Professional Documents

Culture Documents

2001 Dakota / Durango Service Manual

Uploaded by

David SterlingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2001 Dakota / Durango Service Manual

Uploaded by

David SterlingCopyright:

Available Formats

GROUP TAB LOCATOR

Introduction

0

Lubrication & Maintenance

2

Suspension

3

Differential & Driveline

5

Brakes

6

Clutch

7

Cooling

8A

Audio

8B

Chime/Buzzer

8E

Electronic Control Modules

8F

Engine Systems

8G

Heated Systems

8H

Horn

8I

Ignition Control

8J

Instrument Cluster

8L

Lamps

8M

Message Systems

8N

Power Systems

8O

Restraints

8P

Speed Control

8Q

Vehicle Theft Security

8R

Wipers/Washers

8W

Wiring

9

Engine

11

Exhaust System

13

Frame & Bumpers

14

Fuel System

19

Steering

21

Transmission and Transfer Case

22

Tires/Wheels

23

Body

24

Heating & Air Conditioning

25

Emissions Control

30

New Vehicle Preparation

Component and System Index

Service Manual Comment Forms (Rear of Manual)

INTRODUCTION

TABLE OF CONTENTS

page page

VEHICLE SAFETY CERTIFICATION LABEL

DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

VEHICLE IDENTIFICATION NUMBER

DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

VECI LABEL

DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

BODY CODE PLATE

DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

EQUIPMENT IDENTIFICATION PLATE

DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INTERNATIONAL SYMBOLS

DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

FASTENER IDENTIFICATION

DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

FASTENER USAGE

DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

METRIC SYSTEM

DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

TORQUE REFERENCES

DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . 10

VEHICLE SAFETY

CERTIFICATION LABEL

DESCRIPTION

A vehi cl e safety certi fi cati on l abel i s attached to

every Dai ml erChrysl er Corporati on vehi cl e. The l abel

certi fi es that the vehi cl e conforms to al l appl i cabl e

Federal Motor Vehi cl e Safety Standards. The l abel

al so l i sts:

Month and year of vehi cl e manufacture.

Gross Vehi cl e Wei ght Rati ng (GVWR). The gross

front and rear axl e wei ght rati ngs (GAWRs) are

based on a mi ni mum ri m si ze and maxi mum col d ti re

i nfl ati on pressure.

Vehi cl e I denti fi cati on Number (VI N).

Type of vehi cl e.

Type of rear wheel s.

Bar code.

Month, Day and Hour (MDH) of fi nal assembl y.

Pai nt and Tri m codes.

Country of ori gi n.

The l abel i s l ocated on the dri ver-si de door shut-

face (Fi g. 1).

Al l communi cati ons or i nqui ri es regardi ng the

vehi cl e shoul d i ncl ude the Month-Day-Hour and

Vehi cl e I denti fi cati on Number.

Fig. 1 Vehicle Safety Certification Label

AN INTRODUCTION 1

VEHICLE IDENTIFICATION

NUMBER

DESCRIPTION

The Vehi cl e I denti fi cati on Number (VI N) pl ate i s

attached to the top l eft si de of the i nstrument panel

(Fi g. 2). The VI N contai ns 17 characters that provi de

data concerni ng the vehi cl e. Refer to the decodi ng

chart to determi ne the i denti fi cati on of a vehi cl e.

VIN DECODING INFORMATION

POSITION INTERPRETATION CODE = DESCRIPTION

1 Country of Origin 1= USA

2 Make B = Dodge

3 Vehicle Type 7 = Truck

4 Gross Vehicle Weight Rating

F = 4001-5000 lbs.

G = 5001-6000 lbs.

H = 6001-7000 lbs.

5 Vehicle Line

G = Dakota

Dakota Sport

Dakota 4x4

L = Dakota

Dakota Sport

Dakota 4x2

6 Series

2 = Dakota

Dakota Sport

Dakota SLT

7 Body Style

2 = Club Cab

A = Quad Cab

6 = Conventional Cab

8 Engine

P = 2.5L

X = 3.9L

N=4.7L

Y = 5.2L

Z = 5.9L

9 Check Digit

10 Model Year 1=2001

11 Assembly Plant S = Warren Truck Assembly

12 Thru 17 Vehicle Build Sequence Assembly Sequence

Fig. 2 Vehicle Identification Number (VIN)

1 - VIN

2 INTRODUCTION AN

VECI LABEL

DESCRIPTION

Al l vehi cl es are equi pped wi th a combi ned VECI

l abel . Thi s l abel i s l ocated i n the engi ne compart-

ment (Fi g. 3).

The VECI l abel contai ns the fol l owi ng:

Engi ne fami l y and di spl acement

Evaporati ve fami l y

Emi ssi on control system schemati c

Certi fi cati on appl i cati on

Engi ne ti mi ng speci fi cati ons (i f adjustabl e)

I dl e speeds (i f adjustabl e)

Spark pl ug and gap

The l abel al so contai ns an engi ne vacuum sche-

mati c. There are uni que l abel s for vehi cl es bui l t for

sal e i n the state of Cal i forni a and the country of

Canada. Canadi an l abel s are wri tten i n both the

Engl i sh and French l anguages. These l abel s are per-

manentl y attached and cannot be removed wi thout

defaci ng i nformati on and destroyi ng l abel .

BODY CODE PLATE

DESCRIPTION

LOCATION AND DECODING

A metal body code pl ate i s attached to the fl oor pan

under the passenger seat. Remove the passenger

seat, door si l l scuff pl ate and pul l back the carpet to

access the body code pl ate. There are seven l i nes of

i nformati on on the body code pl ate. Li nes 5, 6, and 7

are not used to defi ne servi ce i nformati on. I nforma-

ti on reads from l eft to ri ght, starti ng wi th l i ne 4 i n

the center of the pl ate to l i ne 1 at the bottom of the

pl ate (Fi g. 4).

The l ast code i mpri nted on a vehi cl e code pl ate wi l l

be fol l owed by the i mpri nted word END. When two

vehi cl e code pl ates are requi red, the l ast avai l abl e

spaces on the fi rst pl ate wi l l be i mpri nted wi th the

l etters CTD (for conti nued).

When a second vehi cl e code pl ate i s necessary, the

fi rst four spaces on each row wi l l not be used because

of the pl ate overl ap.

BODY CODE PLATE LINE 4

DIGITS 1 THROUGH 12

Vehi cl e Order Number

DIGITS 13, 14, AND 15

Open Space

DIGITS 16, 17, AND 18

Car Li ne Shel l

AN1 = Dakota 4 X 2

AN5 = Dakota 4 X 4

DIGIT 19

Pri ce Cl ass

L = Dakota (Al l )

DIGITS 20 AND 21

Body Type

31 = Dakota Cl ub Cab (130.9 i n. Wheel Base)

61 = Dakota (111.9 i n. Wheel Base)

62 = Dakota (123.9 i n. Wheel Base)

BODY CODE PLATE LINE 3

DIGITS 1, 2, AND 3

Pai nt Procedure

Fig. 3 VECI Label Location

1 - VEHICLE EMISSION CONTROL INFORMATION (VECI) LABEL

Fig. 4 Body Code

AN INTRODUCTION 3

DIGIT 4

Open Space

DIGITS 5 THROUGH 8

Pri mary Pai nt

Refer to Group 23, Body for col or codes.

