Professional Documents

Culture Documents

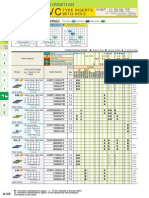

Type Inserts With Hole: TPMH 08 02 02-FV

Uploaded by

TungstenCarbideOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Type Inserts With Hole: TPMH 08 02 02-FV

Uploaded by

TungstenCarbideCopyright:

Available Formats

A116

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

H

6

4

0

0

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

V

P

4

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

FV

TPMH 080202-FV 0.2 [ a a a a

E007

080204-FV 0.4 [ a a a a

090202-FV 0.2 [ a a a a

090204-FV 0.4 [ a a a a

110302-FV 0.2 [ a a a a

110304-FV 0.4 [ a a a a

110308-FV 0.8 [ a a a a

160302-FV 0.2 [ a a a a

160304-FV 0.4 [ a a a a

160308-FV 0.8 [ a a a a

R/L-FS

TPGH 080202R-FS 0.2 a a a

E007

080202L-FS 0.2 a a a a a

080204R-FS 0.4 a a a

080204L-FS 0.4 a a a a a

090202R-FS 0.2 a a a

090202L-FS 0.2 a a a a a

090204R-FS 0.4 a a a

090204L-FS 0.4 a a a a a

110302R-FS 0.2 a a a

110302L-FS 0.2 a a a a a

110304R-FS 0.4 a a a

110304L-FS 0.4 a a a a a

160304R-FS 0.4 a a a

160304L-FS 0.4 a a a a

160308R-FS 0.8 a a a

160308L-FS 0.8 a a a a

TPMH 08 02 02- FV

TP

60

P P M

N

E

W

N

E

W

N

E

W

N

E

W

3

2

1

0

0.1 0.2 0.3 0.4

3

2

1

0

0.1 0.2 0.3 0.4

4

3

2

1

0

0.1 0.2 0.3 0.4

SV

MV

FV

4

3

2

1

0

0.1 0.2 0.3 0.4

SV

MV

FV

4

3

2

1

0

0.1 0.2 0.3 0.4

SV

MV

FV

TURNI NG I NSERTS

[

POSI TI VE

]

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Size Thickness Corner Radius

*

Please refer to page A002.

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

POSI

11

WITH

HOLE

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Chip Breaker

TYPE I NSERTS

WI TH HOLE

CHIP CONTROL RANGE FOR WORK MATERIALS

Mild Steel Carbon Steel Alloy Steel (180280HB) Stainless Steel (<200HB)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

Finish Cutting Light Cutting MediumCutting

Finish Cutting

Finish Cutting

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

a : Inventory maintained in Japan.

[ : Inventory maintained in Japan. To be replaced by new products.

(10 inserts in one case)

