 pagesType Inserts With Hole: VBMT 11 03 04 - SVTungstenCarbideNo ratings yet

- Type Inserts With Hole: WCGT 02 01 02 RDocument1 pageType Inserts With Hole: WCGT 02 01 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: WBGT 02 01 V3 L-FDocument1 pageType Inserts With Hole: WBGT 02 01 V3 L-FTungstenCarbideNo ratings yet

- Type Inserts With Hole: VNMG 16 04 02-FHDocument3 pagesType Inserts With Hole: VNMG 16 04 02-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: WPGT 04 02 04 R-FSDocument1 pageType Inserts With Hole: WPGT 04 02 04 R-FSTungstenCarbideNo ratings yet

- Type Inserts With Hole: XCMT 15 03 02-SVXDocument1 pageType Inserts With Hole: XCMT 15 03 02-SVXTungstenCarbideNo ratings yet

- Type Inserts With Hole: VDGX 16 03 02 RDocument1 pageType Inserts With Hole: VDGX 16 03 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: VPET 08 02 01 R-SRFDocument1 pageType Inserts With Hole: VPET 08 02 01 R-SRFTungstenCarbideNo ratings yet

- Type Inserts With Hole: TEGX 16 03 02 RDocument1 pageType Inserts With Hole: TEGX 16 03 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: TPMH 08 02 02-FVDocument3 pagesType Inserts With Hole: TPMH 08 02 02-FVTungstenCarbideNo ratings yet

- Type Inserts With Hole: VCMT 11 03 02-FPDocument2 pagesType Inserts With Hole: VCMT 11 03 02-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: SPMT 09 03 04Document1 pageType Inserts With Hole: SPMT 09 03 04TungstenCarbideNo ratings yet

- Type Inserts With Hole: TCMT 09 02 02-FPDocument2 pagesType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideNo ratings yet

- Type Inserts Without Hole: Posi 6ºDocument1 pageType Inserts Without Hole: Posi 6ºTungstenCarbideNo ratings yet

- Type Inserts With Hole: SCMT 09 T3 04-FPDocument2 pagesType Inserts With Hole: SCMT 09 T3 04-FPTungstenCarbideNo ratings yet

- VQ-SVR: Roughing End Mill, Short Length of Cut, 4 FL Ute, Irregular Helix FL UtesDocument1 pageVQ-SVR: Roughing End Mill, Short Length of Cut, 4 FL Ute, Irregular Helix FL UtesTungstenCarbideNo ratings yet

- Type Inserts With Hole: DNMG 15 04 02-FHDocument5 pagesType Inserts With Hole: DNMG 15 04 02-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: DEGX 15 04 02 R-FDocument1 pageType Inserts With Hole: DEGX 15 04 02 R-FTungstenCarbideNo ratings yet

- Type Inserts With Hole: RCGT 08 03 M0-AZDocument1 pageType Inserts With Hole: RCGT 08 03 M0-AZTungstenCarbideNo ratings yet

- PYC 1501 Basic Psychology - PersonalityDocument15 pagesPYC 1501 Basic Psychology - Personalityektha_nankoomar91100% (3)

- Quarter 2 Week 5Document54 pagesQuarter 2 Week 5rixzylicoqui.salcedoNo ratings yet

- Passive ROMDocument3 pagesPassive ROMCzarina FayeNo ratings yet

- Datasheet Cofraplus 60Document2 pagesDatasheet Cofraplus 60Žarko JanjićNo ratings yet

- BU2508DFDocument3 pagesBU2508DFRaduNo ratings yet

- TM1 PresentationDocument33 pagesTM1 PresentationJas Sofia90% (10)

- Business-Plan (John Lloyd A Perido Grade 12-Arc)Document4 pagesBusiness-Plan (John Lloyd A Perido Grade 12-Arc)Jaypher PeridoNo ratings yet

- Application of Knowledge QuestionsDocument16 pagesApplication of Knowledge QuestionsElllie TattersNo ratings yet

- Medicina 57 00032 (01 14)Document14 pagesMedicina 57 00032 (01 14)fauzan nandana yoshNo ratings yet

- 8582d Soldering Station English User GuideDocument9 pages8582d Soldering Station English User Guide1valdasNo ratings yet

- Pelatihan Olahan Pangan Ukm LamselDocument6 pagesPelatihan Olahan Pangan Ukm LamselCalista manda WidyapalastriNo ratings yet

- Hernandez Vs CADocument1 pageHernandez Vs CAAnonymous WXk7CCRI9LNo ratings yet

- Food DirectoryDocument20 pagesFood Directoryyugam kakaNo ratings yet

- Morita Therapy For Depression and AnxietyDocument13 pagesMorita Therapy For Depression and AnxietyPedro GuimarãesNo ratings yet

- 03 - Air Ticket Request & Claim Form 2018Document1 page03 - Air Ticket Request & Claim Form 2018Danny SolvanNo ratings yet

- Cardiac PacemakerDocument25 pagesCardiac PacemakerDhvij KmlNo ratings yet

- The Man Booker PrizeDocument2 pagesThe Man Booker PrizeChu Hòa Bình100% (1)

- Msla Business FeesDocument1 pageMsla Business FeesNBC MontanaNo ratings yet

- Neurovascular Assessment PDFDocument5 pagesNeurovascular Assessment PDFNasrullah UllahNo ratings yet

- Applying Sarf Book 1 - Published-46-59Document14 pagesApplying Sarf Book 1 - Published-46-59Nauman AbbasNo ratings yet

- Clipsal RCD Tester 486D PDFDocument4 pagesClipsal RCD Tester 486D PDF322399mk7086No ratings yet

- Aphids and Ants, Mutualistic Species, Share A Mariner Element With An Unusual Location On Aphid Chromosomes - PMCDocument2 pagesAphids and Ants, Mutualistic Species, Share A Mariner Element With An Unusual Location On Aphid Chromosomes - PMC2aliciast7No ratings yet

- Information Technology Solutions: ADMET Testing SystemsDocument2 pagesInformation Technology Solutions: ADMET Testing Systemskrishgen biosystemsNo ratings yet

- Surgical Management in LeprosyDocument33 pagesSurgical Management in Leprosynsv.epicNo ratings yet

- Operator's Manual: SE Series Slab ScissorsDocument52 pagesOperator's Manual: SE Series Slab ScissorsthuanNo ratings yet

- Afico Pipe InsulaionDocument4 pagesAfico Pipe InsulaionProcurement AlamcoNo ratings yet

- Case Analysis of Vishal Jeet V. Union of India Trafficking of Women and ChildrenDocument7 pagesCase Analysis of Vishal Jeet V. Union of India Trafficking of Women and ChildrenTrishani NahaNo ratings yet

- Task 2: Health Services Survey: School Community 1. What Are The Health Services Provided?Document1 pageTask 2: Health Services Survey: School Community 1. What Are The Health Services Provided?Bernadeth BaiganNo ratings yet

- Writing Workshop G7 PDFDocument12 pagesWriting Workshop G7 PDFJobell AguvidaNo ratings yet

- Voca-Book (This Must Be The Place)Document13 pagesVoca-Book (This Must Be The Place)Анастасия ВознесенскаяNo ratings yet