DIGIT 9

Open Space

DIGITS 10 THROUGH 13

Secondary Pai nt

DIGIT 14

Open Space

DIGITS 15 THROUGH 18

I nteri or Tri m Code

DIGIT 19

Open Space

DIGITS 20, 21, AND 22

Engi ne Code

EPE = 2.5 L 4 cyl . MPI Gasol i ne

EHC = 3.9 L 6 cyl . MPI Gasol i ne

ELF = 5.2 L 8 cyl . MPI Gasol i ne

ELM = 5.9 L 8 cyl . MPI Gasol i ne

BODY CODE PLATE LINE 2

DIGITS 1, 2, AND 3

Transmi ssi on Codes

DDK = 5Speed Manual (NVG 1500)

DDQ = 5Speed Manual (AX15)

DDC = 5Speed Manual (NVG 3500)

DGK = 4Speed Automati c (42RE)

DGW = 4Speed Automati c (44RE)

DGT = 4Speed Automati c (46RE)

DIGIT 4

Open Space

DIGIT 5

Market Code

B = I nternati onal

C = Canada

M = Mexi co

U = Uni ted States

DIGIT 6

Open Space

DIGITS 7 THROUGH 23

Vehi cl e I denti fi cati on Number (VI N)

Refer to Vehi cl e I denti fi cati on Number (VI N) para-

graph for proper breakdown of VI N code.

BODY CODE PLATE LINE 1

DIGITS 1 THROUGH 6 Body-in-white assembly sequence.

DIGITS 7 THROUGH 9

Open Space

DIGITS 10 THROUGH 12 Cargo box code

XBS = Sweptl i ne

DIGITS 13 THROUGH 16

Open Space

EQUIPMENT IDENTIFICATION

PLATE

DESCRIPTION

The Equi pment I denti fi cati on Pl ate (Fi g. 5) i s

l ocated at the l eft, front of the i nner hood panel . The

pl ate l i sts i nformati on concerni ng the vehi cl e as fol -

l ows:

The model .

The wheel base.

The VI N (Vehi cl e I denti fi cati on Number).

The T.O.N. (order number).

The opti onal and speci al equi pment i nstal l ed on

the vehi cl e.

Refer to the i nformati on l i sted on the pl ate when

orderi ng repl acement parts.

INTERNATIONAL SYMBOLS

DESCRIPTION

The graphi c symbol s i l l ustrated i n the fol l owi ng

I nternati onal Control and Di spl ay Symbol s Chart

(Fi g. 6) are used to i denti fy vari ous i nstrument con-

trol s. The symbol s correspond to the control s and di s-

pl ays that are l ocated on the i nstrument panel .

Fig. 5 Equipment Identification PlateTypical

4 INTRODUCTION AN

BODY CODE PLATE (Continued)

FASTENER IDENTIFICATION

GRADE/CLASS IDENTIFICATION

DESCRIPTION

The SAE bol t strength grades range from grade 2

to grade 8. The hi gher the grade number, the greater

the bol t strength. I denti fi cati on i s determi ned by the

l i ne marks on the top of each bol t head. The actual

bol t strength grade corresponds to the number of l i ne

marks pl us 2. The most commonl y used metri c bol t

strength cl asses are 9.8 and 10.9. The metri c

strength cl ass i denti fi cati on number i s i mpri nted on

the head of the bol t. The hi gher the cl ass number,

the greater the bol t strength. Some metri c nuts are

i mpri nted wi th a si ngl e-di gi t strength cl ass on the

nut face. Refer to the Fastener I denti fi cati on (Fi g. 7)

and Fastener Strength Charts (Fi g. 8).

FASTENER USAGE

DESCRIPTION

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Fi gure art, speci fi cati ons and ti ghteni ng torque ref-

erences i n thi s manual are i denti fi ed i n metri c and

SAE format.

Duri ng any mai ntenance or repai r procedures, i t i s

i mportant to sal vage al l fasteners (nuts, bol ts, etc.)

for reassembl y. I f the fastener i s not sal vageabl e, a

fastener of equi val ent speci fi cati on must be use.

DESCRIPTION

Most stri pped threaded hol es can be repai red usi ng

a Hel i coi l . Fol l ow the manufacture recommendati on

for appl i cati on and repai r procedures.

Fig. 6 INTERNATIONAL SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

AN INTRODUCTION 5

INTERNATIONAL SYMBOLS (Continued)

Fig. 7 FASTENER IDENTIFICATION

6 INTRODUCTION AN

FASTENER USAGE (Continued)

Fig. 8 FASTENER STRENGTH

AN INTRODUCTION 7

FASTENER USAGE (Continued)

METRIC SYSTEM

DESCRIPTION

The metri c system i s based on quanti ti es of one,

ten, one hundred, one thousand and one mi l l i on.

The fol l owi ng chart wi l l assi st i n converti ng metri c

uni ts to equi val ent Engl i sh and SAE uni ts, or vi se

versa.

Refer to the Metri c Conversi on Chart (Fi g. 9) to

convert torque val ues l i sted i n metri c Newton-

meters (Nm). Al so, use the chart to convert between

mi l l i meters (mm) and i nches (i n.)

CONVERSION FORMULAS AND EQUIVALENT VALUES

MULTIPLY BY TO GET MULTIPLY BY TO GET

in-lbs x 0.11298 = Newton Meters (Nm) Nm x 8.851 = in-lbs

ft-lbs x 1.3558 = Newton Meters (Nm) Nm x 0.7376 = ft-lbs

Inches Hg

(60F)

x 3.377 = Kilopascals (kPa) kPa x 0.2961 = Inches Hg

psi x 6.895 = Kilopascals (kPa) kPa x 0.145 = psi

Inches x 25.4 = Millimeters (mm) mm x 0.03937 = Inches

Feet x 0.3048 = Meters (M) M x 3.281 = Feet

Yards x 0.9144 = Meters M x 1.0936 = Yards

mph x 1.6093 = Kilometers/Hr. (Km/h) Km/h x 0.6214 = mph

Feet/Sec x 0.3048 = Meters/Sec (M/S) M/S x 3.281 = Feet/Sec

mph x 0.4470 = Meters/Sec (M/S) M/S x 2.237 = mph

Kilometers/

Hr. (Km/h)

x 0.27778 = Meters/Sec (M/S) M/S x 3.600 Kilometers/Hr.

(Km/h)

COMMON METRIC EQUIVALENTS

1 inch = 25 Millimeters 1 Cubic Inch = 16 Cubic Centimeters

1 Foot = 0.3 Meter 1 Cubic Foot = 0.03 Cubic Meter

1 Yard = 0.9 Meter 1 Cubic Yard = 0.8 Cubic Meter

1 Mile = 1.6 Kilometers

8 INTRODUCTION AN

Fig. 9 METRIC CONVERSION CHART

AN INTRODUCTION 9

METRIC SYSTEM (Continued)

TORQUE REFERENCES

DESCRIPTION

I ndi vi dual Torque Charts appear at the end of

many Groups. Refer to the Standard Torque Speci fi -

cati ons Chart for torque references not l i sted i n the

i ndi vi dual torque charts (Fi g. 10).

