Professional Documents

Culture Documents

SN

Uploaded by

TungstenCarbideOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SN

Uploaded by

TungstenCarbideCopyright:

Available Formats

A078

SNMG 09 03 04- C

SN

90

P

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

E

6

0

3

5

U

H

6

4

0

0

M

C

7

0

1

5

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

T

F

1

5

C

SNMG 090304-C 0.4 [

C012

015

E014

E035

090308-C 0.8 [

120408-C 0.8 [[

120416-C 1.6 [

R/L-1G

SNMG 120404R-1G 0.4 a

C012

015

E014

E035

120404L-1G 0.4 a

120408R-1G 0.8 a

MP

SNMG 120404-MP 0.4 a a a [ a a

C012

015

E014

E035

120408-MP 0.8 a a a [ a a

120412-MP 1.2 a a a [ a a

MM

SNMG 120408-MM 0.8 a a a

C012

015

E014

E035

120412-MM 1.2 a a a

120416-MM 1.6 a a a

150608-MM 0.8 a a a

150612-MM 1.2 a a a

150616-MM 1.6 a a a

190612-MM 1.2 a a a

190616-MM 1.6 a a a

GM

SNMG 120404-GM 0.4 a a a

C012

015

E014

E035

120408-GM 0.8 a a a

120412-GM 1.2 a a a

NEW

NEW

N

E

W

N

E

W

N

E

W

N

E

W

N

E

W

M K P

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

FH

RP

MP

HX

LP

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

RM

MM

LM

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

MA GH

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

SY

HZ

NEG

TURNI NG I NSERTS

[

NEGATI VE

]

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

Size Thickness Corner Radius

*

Please refer to page A002.

WITH

HOLE

TYPE I NSERTS

WI TH HOLE

Chip Breaker

CHIP CONTROL RANGE FOR WORK MATERIALS

Carbon Steel Alloy Steel (180280HB)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

Light Cutting

Light Cutting

Medium Cutting

Medium Cutting

Medium Cutting

Finish Cutting Light Cutting MediumCutting Rough Cutting Heavy Cutting

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Stainless Steel

a

p

(

m

m

)

f (mm/rev)

Stainless Steel

a

p

(

m

m

)

f (mm/rev)

a : Inventory maintained in Japan.

[ : Inventory maintained in Japan. To be replaced by new products.

(10 inserts in one case)

Stainless Steel (<200HB)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

Cast Iron (<350MPa)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

Standard

Flat Top

Mild Steel

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

A079

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

E

6

0

3

5

U

H

6

4

0

0

M

C

7

0

1

5

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

T

F

1

5

MA

SNMG 120404-MA 0.4 a a a [ a a a a a a

C012

015

E014

E035

120408-MA 0.8 a a a [ a a a [ a a a a a

120412-MA 1.2 a a a [ a a [ a a a a a

120416-MA 1.6 a

150608-MA 0.8 a a [ a a

150612-MA 1.2 a a [ a a a

150616-MA 1.6 a

190612-MA 1.2 a a [ a

190616-MA 1.6 a a [ a a

MH

SNMG 120408-MH 0.8 a a [ [ a

C012

015

E014

E035

120412-MH 1.2 a a [ [ a

190612-MH 1.2 a a [ a

190616-MH 1.6 a a [

SNMG 090304 0.4 a a a [ a a a a

C012

015

E014

E035

090308 0.8 a a a [ a a a a a a

120404 0.4 a a a [ a a a a

120408 0.8 a a a [ a a a a a a a a a a

120412 1.2 a a a [ a a a a a

120416 1.6 a a [ a a a a

120420 2.0 a [

150612 1.2 a a a [ a a a

190612 1.2 a a a [ a a a a

190616 1.6 a a a [ a a a

MS

SNMG 090304-MS 0.4 a

C012

015

E014

E035

090308-MS 0.8 a

120404-MS 0.4 a [ a

120408-MS 0.8 a [ [ a a a a a a a a

120412-MS 1.2 a [ a a a a a

120416-MS 1.6 a

190616-MS 1.6 a

R/L

SNGG 090304R 0.4 a a a a

C012

015

E014

E035

090304L 0.4 a a a

090308R 0.8 a a

090308L 0.8 a a

120404R 0.4 a a a a

120404L 0.4 a a a a

120408R 0.8 a a a

120408L 0.8 a a a a a

RP

SNMG120408-RP 0.8 a a a

C012

015

E014

E035

120412-RP 1.2 a a a

120416-RP 1.6 a a a

150612-RP 1.2 a a a

150616-RP 1.6 a a a

190612-RP 1.2 a a a

190616-RP 1.6 a a a

NEW

N

E

W

N

E

W

N

E

W

N

E

W

N

E

W

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

7

5

3

1

0

0.1 0.3 0.5 0.7

NEG

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

WITH

HOLE

Medium Cutting

Medium Cutting

Standard

Medium Cutting

Medium Cutting

Medium Cutting

Rough Cutting

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

f (mm/rev)

a

p

(

m

m

)

