Professional Documents

Culture Documents

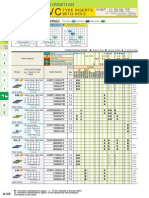

Type Inserts With Hole: VBMT 11 03 04 - SV

Uploaded by

TungstenCarbideOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Type Inserts With Hole: VBMT 11 03 04 - SV

Uploaded by

TungstenCarbideCopyright:

Available Formats

A120

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

H

6

4

0

0

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

V

P

4

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

SV

VBMT 110304-SV 0.4 [ a a

D010

D011

E011

E012

H013

110308-SV 0.8 [ a a

160404-SV 0.4 [ a a

160408-SV 0.8 [ a a

MP

VBMT 160404-MP 0.4 a a u u

D010

D011

E011

E012

H013

160408-MP 0.8 a a u u

MM

VBMT 160404-MM 0.4 a u a

D010

D011

E011

E012

H013

160408-MM 0.8 a u a

VBMT 160404 0.4 a

E011

H013

160408 0.8 a

MV

VBMT 110304-MV 0.4 a [ [ a a a a a a a

D010

D011

E011

E012

H013

110308-MV 0.8 a [ [ a a a a a a a

160404-MV 0.4 a [ [ a a a a a a a

160408-MV 0.8 a [ [ a a a a a a a

R/L-SR

VBET 1103V3R-SR 0.03 a a a

D010

D011

E011

E012

1103V3L-SR 0.03 a a a

110301R-SR 0.1 a a a

110301L-SR 0.1 a a a

110302R-SR 0.2 a a a

110302L-SR 0.2 a a a

110304R-SR 0.4 a a a

110304L-SR 0.4 a a a

NEW

NEW

VBMT 11 03 04 - SV

VB

35

N

E

W

N

E

W

N

E

W

N

E

W

P P M

3

2

1

0

0.1 0.2 0.3 0.4

3

2

1

0

0.1 0.2 0.3 0.4

3

2

1

0

0.1 0.2 0.3 0.4

3

2

1

0

0.1 0.2 0.3 0.4

3

2

1

0

0.1 0.2 0.3 0.4

3

2

1

0

0.1 0.2 0.3 0.4

4

3

2

1

0

4

3

2

1

0

4

3

2

1

0

0.1 0.2 0.3 0.4 0.1 0.2 0.3 0.4 0.1 0.2 0.3 0.4

MM MP MP

LM LP LP

FM FP FP

TURNI NG I NSERTS

[

POSI TI VE

]

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Size Thickness Corner Radius

*

Please refer to page A002.

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

POSI

5

WITH

HOLE

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Chip Breaker

TYPE I NSERTS

WI TH HOLE

CHIP CONTROL RANGE FOR WORK MATERIALS

Finish Cutting Light Cutting MediumCutting

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

Stainless Steel

a

p

(

m

m

)

a

p

(

m

m

)

f (mm/rev)

f (mm/rev)

Light Cutting

Medium Cutting

Medium Cutting

Standard

Medium Cutting

Medium Cutting

Medium Cutting

a : Inventory maintained in Japan. u : To be released in Autumn 2013

[ : Inventory maintained in Japan. To be replaced by new products.

(10 inserts in one case)

Mild Steel Carbon Steel Alloy Steel (180280HB) Stainless Steel (<200HB)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

A121

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

H

6

4

0

0

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

V

P

4

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

R/L-SN

VBET 110300R-SN 0 a a a

D010

D011

E011

E012

110300L-SN 0 a a a

1103V3R-SN 0.03 a a a

1103V3L-SN 0.03 a a a

110301R-SN 0.1 a a a

110301L-SN 0.1 a a a

110302R-SN 0.2 a a a

110302L-SN 0.2 a a a

110304R-SN 0.4 a a a

110304L-SN 0.4 a a a

R/LW-SN

VBET 1103V3RW-SN 0.03 a

D010

D011

E011

E012

1103V3LW-SN 0.03 a

N

E

W

N

E

W

N

E

W

N

E

W

6

4

2

0

0.1 0.3

6

4

2

0

0.1 0.3

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

POSI

5

WITH

HOLE

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Medium Cutting

Medium Cutting

(Wiper)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

CHIP BREAKERS A048

GRADES A030

IDENTIFICATION A002

*

Please refer to A028 before using the R/LW-SN breaker (wiper insert).