Fig. 10 TORQUE SPECIFICATIONS

10 INTRODUCTION AN

LUBRICATION & MAINTENANCE

TABLE OF CONTENTS

page page

LUBRICATION & MAINTENANCE

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . 1

INTERNATIONAL SYMBOLS

DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

PARTS & LUBRICANT

STANDARD PROCEDURE . . . . . . . . . . . . . . . . . . . 2

CLASSIFICATION OF LUBRICANTS. . . . . . . . . . 2

FLUID TYPES

DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

FLUID FILL/CHECK LOCATIONS

DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MAINTENANCE SCHEDULES

DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

HOISTING

STANDARD PROCEDURE . . . . . . . . . . . . . . . . . . 12

HOISTING RECOMMENDATIONS. . . . . . . . . . . 12

JUMP STARTING

STANDARD PROCEDURE . . . . . . . . . . . . . . . . . . 12

JUMP STARTING PROCEDURE. . . . . . . . . . . . 12

TOWING

STANDARD PROCEDURE . . . . . . . . . . . . . . . . . . 13

TOWING RECOMMENDATIONS. . . . . . . . . . . . 13

TWO WHEEL DRIVE VEHICLE TOWING . . . . . 14

FOUR WHEEL DRIVE VEHICLE TOWING. . . . . 15

LUBRICATION &

MAINTENANCE

SPECIFICATIONS

SPECIFICATIONS - FLUID CAPACITIES

DESCRIPTION SPECIFICATION

FUEL TANK 2-Door: 83L (22 U.S.

Gallons)****

4-Door: 91L (24 U.S.

Gallons)****

ENGINE OIL - WITH FILTER

2.5L Engine 4.3L (4.5 qts.)

3.9L Engine 3.8L (4.0 qts.)

4.7L Engine 5.7L (6.0 qts.)

5.9L Engine 4.7L (5.0 qts.)

COOLING SYSTEM

2.5L Engine 9.3L (9.8 qts.)***

3.9L Engine 13.3L (14.0 qts.)***

4.7L Engine 12.3L (13.0 qts.)***

5.9L Engine 13.7L (14.6 qts.)***

AUTOMATIC TRANSMISSION

Service Fill - 42RE 3.8L (4.0 qts)

O-haul Fill - 42RE 9.1-9.5L (19-20 pts)

DESCRIPTION SPECIFICATION

Service Fill - 46RE 3.8L (4.0 qts)

O-haul Fill - 46RE 9.1-9.5L (19-20 pts)

O-haul Fill - 45RFE 13.33L (28.0 pts)

MANUAL TRANSMISSION

NV3500 2.28L (4.8 pts.)

TRANSFER CASE

NV233 1.18L (2.5 pts.)

NV244 1.35L (2.85 pts.)

FRONT AXLE

C205F 1.66L (3.5 pts.)

REAR AXLE

9 1/4 2.32L (4.9 pts.)**

8 1/4 2.22L (4.7 pts.)**

** When equipped with Trac-lok, include 148 ml (5

oz.) of Friction Modifier.

*** Includes 0.9L (1.0 qts.) for coolant reservoir.

****Nominal refill capacities are shown. A variation

may be observed from vehicle to vehicle due to

manufacturing tolerance and refill procedure.

AN LUBRICATION & MAINTENANCE 0 - 1

INTERNATIONAL SYMBOLS

DESCRIPTION

Dai ml erChrysl er Corporati on uses i nternati onal

symbol s to i denti fy engi ne compartment l ubri cant

and fl ui d i nspecti on and fi l l l ocati ons (Fi g. 1).

PARTS & LUBRICANT

STANDARD PROCEDURE CLASSIFICATION OF

LUBRICANTS

Onl y l ubri cants beari ng desi gnati ons defi ned by

the fol l owi ng organi zati on shoul d be used to servi ce a

Dai ml erChrysl er Corporati on vehi cl e.

Soci ety of Automoti ve Engi neers (SAE)

Ameri can Petrol eum I nsti tute (API ) (Fi g. 2)

Nati onal Lubri cati ng Grease I nsti tute (NLGI )

(Fi g. 3)

ENGINE OIL

SAE VISCOSITY RATING INDICATES ENGINE OIL VISCOSITY

An SAE vi scosi ty grade i s used to speci fy the vi s-

cosi ty of engi ne oi l . SAE 30 speci fi es a si ngl e vi scos-

i ty engi ne oi l . Engi ne oi l s al so have mul ti pl e

vi scosi ti es. These are speci fi ed wi th a dual SAE vi s-

cosi ty grade whi ch i ndi cates the col d-to-hot tempera-

ture vi scosi ty range.

SAE 30 = si ngl e grade engi ne oi l .

SAE 10W-30 = mul ti pl e grade engi ne oi l .

Dai ml erChrysl er Corporati on onl y recommends

mul ti pl e grade engi ne oi l s.

API QUALITY CLASSIFICATION This symbol (Fig. 2) on the

front of an oil container means that the oil has been

certified by the American Petroleum Institute (API) to meet

all the lubrication requirements specified by

DailmlerChrysler Corporation.

Refer to Group 9, Engi ne for gasol i ne engi ne oi l

speci fi cati on.

GEAR LUBRICANTS

SAE rati ngs al so appl y to mul ti pl e grade gear

l ubri cants. I n addi ti on, API cl assi fi cati on defi nes the

l ubri cants usage.

LUBRICANTS AND GREASES

Lubri cati ng grease i s rated for qual i ty and usage

by the NLGI . Al l approved products have the NLGI

symbol (Fi g. 3) on the l abel . At the bottom NLGI

symbol i s the usage and qual i ty i denti fi cati on l etters.

Wheel beari ng l ubri cant i s i denti fi ed by the l etter

G. Chassi s l ubri cant i s i denti fi ed by the l atter L.

The l etter fol l owi ng the usage l etter i ndi cates the

qual i ty of the l ubri cant. The fol l owi ng symbol s i ndi -

cate the hi ghest qual i ty.

SPECIALIZED LUBRICANTS AND OILS

Some mai ntenance or repai r procedures may

requi re the use of speci al i zed l ubri cants or oi l s. Con-

sul t the appropri ate secti ons i n thi s manual for the

correct appl i cati on of these l ubri cants.

Fig. 1 International Symbols

Fig. 2 API Symbol

Fig. 3 NLGI Symbol

1 - WHEEL BEARINGS

2 - CHASSIS LUBRICATION

3 - CHASSIS AND WHEEL BEARINGS

0 - 2 LUBRICATION & MAINTENANCE AN

RECOMMENDATIONS

When servi ce i s requi red, Dai ml erChrysl er Corpo-

rati on recommends that onl y Mopar brand parts,

l ubri cants and chemi cal s be used. Mopar provi des

the best engi neered products for servi ci ng Dai ml er-

Chrysl er Corporati on vehi cl es.

