Professional Documents

Culture Documents

BS275-BX275 ServicManual V5.0

Uploaded by

gil_sayuri80%(5)80% found this document useful (5 votes)

3K views87 pagesService MANUAL is applied to BS275 / BX275 projection system. It gives you a brief description of basic technical information to help in service and maintain the product. Please send the product back to the distributor for repairing and do not attempt to do anything that is complex or not mentioned in the troubleshooting.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentService MANUAL is applied to BS275 / BX275 projection system. It gives you a brief description of basic technical information to help in service and maintain the product. Please send the product back to the distributor for repairing and do not attempt to do anything that is complex or not mentioned in the troubleshooting.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

80%(5)80% found this document useful (5 votes)

3K views87 pagesBS275-BX275 ServicManual V5.0

Uploaded by

gil_sayuriService MANUAL is applied to BS275 / BX275 projection system. It gives you a brief description of basic technical information to help in service and maintain the product. Please send the product back to the distributor for repairing and do not attempt to do anything that is complex or not mentioned in the troubleshooting.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 87

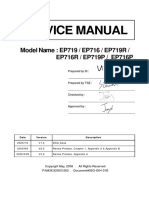

SERVICE MANUAL

prepared: Check: Approved:

Alex

Date Revise Version Description

2010.4.14 V1.0 Initial Issue

2011.11.18 V2.0

According to the customer whole enginge module

requirement to revise service manual,the contents as

following:

1.Cancel charpter 2-13(Disassemble color wheel mod-

ule).

2.Cancel charpter 2-14(Disassemble DMD chip and

DMD board).

3.Cancel No.5,6,7,19,20 parts and modify No.18 part

number in appendix A

2011.12.1 V3.0

According to the customer requirement to add contents

as following:

1.Add charpter 2-13(Disassemble color wheel module).

2.Add charpter 2-14(Disassemble DMD chip and DMD

board).

3.Add No.5,6,7,19,20 parts number in appendix A

2012.1.31 V4.0 Modify No.5,21 parts number in appendix A

2012.3.19 V5.0

1.Add No.31,32 parts number in appendix A

2.Add new photo sensor rework SOP in appendix C

Copyright March. 2012. All Rights Reserved

Confdential BS275/BX275

Preface

This manual is applied to BS275/BX275 projection system. The manual gives you a brief

description of basic technical information to help in service and maintain the product.

Your customers will appreciate the quick response time when you immediately identify

problems that occur with our products. We expect your customers will appreciate the

service that you offer them.

This manual is for technicians and people who have an electronic background. Please

send the product back to the distributor for repairing and do not attempt to do anything

that is complex or is not mentioned in the troubleshooting.

Notice:

The information found in this manual is subject to change without prior notice. Any

subsequent changes made to the data herein will be incorporated in future edition.

BS275/BX275 Service Manual

Copyright March., 2012.

All Rights Reserved

Manual Version 5.0

I

BS275/BX275 Confdential

BS275/BX275 Comparison List

PARTS BS275 BX275

Main BD 80.8HC01G003 80.8HF01G003

Top Cover 51.8HC01G001 51.8HC01G011

DMD 48.8EH01G001 48.8CQ01G003

Engine 70.8HC13GR01 70.8HF05GR01

II

Confdential BS275/BX275 III

Table of Content

Chapter 1 Introduction

Highlight 1-1

Compatible Mode 1-4

Product Overview 1-6

Remote control battery installation 1-12

Chapter 2 Disassembly Process

Equipment Needed & Product Overview 2-1

Disassemble Lamp Cover Module 2-2

Disassemble Lamp Module 2-2

Disassemble Top Cover Module 2-3

Disassemble Zoom Ring Module 2-3

Disassemble Keypad Board Module 2-4

Disassemble Top Shielding 2-4

Disassemble IO Cover 2-5

Disassemble Main Board Module 2-5

Disassemble Main Board Shielding 2-6

Disassemble Front Cover Module and IR Sensor Board 2-8

Disassemble Engine Module 2-8

Disassemble Color Wheel Module 2-9

Disassemble DMD Chip and DMD Board 2-9

Disassemble Focus Ring 2-10

Disassemble Fan Module and Thermal Switch 2-10

Disassemble Blower Module 2-12

Disassemble LVPS Module 2-12

Disassemble Lamp Driver 2-13

BS275/BX275 Confdential

IV

Disassemble Interlock Switch 2-14

Disassemble Bottom Shielding 2-15

Disassemble Speaker 2-15

Disassemble Bottom Cover Module 2-16

Rod Adjustment 2-17

Re-write Lamp Usage Hour 2-19

Chapter 3 Troubleshooting

LED Lighting Message 3-1

Main Procedure 3-2

Chapter 4 Function Test & Alignment Procedure

Test Equipment Needed 4-1

Service Mode 4-1

OSD Reset 4-1

Factory Fan RPM Reset 4-2

Test Condition 4-2

Test Inspection Procedure 4-4

PC MODE 4-5

Video Performance 4-8

Calibration 4-10

Optical Performance Measure 4-12

Chapter 5 Firmware Upgrade

Section 1: System Firmware Upgrade 5-1

Equipment Needed 5-1

DLP Composer Lite Setup Procedure 5-2

Get into FW mode 5-3

Confdential BS275/BX275

NLINK Setup Procedure 5-9

Manley USB Driver Upgrade Procedure 5-10

8051 Firmware Upgrade Procedure 5-13

Chapter 6 EDID Upgrade

EDID Introduction 6-1

Equipment Needed 6-2

Setup Procedure (VGA) 6-3

EDID Key-In Procedure 6-4

Appendix A Exploded Image I

Appendix B

Serial Number Defnition I

PCBA Code Defnition II

Appendix C

New photo sensor board Reworking SOP I

BS275/BX275 Confdential 1-1

Chapter 1

Introduction

1-1 Highlight

No Item Description

1 Technology 0.55 DMD 1 chip 2xLVDS (DarkChip3) S450

2 Dimension (W x D x H) 286.3*88.2*192 mm (without protruding parts)

3 Weight < 2.31Kg

4 Power Supply

Universal AC 100--240V ~ 50 / 60 Hz with PFC input

180W Lamp @ normal operation

160W Lamp @ eco operation

Variance FAN speed control (Depend on temperature

variance)

5 Keystone Correction +/ -15 degree Vertical

6 Resolution Native Resolution: 800 X 600

7 Brightness

2250 ANSI Lumens ( Typical )

2000 ANSI Lumens ( Minimum )

8 Contrast 2200:1 (Full on/Full off)

9 Uniformity

80% Typical (JBMA standard )

65% Minimum (JBMA standard )

10 Throw ratio 1.95 ~ 2.15:1 distance/width @2.37m

11 Projection lens

F# 2.41-2.55, 1.10X Mechanical Zoom Lens.

f=21.8-24mm @ 60

12 Lamp life

3000 hours at typical full power mode.

4000 hours at Eco mode

(The more than 50% of lamp population have light out

put>50% of initial min. Lumen output at the lamp life time.

13 Lens Offset 115%+/-5%

14 Video compatibility

NTSC: M (3.58MHz), 4.43 MHz

PAL: B, D, G, H, I, M, N

SECAM: B, D, G, K, K1, L

HDTV: 480i/p, 576i/p, 720p(50/60Hz), 1080i/p(50/60Hz)

BS275/BX275 Confdential 1-2

No Item Description

15 Terminals

One D-Sub 15-pin female connector for VGA input

and component video input

One Mini DIN 4-pin for S-Video Input

One RCA Jack for Composite Video Input

One Min-pin RS232 port for FW update

One D-Sub 15-pin female connector for VGA output

One Audio in 3.5mm mini-jack

16 System Controller TI DDP2431

17 Color Wheel

40mm diameter, 6 segments (R81Y41G84C31W52B71) &

7200 rpm

18 Lamp 180W Lamp (Osram E20.8)

19 Temperature

Operating: 5 ~ 35C

Storage: -20 ~ 60C

20 Altitude

Operating: 0~2,500 ft, for 5C~35C

2,500~5,000 ft, for 5C~30C

5,000~10,000 ft, for 5C~25C

Storage 40,000 ft

21 Input Signal

Computer analog input

Video

Analog RGB 0.7Vp-p, 75ohm

Sync

Hsync Freq. 31.35~91.1kHz

Vsync Freq. 56~85Hz

Separate Sync: (HV) TTL level (bi-polarity)

Composite Sync: TTL level (bi-polarity)