A117

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

H

6

4

0

0

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

V

P

4

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

R/L

TPGX 080202R 0.2 a

E025

080202L 0.2 a a a

080204R 0.4 a a

080204L 0.4 a a a a

090202R 0.2 a

090202L 0.2 a a a

090204R 0.4 a a

090204L 0.4 a a a a

090208R 0.8 a

090208L 0.8 a a

110302L 0.2 a a a

110304R 0.4 a a a

110304L 0.4 a a a a

110308R 0.8 a a

110308L 0.8 a a a a a

L

TPMX 090204L 0.4 a

E025

110304L 0.4 a

SV

TPMH 080202-SV 0.2 a [ [ a a a a a

E007

080204-SV 0.4 a [ [ a a a a a a

090202-SV 0.2 a [ [ a a a a a

090204-SV 0.4 a [ [ a a a a a a

110302-SV 0.2 a [ [ a a a a a a

110304-SV 0.4 a [ [ a a a a a a

110308-SV 0.8 a [ [ a a a a a a

160302-SV 0.2 a [ [ a a a a a a

160304-SV 0.4 a [ [ a a a a a a

160308-SV 0.8 a [ [ a a a a a a

TPMX 110304 0.4 a a a

E025

110308 0.8 a a a

MV

TPMH 080202-MV 0.2 a [ [ a a a a a

E007

080204-MV 0.4 a [ [ a a a a a a a

090202-MV 0.2 a [ [ a a a a a

090204-MV 0.4 a [ [ a a a a a a a

090208-MV 0.8 a [ a a a

110302-MV 0.2 a [ [ a a a a a a a

110304-MV 0.4 a [ [ a a a a a a a

110308-MV 0.8 a [ [ a a a a a a a

160304-MV 0.4 a [ [ a a a a a a a

160308-MV 0.8 a [ [ a a a a a a a

N

E

W

N

E

W

N

E

W

N

E

W

3

2

1

0

0.1 0.2 0.3 0.4

3

2

1

0

0.1 0.2 0.3 0.4

3

2

1

0

0.1 0.2 0.3 0.4

3

2

1

0

0.1 0.2 0.3 0.4

3

2

1

0

0.1 0.2 0.3 0.4

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

POSI

11

WITH

HOLE

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Finish Cutting

Finish Cutting

Light Cutting

Standard

Medium Cutting

Medium Cutting

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

CHIP BREAKERS A058

GRADES A030

IDENTIFICATION A002

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

A118

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

H

6

4

0

0

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

V

P

4

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

TPGX 080202 0.2 a

E025

080204 0.4 a a a a a

080208 0.8 a a a

090202 0.2 a

090204 0.4 a a a a

090208 0.8 a a a a

110302 0.2 a

110304 0.4 a a a a a a

110308 0.8 a a a a a

160304 0.4 a a a

160308 0.8 a a

TPGX 08 02 02

TP

60

P P M

N

E

W

N

E

W

N

E

W

N

E

W

4

3

2

1

0

0.1 0.2 0.3 0.4

SV

MV

FV

4

3

2

1

0

0.1 0.2 0.3 0.4

SV

MV

FV

4

3

2

1

0

0.1 0.2 0.3 0.4

SV

MV

FV

3

2

1

0

0.1 0.2 0.3 0.4

TURNI NG I NSERTS

[

POSI TI VE

]

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Size Thickness Corner Radius

*

Please refer to page A002.

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

POSI

11

WITH

HOLE

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

TYPE I NSERTS

WI TH HOLE

CHIP CONTROL RANGE FOR WORK MATERIALS

Mild Steel Carbon Steel Alloy Steel (180280HB) Stainless Steel (<200HB)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

Finish Cutting Light Cutting MediumCutting

Cast Iron

a

p

(

m

m

)

f (mm/rev)

CHIP BREAKERS A058

Flat Top

a : Inventory maintained in Japan. u : To be released in Autumn 2013

[ : Inventory maintained in Japan. To be replaced by new products.

(10 inserts in one case)

You might also like

- Type Inserts With Hole: VBMT 11 03 04 - SVDocument2 pagesType Inserts With Hole: VBMT 11 03 04 - SVTungstenCarbideNo ratings yet

- Type Inserts With Hole: WNMG 08 04 04-FHDocument4 pagesType Inserts With Hole: WNMG 08 04 04-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: VCMT 11 03 02-FPDocument2 pagesType Inserts With Hole: VCMT 11 03 02-FPTungstenCarbideNo ratings yet

- CPDocument1 pageCPTungstenCarbideNo ratings yet

- Type Inserts With Hole: SCMT 09 T3 04-FPDocument2 pagesType Inserts With Hole: SCMT 09 T3 04-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: WPGT 04 02 04 R-FSDocument1 pageType Inserts With Hole: WPGT 04 02 04 R-FSTungstenCarbideNo ratings yet

- CCDocument2 pagesCCTungstenCarbideNo ratings yet

- Type Inserts With Hole: TCMT 09 02 02-FPDocument2 pagesType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: DNMG 15 04 02-FHDocument5 pagesType Inserts With Hole: DNMG 15 04 02-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: SPMT 09 03 04Document1 pageType Inserts With Hole: SPMT 09 03 04TungstenCarbideNo ratings yet

- Type Inserts With Hole: WCGT 02 01 02 RDocument1 pageType Inserts With Hole: WCGT 02 01 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: WBGT 02 01 V3 L-FDocument1 pageType Inserts With Hole: WBGT 02 01 V3 L-FTungstenCarbideNo ratings yet

- Type Inserts With Hole: VNMG 16 04 02-FHDocument3 pagesType Inserts With Hole: VNMG 16 04 02-FHTungstenCarbideNo ratings yet

- Thread o Ring Flanged FittingDocument4 pagesThread o Ring Flanged FittingsureshisisisNo ratings yet

- C006a ADocument152 pagesC006a ASugatSravastiNo ratings yet

- Type Inserts With Hole: RCGT 08 03 M0-AZDocument1 pageType Inserts With Hole: RCGT 08 03 M0-AZTungstenCarbideNo ratings yet

- General Purpose Solenoid Valves for Automation, High Temperatures & HeatingDocument16 pagesGeneral Purpose Solenoid Valves for Automation, High Temperatures & HeatingFimoca Energy C.ANo ratings yet