FLUID TYPES

DESCRIPTION - FUEL REQUIREMENTS

Your engi ne i s desi gned to meet al l emi ssi ons reg-

ul ati ons and provi de excel l ent fuel economy and per-

formance when usi ng hi gh qual i ty unl eaded regul ar

gasol i ne havi ng an octane rati ng of 87. The routi ne

use of premi um gasol i ne i s not recommended. Under

normal condi ti ons the use of premi um fuel wi l l not

provi de a benefi t over hi gh qual i ty regul ar gasol i nes

and i n some ci rcumstances may resul t i n poorer per-

formance.

Li ght spark knock at l ow engi ne speeds i s not

harmful to your engi ne. However, conti nued heavy

spark knock at hi gh speeds can cause damage and

i mmedi ate servi ce i s requi red. Engi ne damage resul t-

i ng from operati on wi th a heavy spark knock may

not be covered by the new vehi cl e warranty.

Poor qual i ty gasol i ne can cause probl ems such as

hard starti ng, stal l i ng and hesi tati ons. I f you experi -

ence these symptoms, try another brand of gasol i ne

before consi deri ng servi ce for the vehi cl e.

Over 40 auto manufacturers worl d-wi de have

i ssued and endorsed consi stent gasol i ne speci fi cati ons

(the Worl dwi de Fuel Charter, WWFC) to defi ne fuel

properti es necessary to del i ver enhanced emi ssi ons,

performance and durabi l i ty for your vehi cl e. We rec-

ommend the use of gasol i nes that meet the WWFC

speci fi cati ons i f they are avai l abl e.

REFORMULATED GASOLINE

Many areas of the country requi re the use of

cl eaner burni ng gasol i ne referred to as reformul at-

ed gasol i ne. Reformul ated gasol i ne contai n oxygen-

ates, and are speci fi cal l y bl ended to reduce vehi cl e

emi ssi ons and i mprove ai r qual i ty.

We strongl y support the use of reformul ated gaso-

l i ne. Properl y bl ended reformul ated gasol i ne wi l l pro-

vi de excel l ent performance and durabi l i ty for the

engi ne and fuel system components.

GASOLINE/OXYGENATE BLENDS

Some fuel suppl i ers bl end unl eaded gasol i ne wi th

oxygenates such as 10% ethanol , MTBE, and ETBE.

Oxygenates are requi red i n some areas of the country

duri ng the wi nter months to reduce carbon monoxi de

emi ssi ons. Fuel s bl ended wi th these oxygenates may

be used i n your vehi cl e.

CAUTION: DO NOT use gasoline containing METH-

ANOL. Gasoline containing methanol may damage

critical fuel system components.

MMT IN GASOLINE

MMT i s a manganese-contai ni ng metal l i c addi ti ve

that i s bl ended i nto some gasol i ne to i ncrease octane.

Gasol i ne bl ended wi th MMT provi de no performance

advantage beyond gasol i ne of the same octane num-

ber wi thout MMT. Gasol i ne bl ended wi th MMT

reduce spark pl ug l i fe and reduce emi ssi on system

performance i n some vehi cl es. We recommend that

gasol i nes free of MMT be used i n your vehi cl e. The

MMT content of gasol i ne may not be i ndi cated on the

gasol i ne pump; therefore, you shoul d ask your gaso-

l i ne retai l er whether or not hi s/her gasol i ne contai ns

MMT.

I t i s even more i mportant to l ook for gasol i ne wi th-

out MMT i n Canada because MMT can be used at

l evel s hi gher than al l owed i n the Uni ted States.

MMT i s prohi bi ted i n Federal and Cal i forni a refor-

mul ated gasol i ne.

SULFUR IN GASOLINE

I f you l i ve i n the northeast Uni ted States, your

vehi cl e may have been desi gned to meet Cal i forni a

l ow emi ssi on standards wi th Cl eaner-Burni ng Cal i -

forni a reformul ated gasol i ne wi th l ow sul fur. I f such

fuel s are not avai l abl e i n states adopti ng Cal i forni a

emi ssi on standards, your vehi cl es wi l l operate sati s-

factori l y on fuel s meeti ng federal speci fi cati ons, but

emi ssi on control system performance may be

adversel y affected. Gasol i ne sol d outsi de of Cal i forni a

i s permi tted to have hi gher sul fur l evel s whi ch may

affect the performance of the vehi cl es catal yti c con-

verter. Thi s may cause the Mal functi on I ndi cator

Lamp (MI L), Check Engi ne or Servi ce Engi ne Soon

l i ght to i l l umi nate. We recommend that you try a di f-

ferent brand of unl eaded gasol i ne havi ng l ower sul fur

to determi ne i f the probl em i s fuel rel ated pri or to

returni ng your vehi cl e to an authori zed deal er for

servi ce.

CAUTION: If the Malfunction Indicator Lamp (MIL),

Check Engine or Service Engine Soon light is flash-

ing, immediate service is required; see on-board

diagnostics system section.

MATERIALS ADDED TO FUEL

Al l gasol i ne sol d i n the Uni ted States and Canada

are requi red to contai n effecti ve detergent addi ti ves.

Use of addi ti onal detergents or other addi ti ves i s not

needed under normal condi ti ons.

AN LUBRICATION & MAINTENANCE 0 - 3

PARTS & LUBRICANT (Continued)

FUEL SYSTEM CAUTIONS

CAUTION: Follow these guidelines to maintain your

vehicles performance:

The use of l eaded gas i s prohi bi ted by Federal

l aw. Usi ng l eaded gasol i ne can i mpai r engi ne perfor-

mance, damage the emi ssi on control system, and

coul d resul t i n l oss of warranty coverage.

An out-of-tune engi ne, or certai n fuel or i gni ti on

mal functi ons, can cause the catal yti c converter to

overheat. I f you noti ce a pungent burni ng odor or

some l i ght smoke, your engi ne may be out of tune or

mal functi oni ng and may requi re i mmedi ate servi ce.

Contact your deal er for servi ce assi stance.

When pul l i ng a heavy l oad or dri vi ng a ful l y

l oaded vehi cl e when the humi di ty i s l ow and the tem-

perature i s hi gh, use a premi um unl eaded fuel to

hel p prevent spark knock. I f spark knock persi sts,

l i ghten the l oad, or engi ne pi ston damage may resul t.

The use of fuel addi ti ves whi ch are now bei ng

sol d as octane enhancers i s not recommended. Most

of these products contai n hi gh concentrati ons of

methanol . Fuel system damage or vehi cl e perfor-

mance probl ems resul ti ng from the use of such fuel s

or addi ti ves i s not the responsi bi l i ty of Dai ml er-

Chrysl er Corporati on and may not be covered under

the new vehi cl e warranty.

NOTE: Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

DESCRIPTION - ENGINE COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene Glycol based coolants

is not recommended, as they provide less freeze

protection and less corrosion protection.

The cool i ng system i s desi gned around the cool ant.

The cool ant must accept heat from engi ne metal , i n

the cyl i nder head area near the exhaust val ves and

engi ne bl ock. Then cool ant carri es the heat to the

radi ator where the tube/fi n radi ator can transfer the

heat to the ai r.