Sync-on-green: negative sync. 0.3Vp-p

Analog Video

Composite video 75ohm

S-video (Y/C) 75ohm

Component video (Y/Pb/Pr) 75ohm

BS275/BX275 Confdential 1-3

No Item Description

22 Projection Distance 1.2~12m

23 Projection Screen Size Adjustable from 27.46 to 302.8 (Focus range)(Diagonal)

24 Color Wheel

UL/ cUL, FCC B, TUV-GS & CB report, CE, C-Tick, CCC,

KC, Gost-R, NOM, SASO

25 Audio speaker Built-in one 2W speaker

26 Projection method Desktop/Ceiling (Front/Rear)

BS275/BX275 Confdential 1-4

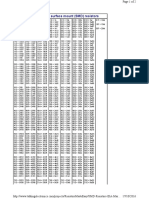

1-2 Compatible Mode

Computer Compatibility (Analog)

Compatibility Resolution V-Sync [Hz]

VGA

640x350 70

640x350 85

640x400 85

640x480 60

640x480 72

640x480 75

640x480 85

720x400 70

720x400 85

SVGA

800x600 56

800x600 60

800x600 72

800x600 75

800x600 85

XGA

1024x768 60

1024x768 70

1024x768 75

1024x768 85

WXGA

1280x768 60

1280x768 75

1280x720 60

1280x800 60

SXGA

1152x864 60

1152x864 70

1152x864 75

1152x864 85

1280x1024 60

1280x1024 75

1280x1024 85

1280 x 960 60

SXGA+ 1400x1050 60

BS275/BX275 Confdential 1-5

Compatibility Resolution V-Sync [Hz]

UXGA 1600 x 1200 60

MAC LC 13 640x480 66.66

MAC II 13 640x480 66.68

MAC 16 832x624 74.55

MAC 19 1024x768 75

MAC 1152x870 75.06

MAC G4 640x480 60

i Mac DV 1024x768 75

i Mac DV 1152x870 75

i Mac DV 1280x960 75

Note: If the Computer Compatibility supportive signal is different from User's Manual, please refer

to User's Manual.

BS275/BX275 Confdential 1-6

1-3 Product Overview

Projector Outlook

Front /Upper side

Item Description Item Description

1 Control Panel 6 Focus Ring

2 Remote Sensor 7 Ventilation (outlet)

3 Zoom Ring 8 Lens

4 Ventilation (inlet) 9 Lens Cap

5 Speaker

BS275/BX275 Confdential 1-7

Rear side

Item Description Item Description

1 RGB IN Connector 5 RGB OUT Connector

2 S-VIDEO Connector 6 AUDIO-IN Jack

3 VIDEO Connector 7 AC IN

4 RS232C Service Port 8 KensingtonTM Lock

BS275/BX275 Confdential 1-8

Control Panel

Item Function Description

1 POWER Power On/Off the Projector

2 POWER LED Indicate the projectors status.

3 LAMP LED Indicate the projectors lamp status.

4 TEMP LED Indicate the projectors temperature status..

5 KEYSTONE

Adjust the image to compensate for distortion caused by tilting

the projector.

6

Four Directional

Select Keys

Use to select items or make adjustments to your

selection.

7 SOURCE Press SOURCE to select an input signal.

8 MENU

Press Menu to launch the on-screen display (OSD) menu. To

exit OSD, Press Menu again.

9 VOLUME Adjust to increase / decrease the volume.

10 OK Confrm your item selection.

11 AUTO

Automatically synchronizes the projector

to the input source.

BS275/BX275 Confdential 1-9

Remote Control Layout

BS275/BX275 Confdential 1-10

Item Function Description

1

Infrared

transmitter

Sends signals to the projector.

2 DIS-MODE

Select the Image mode from Presentation,Bright, Movie, SRGB,

Blackboard,Classroom, User1 and User2.

3 POWER Turning the Projector On/Off

4 COMPUTER Press COMPUTER to choose RGB IN connector.

5 FREEZE

Pause the screen image. Press again to resume the screen

image.

7 ENTER Confrm your section of items in sub menu operation.

8 SOURCE

Press SOURCE to choose RGB, Component, S-Video and

Composite sources.

9 MENU

Press MENU to launch the Onscreen

display (OSD), back to the top level of OSD for the OSD main

menu operation

10 KEYSTONE -

Adjust the image to compensate for distortion caused by tilting

the projector.

11 AV-MUTE Momentarily turn off/on the audio and video.

12 RESET

Return the adjustments and settings to the factory default val-

ues. (except for lamp counter)

13

VIDEO 1

(S-VIDEO)

Press VIDEO 1 to choose S-VIDEO connector.

14

VIDEO 2

(VIDEO)

Press VIDEO 2 to choose VIDEO connector.

15 KEYSTONE +

Adjust the image to compensate for distortion caused by tilting

the projector.

16 D.ZOOM Zoom out or Zoom in the projector display.

17

Four Directional

Select Keys

Use to select items or make adjustments to your

selection.

18 RE-SYNC

Automatically synchronize the projector

to the input source.

19 SOURCE-LOCK

This function detects the input signal automatically. When fnd-

ing a signal, the search will stop.

20 VOLUME +/- Increase/decrease speaker volume.

BS275/BX275 Confdential 1-11

Bottom Cover Dimension

BS275/BX275 Confdential 1-12

1-4 Remote control battery installation

- Press frmly and slide the battery cover off.

- Install new battery (CR2025 type battery)into the compartment.Ensure

that the side with a +

- Install new battery into the compartment.

BS275/BX275 Confdential 2-1

Chapter 2

Disassembly Process

2-1 Equipment Needed & Product Overview

1. Screw Bit (+): 105

2. Screw Bit (+): 107

3. Screw Bit (-): 107

4. Hex Sleeves 5 mm

5. Tweezers

6. Projector

* Before you start: This process is protective level II. Operators should wear electrostatic chains.

* Note: - If you need to replace the main board, you have to record the lamp usage hour.

BS275/BX275 Confdential 2-2

2-2 Disassemble Lamp

Cover Module

1. Loosen 2 screws (as red circle) on the

Lamp Cover.

2. Disassemble the Lamp Cover Module

and tear off the Aluminum foil.

2-3 Disassemble Lamp

Module

1. Loosen 2 screws (as red circle) on the

Lamp Module.

2. Take off the Lamp Module.

BS275/BX275 Confdential 2-3

2-4 Disassemble Top Cover

Module

1. Unscrew 2 screws (as red circle) from the

Bottom Cover.

2. Unscrew 2 screws (as green circle) from

the IO Cover .

3. Remove the Top Cover Module.

Note:When you disassemble the top

cover, please pay attention to the

tenons(as yellow square).

2-5 Disassemble Zoom Ring

Module

1. Unscrew 7 screws (as red circle) from

the Top Cover Module.

2. Remove the Zoom Ring Module.

BS275/BX275 Confdential 2-4

2-7 Disassemble Top

Shielding

1. Unscrew 9 screws (as red circle).

2. Disassembled the Top Shielding.

2-6 Disassemble Keypad

Board Module

1. Unscrew 4 screws (as red circle) to

disassemble Keypad Board Module.

2. Tear off 2 EMI gaskets from Keypad

Board Module.

3. Separate Keypad Button from Top Cover

Module.

BS275/BX275 Confdential 2-5

2-8 Disassemble IO Cover

1. Unscrew 4 hex screws (as red circle).

2. Unfasten 2 tenons (as yellow square).

3. Disassembled the IO cover.

Note:Take care the tenons when you

disassemble the unit.

2-9 Disassemble Main Board

Module

1. Unscrew 3 screws (as red circle).

2. Unplug 1 connector (as green square)

of Color Wheel.

3. Unplug 6 connectors (as orange square).

BS275/BX275 Confdential 2-6

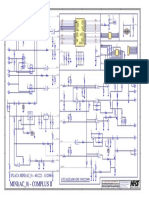

Item

Male Connector

on Main Board

The key feature Figure

A Lamp Driver Black wire tube (5 pin)

B Fan

Compose of Red/Yellow/Black

Wire (3 pin)

C Blower

Compose of Red/Black/White

Wire, white connector and Black

wire tube (3 pin)

D Photo Sensor

Compose of Red/Black/White

Wire, red connector and Black

wire tube (3 pin)

E IR

Compose of Red/Black/White

Wire, green connector and Black

wire tube (3 pin)

F Speaker

Compose of Red/Black Wire and

Black wire tube (2 pin)

F E D C B A

Please refer to the table as below for

details of each connector.

BS275/BX275 Confdential 2-7

4. Unplug 1 connector (as yellow square).

5. Remove the Main Board.

2-10 Disassemble Main

Board Shielding

1. Unscrew 2 screws (as red circle).

2. Disassemble the Main Board Shielding.

BS275/BX275 Confdential 2-8

2-11 Disassemble Front

Cover Module and IR

Sensor Board

1. Unscrew 1 screw (as red circle).

2. Unfasten 2 tenons (as green square).

3. Remove the Front Cover Module.

4. Unfasten 2 tenons (as green square) to

disassemble the IR Sensor Board and IR

Cover.