*

You might also like

- Type Inserts With Hole: WPGT 04 02 04 R-FSDocument1 pageType Inserts With Hole: WPGT 04 02 04 R-FSTungstenCarbideNo ratings yet

- Type Inserts With Hole: WBGT 02 01 V3 L-FDocument1 pageType Inserts With Hole: WBGT 02 01 V3 L-FTungstenCarbideNo ratings yet

- Type Inserts With Hole: TPMH 08 02 02-FVDocument3 pagesType Inserts With Hole: TPMH 08 02 02-FVTungstenCarbideNo ratings yet

- Type Inserts With Hole: VCMT 11 03 02-FPDocument2 pagesType Inserts With Hole: VCMT 11 03 02-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: SCMT 09 T3 04-FPDocument2 pagesType Inserts With Hole: SCMT 09 T3 04-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: SPMT 09 03 04Document1 pageType Inserts With Hole: SPMT 09 03 04TungstenCarbideNo ratings yet

- CCDocument2 pagesCCTungstenCarbideNo ratings yet

- Type Inserts With Hole: WNMG 08 04 04-FHDocument4 pagesType Inserts With Hole: WNMG 08 04 04-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: WCGT 02 01 02 RDocument1 pageType Inserts With Hole: WCGT 02 01 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: DNMG 15 04 02-FHDocument5 pagesType Inserts With Hole: DNMG 15 04 02-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: RCGT 08 03 M0-AZDocument1 pageType Inserts With Hole: RCGT 08 03 M0-AZTungstenCarbideNo ratings yet

- Type Inserts With Hole: TCMT 09 02 02-FPDocument2 pagesType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideNo ratings yet

- Thread o Ring Flanged FittingDocument4 pagesThread o Ring Flanged FittingsureshisisisNo ratings yet

- Type Inserts With Hole: VNMG 16 04 02-FHDocument3 pagesType Inserts With Hole: VNMG 16 04 02-FHTungstenCarbideNo ratings yet

- Metal Table JISDocument1 pageMetal Table JISNakkolopNo ratings yet

- C006a ADocument152 pagesC006a ASugatSravastiNo ratings yet

- Type Inserts Without Hole: Posi 6ºDocument1 pageType Inserts Without Hole: Posi 6ºTungstenCarbideNo ratings yet

- Vc4Mb: Ball Nose, Medium Cut Length, 4 FL UteDocument1 pageVc4Mb: Ball Nose, Medium Cut Length, 4 FL UteTungstenCarbideNo ratings yet

- Catalogo Parker Scem PDFDocument16 pagesCatalogo Parker Scem PDFFimoca Energy C.ANo ratings yet

- 20F2041 Pick ListDocument9 pages20F2041 Pick Listvio_tani4812No ratings yet

- AlkatreszDocument2 pagesAlkatreszgia maxniashviliNo ratings yet

- Type Inserts With Hole: DEGX 15 04 02 R-FDocument1 pageType Inserts With Hole: DEGX 15 04 02 R-FTungstenCarbideNo ratings yet

- KOBELCO-Copper-Alloy Tubes For Heat ExchangersDocument20 pagesKOBELCO-Copper-Alloy Tubes For Heat Exchangerssumant.c.singh1694No ratings yet

- Tac PDFDocument3 pagesTac PDFfonsecaglNo ratings yet

- Vc3Mb: Ball Nose End Mill, Medium Cut Length, 3 FL UteDocument1 pageVc3Mb: Ball Nose End Mill, Medium Cut Length, 3 FL UteTungstenCarbideNo ratings yet

- Turbine Blade MachiningDocument36 pagesTurbine Blade Machiningyh1.yuNo ratings yet

- Technical Manual: Five-Channel Power AmplifierDocument8 pagesTechnical Manual: Five-Channel Power Amplifierudal64No ratings yet

- Es LFB6080G2Document2 pagesEs LFB6080G2WattsNo ratings yet

- 18v32 E#2 SettingsDocument3 pages18v32 E#2 SettingsAnonymous 05tfMB3ENo ratings yet

- Drill Bit DetailsDocument82 pagesDrill Bit DetailsvmgobinathNo ratings yet

- O-Rings & SealsDocument10 pagesO-Rings & SealsPartsGopher.comNo ratings yet

- Series G4000M1 Specification SheetDocument2 pagesSeries G4000M1 Specification SheetWattsNo ratings yet

- Dharwad Pump House BoqDocument9 pagesDharwad Pump House Boqmeena34No ratings yet

- BTC Gate ValvesDocument26 pagesBTC Gate ValvesCamilo Sanchez VanegasNo ratings yet

- rc33026 D12-UscDocument7 pagesrc33026 D12-Usceww08No ratings yet

- Unj Roscas InsertosDocument6 pagesUnj Roscas InsertosCreativo2013No ratings yet

- Bom - NotepadDocument1 pageBom - NotepadUPSIDE-DOWNNo ratings yet

- QSC RMX2450 PDFDocument10 pagesQSC RMX2450 PDFJohnny Tenezaca Duarte0% (1)

- 01SA0S02Document5 pages01SA0S02raobabar21No ratings yet

- Service Information: GeneralDocument2 pagesService Information: GeneralAbdulSattarNo ratings yet