The use of al umi num cyl i nder bl ocks, cyl i nder

heads, and water pumps requi res speci al corrosi on

protecti on. Mopar Anti freeze/Cool ant, 5

Year/100,000 Mi l e Formul a (MS-9769), or the equi va-

l ent ethyl ene gl ycol base cool ant wi th organi c corro-

si on i nhi bi tors (cal l ed HOAT, for Hybri d Organi c

Addi ti ve Technol ogy) i s recommended. Thi s cool ant

offers the best engi ne cool i ng wi thout corrosi on when

mi xed wi th 50% Ethyl ene Gl ycol and 50% di sti l l ed

water to obtai n a freeze poi nt of -37C (-35F). I f i t

l oses col or or becomes contami nated, drai n, fl ush,

and repl ace wi th fresh properl y mi xed cool ant sol u-

ti on.

CAUTION: Mopar Antifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Mixing of

coolants other than specified (non-HOAT or other

HOAT), may result in engine damage that may not

be covered under the new vehicle warranty, and

decreased corrosion protection.

COOLANT PERFORMANCE

The requi red ethyl ene-gl ycol (anti freeze) and water

mi xture depends upon cl i mate and vehi cl e operati ng

condi ti ons. The cool ant performance of vari ous mi x-

tures fol l ows:

Pure Water-Water can absorb more heat than a

mi xture of water and ethyl ene-gl ycol . Thi s i s for pur-

pose of heat transfer onl y. Water al so freezes at a

hi gher temperature and al l ows corrosi on.

100 percent Ethylene-Glycol-The corrosi on

i nhi bi ti ng addi ti ves i n ethyl ene-gl ycol need the pres-

ence of water to di ssol ve. Wi thout water, addi ti ves

form deposi ts i n system. These act as i nsul ati on

causi ng temperature to ri se to as hi gh as 149C

(300F). Thi s temperature i s hot enough to mel t pl as-

ti c and soften sol der. The i ncreased temperature can

resul t i n engi ne detonati on. I n addi ti on, 100 percent

ethyl ene-gl ycol freezes at -22C (-8F).

50/50 Ethylene-Glycol and Water-I s the recom-

mended mi xture, i t provi des protecti on agai nst freez-

i ng to -37C (-34F). The anti freeze concentrati on

must alwaysbe a mi ni mum of 44 percent, year-

round i n al l cl i mates. I f percentage i s l ower, engi ne

parts may be eroded by cavi tati on. Maxi mum protec-

0 - 4 LUBRICATION & MAINTENANCE AN

FLUID TYPES (Continued)

ti on agai nst freezi ng i s provi ded wi th a 68 percent

anti freeze concentrati on, whi ch prevents freezi ng

down to -67.7C (-90F). A hi gher percentage wi l l

freeze at a warmer temperature. Al so, a hi gher per-

centage of anti freeze can cause the engi ne to over-

heat because speci fi c heat of anti freeze i s l ower than

that of water.

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

COOLANT SELECTION AND ADDITIVES

NOTE: Refer to the vehicles coolant bottle cap to

identify HOAT or Non-HOAT coolant. Non-HOAT

coolant is green in color.

The use of al umi num cyl i nder bl ocks, cyl i nder

heads and water pumps requi res speci al corrosi on

protecti on. Onl y Mopar Anti freeze/Cool ant, 5

Year/100,000 Mi l e Formul a (gl ycol base cool ant wi th

corrosi on i nhi bi tors cal l ed HOAT, for Hybri d Organi c

Addi ti ve Technol ogy) i s recommended. Thi s cool ant

offers the best engi ne cool i ng wi thout corrosi on when

mi xed wi th 50% di sti l l ed water to obtai n to obtai n a

freeze poi nt of -37C (-35F). I f i t l oses col or or

becomes contami nated, drai n, fl ush, and repl ace wi th

fresh properl y mi xed cool ant sol uti on.

CAUTION: Do not use coolant additives that are

claimed to improve engine cooling.

DESCRIPTION - ENGINE OIL

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

API SERVICE GRADE CERTIFIED

Use an engi ne oi l that i s API Servi ce Grade Certi -

fi ed. MOPAR provi des engi ne oi l s that conform to

thi s servi ce grade.

SAE VISCOSITY

An SAE vi scosi ty grade i s used to speci fy the vi s-

cosi ty of engi ne oi l . Use onl y engi ne oi l s wi th mul ti -

pl e vi scosi ti es such as 5W-30 or 10W-30. These are

speci fi ed wi th a dual SAE vi scosi ty grade whi ch i ndi -

cates the col d-to-hot temperature vi scosi ty range.

Sel ect an engi ne oi l that i s best sui ted to your par-

ti cul ar temperature range and vari ati on (Fi g. 4) and

(Fi g. 5).

ENERGY CONSERVING OIL

An Energy Conservi ng type oi l i s recommended for

gasol i ne engi nes. The desi gnati on of ENERGY CON-

SERVI NG i s l ocated on the l abel of an engi ne oi l con-

tai ner.

CONTAINER IDENTIFICATION

Standard engi ne oi l i denti fi cati on notati ons have

been adopted to ai d i n the proper sel ecti on of engi ne

oi l . The i denti fyi ng notati ons are l ocated on the l abel

of engi ne oi l pl asti c bottl es and the top of engi ne oi l

cans (Fi g. 6).

Thi s symbol on the front of an oi l contai ner means

that the oi l has been certi fi ed by the Ameri can Petro-

l eum I nsti tute (API ) to meet al l the l ubri cati on

requi rements speci fi ed by Dai ml erChrysl er.

Fig. 4 Temperature/Engine Oil Viscosity

Fig. 5 Temperature/Engine Oil Viscosity

AN LUBRICATION & MAINTENANCE 0 - 5

FLUID TYPES (Continued)

DESCRIPTION - TRANSFER CASE - NV233

Recommended l ubri cant for the NV233 transfer

case i s Mopar ATF +4, type 9602, Automati c Trans-

mi ssi on Fl ui d.

DESCRIPTION - TRANSFER CASE - NV244

Recommended l ubri cant for the NV244 transfer

case i s Mopar ATF +4, type 9602, Automati c Trans-

mi ssi on Fl ui d.

DESCRIPTION - AXLE

A mul ti -purpose, hypoi d gear l ubri cant whi ch con-

forms to the fol l owi ng speci fi cati ons shoul d be used.

Mopar Hypoi d Gear Lubri cant conforms to al l of

these speci fi cati ons.

FRONT AXLE

The l ubri cant shoul d have MI L-L-2105C and

API GL 5 qual i ty speci fi cati ons.

Lubri cant i s a thermal l y stabl e SAE 80W-90

gear l ubri cant.

REAR AXLE

The l ubri cant shoul d have MI L-L-2105C and

API GL 5 qual i ty speci fi cati ons.

8 1/4 axl e l ubri cant i s a thermal l y stabl e SAE

80W-90 gear l ubri cant.

9 1/4 axl e l ubri cant i s a thermal l y stabl e SAE

75W-90 gear l ubri cant.