Note: - Take care the tenons when you

disassemble the unit.

IR Cover

IR Sensor Board

2-12 Disassemble Engine

Module

1. Unscrew 4 screws (as yellow circle) to

disassemble the Engine Module.

BS275/BX275 Confdential 2-9

2-13 Disassemble Color

Wheel Module

1. Unscrew 2 screws (as red circle) to

disassemble the Color Wheel Module.

2. Unscrew 1 screw (as blue circle) to

disassemble the Photo Sensor Board

from the Color Wheel Module.

Note: - Avoid touching the glass parts of color

wheel.

2-14 Disassemble DMD Chip

and DMD Board

1. Unscrew 2 screws (as red circle) to

disassemble the Heat Sink and DMD

Module.

2. Rotate the screw counterclockwise (as

yellow circle) to disassemble the DMD

Board and DMD Chip.

Note: - Avoid touching the DMD Chip when you

disassemble it.

- Found that the DMD Chip has scrapes

or dirt use of a magnifying glass, you

may use an electrostatic ion gun to

clean it.

- Pay attention to the fxed position when

assembling the DMD Chip.

BS275/BX275 Confdential 2-10

2-15 Disassemble Focus

Ring

1. Unscrew 3 screws (as red circle) to

disassemble the Focus Ring.

Focus Ring

2-16 Disassemble Fan

Module and Thermal

Switch

1. Unscrew 3 screws (as red circle).

2. Unscrew 1 screw (as orange circle).

3. Disassembled the Fan Module.

BS275/BX275 Confdential 2-11

Note: - Take the Fan Module as the right

gesture.

the wrong gesture the right gesture

4. Unscrew 4 screws (as blue circle) to

disassemble the Fan Shielding and Fan.

5. Unscrew 1 screw (as green circle) to

disassemble the Thermal Switch.

Thermal Switch

BS275/BX275 Confdential 2-12

2-17 Disassemble Blower

Module

1. Unscrew 3 screws (as red circle) to

disassemble the Blower Module.

2. Seprate the Blower and Blower Rubber.

2-18 Disassemble LVPS

Module

1. Unscrew 6 screws (as red circle).

2. Unplug 3 connectors (as yellow square).

3. Cut off the cable tie (as green square).

4. Disassemble the LVPS Module, AC

Inlet Bracket and LVPS to MB cable.

AC Inlet Bracket

LVPS to MB cable

BS275/BX275 Confdential 2-13

Note: when you assemble the unit must do

actions as below:

1. Use the cable tie to pierce the frst hole of

LVPS for binding the Interlock Switch and

Lamp Driver to LVPS cable (as blue

square).

2. Use clamp to fx the Lamp Driver to LVPS

cable (as orange square).

2-19 Disassemble Lamp

Driver

1. Unscrew 1 screw (as red circle) to

disassemble the Lamp Driver Module.

BS275/BX275 Confdential 2-14

Interlock Switch

2-20 Disassemble Interlock

Switch

1. Unscrew 1 screw (as red circle) to

disassemble the Interlock Switch.

Note: Make sure the Interlock Switch cable be

wedged fllister as the picture shown.

Lamp Driver

Lamp Driver Holder

2. Unscrew 4 screws (as yellow circle).

3. Unplug 3 connectors (as blue square).

4. Disassemble the Lamp Driver and Lamp

Driver Holder.

BS275/BX275 Confdential 2-15

2-21 Disassemble Bottom

Shielding

1. Unscrew 3 screws (as red cricle) to

disassemble the Bottom Shielding.

2-22 Disassemble Speaker

1. Unscrew 2 screws (as yellow circle) to

disassemble the Speaker.

BS275/BX275 Confdential 2-16

2-23 Disassemble Bottom

Cover Module

1. Unscrew 3 nuts (as red circle) to

remove the rubber adjust foot.

BS275/BX275 Confdential 2-17

2-24 Rod Adjustment

1. Environment Adjustment

- The distance between the engine and

the screen is 2.4 M.

- This process should be done at a dark

environment (under 2 Lux).

2. Procedure Adjustment

- Change the screen to "white screen".

- Adjust the screws by using the rod

on the engine module to readjust the

image.

("screw 1" should be adjusted frst, and

then "screw 2". Adjust until the yellowish

or bluish parts disappeared.)

3. Abnormal image inspection

- It should not have any abnormal color

at the rim of the image by estimating

through the eyes.

Note:To avoid over adjusting the rod. After

the operation, please use the glue to

fx the screws.

please refer to the blow table for rod

adjustment:

Z type driver

Screw1

Screw2

BS275/BX275 Confdential 2-18

Adjustment

Part

Screw direction

Screen State

Description

Initial state

State after

adjusting

Right/Left

screw1

Right(tighten

direction)

When the right color

band appeared,rotate

scew1 clockwise,then

the color band disap-

peared.

Lift(loosen direc-

tion

When the left color band

appeared,rotate scew1

anti-clockwise,then the

color band disappeared.

Up/Down

screw2

Right(tighten

direction)

When the bottom color

band appeared,rotate

scew2 clockwise,then

the color band disap-

peared.

Lift(loosen direc-

tion

When the top color band

appeared,rotate scew2

anti-clockwise,then the

color band disappeared.

BS275/BX275 Confdential 2-19

2-25 Re-write Lamp Usage

Hour

1.Press "Menu",when "OSD" is displayed.

- Use Left or Right key to select

"OPTIONS" .

- Use "UP" or "DOWN" key to select

"Lamp settings",then press"OK".

- Use"UP" or "DOWN" key to select

"Eco Mode".

- UseLeft or Right key to select

"on"or"off",then press "OK".

2. Get into service mode.

- Press Power --> Left --> Left --> Menu

to get into service mode.

- Use Down key to select Exit"

- Use Left or Right key to re-write the

Normal Lamp hour or Eco Lamp hour.

Note:"Eco Mode" status is"on",you can Re-

write Eco Lamp Hour.

"Eco Mode"status is"off",you can Re-write

Normal Lamp Hour.

3. Choose Exit, press OK to exit service

mode.

Note: Reset the lamp hour counter after replacing

the lamp.(as red square)

Left key = decrease lamp hour

Right key=increase lamp hour

BS275/BX275

Confdential 3-1

Chapter 3

Troubleshooting

3-1 LED Lighting Message

Message

Power-LED LED

Green Amber

LAMP

(Red)

TEMP

(Red)

Standby

(Input power cable)

O

Normal (Power on)

O

Powering up

(Warming up)

Flashing

O

Power off

(Cooling-I: It cant accept

any key at this status)

Flashing

O

Power off (Cooling-II: It can

accept power key to turn on

the projector)

O

Flashing

Error (Lamp failed)

O O O

Error (Fan lock)

O O O

Flashing

Error (Over temp.)

O O O

Note:Steady by=>

No light=>O

BS275/BX275

Confdential 3-2

3-2 Equipment Needed

1. Projector

2. PC (Personal computer)

3. DVD player

4. Screw drivers

5. VGA cable, power cord, S-video cable,Video-cable, audio cable,

6. Voltage test meter

7. Oscilloscope

BS275/BX275

Confdential 3-3

3-3 Main Procedure

BS275/BX275

Confdential 3-4

3-4 Power troubleshooting

BS275/BX275

Confdential 3-5

Power troubleshooting

BS275/BX275

Confdential 3-6

3-5 Image troubleshooting

BS275/BX275

Confdential 3-7

Image troubleshooting

BS275/BX275

Confdential 3-8

Image troubleshooting

BS275/BX275

Confdential 3-9

Image troubleshooting

BS275/BX275

Confdential 3-10

3-6 Audio Troubleshooting Troubleshooting

BS275/BX275

Confdential 3-11

3-7 Remote Troubleshooting

BS275/BX275

Confdential 4-1

Chapter 4

Function Test & Alignment Procedure

4-1 Test Equipment Needed

- IBM PC with HDTV resolution

- DVD player with Multi-system, equipped Component, Composite, S-Video and HDMI.

- HDTV Source (720P, 1080P, 1080i)

- Minolta CL-100

- Quantum Data 802B or CHROMA2327 (Color Video Signal & Pattern Generator)

4-2 Service Mode

1. Turn on the projector

2. Press Power, Left, Left and Menu buttons sequentially on

keypad to get into service mode.

4-3 OSD Reset

After fnal QC step, we have to erase all saved

change again and restore the default setting:

(1) Please get into OSD menu.

(2) Execute OSD reset function under Options.

BS275/BX275 Confdential 4-2

4-4 Factory Fan RPM Reset

After replace main board, fan or upgrade system FW, you need to do: Picture A

1. Plug in the power cord, hold on "left" button then press "power"

button, when the power LED lighted green, Temp LED and Lamp

LED lighted red about one second, loosen "left" button.