- Maco V5000Document8 pagesMaco V5000Fjga AlcarazNo ratings yet

- Ms2Mb: Ball Nose End Mill, Medium Cut Length, 2 FluteDocument1 pageMs2Mb: Ball Nose End Mill, Medium Cut Length, 2 FluteTungstenCarbideNo ratings yet

- Process Vessels and Storage Vessels: Drawing N°Document7 pagesProcess Vessels and Storage Vessels: Drawing N°Rodrigo BeldaNo ratings yet

- 240 268Document29 pages240 268jl_arvizoNo ratings yet

- VFHDocument3 pagesVFHTungstenCarbideNo ratings yet

- Ferramentas HSK TDocument0 pagesFerramentas HSK Tandreia_janaina9629No ratings yet

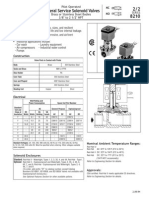

- SELENOIDE-Valv Solen 8210Document6 pagesSELENOIDE-Valv Solen 8210MARACO46No ratings yet

- VQ-SVR: Roughing End Mill, Short Length of Cut, 4 FL Ute, Irregular Helix FL UtesDocument1 pageVQ-SVR: Roughing End Mill, Short Length of Cut, 4 FL Ute, Irregular Helix FL UtesTungstenCarbideNo ratings yet

- Odular YPE A F S AF: IR Ilter EriesDocument9 pagesOdular YPE A F S AF: IR Ilter ErieshadeNo ratings yet

- Insertos KYOCERA RoscadoDocument3 pagesInsertos KYOCERA RoscadoCristian AlonsoNo ratings yet

- Valve ListDocument10 pagesValve ListShanmuga NavaneethanNo ratings yet

- Codigos de OBD 2Document48 pagesCodigos de OBD 2Rommel VacaNo ratings yet

- Schedule of Loads: Arch. Hervy G. Catilogo, UapDocument1 pageSchedule of Loads: Arch. Hervy G. Catilogo, UapEmmanuel Linguaje Managbanag IINo ratings yet

- Smooth Flow: Tubing & Fittings SpecificationsDocument28 pagesSmooth Flow: Tubing & Fittings SpecificationsedgardomichligNo ratings yet

- Electrodes EnglishDocument139 pagesElectrodes Englishcostelino72No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Through Holes Steam Oxide External Cooling: Series 4402Document8 pagesThrough Holes Steam Oxide External Cooling: Series 4402TungstenCarbideNo ratings yet

- Gy2g0200d020n-Mf VP10RTDocument6 pagesGy2g0200d020n-Mf VP10RTTungstenCarbideNo ratings yet

- CC CC: Type Inserts With HoleDocument4 pagesCC CC: Type Inserts With HoleTungstenCarbideNo ratings yet

- CBN InsertsDocument27 pagesCBN InsertsTungstenCarbideNo ratings yet

- Nnmu200608zen-Hk MC5020Document1 pageNnmu200608zen-Hk MC5020TungstenCarbideNo ratings yet

- VFX5UR0203CA10Document3 pagesVFX5UR0203CA10TungstenCarbideNo ratings yet

- Any Size Kits Are All $400.00: Steel ApplicationsDocument2 pagesAny Size Kits Are All $400.00: Steel ApplicationsTungstenCarbideNo ratings yet

- Cpmt1205zpen-M2 VP15TFDocument1 pageCpmt1205zpen-M2 VP15TFTungstenCarbideNo ratings yet

- Aemw150304er Up20mDocument1 pageAemw150304er Up20mTungstenCarbideNo ratings yet

- AOMT 123602 PEER-M VP15TF Mitsubishi CarbideDocument2 pagesAOMT 123602 PEER-M VP15TF Mitsubishi CarbideTungstenCarbideNo ratings yet

- Aemw150304er Up20mDocument1 pageAemw150304er Up20mTungstenCarbideNo ratings yet

- CCMXDocument1 pageCCMXTungstenCarbideNo ratings yet

- Type Inserts With Hole: XCMT 15 03 02-SVXDocument1 pageType Inserts With Hole: XCMT 15 03 02-SVXTungstenCarbideNo ratings yet

- Type Inserts With Hole: VPET 08 02 01 R-SRFDocument1 pageType Inserts With Hole: VPET 08 02 01 R-SRFTungstenCarbideNo ratings yet

- Type Inserts With Hole: VDGX 16 03 02 RDocument1 pageType Inserts With Hole: VDGX 16 03 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: WNMG 08 04 04-FHDocument4 pagesType Inserts With Hole: WNMG 08 04 04-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: WCGT 02 01 02 RDocument1 pageType Inserts With Hole: WCGT 02 01 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: VNMG 16 04 02-FHDocument3 pagesType Inserts With Hole: VNMG 16 04 02-FHTungstenCarbideNo ratings yet