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

CHIP BREAKERS A040

GRADES A030

IDENTIFICATION A002

Diffcult-to-Cut Materials

A080

SNMG 12 04 08- RM

SN

90

P

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

E

6

0

3

5

U

H

6

4

0

0

M

C

7

0

1

5

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

T

F

1

5

RM

SNMG 120408-RM 0.8 a a a

C012

015

E014

E035

120412-RM 1.2 a a a

120416-RM 1.6 a a a

150612-RM 1.2 a a a

150616-RM 1.6 a a a

190612-RM 1.2 a a a

190616-RM 1.6 a a a

GH

SNMG 120408-GH 0.8 a a [ [ a a a

C012

015

E014

E035

120412-GH 1.2 a a [ [ a a a

120416-GH 1.6 a a a

150612-GH 1.2 a a

150616-GH 1.6 a

190612-GH 1.2 a a a

190616-GH 1.6 a a [ a

HZ

SNMM 120408-HZ 0.8 a [

C012

015

E014

E035

120412-HZ 1.2 a [

150612-HZ 1.2 a [

190612-HZ 1.2 a [ a

190616-HZ 1.6 a [ a

HX

SNMM 190612-HX 1.2 a [ a

C012

014

190616-HX 1.6 a [ a

190624-HX 2.4 a [ a

250724-HX 2.4 a [ a

250924-HX 2.4 a [ a

HV

SNMM 190616-HV 1.6 a [ a

C012

014

190624-HV 2.4 a [ a

250724-HV 2.4 a [ a

250924-HV 2.4 a [ a

NEW

N

E

W

N

E

W

N

E

W

N

E

W

N

E

W

M K P

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

HX

RP

FH

MP

LP

7

5

3

1

0

0.1 0.3 0.5 0.7

14

10

6

2

0

0.2 0.6 1.0 1.4

14

10

6

2

0

0.2 0.6 1.0 1.4

14

10

6

2

0

0.2 0.6 1.0 1.4

7

5

3

1

0

0.1 0.3 0.5 0.7

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

RM

MM

LM

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

MA GH

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

SY

HZ

NEG

TURNI NG I NSERTS

[

NEGATI VE

]

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

Size Thickness Corner Radius

*

Please refer to page A002.

WITH

HOLE

TYPE I NSERTS

WI TH HOLE

Chip Breaker

CHIP CONTROL RANGE FOR WORK MATERIALS

Carbon Steel Alloy Steel (180280HB)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

Rough Cutting

Rough Cutting

Heavy Cutting

Heavy Cutting

Heavy Cutting

Finish Cutting Light Cutting MediumCutting Rough Cutting Heavy Cutting

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

a

p

(

m

m

)

f (mm/rev)

f (mm/rev)

Mild Steel

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Stainless Steel

a

p

(

m

m

)

f (mm/rev)

a : Inventory maintained in Japan.

[ : Inventory maintained in Japan. To be replaced by new products.

(10 inserts in one case)

Cast Iron

Stainless Steel (<200HB)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

Cast Iron (<350MPa)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

Standard

Flat Top

Mild Steel

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

A081

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

E

6

0

3

5

U

H

6

4

0

0

M

C

7

0

1

5

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

T

F

1

5

SNMA 090304 0.4 a

C012

015

E014

E035

090308 0.8 a a a

120408 0.8 a a a a a

120412 1.2 a a a

120416 1.6 a a

190612 1.2 a a

190616 1.6 a a

SNGA 090304 0.4 a

C012

015

E014

E035

120404 0.4 a

120408 0.8 a a a

N

E

W

N

E

W

N

E

W

N

E

W

N

E

W

8

6

4

2

0

0.1 0.3 0.5 0.7

8

6

4

2

0

0.1 0.3 0.5 0.7

NEG

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

WITH

HOLE

Flat Top

Flat Top

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Cast Iron

Cast Iron

a

p

(

m

m

)

a

p

(

m

m

)

f (mm/rev)

f (mm/rev)