2. After the Logo disappeared, Picture A will be shown.

3. After several minutes, you can check the fan RPM as red circle.

a.Please get into Service Mode (refer to 4-2)

b.Select Thermal Settings, then press OK, Fan detail

information will be shown.

Note: 1.The steps must be fnished in 50 seconds after

powering on projector.

2. If the factory fan Value dont show in service

mode,please repeat the step 1,2 again.

4-5 Test Condition

- Circumstance brightness: Dark room less than 2 lux.

- Inspection distance: 0.5m~1.0m functional inspection.

- Screen size: 60 inches diagonal.

- After repairing each unit, a Run-in test is necessary (refer to the below table).

Symptom Run-in Time

Normal repair 2 hours

NFF 4 hours

Auto shutdown 6 hours

Get into Burn-In Mode

* Cycle setting is based on the defect symptoms. ie: If it is NFF, the run-in time is 4 hours. You have

to set the lamp on for 50 min. and lamp off for 10 min for 4 cycles.

Press power > Left > Left > Menu buttons sequentially on remote controller to get into

service mode

Choose Burn-In Test > enter

Lamp On Press right key to adjust the time (50)

Lamp Off Press right key to adjust the time (10)

Set burn in cycle Press right key to adjust the cycle

After setting up the time, choose Get into Burn-In Mode and press enter

Picture A

Confdential 4-3 BS275/BX275

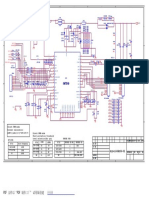

Defect specifcation table

< Figure: Zone A, Zone B & Frame(as green line) Defnition, Active area=Zone A+ Zone B >

Screen Defects (While replacing DMD Chip, DMD Board and Main Board)

Frame

Order Symptom Pattern Criteria

1 Bright pixel (dots) Gray 10 pattern A+B1

2 Dark pixel (dots) White pattern A+B 6

3 Bright blemish Gray 15 pattern A+B 10

4 Dark blemish Blue 60 pattern A+B 10

5 Bright dot on frame Gray 10 pattern 1

6 Unstable pixel White & Black pattern A+B 1

7 Adjacent dark pixel White & Black pattern A+B = 0

BS275/BX275 Confdential 4-4

4-6 Test Inspection Procedure

Update

Change Parts

Main

Board

FW

Color

wheel

Lamp

module

Engine

module

Rod

module

Fan

FW Version Update

(refer to chapter 5) V V

Color Wheel Index

(refer to chapter 4-9)

V V

Lamp counter reset

(refer to chapter 2-25)

V

PC Calibration

(refer to chapter 4-9)

V V

Video Calibration

(refer to chapter 4-9)

V V

OSD Reset

(refer to chapter 4-3) V V

Re-write Lamp Hour

Usage

(refer to chapter 2-25) V

EDID

(refer to chapter 6) V

ROD Adjustment(refer

to chapter 2-24) V V

Factory Fan RPM

Reset

(refer to chapter 4-4) V V V

Note: - If Color appears abnormal after changing Main Board Module, please do Color

Wheel index adjustment.

- After changing parts, check the information above table.

Confdential 4-5 BS275/BX275

4-7 PC MODE

For BS275, the native resolution of test signal is 800x600@60HZ.

BX275, the native resolution of test signal is 1024x768@60HZ

- We take BS275 for example here.

1. Frequency and tracking boundary

Procedure - Test equipment: video generator.

- Test signal: analog 800 x 600@60Hz

- Test Pattern: general-1 or master

- Check and see if the image sharpness is well

performed.

- If not, re-adjust by the following steps:

(1) Select Frequency function to adjust the total

pixel number of pixel clock in one line period.

(2) Select Tracking function and use right or left

arrow key to adjust the value to minimize video

ficker.

- Adjust Resync or Frequency/Tracking/H. Position/

V. Position to the inner screen.

Inspection item - Eliminate visual wavy noise by Resync,

Frequency or Tracking selection.

- Check if there is noise on the screen.

- Horizontal and vertical position of the video should

be adjustable to the screen frame.

Criteria - If there is noise on the screen, the product is con-

sidered as failure product.

- If there is noise on the screen, use auto or manual

frequency function or tracking function to adjust

the screen.

- The PC mode functionally sure be workable include

support format with frequency and auto detected

functional will be workable.

Master

General-1

BS275/BX275 Confdential 4-6

2. Bright Pixel

Procedure - Test equipment: video generator.

- Test signal: analog 800 x 600@60Hz

- Test Pattern: gray 10

Inspection item - Bright pixel check.

Criteria - Bright pixel should be no more than 1 in the active

zone; 1 pixel is allowed on the frame.

- Ref. Defect specifcation table

3. Dark Pixel

Procedure - Test equipment: video generator.

- Test signal: analog 800 x 600@60Hz

- Test Pattern: full white

Inspection item - Dead pixels check.

- White pattern (IRE=100)

Criteria - The dark pixel can accept no more than 6 dark pixels.

- Adjacent pixels are unacceptable.

- Ref. Defect specifcation table

4. Bright Blemish

Procedure - Test equipment: video generator.

- Test signal: analog 800 x 600@60Hz

- Test Pattern: gray 15

Inspection item - Bright blemish check.

Criteria - The bright blemish should be no more than 10

under gray 15 pattern.

- Ref. Defect specifcation table

5. Dark Blemish

Procedure - Test equipment: video generator.

- Test signal: analog 800 x 600@60Hz

- Test Pattern: blue 60

Full white

Gray 10

Gray 15

Confdential 4-7 BS275/BX275

Inspection item - Dark blemish check

Criteria - The dark blemish should be no more than 10

under blue 60 pattern.

- Ref. Defect specifcation table

6. Focus Test

Procedure - Test equipment: video generator.

- Test signal: analog 800 x 600@60Hz

- Test Pattern: full screen

Inspection item - Focus check

Criteria - From screen 2.6 M via visual to check the focus,

look at the entire screen, focus shall be clear,

crisp, and sharp over the entire surface of the

display pattern. (Blur word on one of the corner

after adjustment is acceptable. However, the

word should at least be recognizable.)

7. Color Performance

Procedure - Test equipment: video generator.

- Test signal: 800 x 600@60Hz, 1080i

- Test Pattern: Master, 64 gray RGBW

* Please Use 800 x 600@60Hz signal & 64 gray

RGBW pattern and 1080i signal & master pat-

tern to do color performance test. Color can not

discolor to purple and blue.

Inspection item - Check if each color level is well-functioned.

- Color saturation

Criteria - Screen appears normal. It should not have any

abnormal condition, such as lines appear on the

screen and so on.

- Color appears normal.

- It is unacceptable to have few lines fashing.

- RGBW should all appear normal on the screen

and sort from R -G-B-W.

- Color levels should be suffcient and normal.

Blue 60

Full screen

Master

64 gray RGBW

BS275/BX275 Confdential 4-8

(The unidentifed color levels on both left and

right sides should not over 4 color levels.)

- Gray level should not have abnormal color or

heavy lines.

- If color appears abnormal, please get into ser-

vice mode to do color wheel index adjustment.

4-8 Video Performance

1. CVBS

Procedure - Test equipment: DVD player

- Test signal: CVBS

Inspection item - Video performance test

Inspection Distance - 1.8M ~2.8M

Criteria - Check any abnormal color, line distortion or

any noise on the screen.

2. HDTV/ Component

Procedure - Test equipment: DVD player

- Test signal: Ycbcr/YPbPr

Inspection item - HDTV performance test

Inspection Distance - 1.8M ~2.8M

Criteria - Check any abnormal color, line distortion or

any noise on the screen.

3. Audio Test

Procedure - Test equipment: DVD Player

- Test signal: CVBS

Inspection item - Audio performance test

Inspection Distance - 1.8M ~2.8M

Motion video

Confdential 4-9 BS275/BX275

Criteria - Check the sound from speaker

- Plug Audio cable into Audio in port, check

whether Volume is normal.

- Adjust the volume to 0 9 by using the remote con

troller.

- Check the sound from speaker.

- Check whether the mute is normal.

4. S-Video

Procedure - Test equipment: DVD player

- Test signal: S-Video

Inspection item - Video performance test

Inspection Distance - 1.8M ~2.8M

Criteria - Check any abnormal color, line distortion or any noise

on the screen.

- Check the sound from speaker.

5. 3D Test

Procedure - Test equipment: DVD Player

- Test signal:HQFS format CD

Inspection item - 3D test

Inspection Distance - < 6M

Criteria The image should not appear noise, ficker,

shadow, shocking, abnormal color.

BS275/BX275 Confdential 4-10

4-9 Calibration

1. Color Wheel Index Adjust

Check pattern - Test signal: 800*600@60Hz

- Test pattern: 64 gray RGBW

Procedure - Test equipment: video generator

- Please press "Power", "Left", "Left" and

"Menu" buttons sequentially to get into

Service Mode.