- TNDocument6 pagesTNTungstenCarbideNo ratings yet

- Type Inserts With Hole: TCMT 09 02 02-FPDocument2 pagesType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideNo ratings yet

- SNDocument4 pagesSNTungstenCarbideNo ratings yet

- Type Inserts With Hole: TEGX 16 03 02 RDocument1 pageType Inserts With Hole: TEGX 16 03 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: SPMT 09 03 04Document1 pageType Inserts With Hole: SPMT 09 03 04TungstenCarbideNo ratings yet

- Type Inserts Without Hole: Posi 6ºDocument1 pageType Inserts Without Hole: Posi 6ºTungstenCarbideNo ratings yet

- CollectionDocument10 pagesCollectionqafewghtrhgfNo ratings yet

- Arbor Press Drawings PDFDocument16 pagesArbor Press Drawings PDFCalixto Milla EsauNo ratings yet

- Walktrough LaS 0.8 PDFDocument14 pagesWalktrough LaS 0.8 PDFCh AmeenNo ratings yet

- 120542A Manual Instalación Antenas HDTF - Es PDFDocument2 pages120542A Manual Instalación Antenas HDTF - Es PDFCarloMagnoCurtisNo ratings yet

- Charlie and The Chocolate Factory QuizDocument2 pagesCharlie and The Chocolate Factory QuizmaryNo ratings yet

- Test Everybody Up 2Document4 pagesTest Everybody Up 2Nguyên Mi57% (7)

- Long Quiz 4thDocument1 pageLong Quiz 4thJhay Mhar ANo ratings yet

- The Regional KingdomsDocument35 pagesThe Regional KingdomsLutz Alexander Keferstein100% (1)

- Combinados 1-CopiarDocument45 pagesCombinados 1-CopiarEliezer Peña del AguilaNo ratings yet

- Service ManualDocument87 pagesService ManualvimannNo ratings yet

- Dissertation Abtract PDFDocument2 pagesDissertation Abtract PDFJuan GallasteguiNo ratings yet

- Stormbreaker Work BookletDocument14 pagesStormbreaker Work Bookletapi-367866419No ratings yet

- Chapter 2 CFE 101Document23 pagesChapter 2 CFE 101ton-ton elcanoNo ratings yet

- HandsUpPunk08 - StillDocument82 pagesHandsUpPunk08 - StillIrbah KhoirunisaNo ratings yet

- Fcim Frecventa Redusa ContractDocument4 pagesFcim Frecventa Redusa ContractValeria BatereanuNo ratings yet

- Joe Dalton Riffs TabDocument2 pagesJoe Dalton Riffs TabPoss HumNo ratings yet

- Riot GRRRL Manifesto PDFDocument4 pagesRiot GRRRL Manifesto PDFVent de GregalNo ratings yet

- Hannah Mary RothschildDocument14 pagesHannah Mary RothschildCazzac111No ratings yet

- English Marks: 70 Class: 6 (Subjective) : Q.2: Translate Passages Into Urdu of The FollowingDocument2 pagesEnglish Marks: 70 Class: 6 (Subjective) : Q.2: Translate Passages Into Urdu of The FollowingSajid HussainNo ratings yet

- Ferry TerminalDocument2 pagesFerry TerminalboB RudisNo ratings yet

- Ben Lerner - Topekan Ethos PDFDocument21 pagesBen Lerner - Topekan Ethos PDFTito Manfred Van BattenburgNo ratings yet

- UML Diagram Case StudyDocument25 pagesUML Diagram Case StudyZumer FatimaNo ratings yet

- Allretailamended 160405122419Document97 pagesAllretailamended 160405122419LabdhiNo ratings yet

- Death - The Sound of PerseveranceDocument11 pagesDeath - The Sound of Perseverancerahul_mannapperumaNo ratings yet

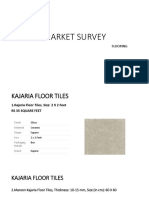

- Market Survey FlooringDocument12 pagesMarket Survey FlooringJhanviNo ratings yet

- Emily DickensonDocument4 pagesEmily DickensonBiancaNo ratings yet

- In Our Tenth Year GCSE English Literature - Poems Deep and Dangerous Study GuideDocument3 pagesIn Our Tenth Year GCSE English Literature - Poems Deep and Dangerous Study Guidefaryal khanNo ratings yet

- Roman LDocument4 pagesRoman Lapi-549448040No ratings yet

- (Simple, Continuous, Perfect: Present TenseDocument8 pages(Simple, Continuous, Perfect: Present TenseHoliNo ratings yet

- Final 2D Transformations Heran Baker NewDocument64 pagesFinal 2D Transformations Heran Baker NewImmensely IndianNo ratings yet