- Metal Table JISDocument1 pageMetal Table JISNakkolopNo ratings yet

- 196000-3270 BOMBA INJETORA DENSO - pdf-4Document2 pages196000-3270 BOMBA INJETORA DENSO - pdf-4militar1968No ratings yet

- 23Document2 pages23Muco MucaviNo ratings yet

- Service Information: GeneralDocument2 pagesService Information: GeneralAbdulSattarNo ratings yet

- Vc4Mb: Ball Nose, Medium Cut Length, 4 FL UteDocument1 pageVc4Mb: Ball Nose, Medium Cut Length, 4 FL UteTungstenCarbideNo ratings yet

- TPP Motorised ValveDocument1 pageTPP Motorised ValvenogeshwarNo ratings yet

- 18v32 E#2 SettingsDocument3 pages18v32 E#2 SettingsAnonymous 05tfMB3ENo ratings yet

- Es LFB6080G2Document2 pagesEs LFB6080G2WattsNo ratings yet

- Turbine Blade MachiningDocument36 pagesTurbine Blade Machiningyh1.yuNo ratings yet

- Process Vessels and Storage Vessels: Drawing N°Document7 pagesProcess Vessels and Storage Vessels: Drawing N°Rodrigo BeldaNo ratings yet

- Obl - NXTDocument3 pagesObl - NXTKumar DevvratNo ratings yet

- GD 930 & GD 930S2: Parts ListDocument24 pagesGD 930 & GD 930S2: Parts ListAngel De la TorreNo ratings yet

- Material EquivalentDocument88 pagesMaterial EquivalentGabriel Milicu67% (3)

- Ferramentas HSK TDocument0 pagesFerramentas HSK Tandreia_janaina9629No ratings yet

- Group 6: 10K High Pressure Fittings Tubing Nipples AdaptorsDocument26 pagesGroup 6: 10K High Pressure Fittings Tubing Nipples AdaptorskarthikNo ratings yet

- Catalog VaneDocument16 pagesCatalog VanehbcbmwtuningNo ratings yet

- Torches NM Series Combination Torch: Part Number....... 0700017241Document1 pageTorches NM Series Combination Torch: Part Number....... 0700017241Dries VandezandeNo ratings yet

- Bom - NotepadDocument1 pageBom - NotepadUPSIDE-DOWNNo ratings yet

- OCTP Development Project ComponentsDocument183 pagesOCTP Development Project ComponentsphdvnkNo ratings yet

- WPMP NDT Request FormDocument7 pagesWPMP NDT Request FormVimin PrakashNo ratings yet

- ASV Posi-Track PT-70 Track Loader Master Parts Catalogue Manual PDFDocument13 pagesASV Posi-Track PT-70 Track Loader Master Parts Catalogue Manual PDFfisekkkdNo ratings yet

- Detailed assembly drawings for gas separator towerDocument1 pageDetailed assembly drawings for gas separator towerDmmxy14No ratings yet

- Register of laboratory instruments and gaugesDocument2 pagesRegister of laboratory instruments and gaugesEdwin MPNo ratings yet

- ASV Posi-Track PT-80 Track Loader Parts Catalogue Manual PDFDocument14 pagesASV Posi-Track PT-80 Track Loader Parts Catalogue Manual PDFfisekkkdNo ratings yet

- Catalogo Sap Nov-11 Excel1 1Document953 pagesCatalogo Sap Nov-11 Excel1 1Jorge Luis Campos Sinarahua100% (1)

- Replacement Parts List: Veebloc & Hallscrew CouplingsDocument4 pagesReplacement Parts List: Veebloc & Hallscrew CouplingsJaganathan KrishnanNo ratings yet

- Controlled Bolt Tightening ChecklistDocument10 pagesControlled Bolt Tightening Checklistanjangandak2932No ratings yet

- Technical Manual: Five-Channel Power AmplifierDocument8 pagesTechnical Manual: Five-Channel Power Amplifierudal64No ratings yet

- Drill Bit DetailsDocument82 pagesDrill Bit DetailsvmgobinathNo ratings yet

- Technical Service Bulletin: SANY ExcavatorDocument3 pagesTechnical Service Bulletin: SANY ExcavatorpradipNo ratings yet

- 09 - Ball ValvesDocument10 pages09 - Ball ValvesacildeNo ratings yet

- Esploso DPH220Document4 pagesEsploso DPH220JAVIER DELTORONo ratings yet

- Welding and Welder Performance 10 July 2015Document26 pagesWelding and Welder Performance 10 July 2015Achmad AffandyNo ratings yet