- Adjust "Color Wheel Index" to correct the test

patten.

Inspection item - Color saturation

Criteria - There should not have any lack of RGBW.

- Color levels should be suffcient and normal.

note: Color Wheel Index should be adjusted when

the test pattern appears fashing,abnormal

color,missing color.

1. PC Calibration

Procedure - Test equipment: video generator

- Once Main Board is changed, PC calibration

should be done as well.

(1) Test signal: 800 x 600@60Hz

(2) Test Pattern: White/Black

- Note

(1) Calibration pattern should be in full screen

mode.

(2) Please refer to 4-2 Guide to get into service

mode, then get into ADC/DEC color, and

choose PC Calibration.

Inspection item - Check if there is lines on the screen.

- Check if there is noise on the screen.

- Horizontal and vertical position of the video should

be adjustable to the screen frame.

Criteria - If there is noise on the screen, the product is

considered as failure product.

- The screen appears normal, it shouldnt appear

SMPTE BAR

64 gray RGBW

Confdential 4-11 BS275/BX275

any abnormal condition, such as lines and so on.

- Check if the projection is same as monitor diplayed.

2. Video Calibration

Procedure - Test equipment: video generator.

- Once main board is changed, Video calibration

should be done as well.

(1) Test signal: 480i

(2) Test Pattern: SMPTE BAR

- Note

(1) Calibration pattern should be in full screen mode.

(2) Please refer to 4-2 Guide to get into Service Mode

select ADC/DEC color, and choose Video Calibration.

Inspection item - Color sturations

Criteria - There should not have any lack of SMPTE BAR.Color

levels should be suffcient and normal.

- There is not any abnormal lines on the image.

BS275/BX275 Confdential 4-12

Full white pattern

4-10 Optical Performance Measure

Inspection Condition

- Environment luminance: 2 Lux

- Product must be warmed up for 5 minutes

- Distances from the screen: 2.4 M

- Screen Size: 60 inches diagonal

1. Test equipment

Procedure - Please get into OSD menu, select Lamp

Setting under Options, press Enter but

ton, then select Bright mode.

- Test equipment: video generator.

- Test signal: analog 800 x 600@60Hz

2. Brightness

Procedure - Full white pattern

- Use CL100 to measure brightness values of

P1~P9.

- Follow the brightness formula to calculate

brightness values.

Brightness Formula

Avg. (P1~P9)*1.1m

2

Criteria 1100 ANSI lumen

3. Full On/Full Off Contrast

Procedure - Full white pattern & Full black pattern

- Use CL100 to measure brightness values of

Confdential 4-13 BS275/BX275

Full black pattern

Full white pattern

X100%

full white pattern P5 & full black pattern B5

(see image: full white)

- Follow Contrast formula to calculate contrast

values.

Contrast Formula

P5/B5

Note: P5 = Lux of center in full white pattern

B5 = Lux of center in full black pattern

Criteria 1800:1

4. Uniformity

Procedure - Full white pattern

- Use CL100 to measure brightness values of

P1~P9 (see image: full white).

- Follow the Uniformity formula to calculate

average values.

Uniformity Formula

JBMA Uniformity = Avg. (P1, P3, P7, P9)

P5

Criteria 65%

4-11 Others

1. Functional Inspection

Power Key - Power key must operate smoothly.

Remote Controller - Check whether the remote controller

can work normal, Menu, Left and

Right buttons work smoothly.

General - All OSD functions must be checked for func-

tionality. When OSD menu is displayed, there

shall be no visible peaking, ringing, streaking,

or smearing artifacts on the screen.

Full white pattern

BS275/BX275 Confdential 4-14

Factory Default - The factory settings (with appropriate centering,

size, geometry distortion, etc.) shall be dis-

played upon Recall is selected from OSD.

Display Size - All preset modes shall expand to full screen size

using OSD Horizontal and Vertical Size controls.

Display Data Channel (DDC) - The purpose of the DDC test is to verify the

DDC1/DDC2B operation of the projector and to

verify Plug & Play function.

Acoustic - High pitch sound from cooling fan and color

wheel is unacceptable.

2. Check points for exterior and print pattern

Check item Check point

Text & Pattern

Missing letters & pattern or blurry prints are

unacceptable.

Exterior

Dirt, scrape, water ripples and uneven color are

unacceptable.

Focus ring/ Zoom ring

Focus ring and Zoom ring should be moved

smoothly.

Logo

Missing logo, missing prints and blurry prints are

unacceptable

Screw All screws sure be fxed and in right type.

Pedestal Well-functioned

Lamp Cover It should be locked in the correct place.

Plastic Parts All plastic parts can not be broken and damaged.

Safety or warning label

All safety and warning labels should be visible,

including all contents.

Connector

All interface connectors should be complete and

workable.

Adjust foot Adjust foot should be adjusted smoothly.

BS275/BX275 Confdential 5-1

Chapter 5

Firmware Upgrade

Section 1: System Firmware Upgrade

5-1-1 Equipment Needed

Software: (DDP2431-RS232)

- DLP Composer Lite 9.2

- Firmware (*.img)

- 1510X library

Hardware:

- Projector

- Power Cord (42.50115G001)

- RS232 Cable 9PIN to 3PIN (42.83618G001)

- PC or Laptop

Confdential 5-2

BS275/BX275

5-1-2 DLP Composer Lite

Setup Procedure

1. Choose "DLP Composer Lite V9.2 Setup"

Program.

2. Click "Next".

3. Read "License Agreement".

- Choose "I accept and agree to be bound

by all the terms and conditions of this

License Agreement".

- Click "Next".

4. Click "Next".

BS275/BX275 Confdential 5-3

5. Click "Next".

6. Click "Next".

7. The program is executing "installing"

status.

8. Click "Finish".

Confdential 5-4

BS275/BX275

5-1-3 Get into FW mode

1. Get into Firmware mode

Hold on POWER button and plug in the power cord.

- The LED will light red and amber.

- Loosen POWER button.

- Connect projector with RS232 cable to PC.

Note: - The system fan and the lamp will not

operate.

2. Execute the "DLP Composer

TM

Lite 9.2" fle.

3. Click "Edit" and "Perferences".

BS275/BX275 Confdential 5-5

4. Click "Library".

- Click the "Browse" and navigate to

the directory where you put the DLP

Composer fles in.

- Click "1510X Library" folder.

- Click "OK".

5. Click Communications.

- Select Serial Port.

- Select the COM Port which you are using.

- Click Confgure.

6. Serial Port Confguration picture will

appear on the screen.

- Make sure the settings are as below:

(1) In Baud Rate item, select 115200.

(2) In Data Bits item, select 8.

(3) In Stop Bits item, select 1.

(4) In Parity item, select None.

(5) In RTS item, select Enable.

(6) In CTS item, select Disable.

(7) Key in 4000 into Read and Write

items of Timeouts (in milliseconds).

- Click OK.

7. Click OK.

Confdential 5-6

BS275/BX275

6. Choose "Flash Loader".

- Click "Browse" to search the frmware fle

(*.img).

- Click "Open".

7. Select "Skip Boot Loader Area".

(select "32KB").

- Click "Reset Bus" to erase the fash

memory.

8. If the FW is ready, click "Start Download" to

execute the frmware upgrade.

- Click "Yes".

9. Proceeding Picture.

BS275/BX275 Confdential 5-7

10. It takes about several minutes, the

frmware upgrade process is fnished,

"Download completed" will appear on the

screen.

- Unplug RS232 cable and power cord.

11. Check FW version.

- Re-plug in power cord, then restart the

unit and get into the Service mode to

check the frmware version.

(To get into service mode, please press

"Power", "Left", "Left" and "Menu" buttons

sequentially on remote controller.)

Confdential 5-8

BS275/BX275

Section 2: 8051 FW Upgrade

5-2-1 Equipment Needed

Software: (N79A901R-USB)

- Setup _NLINK_en

- Manley USB Driver_NLINK (for N79A901R)

- XXX_8051_XXX.hex

Hardware:

- Projector

- Power cord: 42.50115G001

- USB Cable mini USB to USB (A) (42.00284G001)

- NLINK Fixture

- PC or Laptop

BS275/BX275 Confdential 5-9

5-2-2 NLINK Setup Procedure

1. Choose "setup_NLINK_en.exe" program.

2. Click "Next".

3. Click "Next".

4. Click "Next".

Confdential 5-10

BS275/BX275

5. Click "Next".

- Select the additional task that you may

create a desktop icon.

6. Click "Install" to begin installing NLINK

Procedure.

7. Click "Finish".

- Complete the NLINK setup.

8. "MCU Choose" picture will appear on the

screen.

- Close the picture.

BS275/BX275 Confdential 5-11

5-2-3 Manley USB Driver

Upgrade Procedure

1. Set-up

- Plug in the power cord, the power LED will

light on red.