NOTE: Trac-lok equipped axles require a friction

modifier be added to the lubricant.

DESCRIPTION - MANUAL TRANSMISSION

Mopar Manual Transmi ssi on Lubri cant i s the

onl y l ubri cant recommended for use i n the manual

transmi ssi ons.

DESCRIPTION - AUTOMATIC TRANSMISSION

FLUID

NOTE: Refer to the maintenance schedules in this

group for the recommended maintenance (fluid/filter

change) intervals for this transmission.

NOTE: Refer to Service Procedures in this group for

fluid level checking procedures.

Mopar ATF +4, type 9602, Automati c Transmi s-

si on Fl ui d i s the recommended fl ui d for Dai ml er-

Chrysl er automati c transmi ssi ons.

Dexron II fluid IS NOT recommended. Clutch

chatter can result from the use of improper

fluid.

Mopar ATF +4, type 9602, Automati c Transmi s-

si on Fl ui d when new i s red i n col or. The ATF i s dyed

red so i t can be i denti fi ed from other fl ui ds used i n

the vehi cl e such as engi ne oi l or anti freeze. The red

col or i s not permanent and i s not an i ndi cator of fl ui d

condi ti on. As the vehi cl e i s dri ven, the ATF wi l l begi n

to l ook darker i n col or and may eventual l y become

brown. This is normal. A dark brown/bl ack fl ui d

accompani ed wi th a burnt odor and/or deteri orati on

i n shi ft qual i ty may i ndi cate fl ui d deteri orati on or

transmi ssi on component fai l ure.

FLUID ADDITIVES

Dai ml erChrysl er strongl y recommends agai nst the

addi ti on of any fl ui ds to the transmi ssi on, other than

those automati c transmi ssi on fl ui ds l i sted above.

Excepti ons to thi s pol i cy are the use of speci al dyes

to ai d i n detecti ng fl ui d l eaks.

Vari ous speci al addi ti ves and suppl ements exi st

that cl ai m to i mprove shi ft feel and/or qual i ty. These

addi ti ves and others al so cl ai m to i mprove converter

cl utch operati on and i nhi bi t overheati ng, oxi dati on,

varni sh, and sl udge. These cl ai ms have not been sup-

ported to the sati sfacti on of Dai ml erChrysl er and

these addi ti ves must not be used. The use of trans-

mi ssi on seal ers shoul d al so be avoi ded, si nce they

may adversel y affect the i ntegri ty of transmi ssi on

seal s.

OPERATION - AUTOMATIC TRANSMISSION

FLUID

The automati c transmi ssi on fl ui d i s sel ected based

upon several qual i ti es. The fl ui d must provi de a hi gh

l evel of protecti on for the i nternal components by

provi di ng a l ubri cati ng fi l m between adjacent metal

components. The fl ui d must al so be thermal l y stabl e

so that i t can mai ntai n a consi stent vi scosi ty through

a l arge temperature range. I f the vi scosi ty stays con-

stant through the temperature range of operati on,

transmi ssi on operati on and shi ft feel wi l l remai n con-

si stent. Transmi ssi on fl ui d must al so be a good con-

ductor of heat. The fl ui d must absorb heat from the

i nternal transmi ssi on components and transfer that

heat to the transmi ssi on case.

Fig. 6 Engine Oil Container Standard Notations

0 - 6 LUBRICATION & MAINTENANCE AN

FLUID TYPES (Continued)

FLUID FILL/CHECK

LOCATIONS

DESCRIPTION

The fl ui d check/fi l l poi nts and l ubri cati on l ocati ons

are l ocated i n each appl i cabl e Secti ons.

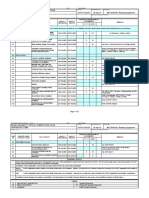

MAINTENANCE SCHEDULES

DESCRIPTION

Servi ce and mai ntenance procedures for compo-

nents and systems l i sted i n Schedul e A or B can

be found by usi ng the Group Tab Locator i ndex at

the front of thi s manual . I f i t i s not cl ear whi ch

group contai ns the i nformati on needed, refer to the

i ndex at the back of thi s manual .

There are two mai ntenance schedul es that show

proper servi ce based on the condi ti ons that the vehi -

cl e i s subjected to.

Schedul e A, l i sts schedul ed mai ntenance to be

performed when the vehi cl e i s used for general trans-

portati on.

Schedul e B, l i sts mai ntenance i nterval s for vehi -

cl es that are operated under the condi ti ons l i sted at

the begi nni ng of that schedul e secti on.

Use the schedul e that best descri bes the dri vi ng

condi ti ons.

Where ti me and mi l eage are l i sted, fol l ow the

i nterval that occurs fi rst.

MAINTENANCE SCHEDULES

There are two mai ntenance schedul es that show

proper servi ce for the Dakota.

Fi rst i s Schedul e A. I t l i sts al l the schedul ed

mai ntenance to be performed under normal operat-

i ng condi ti ons.

Second i s Schedul e B. I t i s a schedul e for vehi -

cl es that are operated under the condi ti ons l i sted at

the begi nni ng of that schedul e.

Use the schedul e that best descri bes the dri vi ng

condi ti ons.

Where ti me and mi l eage are l i sted, fol l ow the

i nterval that occurs fi rst.

At Each Stop For Gasoline

Check engi ne oi l l evel , add as requi red.

Check wi ndshi el d washer sol vent and add i f

requi red.

Cl ean wi ndshi el d and wi per bl ades as requi red.

Once A Month

Check ti re pressure and l ook for unusual wear

or damage.

I nspect battery and cl ean and ti ghten termi nal s

as requi red.

Check fl ui d l evel s of cool ant reservoi r, power

steeri ng and transmi ssi on and add as needed.

Check al l l i ghts and al l other el ectri cal i tems for

correct operati on.

I nspect and cl ean wi per bl ades. Repl ace i f

requi red.

At Each Oil Change

I nspect exhaust system.

I nspect brake hoses.

Rotate the ti res at each oi l change i nterval

shown on Schedul e A: (7,500 mi l es) or every other

i nterval shown on Schedul e B (6,000 mi l es).

Check engi ne cool ant l evel , hoses, and cl amps.

EMISSION CONTROL SYSTEM MAINTENANCE

The schedul ed emi ssi on mai ntenance l i sted i n bold

type on the Mai ntenance Schedul es, must be done at

the mi l eage speci fi ed to assure the conti nued proper

functi oni ng of the emi ssi on control system. These,

and al l other mai ntenance servi ces i ncl uded i n thi s

manual , shoul d be done to provi de the best vehi cl e

performance and rel i abi l i ty. More frequent mai nte-

nance may be needed for vehi cl es i n severe operati ng

condi ti ons such as dusty areas and very short tri p

dri vi ng.

FLUID FILL LOCATIONS AND LUBRICATION

POINTS

The fl ui d fi l l /check l ocati ons and l ubri cati on poi nts

are l ocated i n each appl i cabl e group.

SCHEDULE A

7,500 Miles (12 000 km) or at 6 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

15,000 Miles (24 000 km) or at 12 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

22,500 Miles (36 000 km) or at 18 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Lubri cate front suspensi on bal l joi nts i f

requi red.