CHIP BREAKERS A040

GRADES A030

IDENTIFICATION A002

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CBN InsertsDocument27 pagesCBN InsertsTungstenCarbideNo ratings yet

- Through Holes Steam Oxide External Cooling: Series 4402Document8 pagesThrough Holes Steam Oxide External Cooling: Series 4402TungstenCarbideNo ratings yet

- CC CC: Type Inserts With HoleDocument4 pagesCC CC: Type Inserts With HoleTungstenCarbideNo ratings yet

- Cpmt1205zpen-M2 VP15TFDocument1 pageCpmt1205zpen-M2 VP15TFTungstenCarbideNo ratings yet

- VFX5UR0203CA10Document3 pagesVFX5UR0203CA10TungstenCarbideNo ratings yet

- AOMT 123602 PEER-M VP15TF Mitsubishi CarbideDocument2 pagesAOMT 123602 PEER-M VP15TF Mitsubishi CarbideTungstenCarbideNo ratings yet

- Gy2g0200d020n-Mf VP10RTDocument6 pagesGy2g0200d020n-Mf VP10RTTungstenCarbideNo ratings yet

- Any Size Kits Are All $400.00: Steel ApplicationsDocument2 pagesAny Size Kits Are All $400.00: Steel ApplicationsTungstenCarbideNo ratings yet

- Aemw150304er Up20mDocument1 pageAemw150304er Up20mTungstenCarbideNo ratings yet

- Nnmu200608zen-Hk MC5020Document1 pageNnmu200608zen-Hk MC5020TungstenCarbideNo ratings yet

- Type Inserts With Hole: XCMT 15 03 02-SVXDocument1 pageType Inserts With Hole: XCMT 15 03 02-SVXTungstenCarbideNo ratings yet

- Type Inserts With Hole: VBMT 11 03 04 - SVDocument2 pagesType Inserts With Hole: VBMT 11 03 04 - SVTungstenCarbideNo ratings yet

- Type Inserts With Hole: WPGT 04 02 04 R-FSDocument1 pageType Inserts With Hole: WPGT 04 02 04 R-FSTungstenCarbideNo ratings yet

- CCMXDocument1 pageCCMXTungstenCarbideNo ratings yet

- Aemw150304er Up20mDocument1 pageAemw150304er Up20mTungstenCarbideNo ratings yet

- Type Inserts With Hole: WCGT 02 01 02 RDocument1 pageType Inserts With Hole: WCGT 02 01 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: WNMG 08 04 04-FHDocument4 pagesType Inserts With Hole: WNMG 08 04 04-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: VCMT 11 03 02-FPDocument2 pagesType Inserts With Hole: VCMT 11 03 02-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: VNMG 16 04 02-FHDocument3 pagesType Inserts With Hole: VNMG 16 04 02-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: VPET 08 02 01 R-SRFDocument1 pageType Inserts With Hole: VPET 08 02 01 R-SRFTungstenCarbideNo ratings yet

- Type Inserts With Hole: TCMT 09 02 02-FPDocument2 pagesType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: TPMH 08 02 02-FVDocument3 pagesType Inserts With Hole: TPMH 08 02 02-FVTungstenCarbideNo ratings yet

- Type Inserts With Hole: VDGX 16 03 02 RDocument1 pageType Inserts With Hole: VDGX 16 03 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: WBGT 02 01 V3 L-FDocument1 pageType Inserts With Hole: WBGT 02 01 V3 L-FTungstenCarbideNo ratings yet

- TNDocument6 pagesTNTungstenCarbideNo ratings yet

- Type Inserts With Hole: SPMT 09 03 04Document1 pageType Inserts With Hole: SPMT 09 03 04TungstenCarbideNo ratings yet

- Type Inserts With Hole: SCMT 09 T3 04-FPDocument2 pagesType Inserts With Hole: SCMT 09 T3 04-FPTungstenCarbideNo ratings yet

- Type Inserts Without Hole: Posi 6ºDocument1 pageType Inserts Without Hole: Posi 6ºTungstenCarbideNo ratings yet

- Type Inserts With Hole: TEGX 16 03 02 RDocument1 pageType Inserts With Hole: TEGX 16 03 02 RTungstenCarbideNo ratings yet

- Crude Oil Viscosity Correlations - A Novel Approach For Upper Assam BasinDocument6 pagesCrude Oil Viscosity Correlations - A Novel Approach For Upper Assam BasinAbhishek BihaniNo ratings yet