- Connect RGB-IN Port of projector with NLINK

Fixture .

- Connect NLINK Fixture with PC by USB cable.

2. Execute Program

(1) "Found New Hardware Wiszard" picture

will appear on the screen.

(2) Select "Install from a list or specifc

location (Advanced)".

(3) Click "Next".

(4) Select "Include this location in the

search", then click "Browse".

(5) "Browse For Folder" picture will appear

on the screen.

(6) Select "TPRP1" folder in the "Manley

USB Driver_N-Link" folder, then click

"OK".

(1)

(3)

(2)

(4)

(6)

(5)

Confdential 5-12

BS275/BX275

(7) Click "Next".

(8) Click "Continue Anyway".

(9) Click "Finish".

- "Manley TPRP1-Protocol Emulator"

will appear on the picture.

- Complete the USB Driver Upgrade

Procedure.

Note: - If "Found New Hardware Wiszard" picture

appear again, repeat step 2 to install USB

Drivier.

(7)

(8)

(9)

BS275/BX275 Confdential 5-13

5-2-4 8051 Firmware Upgrade

Procedure

1. Execute 8051 FW Program

- Double click "NLINK V1.2" to execute

NLINK program.

Note: - When we execute NLINK program, the

power LED and Fixture LED fash red.

2. Choose the right type of MCU

- "MCU Choose" picture will appear on the

screen, select "N79A901R".

- Click "OK".

3. Choose 8051 fle (*.hex)

- "Manley Nlink" picture will appear on the

screen.

- Ensure "MCU" is the one you chose in the

last step (as green square).

- Click "Open".

- Select the 8051 fle where you put the fle

in, then click "Open".

4. Program settings

- Ensure NLlNK Fixture and PC are

securely connected: the indicator lights on

green, and the state is "Connect" (as

blue square).

- Select "Internel RC(11.0592MHz)" (as

green square).

- Click "Erase/Write(W)" to execute 8051

FW upgrade.

Confdential 5-14

BS275/BX275

5. Finish

- When 8051 FW upgrade process is

fnished, "Write Chip success" will be shown.

6. Check 8051 FW version

- Turn on the unit and get into the service

mode to check the 8051 FW version.

(To get into service mode, please press

"Power", "Left", "Left" and "Menu" buttons

sequentially on remote controller.)

BS275/BX275 Confdential 6-1

Chapter 6

EDID Upgrade

6-1 EDID Introduction

Extended Display Identifcation Data is a VESA standard data format that contains basic

information about a display device and its capabilities, including vendor information,

maximum image size, color characteristics, factory pre-set timings, frequency range limits,

and character strings for the monitor name and serial number.

The information is stored in the display and is used to communicate with the system

through a Display Data Channel (DDC), which sites between the display device and the

PC graphics adapter. The system uses this information for confguration purposes, so the

monitor and system can work together.

Note: - If a display device has digital input ports, like DVI or HDMI, but without EDID in its Main

Board, the display device will show no image while the input source is digital signal.

- The EDID Upgrade procedure for BS275 is the same as BX275, we take BS275 for

example here.

Confdential 6-2 BS275/BX275

6-2 Equipment Needed

Software

- EDID Program

- EDID File (*.ini)

Hardware

- Projector

- Power Cord for Projector (42.50115G001)

- VGA Cable (42.87305G102)

- Generic Fixture (80.00001.001) for EDID Key-in (Fixture: JP3 must be closed)

- RS-232 9 Pin Cable (pin to pin, F-M) (42.83C07G001)

- Power Adapter (42.50115G001)

- Monitor

- PC

Confdential 6-3 BS275/BX275

6-3 Setup Procedure (VGA)

1. Connect all ports

(1) Connect P1 of fxture with COM Port of

PC/Laptop by RS232 Cable.

(2) Connect P3 of fxture with RGB-IN Port

of projector by VGA Cable.

(3) Plug Power Adapter to JP1 of fxture.

(5) Power on fxture.

(6) Plug Power Cord to projector.

Note: -You must confrm that the JP3 is closed

in all procedure.

6-4 EDID Key-In Procedure

1. Execute EDID Program

- Double click "EDID" to execute EDID

program.

JP3

Adapter

RS232 Cable

VGA Cable

JP1

P1

P3

Confdential 6-4 BS275/BX275

2. Process

(1) Select the COM Port which you are

using.

(2) Click "Model".

(3) Select the EDID fle (*.ini).

(4) Click "Open".

(5) Key in the Serial Number into the

Barcode blank space.

(6) In "Write Source Select" item, select

"VGA".

(7) Click "Program".

3. Change the cable to VGA

- When the message "Please change the

cable to VGA" appears on the screen,

click "OK".

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Confdential 6-5 BS275/BX275

4. When the EDID program is completed, a

message "OK" will appear on the screen.

5. Read EDID "VGA" information

- In "Read item", select "Analog" and

"Trans", then click the "Read".

6. EDID information will show the result.

Condential

Appendix A (Exploded Image)

Note: This chapter is only designed to show the exploded image of the projector.

For updated part numbers, please refer to RSPL report.

