Professional Documents

Culture Documents

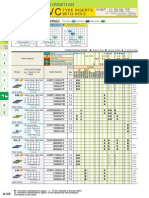

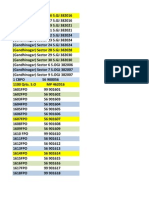

Type Inserts With Hole: TEGX 16 03 02 R

Uploaded by

TungstenCarbideOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Type Inserts With Hole: TEGX 16 03 02 R

Uploaded by

TungstenCarbideCopyright:

Available Formats

A115

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

H

6

4

0

0

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

V

P

4

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

R/L

TEGX 160302R 0.2 a

C033

E043

160302L 0.2 a

160304R 0.4 a

160304L 0.4 a

TEGX 16 03 02 R

TE

60

N

N

E

W

N

E

W

N

E

W

N

E

W

4

3

2

1

0

0.1 0.3 0.5

4

3

2

1

0

0.1 0.2 0.3 0.4

R/L

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Size Thickness Corner Radius

*

Please refer to page A002.

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

POSI

20

WITH

HOLE

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Chip Breaker

TYPE I NSERTS

WI TH HOLE

CHIP CONTROL RANGE FOR WORK MATERIALS

Aluminium Alloy

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

MediumCutting

Medium Cutting

(For AluminiumAlloy)

Aluminium Alloy

f (mm/rev)

a

p

(

m

m

)

CHIP BREAKERS A062

GRADES A030

IDENTIFICATION A002

You might also like

- Type Inserts With Hole: VDGX 16 03 02 RDocument1 pageType Inserts With Hole: VDGX 16 03 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: DEGX 15 04 02 R-FDocument1 pageType Inserts With Hole: DEGX 15 04 02 R-FTungstenCarbideNo ratings yet

- Type Inserts With Hole: VPET 08 02 01 R-SRFDocument1 pageType Inserts With Hole: VPET 08 02 01 R-SRFTungstenCarbideNo ratings yet

- Type Inserts With Hole: XCMT 15 03 02-SVXDocument1 pageType Inserts With Hole: XCMT 15 03 02-SVXTungstenCarbideNo ratings yet

- Type Inserts With Hole: VNMG 16 04 02-FHDocument3 pagesType Inserts With Hole: VNMG 16 04 02-FHTungstenCarbideNo ratings yet

- RTAC Customer PackageDocument15 pagesRTAC Customer PackageAldo MartinezNo ratings yet

- List PompaDocument10 pagesList PompamarthtjuluNo ratings yet

- Type Inserts With Hole: WBGT 02 01 V3 L-FDocument1 pageType Inserts With Hole: WBGT 02 01 V3 L-FTungstenCarbideNo ratings yet

- g3500c and G3500e Generator Electrical System PDFDocument4 pagesg3500c and G3500e Generator Electrical System PDFСергей Шевченко0% (1)

- Bustan Developers .PVT - LTD: Project - Bustan City Phase - 12 Location - Rahim Nagar LucknowDocument1 pageBustan Developers .PVT - LTD: Project - Bustan City Phase - 12 Location - Rahim Nagar LucknowsaaNo ratings yet

- Par KD Eck 1: M/C Ycl Elo TSDocument1 pagePar KD Eck 1: M/C Ycl Elo TSWu ChengbaoNo ratings yet

- Typical MSW SchematicDocument9 pagesTypical MSW SchematicSam Wing HongNo ratings yet

- Marca Odelc Orimp Resso Raso Vant. TO: HPC B 4 3 5Document39 pagesMarca Odelc Orimp Resso Raso Vant. TO: HPC B 4 3 5Renan LealNo ratings yet

- Abb Price ListDocument12 pagesAbb Price ListShamim Ahsan Parvez47% (15)

- Type Inserts Without Hole: Posi 6ºDocument1 pageType Inserts Without Hole: Posi 6ºTungstenCarbideNo ratings yet

- Type Inserts With Hole: TCMT 09 02 02-FPDocument2 pagesType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideNo ratings yet

- Spark PlugsDocument400 pagesSpark PlugssinteguaNo ratings yet

- Type Inserts With Hole: SPMT 09 03 04Document1 pageType Inserts With Hole: SPMT 09 03 04TungstenCarbideNo ratings yet

- Gas ValveDocument9 pagesGas ValveJJNo ratings yet

- Type Inserts With Hole: WPGT 04 02 04 R-FSDocument1 pageType Inserts With Hole: WPGT 04 02 04 R-FSTungstenCarbideNo ratings yet

- 06na NW Parts BreakdownDocument14 pages06na NW Parts BreakdownAmaurys Centeno100% (6)