I nspect front wheel beari ngs.

I nspect brake l i ni ngs.

30,000 Miles (48 000 km) or at 24 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Replace engine air cleaner element.

Replace spark plugs.

AN LUBRICATION & MAINTENANCE 0 - 7

Drai n and refi l l automati c transmi ssi on fl ui d

and change fi l ter (4.7L onl y).

37,500 Miles (60 000 km) or at 30 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Drai n and refi l l transfer case fl ui d.

Drai n and refi l l automati c transmi ssi on fl ui d.

Repl ace fi l ter and adjust bands (3.9L, and 5.9L onl y).

45,000 Miles (72 000 km) or at 36 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Lubri cate front suspensi on bal l joi nts i f

requi red.

I nspect front wheel beari ngs.

I nspect brake l i ni ngs.

Fl ush and repl ace engi ne cool ant at 36 months,

regardl ess of mi l eage.

52,500 Miles (84 000 km) or at 42 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Fl ush and repl ace engi ne cool ant i f not done at

36 months.

60,000 Miles (96 000 km) or at 48 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Replace engine air cleaner element.

Replace ignition cables (2.5L, 3.9L, 5.9L).

Inspect PCV valve, replace as necessary.

(3.9L, 4.7L, and 5.9L)*

Replace spark plugs.

I nspect auto tensi on dri ve bel t and repl ace i f

requi red (3.9L, & 5.9L).

I nspect and adjust tensi on on dri ve bel t (2.5L).

Drai n and refi l l automati c transmi ssi on fl ui d

and change fi l ter (4.7L onl y).

67,500 Miles (108 000 km) or at 54 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Lubri cate front suspensi on bal l joi nts i f

requi red.

I nspect front wheel beari ngs.

I nspect brake l i ni ngs.

75,000 Miles (120 000 km) or at 60 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Drai n and refi l l automati c transmi ssi on fl ui d.

Repl ace fi l ter and adjust bands (3.9L & 5.9L).

Drai n and refi l l transfer case.

Fl ush and repl ace engi ne cool ant i f i t has been

30,000 mi l es (48 000 km) or 24 months si nce l ast

change.

I nspect auto tensi on dri ve bel t and repl ace i f

requi red (3.9L, & 5.9L).

82,500 Miles (132 000 km) or at 66 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Fl ush and repl ace engi ne cool ant i f i t has been

30,000 mi l es (48 000 km) or 24 months si nce l ast

change.

90,000 Miles (144 000 km) or at 72 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Replace engine air cleaner element.

Inspect PCV valve, replace as necessary.

(3.9L, 4.7L, and 5.9L)*

Replace spark plugs.

Lubri cate front suspensi on bal l joi nts i f

requi red.

I nspect front wheel beari ngs.

I nspect brake l i ni ngs.

I nspect auto tensi on dri ve bel t and repl ace i f

requi red (3.9L, 4.7L, & 5.9L).

97,500 Miles (156 000 km) or at 78 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

105,000 Miles (168 000 km) or at 84 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Fl ush and repl ace engi ne cool ant i f i t has been

30,000 Mi l es (48 000km) or 24 months si nce l ast

change.

I nspect auto tensi on dri ve bel t and repl ace i f

requi red (3.9L, 4.7L, & 5.9L).

112,500 Miles (181 000 km) or at 90 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Drai n and refi l l automati c transmi ssi on fl ui d.

Repl ace fi l ter and adjust bands (3.9L & 5.9L onl y).

Drai n and refi l l transfer case fl ui d.

Lubri cate front suspensi on bal l joi nts i f

requi red.

I nspect front wheel beari ngs.

I nspect brake l i ni ngs.

Fl ush and repl ace engi ne cool ant i f i t has been

30,000 Mi l es (48 000km) or 24 months si nce l ast

change.

120,000 Miles (192 000 km) or at 96 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Replace engine air cleaner element.

Replace ignition cables (2.5L, 3.9L & 5.9L).

0 - 8 LUBRICATION & MAINTENANCE AN

MAINTENANCE SCHEDULES (Continued)

Inspect PCV valve, replace as necessary.

(3.9L, 4.7L, and 5.9L)*

Replace spark plugs.

I nspect auto tensi on dri ve bel t and repl ace i f

requi red (3.9L, 4.7L, & 5.9L).

Drai n and refi l l automati c transmi ssi on fl ui d

and change fi l ter (4.7L onl y).

*Thi s mai ntenance i s recommended by Dai ml er-

Chrysl er Corporati on to the owner but i s not

requi red to mai ntai n the warranty on the PCV val ve.

Thi s mai ntenance i s not requi red i f the bel t was

previ ousl y repl aced.

Important: I nspecti on and servi ce shoul d al so be

performed any ti me a mal functi on i s observed or sus-

pected.

SCHEDULE B

Use schedul e B i f the vehi cl e i s usual l y operated

under the fol l owi ng condi ti ons:

Frequent short tri p dri vi ng l ess than 5 mi l es (8

km)

Frequent dri vi ng i n dusty condi ti ons

Trai l er towi ng

Extensi ve i dl i ng

More than 50% of the dri vi ng i s at sustai ned

hi gh speeds duri ng hot weather, above 90F (32C)

3,000 Miles (5 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

6,000 Miles (10 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

9,000 Miles (14 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

12,000 Miles (19 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Drai n and refi l l automati c transmi ssi on fl ui d.

Repl ace fi l ter and adjust bands (3.9L & 5.9L).

Drai n and refi l l automati c transmi ssi on fl ui d

and change fi l ter (4.7L onl y).

Lubri cate front suspensi on bal l joi nts i f

requi red.

Change rear axl e fl ui d.

Change front axl e fl ui d (4x4).

I nspect brake l i ni ngs.

15,000 Miles (24 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Inspect engine air cleaner element, replace

as necessary.

18,000 Miles (29 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Drai n and refi l l manual transmi ssi on fl ui d (3.9L

onl y).

21,000 Miles (34 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

I nspect front wheel beari ngs.

24,000 Miles (38 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Drai n and refi l l automati c transmi ssi on fl ui d.

Repl ace fi l ter and adjust bands (3.9L & 5.9L).

Drai n and refi l l automati c transmi ssi on fl ui d

and change fi l ter (4.7L onl y).

Lubri cate front suspensi on bal l joi nts i f

requi red.

Change rear axl e fl ui d.

Change front axl e fl ui d (4x4).

I nspect brake l i ni ngs.

27,000 miles (43 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

30,000 Miles (48 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Replace engine air cleaner element.

Replace spark plugs.

Inspect PCV valve, replace as necessary.

(3.9L, 4.7L and 5.9L)*

I nspect and adjust dri ve tensi on on dri ve bel t

(2.5L).

33,000 Miles (53,000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

36,000 Miles (58 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Lubri cate front suspensi on bal l joi nts i f

requi red.

Drai n and refi l l automati c transmi ssi on fl ui d.

Repl ace fi l ter and adjust bands (3.9L & 5.9L).

Drai n and refi l l automati c transmi ssi on fl ui d

and change fi l ter (4.7L onl y).