22

21

20

19

18

17

16

15

14

13

12

11

10

7

6

5

4

2

3

8

9

1

24

23

29

28

30

27

25

26

5

31

32

33

BS275/BX275 Confdential 3

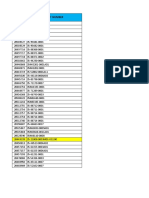

Item P/N LG P/N Description BX275 BS275

1 51.8HC01G001 COV30352901 TOP COVER MN3600H BLACK BS275 v

51.8HC01G011 COV30353001 TOP COVER MN3600H BLACK BX275 v

2 80.8CP05G001 COV30386901 PCBA IR SENSOR BD FOR X1161 v v

3 51.8CS03G012 COV30352801 FRONT COVER FOR IR PC MN3600H BLACK ES526 v v

4

49.8CP02G003 COV30352501 SUNON 70*70*20mm AXIAL FAN, SHRINK TUBE, WIRE

LENGTH 155mm

v v

5 80.8LP04G001 COV30387002 PCBA PHOTO SENSOR BOARD FOR ES526X PROJECOR v v

6 70.8HC09GR01 COV30353501 ASSY COLOR WHEEL MODULE BS275, BX275(SERVICE) v v

7 70.8HC10GR01 COV30388201 ASSY ROD MODULE BS275, BX275(SERVICE) v v

8 49.8CS01G002 COV30352601 SUNON 45*20mm GB1245PKV1-8AY, F TYPE BLOWER v v

9 70.8CQ14GR01 COV30386401 ASSY LAMP DRIVER MODULE X1261 3D (SERVICE) v v

10 49.8CQ01G001 COV30386301 SPEAKER 2W 16OHM DAB128 90mm X1261 v v

11 SP.8HF01GC01 COV30389301 LAMP MODULE FOR PROJECTOR Z15-XGA/Z15-SVGA v v

12 70.8HC12GR01 COV30389001 ASSY LAMP COVER MODULE BS275, BX275(SERVICE) v v

13 52.8EH05G001 COV30353101 RUBBER ADJUST FOOT ES526 v v

14 51.8CS02G001 COV30352701 BOTTOM COVER PC MN3600H BLACK PDG-DSU30 v v

15 75.8AA04G001 COV30386601 BUY ASSY INTERLOCK SWITCH 1409X v v

16 75.8CP03GP01 COV30386701 LVPS 180W X1161 STB<1W CT-258C v v

17 70.8HC11GR01 COV30388601 ASSY IO COVER MODULE BS275, BX275(SERVICE) v v

18 70.8HC13GR01 COV30353302 WHOLE ASSY ENGINE MODULE 800*600 8HC(SERVICE) v

70.8HF05GR01 COV30353303 WHOLE ASSY ENGINE MODULE 1024*768 8HF(SERVICE) v

19 80.8CP02G001 COV30386801 PCBA DMD BOARD FOR X1161 v v

20 48.8CQ01G003 COV30387401 0.55" XGA 2xLVDS SERIES 450 DMD -8 TI 8060-603cB v

48.8EH01G001 COV30387501 0.55" SVGA 2xLVDS SERIES 450 DMD -8 TI 8060-603cB v

21 80.8HC01G003 COV30387301 PCBA MAIN BD FOR LGE BS275 NEW PHOTO SENSOR v

80.8HF01G003 COV30387102 PCBA MAIN BD FOR LGE BX275 NEW PHOTO SENSOR v

22 42.00304G001 COV30386101 FFC KEYPAD TO FORMATTER BD 16P P=0.5 122mm HD80 v v

23 80.8HC03G001 COV30387201 PCBA KEYPAD BD FOR LGE Z15-SVGA PROJECTOR v v

24 52.8HC01G001 COV30353201 KEYPAD RUBBER FOR BS275, BX275 v v

25

42.50115G001 COV30386201 CABLE POWER CORD 1.8M SP30+IS14 US v v

42.00110G011 COV30385801 CABLE POWER CORD 1.8M SP-62/IS-14 UK DIS-WARNING

LABEL

v v

42.00120G011 COV30385901 CABLE POWER CORD 1.8M SP-023/IS-14 EUROPE DIS-

WARNING LABEL

v v

42.00191G001 COV30386001 CABLE POWER CORD 1.8M SP-022/IS-14 KOREA v v

26 55.8HC01G001 COV30392401 CARTON AB FLUTE 18KG 395*163*312MM BS275 v v

27 75.8FL03G001 COV30389201 8FL LENS CAP MODULE v v

28 36.8HF01G001 SAC30666021 USER'S GUIDE MULTILINGUAL (CD) BS275/BX275 v v

29 36.8HF02G001 MBM36259605 WARRANTY CARD EU 9L FOR LG v v

36.8HF03G001 3840TWL005J WARRANTY CARD INDONESIA FOR LG v v

36.8HF04G001 3840TWL005B WARRANTY CARD KOREA FOR LG v v

36.8HF06G001 MBM36259609 WARRANTY CARD TURKEY FOR LG v v

30 45.8HC01G001 COV30392301 REMOTE CONTROLLER FOR LGE BS275&BX275 v v

31 85.1A126G080 COV31453101 SCREW PAN MECH M2.6*8 Ni v v

32

51.8HH17G001 COV31453201 PHOTO SENSOR BD SPACER UF65 v v

BS275/BX275 Confdential 1

Appendix B

I. Serial Number System Defnition

Serial Number Format for Projecto

Y MM RR CC SSSSS

1 2 3 4 5

1: Y = YEAR(Last digit of Year) (ex:2010 = 0)

2: MM =Month(Jan = 01,Feb =02,...Dec=12)

3: RR =Site code for each production factory (For Coretronic:CT)

4: CC =Code is self-produced by coding program.

5: SSSSSS = Serial code (00001~09999)

EX:

This label "003CTCC00001 represents the serial number for LG. It is produced in China

Coretronic on March, 2010. Its serial code is 00001.

BS275/BX275 Confdential 2

II. PCBA Code Defnition

PCBA Code for Projector

A B XXXXXXXXXX C XXX EEEE

1 2 3 4 5 6

1 : ID

2 : Vendor Code

3 : P/N

4 : Revision

5 : Date Code

6 : S/N

BS275/BX275 Confdential 1

Appendix C

New photo sensor board Reworking SOP

Note:

1.This procedure only for reworking old photo sensor(80.8EG04G002) to improve auto

shutdown, image ficker issue

2. The new photo sensor(80.8LP04G001) board must match with new main board

The PN of new main board of BS275 is 80.8HC01G003

The PN of new main board of BX275 is 80.8HF01G003

3. For main board rework, refer to chapter 2 (2-1~2-9)for details

1. Parts Required

Coretronic P/N LG P/N Description Quantity

80.8LP04G001 COV30387002 PCBA PHOTO SENSOR BOARD 1

85.1A126G080 COV31453101 SCREW PAN MECH M2.6*8 NI 1

51.8HH17G001 COV31453201 PHOTO SENSOR BD SPACER 1

2. Disassemble Photo Sensor Board

1).Unscrew 1 screw (as blue circle) to disassemble the photo sensor board from the Color

Wheel Module.

BS275/BX275 Confdential 2

3. Assemble New Photo Sensor Board

1). Add spacer with tape to new photo sensor board (as below picture shows).

2). Assemble new photo sensor board on color wheel module.

Note: When fx photo sensor screw, photo sensor board must be placed on color

wheel bracket horizontally.

You might also like

- Schematic - YAXUN 881D+ - 2022-01-01Document1 pageSchematic - YAXUN 881D+ - 2022-01-01Murilo de Andrade Melo88% (8)

- EM2U60HLP - Data Sheet PDFDocument3 pagesEM2U60HLP - Data Sheet PDFCayqueCasaleNo ratings yet

- Brastemp Twin System 410 Service Manual PDFDocument17 pagesBrastemp Twin System 410 Service Manual PDFMarceloAndrade50% (2)

- EIA Marking Code For Surface Mount (SMD) ResistorsDocument2 pagesEIA Marking Code For Surface Mount (SMD) Resistorsqashqai q100% (1)

- Manual de Serviço TV PTV50RCG70BL 4K Led V.ADocument28 pagesManual de Serviço TV PTV50RCG70BL 4K Led V.ACarlos Alberto Bandeira Soares100% (3)

- BN44 00201a PDFDocument3 pagesBN44 00201a PDFEgnaldo PierettiNo ratings yet

- Dgi ps-3206 SMDocument229 pagesDgi ps-3206 SMHoffman Elizalde100% (1)

- TP Series Compressor SpecsDocument3 pagesTP Series Compressor Specssistec Industrial0% (1)

- Esquema Nhs Laser 3000 vaPRPWM (9R2) - 96V.10.02.10Document1 pageEsquema Nhs Laser 3000 vaPRPWM (9R2) - 96V.10.02.10AlexandreNo ratings yet

- D&T Manual ABBG45+54 - DR - AB004EF - 04Document82 pagesD&T Manual ABBG45+54 - DR - AB004EF - 04rodrigo100% (1)

- Rittal 3304500 Instructions 3 6292Document60 pagesRittal 3304500 Instructions 3 6292Dirceu Soares100% (5)

- Philco Ph32f33dg Led FonteDocument4 pagesPhilco Ph32f33dg Led FonteOtávio Sbaraini86% (7)

- Multi All Fujitsu ManualDocument93 pagesMulti All Fujitsu ManualJulio Holzbach75% (4)

- Esquema Nobreak - Nhs Mini III AC 0 PDFDocument1 pageEsquema Nobreak - Nhs Mini III AC 0 PDFJuliano EstevamNo ratings yet

- NKS PK-5000 PK-1000Document15 pagesNKS PK-5000 PK-1000FRANK NIELE DE OLIVEIRANo ratings yet

- Manual de Instalação SAMSUNGDocument16 pagesManual de Instalação SAMSUNGCinthya GuimarãesNo ratings yet

- Service Manual: ConfidentialDocument139 pagesService Manual: ConfidentialSantacruzmateo SantacruzmateoNo ratings yet

- Power supply circuit board component overviewDocument1 pagePower supply circuit board component overviewCezao Doidão0% (1)

- Esquema NHS Laser 36v 3300VADocument1 pageEsquema NHS Laser 36v 3300VAAnildo Eldivar De Oliveira Sarmento75% (4)

- TSB1380YGSDocument2 pagesTSB1380YGSlelopNo ratings yet

- LCD Monitor - DC - XL2420TX - 20120302 - 150546 - 5E.1M001.002 (4H.1M001.A00)Document11 pagesLCD Monitor - DC - XL2420TX - 20120302 - 150546 - 5E.1M001.002 (4H.1M001.A00)pasmanteriabellaNo ratings yet

- Tabela de SensoresDocument39 pagesTabela de SensoresMarcos Antônio Pires Pires100% (1)

- Setup guide for Oneal Audio amplifiersDocument11 pagesSetup guide for Oneal Audio amplifiersGuto LiberatoNo ratings yet

- P1027P65 (SMPS)Document30 pagesP1027P65 (SMPS)Jesus Silva67% (3)

- EM2P70CLP-513304568 S-DatasheetDocument3 pagesEM2P70CLP-513304568 S-DatasheetDavidsonSilveiraESilva100% (1)

- DL2971 (B) W DL3271 (B) W DL3971 (B) F DL2970 (B) W DL3270 (B) W DL3970 (B) F Le3274 (A) W Le3974 (A) F de Servico 1326 Sky Ne 770 455 Color PDFDocument49 pagesDL2971 (B) W DL3271 (B) W DL3971 (B) F DL2970 (B) W DL3270 (B) W DL3970 (B) F Le3274 (A) W Le3974 (A) F de Servico 1326 Sky Ne 770 455 Color PDFotaviojose70% (10)

- Sphe 8202 RQDocument24 pagesSphe 8202 RQSheraz Shaikh100% (2)

- LG 32LH35FD, 32LH35FD-SF Service Manual PDFDocument35 pagesLG 32LH35FD, 32LH35FD-SF Service Manual PDFwalter souzaNo ratings yet

- FFU160HAX DatasheetDocument3 pagesFFU160HAX Datasheetracini454No ratings yet

- Philips Chassis Q552.2lla 40pfl7606d 312278519115Document203 pagesPhilips Chassis Q552.2lla 40pfl7606d 312278519115Gaston TolozaNo ratings yet

- Esquema Eletrico Nobreak MICROSOL STAY700 AUTO 115VDocument1 pageEsquema Eletrico Nobreak MICROSOL STAY700 AUTO 115Vwalter souza100% (6)