- Type Inserts With Hole: VCMT 11 03 02-FPDocument2 pagesType Inserts With Hole: VCMT 11 03 02-FPTungstenCarbideNo ratings yet

- KMSP - All STARsDocument8 pagesKMSP - All STARsPFunk49No ratings yet

- Embraco Compressors 2000Document11 pagesEmbraco Compressors 2000Emiliano Ibañez100% (1)

- CHANDWA List of Designations TGE2745-R03Document13 pagesCHANDWA List of Designations TGE2745-R03suleman247No ratings yet

- Type Inserts With Hole: VBMT 11 03 04 - SVDocument2 pagesType Inserts With Hole: VBMT 11 03 04 - SVTungstenCarbideNo ratings yet

- 7E571N6 0F An Arr0W-Head VER71CAL-Ax15 W1Nd 7Ur81Ne M0Del V. H. M 0 R C 0 5 and 0. M. E. A8Del-Hafe2Document9 pages7E571N6 0F An Arr0W-Head VER71CAL-Ax15 W1Nd 7Ur81Ne M0Del V. H. M 0 R C 0 5 and 0. M. E. A8Del-Hafe2Revan TaeNo ratings yet

- MMLODocument12 pagesMMLOAr AbisaiNo ratings yet

- Switchgear 13800VDocument38 pagesSwitchgear 13800VYeissonSanabriaNo ratings yet

- Type Inserts With Hole: DNMG 15 04 02-FHDocument5 pagesType Inserts With Hole: DNMG 15 04 02-FHTungstenCarbideNo ratings yet

- Sonalika Motor Solis 50-60-75 - 90Document56 pagesSonalika Motor Solis 50-60-75 - 90Dmitry HodNo ratings yet

- PIC16f877a Va 15x8 LedDocument1 pagePIC16f877a Va 15x8 LedTu PhamNo ratings yet

- Part Dump Truck QuesterDocument1 pagePart Dump Truck QuesterSilvia GosalNo ratings yet

- Chimp Spanner - Harvey WallbangerDocument8 pagesChimp Spanner - Harvey WallbangerKenneth CastilloNo ratings yet

- Eiffel Tower PDFDocument25 pagesEiffel Tower PDFIndroyal PropertiesNo ratings yet

- Stock ListDocument22 pagesStock ListIthink'bree-mahana Anak'sintua Lau'gunungs-shimalemnari Prnmbeh'ningen-prpusuhNo ratings yet

- Frequency Central's Superfly, by ThomasDocument3 pagesFrequency Central's Superfly, by ThomasThomas Eduardt HafemannNo ratings yet

- 3 Storey Apartment PlansDocument1 page3 Storey Apartment PlansC-jheySiadorNo ratings yet

- Roteador Wirelles Conectores de Força Monitor: CA T 5eDocument1 pageRoteador Wirelles Conectores de Força Monitor: CA T 5eFilipeSalvadorSilveiraNo ratings yet

- Type Inserts With Hole: WCGT 02 01 02 RDocument1 pageType Inserts With Hole: WCGT 02 01 02 RTungstenCarbideNo ratings yet

- Atmel ComponentDocument1 pageAtmel ComponentSyazwan AzamNo ratings yet

- MasterDocument2 pagesMasterTrần Lê ThanhNo ratings yet

- Service Data Sheet: Standard - Automatic Defrost Top Freezer Models (R134A)Document2 pagesService Data Sheet: Standard - Automatic Defrost Top Freezer Models (R134A)luisperozoNo ratings yet

- So Do Mach Nguyen LyDocument1 pageSo Do Mach Nguyen LyNguyễn Thị Cẩm NhungNo ratings yet

- Stereo Headphone Amplifier: Limited WarrantyDocument4 pagesStereo Headphone Amplifier: Limited WarrantyFlorian HenselNo ratings yet

- Plano FinalDocument1 pagePlano FinalVictor LunaNo ratings yet

- Válvula Expansão 2 5TR (Emerson A-Series)Document3 pagesVálvula Expansão 2 5TR (Emerson A-Series)rcbandeiraNo ratings yet

- Aerotech B Series Data SheetDocument2 pagesAerotech B Series Data SheetjadetorresNo ratings yet

- India PincodeDocument844 pagesIndia PincodeNKumar Rajendra100% (1)

- Cable ListDocument1 pageCable ListDwi YuliantoNo ratings yet

- Al Plate Heat Ex ChangersDocument686 pagesAl Plate Heat Ex ChangersMario Mendoza33% (3)