- Models Heat ParasolDocument16 pagesModels Heat ParasolFrancisco ValdesNo ratings yet

- Introduction To Space EnvironmentDocument250 pagesIntroduction To Space EnvironmentIKOROMILOS100% (1)

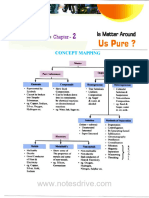

- Chapter 2 Is Matter Around Us Pure NotesDocument16 pagesChapter 2 Is Matter Around Us Pure NotesManjusha MathewNo ratings yet

- A Guide To Common Plastics PDFDocument1 pageA Guide To Common Plastics PDFmahyarbNo ratings yet

- Quality Certificate For Low Range Alkalinity Chemkey - Revision 2Document1 pageQuality Certificate For Low Range Alkalinity Chemkey - Revision 2cristi5cNo ratings yet

- 369 Chiguard 1064 DS UsDocument2 pages369 Chiguard 1064 DS UsOliver RisteskiNo ratings yet

- Hego Obdii FordDocument17 pagesHego Obdii FordIchigo KurosakiiNo ratings yet

- Design CalculationDocument16 pagesDesign Calculationlokesh sapraNo ratings yet

- Risk Based Process Safety Management Pillars and ElementsDocument107 pagesRisk Based Process Safety Management Pillars and ElementsIman Kurnia Shiddiq100% (1)

- PJC H2 PHY 9646 Mid-Year Paper 2012Document22 pagesPJC H2 PHY 9646 Mid-Year Paper 2012Ng Jia ChengNo ratings yet

- Equipment Costing SizingDocument108 pagesEquipment Costing Sizingjk100% (1)

- Gas-Gas Exchanger DatasheetDocument3 pagesGas-Gas Exchanger DatasheetidilfitriNo ratings yet

- Quantum Numbers Structure 2Document22 pagesQuantum Numbers Structure 2vishalsingh1997No ratings yet

- S TN HNG 001 PDFDocument11 pagesS TN HNG 001 PDFIhab El AghouryNo ratings yet

- Transition Fittings: Gas Distribution ProductsDocument20 pagesTransition Fittings: Gas Distribution ProductsAdam KnottNo ratings yet

- Manual de Usuario BioClaveDocument15 pagesManual de Usuario BioClaveMJ DentalNo ratings yet

- MetalDocument57 pagesMetalPrashant PuriNo ratings yet

- Edited 2DDocument13 pagesEdited 2DLennon DavalosNo ratings yet

- Adhesive Performance of A Multi-Mode Adhesive System - 1-Year in Vitro Study Lorenzo Breschi DDocument10 pagesAdhesive Performance of A Multi-Mode Adhesive System - 1-Year in Vitro Study Lorenzo Breschi DEliseu LucenaNo ratings yet

- Ch.11 Heat and ThermoDocument10 pagesCh.11 Heat and ThermoJoanne Aga EslavaNo ratings yet

- The Quality and Impact of Teachers' Subject KnowledgeDocument37 pagesThe Quality and Impact of Teachers' Subject KnowledgeLhendonNo ratings yet

- Edr IonicsDocument3 pagesEdr IonicsMax JacintoNo ratings yet

- Acid Phosphatase Procedure Brief OverviewDocument3 pagesAcid Phosphatase Procedure Brief OverviewRochellane Ramos PlasabasNo ratings yet

- William C. Davis - Introduction To Detonation PhenomenaDocument33 pagesWilliam C. Davis - Introduction To Detonation PhenomenaGhoree23456No ratings yet

- EMWTLDocument2 pagesEMWTLV'nod Rathode BNo ratings yet

- AstmDocument5 pagesAstmjohann tousNo ratings yet

- Instrumental Analytical Methods Experiment 2 - Turbidimetric Quantitative Analysis of Casein in SolutionDocument4 pagesInstrumental Analytical Methods Experiment 2 - Turbidimetric Quantitative Analysis of Casein in Solutionapi-235187189No ratings yet

- Chapter 1 Short 1 ChemistryDocument12 pagesChapter 1 Short 1 ChemistryvaibhavikamatarNo ratings yet

- 016 - 3C - Paper - Asset Integrity Management Programs For Ammonia Plant FacilitiesDocument10 pages016 - 3C - Paper - Asset Integrity Management Programs For Ammonia Plant FacilitiesNendra GunawanNo ratings yet