- 2 RD74Document1 page2 RD74Igor KalvanovNo ratings yet

- Skid Steer Loader Master Part ManualDocument39 pagesSkid Steer Loader Master Part Manualkeno73No ratings yet

- Weld FittingsDocument8 pagesWeld FittingsNilesh MistryNo ratings yet

- 20F2041 Pick ListDocument9 pages20F2041 Pick Listvio_tani4812No ratings yet

- 4D84E-3E Cylinder Head PartsDocument1 page4D84E-3E Cylinder Head PartsDmitryNo ratings yet

- 240 268Document29 pages240 268jl_arvizoNo ratings yet

- AlkatreszDocument2 pagesAlkatreszgia maxniashviliNo ratings yet

- Threading Tools (SST Series)Document8 pagesThreading Tools (SST Series)Gilberto ManhattanNo ratings yet

- VQ-SVR: Roughing End Mill, Short Length of Cut, 4 FL Ute, Irregular Helix FL UtesDocument1 pageVQ-SVR: Roughing End Mill, Short Length of Cut, 4 FL Ute, Irregular Helix FL UtesTungstenCarbideNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Through Holes Steam Oxide External Cooling: Series 4402Document8 pagesThrough Holes Steam Oxide External Cooling: Series 4402TungstenCarbideNo ratings yet

- CC CC: Type Inserts With HoleDocument4 pagesCC CC: Type Inserts With HoleTungstenCarbideNo ratings yet

- CBN InsertsDocument27 pagesCBN InsertsTungstenCarbideNo ratings yet

- CCMXDocument1 pageCCMXTungstenCarbideNo ratings yet

- Aemw150304er Up20mDocument1 pageAemw150304er Up20mTungstenCarbideNo ratings yet

- Any Size Kits Are All $400.00: Steel ApplicationsDocument2 pagesAny Size Kits Are All $400.00: Steel ApplicationsTungstenCarbideNo ratings yet

- VFX5UR0203CA10Document3 pagesVFX5UR0203CA10TungstenCarbideNo ratings yet

- Cpmt1205zpen-M2 VP15TFDocument1 pageCpmt1205zpen-M2 VP15TFTungstenCarbideNo ratings yet

- Nnmu200608zen-Hk MC5020Document1 pageNnmu200608zen-Hk MC5020TungstenCarbideNo ratings yet

- Gy2g0200d020n-Mf VP10RTDocument6 pagesGy2g0200d020n-Mf VP10RTTungstenCarbideNo ratings yet

- AOMT 123602 PEER-M VP15TF Mitsubishi CarbideDocument2 pagesAOMT 123602 PEER-M VP15TF Mitsubishi CarbideTungstenCarbideNo ratings yet

- Aemw150304er Up20mDocument1 pageAemw150304er Up20mTungstenCarbideNo ratings yet

- Type Inserts With Hole: VNMG 16 04 02-FHDocument3 pagesType Inserts With Hole: VNMG 16 04 02-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: XCMT 15 03 02-SVXDocument1 pageType Inserts With Hole: XCMT 15 03 02-SVXTungstenCarbideNo ratings yet

- Type Inserts With Hole: SPMT 09 03 04Document1 pageType Inserts With Hole: SPMT 09 03 04TungstenCarbideNo ratings yet

- Type Inserts With Hole: WPGT 04 02 04 R-FSDocument1 pageType Inserts With Hole: WPGT 04 02 04 R-FSTungstenCarbideNo ratings yet

- Type Inserts With Hole: WCGT 02 01 02 RDocument1 pageType Inserts With Hole: WCGT 02 01 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: TEGX 16 03 02 RDocument1 pageType Inserts With Hole: TEGX 16 03 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: VPET 08 02 01 R-SRFDocument1 pageType Inserts With Hole: VPET 08 02 01 R-SRFTungstenCarbideNo ratings yet

- Type Inserts With Hole: VDGX 16 03 02 RDocument1 pageType Inserts With Hole: VDGX 16 03 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: WBGT 02 01 V3 L-FDocument1 pageType Inserts With Hole: WBGT 02 01 V3 L-FTungstenCarbideNo ratings yet

- Type Inserts With Hole: TCMT 09 02 02-FPDocument2 pagesType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideNo ratings yet

- SNDocument4 pagesSNTungstenCarbideNo ratings yet

- TNDocument6 pagesTNTungstenCarbideNo ratings yet

- Type Inserts Without Hole: Posi 6ºDocument1 pageType Inserts Without Hole: Posi 6ºTungstenCarbideNo ratings yet