- Fujitsu Air Conditioner Service ManualDocument44 pagesFujitsu Air Conditioner Service ManualnovyNo ratings yet

- Samsung UN39FH5005GCTC - Fuente BN44-0066E - DiagramaDocument1 pageSamsung UN39FH5005GCTC - Fuente BN44-0066E - DiagramaJuan Sebastián Ledesma50% (2)

- 5800 P24QB WP20 C PDFDocument1 page5800 P24QB WP20 C PDF81968No ratings yet

- Equivalencia CIs Fontes ChaveadasDocument14 pagesEquivalencia CIs Fontes ChaveadasRobmixNo ratings yet

- NCP1234 Fixed Frequency Current Mode Controller For Flyback ConvertersDocument3 pagesNCP1234 Fixed Frequency Current Mode Controller For Flyback ConvertersRobinson Fernando100% (2)

- A4W (Bav70)Document4 pagesA4W (Bav70)AngeloNo ratings yet

- Map 8800Document2 pagesMap 8800Vehid Parić100% (4)

- Iw7019 PDFDocument1 pageIw7019 PDFhectorsevillaNo ratings yet

- MV 4 94v 0 Schematic DigramDocument39 pagesMV 4 94v 0 Schematic DigramNaing TunNo ratings yet

- 5800-P24QB-WP20-C (Electric Diagram) 2012.9.13Document1 page5800-P24QB-WP20-C (Electric Diagram) 2012.9.13GiancarloRichardRivadeneyraMirandaNo ratings yet

- KD 49x727Document67 pagesKD 49x727Uzziel Mague100% (3)

- California Eastern Laboratories Optocoupler and Solid State Relay Cross Reference GuideDocument40 pagesCalifornia Eastern Laboratories Optocoupler and Solid State Relay Cross Reference Guideherberttdias0% (1)

- Product Specification FOR Approval: LenovoDocument34 pagesProduct Specification FOR Approval: LenovoRafael SenaNo ratings yet

- Highly Rotary Compressor CatalogueDocument16 pagesHighly Rotary Compressor CatalogueMohamed SaidNo ratings yet

- Equivalencia PolivoxDocument1 pageEquivalencia PolivoxMarcial MenegatoNo ratings yet

- Power Circuit: Power For Chip Standby Power +3V3Document12 pagesPower Circuit: Power For Chip Standby Power +3V3Joseni FigueiredoNo ratings yet

- Tabela Com Codigos e Caracteristicas de Capacitores de TantaloDocument51 pagesTabela Com Codigos e Caracteristicas de Capacitores de TantaloArialdo FurlaniNo ratings yet

- Tecumseh Do BrazilDocument15 pagesTecumseh Do BrazilSigfrido Bader GNo ratings yet

- Semp Toshiba Manual de Servico PDFDocument49 pagesSemp Toshiba Manual de Servico PDFAnildo Eldivar De Oliveira SarmentoNo ratings yet

- Acer x1161 x1261 SMDocument103 pagesAcer x1161 x1261 SMlazy campersNo ratings yet

- Optoma HD82 - HD8200 V3.0 (DDP 3021, 36.8AF05G001) Service ManualDocument96 pagesOptoma HD82 - HD8200 V3.0 (DDP 3021, 36.8AF05G001) Service ManualAndrij PNo ratings yet

- LG Be320-Sd Be325-Sp Ver.3.0 SMDocument83 pagesLG Be320-Sd Be325-Sp Ver.3.0 SMalexNo ratings yet

- Service Manual: Model Name: P5270/P5270 RefreshDocument113 pagesService Manual: Model Name: P5270/P5270 RefreshslalNo ratings yet

- Ew675ut Ex665ut Ex565ut Ew675uti Ex665uti Series Service Manual v4.0Document110 pagesEw675ut Ex665ut Ex565ut Ew675uti Ex665uti Series Service Manual v4.0Carlos Eduardo AbrantesNo ratings yet

- Service Manual: EP1080/DX1080/OP1990/VE810/DP7290/ PV8530/P350/TX1080Document90 pagesService Manual: EP1080/DX1080/OP1990/VE810/DP7290/ PV8530/P350/TX1080Alejandro LeviNo ratings yet

- HD67 Service Manual (DDP2431) V1.0Document37 pagesHD67 Service Manual (DDP2431) V1.0Bartolo PelaezNo ratings yet

- EP719H and EP749 Service ManualDocument88 pagesEP719H and EP749 Service ManualHoàng Lân NguyễnNo ratings yet

- EP716&EP719 or TX700 Serial Service Manual-P and R Series IncludedDocument84 pagesEP716&EP719 or TX700 Serial Service Manual-P and R Series IncludedHoàng Lân NguyễnNo ratings yet

- Optomaex 615Document110 pagesOptomaex 615Nathan PullenNo ratings yet

- Tissue SectioningDocument21 pagesTissue SectioningGirum TesfayeNo ratings yet

- Switchgears: Tested Power... Trusted SolutionDocument2 pagesSwitchgears: Tested Power... Trusted SolutionNimish TaterhNo ratings yet

- REN RC310xxA DST 20230531Document67 pagesREN RC310xxA DST 20230531杉澤 佑樹No ratings yet

- RC ChargingDocument6 pagesRC ChargingkaushalNo ratings yet

- SI210 SystemDocument17 pagesSI210 SystemAgus YohanesNo ratings yet

- Procurement IssuesDocument1,021 pagesProcurement Issuesriyadh al kamalNo ratings yet

- DPB181 Bandsaw Instruction ManualDocument13 pagesDPB181 Bandsaw Instruction ManualHD QuanNo ratings yet

- MTH400 / MTH4000Document5 pagesMTH400 / MTH4000SORINNo ratings yet

- Transformer Concepts ReportDocument15 pagesTransformer Concepts ReportJoel ThomasNo ratings yet

- 3GBP352220 ADG 3gbp352220 AdgDocument3 pages3GBP352220 ADG 3gbp352220 Adgbimasakti unitamaNo ratings yet

- Sound Bar: Owner'S ManualDocument28 pagesSound Bar: Owner'S ManualjakocNo ratings yet

- Presentation On DELD FinalDocument23 pagesPresentation On DELD Finalsalma akterNo ratings yet

- 2018.08.02 RPT Catalog Without ImagesDocument358 pages2018.08.02 RPT Catalog Without Imagesiturcic9No ratings yet

- Course: Industrial Electrician: Day 4: TopicsDocument37 pagesCourse: Industrial Electrician: Day 4: TopicsKiyoshi Jiro MalinaoNo ratings yet

- Ba Bfk458 enDocument52 pagesBa Bfk458 enWalterLlenqueTrellesNo ratings yet

- 3copy Black Se GoldeDocument56 pages3copy Black Se GoldeshobhitNo ratings yet

- SOP For Automatic Capsule Filling LineDocument9 pagesSOP For Automatic Capsule Filling LineAshok KumarNo ratings yet

- Ca1000 CN235Document3 pagesCa1000 CN235indra pratamaNo ratings yet

- Section Dimensions and Shipping Data 1HSM 9543 22-00en, Edition 6, 2014-04Document28 pagesSection Dimensions and Shipping Data 1HSM 9543 22-00en, Edition 6, 2014-04Vishnu ShankerNo ratings yet

- 8l Pkgcomparison 1220a 003Document1 page8l Pkgcomparison 1220a 003Ben LernerNo ratings yet

- Dodge Avenger IAT Sensor DTC P0112 P0113 FixDocument7 pagesDodge Avenger IAT Sensor DTC P0112 P0113 Fixflash_24014910No ratings yet

- Acme A349 Service ManualDocument34 pagesAcme A349 Service ManualCristian DavidNo ratings yet

- Ase 165 GT FT Mci - eDocument2 pagesAse 165 GT FT Mci - eDragan BabicNo ratings yet

- McIntosh MAC-4200 Owners ManualDocument28 pagesMcIntosh MAC-4200 Owners ManualSaleem AhmadNo ratings yet

- IECEx SIR 09.0111 Issue 0Document6 pagesIECEx SIR 09.0111 Issue 0Junardi SilabanNo ratings yet

- Catalogo Trane LwhaDocument26 pagesCatalogo Trane LwhaAlejandro MoralesNo ratings yet

- MaxxForce11 13SpecCardDocument2 pagesMaxxForce11 13SpecCardJohn MkCito KINo ratings yet

- VDV500-705 ManualDocument2 pagesVDV500-705 ManualJuan CastroNo ratings yet

- Unit 2 WS2Document15 pagesUnit 2 WS2Prasanti MVNo ratings yet

- Virtual Amplification V-Amp 3: User ManualDocument18 pagesVirtual Amplification V-Amp 3: User Manualoeqk25No ratings yet