- Type Inserts With Hole: SCMT 09 T3 04-FPDocument2 pagesType Inserts With Hole: SCMT 09 T3 04-FPTungstenCarbideNo ratings yet

- 5 AQV09AWBN SM en Exploded View Part List (Ver2.0)Document7 pages5 AQV09AWBN SM en Exploded View Part List (Ver2.0)Leonel ValençaNo ratings yet

- XR-P560 - RRV1626 Service ManualDocument21 pagesXR-P560 - RRV1626 Service ManualBarry John FitzGeradNo ratings yet

- Service Philips 2005Document188 pagesService Philips 2005acostaricciNo ratings yet

- Contents:: Technical DataDocument6 pagesContents:: Technical DataDavid HicksNo ratings yet

- Final Procurement ListDocument586 pagesFinal Procurement Listrajabharath12No ratings yet

- WinDocument55 pagesWinNur TeguhNo ratings yet

- Electronic Circuit Design Ideas: Edn Series for Design EngineersFrom EverandElectronic Circuit Design Ideas: Edn Series for Design EngineersRating: 5 out of 5 stars5/5 (2)

- CBN InsertsDocument27 pagesCBN InsertsTungstenCarbideNo ratings yet

- Through Holes Steam Oxide External Cooling: Series 4402Document8 pagesThrough Holes Steam Oxide External Cooling: Series 4402TungstenCarbideNo ratings yet

- CC CC: Type Inserts With HoleDocument4 pagesCC CC: Type Inserts With HoleTungstenCarbideNo ratings yet

- VFX5UR0203CA10Document3 pagesVFX5UR0203CA10TungstenCarbideNo ratings yet

- Nnmu200608zen-Hk MC5020Document1 pageNnmu200608zen-Hk MC5020TungstenCarbideNo ratings yet

- Any Size Kits Are All $400.00: Steel ApplicationsDocument2 pagesAny Size Kits Are All $400.00: Steel ApplicationsTungstenCarbideNo ratings yet

- Gy2g0200d020n-Mf VP10RTDocument6 pagesGy2g0200d020n-Mf VP10RTTungstenCarbideNo ratings yet

- Type Inserts With Hole: WPGT 04 02 04 R-FSDocument1 pageType Inserts With Hole: WPGT 04 02 04 R-FSTungstenCarbideNo ratings yet

- Type Inserts With Hole: VCMT 11 03 02-FPDocument2 pagesType Inserts With Hole: VCMT 11 03 02-FPTungstenCarbideNo ratings yet

- Cpmt1205zpen-M2 VP15TFDocument1 pageCpmt1205zpen-M2 VP15TFTungstenCarbideNo ratings yet

- AOMT 123602 PEER-M VP15TF Mitsubishi CarbideDocument2 pagesAOMT 123602 PEER-M VP15TF Mitsubishi CarbideTungstenCarbideNo ratings yet

- Aemw150304er Up20mDocument1 pageAemw150304er Up20mTungstenCarbideNo ratings yet

- Aemw150304er Up20mDocument1 pageAemw150304er Up20mTungstenCarbideNo ratings yet

- CCMXDocument1 pageCCMXTungstenCarbideNo ratings yet

- Type Inserts With Hole: WCGT 02 01 02 RDocument1 pageType Inserts With Hole: WCGT 02 01 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: WNMG 08 04 04-FHDocument4 pagesType Inserts With Hole: WNMG 08 04 04-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: WBGT 02 01 V3 L-FDocument1 pageType Inserts With Hole: WBGT 02 01 V3 L-FTungstenCarbideNo ratings yet

- Type Inserts With Hole: TPMH 08 02 02-FVDocument3 pagesType Inserts With Hole: TPMH 08 02 02-FVTungstenCarbideNo ratings yet

- Type Inserts With Hole: VBMT 11 03 04 - SVDocument2 pagesType Inserts With Hole: VBMT 11 03 04 - SVTungstenCarbideNo ratings yet

- SNDocument4 pagesSNTungstenCarbideNo ratings yet

- Type Inserts Without Hole: Posi 6ºDocument1 pageType Inserts Without Hole: Posi 6ºTungstenCarbideNo ratings yet

- TNDocument6 pagesTNTungstenCarbideNo ratings yet

- Type Inserts With Hole: TCMT 09 02 02-FPDocument2 pagesType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: SPMT 09 03 04Document1 pageType Inserts With Hole: SPMT 09 03 04TungstenCarbideNo ratings yet

- Type Inserts With Hole: SCMT 09 T3 04-FPDocument2 pagesType Inserts With Hole: SCMT 09 T3 04-FPTungstenCarbideNo ratings yet