- Water Sorption and The Plasticization Effect in WafersDocument8 pagesWater Sorption and The Plasticization Effect in WafersElkin G ArcosNo ratings yet

- Mol 2Document54 pagesMol 2Trung Tin NguyenNo ratings yet

- SGM1 - Study Guide For Module 1 PDFDocument25 pagesSGM1 - Study Guide For Module 1 PDFEj ParañalNo ratings yet

- Series 500Document4 pagesSeries 500Nilton GarcíaNo ratings yet

- Curriculum C-14 FOR Diploma in Electrical & Electronics EngineeringDocument224 pagesCurriculum C-14 FOR Diploma in Electrical & Electronics EngineeringM B Hemanth KumarNo ratings yet

- Chemistry 0330 Exam 1 - October 10, 2018: Read Instructions CarefullyDocument7 pagesChemistry 0330 Exam 1 - October 10, 2018: Read Instructions CarefullyBananaNo ratings yet

- Cyltech 40 XDC - BrochureDocument3 pagesCyltech 40 XDC - Brochureprabu680No ratings yet

- EQ: How Do We Use The Kinetic Molecular Theory To Explain The Behavior of Gases?Document42 pagesEQ: How Do We Use The Kinetic Molecular Theory To Explain The Behavior of Gases?Mark Niño JavierNo ratings yet

- GDL in Meat ProcessingDocument3 pagesGDL in Meat Processingadiy0n9100% (1)

- Chemical Ammonia Report PDFDocument72 pagesChemical Ammonia Report PDFAli J. Hojeij100% (1)

- CH 9 Cellular Respiration and Fermentation NotesDocument11 pagesCH 9 Cellular Respiration and Fermentation NotesEvannaCoronaNo ratings yet

- Equipment Included in A CO2 PlantDocument3 pagesEquipment Included in A CO2 Plantgama tokNo ratings yet

- How I was floored by a tick reveals Lyme disease diagnosis journeyDocument12 pagesHow I was floored by a tick reveals Lyme disease diagnosis journeyKylie GolindangNo ratings yet

- Chemical formulas, synonyms and CAS numbers for various chemical compoundsDocument64 pagesChemical formulas, synonyms and CAS numbers for various chemical compoundsFareez IzwanNo ratings yet

- Sulfur P&IDDocument25 pagesSulfur P&IDKrismawan Saptya Yudha0% (1)

- Letter To ParentsDocument2 pagesLetter To Parentsapi-293522278No ratings yet

- The Hydrophilic - Hydrophobic Transition On SilicaDocument10 pagesThe Hydrophilic - Hydrophobic Transition On SilicaDarkwitchAbbNo ratings yet

- CBN Turning InsertsDocument1 pageCBN Turning InsertsknujdloNo ratings yet

- Chap 11Document7 pagesChap 11Nguyễn Bảo ThoaNo ratings yet

- Physics Andits Laws in AnaesthesiaDocument111 pagesPhysics Andits Laws in AnaesthesiaRobin TolentinoNo ratings yet

- ETRF Endotoxin FilterDocument12 pagesETRF Endotoxin FilterMutiara RizkyNo ratings yet

- Espectofotometro Uv 1900iDocument16 pagesEspectofotometro Uv 1900iAlecitaGutierrezMartinezNo ratings yet

- 1840 FullDocument17 pages1840 FullCarlos Garcia GarciaNo ratings yet

- AlakalinePhos ARC CHEMDocument8 pagesAlakalinePhos ARC CHEMTanveerNo ratings yet

- Homework #1 For Chemical Engineering ThermodynamicsDocument2 pagesHomework #1 For Chemical Engineering Thermodynamicsramesh pokhrelNo ratings yet

- H5 Thesis 1 RevisedDocument64 pagesH5 Thesis 1 Revisedhadprince2023No ratings yet

- Pool Heater ManualDocument53 pagesPool Heater ManualkmduffNo ratings yet

- Aluminum Sulfate GHSDocument9 pagesAluminum Sulfate GHSJean Carla RosarioNo ratings yet

- Phytoextraction of Mercury-Contaminated Soil Using Cogon Grass (Imperata Cylindrica)Document15 pagesPhytoextraction of Mercury-Contaminated Soil Using Cogon Grass (Imperata Cylindrica)Maria lalaine TrinidadNo ratings yet

- Bio PDF 1Document7 pagesBio PDF 1Shin3 KimNo ratings yet