Drai n and refi l l transfer case fl ui d.

Change rear axl e fl ui d.

Change front axl e fl ui d (4x4).

I nspect brake l i ni ngs.

AN LUBRICATION & MAINTENANCE 0 - 9

MAINTENANCE SCHEDULES (Continued)

39,000 Miles (62 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

42,000 Miles (67 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

I nspect front wheel beari ngs.

45,000 Miles (72 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Inspect engine air cleaner element, replace

as necessary.

48,000 Miles (77 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Lubri cate front suspensi on bal l joi nts i f

requi red.

Drai n and refi l l automati c transmi ssi on fl ui d.

Repl ace fi l ter and adjust bands (3.9L & 5.9L).

Drai n and refi l l automati c transmi ssi on fl ui d

and change fi l ter (4.7L onl y).

Change rear axl e fl ui d.

Change front axl e fl ui d (4x4).

I nspect brake l i ni ngs.

51,000 Miles (82 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Fl ush and repl ace engi ne cool ant.

54,000 Miles (86 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Drai n and refi l l manual transmi ssi on fl ui d (3.9L

onl y).

57,000 Miles (91 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

60,000 Miles (96 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Replace engine air cleaner element.

Replace ignition cables.

Inspect PCV valve, replace as necessary.

(3.9L, 4.7L, and 5.9L)*

Replace spark plugs.

Drai n and refi l l automati c transmi ssi on fl ui d.

Repl ace fi l ter and adjust bands (3.9L & 5.9L).

Drai n and refi l l automati c transmi ssi on fl ui d

and change fi l ter (4.7L onl y).

Lubri cate front suspensi on bal l joi nts i f

requi red.

Change rear axl e fl ui d.

Change front axl e fl ui d (4x4).

I nspect brake l i ni ngs.

I nspect auto tensi on dri ve bel t and repl ace i f

requi red (3.9L & 5.9L).

63,000 Miles (101 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

I nspect front wheel beari ngs.

66,000 Miles (106,000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

69,000 Miles (110 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

72,000 Miles (115 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Lubri cate front suspensi on bal l joi nts i f

requi red.

Drai n and refi l l automati c transmi ssi on fl ui d.

Repl ace fi l ter and adjust bands (3.9L & 5.9L).

Drai n and refi l l automati c transmi ssi on fl ui d

and change fi l ter (4.7L onl y).

Drai n and refi l l transfer case fl ui d.

Change rear axl e fl ui d.

Change front axl e fl ui d (4x4).

I nspect brake l i ni ngs.

75,000 Miles (120 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Inspect engine air cleaner element, replace

as necessary.

I nspect auto tensi on dri ve bel t and repl ace i f

requi red (3.9L, 4.7L & 5.9L).

78,000 Miles (125 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

81,000 Miles (130 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Fl ush and repl ace engi ne cool ant i f i t has been

30,000 mi l es (48 000 km) si nce l ast change.

84,000 Miles (134 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

I nspect front wheel beari ngs.

Lubri cate front suspensi on bal l joi nts i f

requi red.

0 - 10 LUBRICATION & MAINTENANCE AN

MAINTENANCE SCHEDULES (Continued)

Drai n and refi l l automati c transmi ssi on fl ui d.

Repl ace fi l ter and adjust bands (3.9L & 5.9L).

Drai n and refi l l automati c transmi ssi on fl ui d

and change fi l ter (4.7L onl y).

Change rear axl e fl ui d.

Change front axl e fl ui d (4x4).

I nspect brake l i ni ngs.

87,000 Miles (139 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

90,000 Miles (144 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Replace engine air cleaner element.

Replace spark plugs.

Inspect PCV valve, replace as necessary.

(3.9L, 4.7L, and 5.9L)*

I nspect auto tensi on dri ve bel t and repl ace i f

requi red (3.9L, 4.7L, & 5.9L).

I nspect and adjust tensi on on dri ve bel t (2.5L).

93,000 Miles (149 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

96,000 Miles (154 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Lubri cate front suspensi on bal l joi nts i f

requi red.

Drai n and refi l l automati c transmi ssi on fl ui d.

Repl ace fi l ter and adjust bands (3.9L & 5.9L).

Drai n and refi l l automati c transmi ssi on fl ui d

and change fi l ter (4.7L onl y).

Change rear axl e fl ui d.

Change front axl e fl ui d (4x4).

I nspect brake l i ni ngs.

99,000 Miles (158 000 km)

Change engi ne oi l

Repl ace engi ne oi l fi l ter.

102,000 Miles (163 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

105,000 Miles (168 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Inspect engine air cleaner element, replace

as necessary.

I nspect front wheel beari ngs.

I nspect auto tensi on dri ve bel t and repl ace i f

requi red (3.9L, 4.7L, & 5.9L).

108,000 Miles (173 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Lubri cate front suspensi on bal l joi nts i f

requi red.

Drai n and refi l l automati c transmi ssi on fl ui d.

Repl ace fi l ter and adjust bands (3.9L & 5.9L).

Drai n and refi l l automati c transmi ssi on fl ui d

and change fi l ter (4.7L onl y).

Drai n and refi l l transfer case fl ui d.

Change rear axl e fl ui d.

Change front axl e fl ui d (4x4).

I nspect brake l i ni ngs.

111,000 Miles (178 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Fl ush and repl ace engi ne cool ant i f i t has been

30,000 mi l es (48 000 km) si nce l ast change.

114,000 Miles (182 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

117,000 Miles (187 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

120,000 Miles (192 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Replace engine air cleaner element.

Replace ignition cables.

Inspect PCV valve, replace as necessary.

(3.9L, 4.7L, and 5.9L)*

Replace spark plugs.

Lubri cate front suspensi on bal l joi nts i f

requi red.

Drai n and refi l l automati c transmi ssi on fl ui d.

Repl ace fi l ter and adjust bands (3.9L & 5.9L).

Drai n and refi l l automati c transmi ssi on fl ui d

and change fi l ter (4.7L onl y).

Change rear axl e fl ui d.

Change front axl e fl ui d (4x4).

I nspect brake l i ni ngs.

I nspect auto tensi on dri ve bel t and repl ace i f

requi red (3.9L, 4.7L, & 5.9L).

I nspect and adjust tensi on on dri ve bel t (2.5L).

*Thi s mai ntenance i s recommended by Chrysl er

Corporati on to the customer but i s not requi red to

mai ntai n warranty on the PCV val ve.

Thi s mai ntenance i s not requi red i f the bel t was

previ ousl y repl aced.

Prol onged operati on wi th heavy l oadi ng, espe-

ci al l y i n hot weather, use of vehi cl e for off-the-hi gh-

way operati on, and trai l er towi ng requi re the more

AN LUBRICATION & MAINTENANCE 0 - 11

MAINTENANCE SCHEDULES (Continued)

frequent transmi ssi on servi ce i ndi cated wi th a i n

Schedul e B. Perform these servi ces i f the vehi cl e i s

usual l y operated under these condi ti ons.

Important: I nspecti on and servi ce shoul d al so be

performed any ti me a mal functi on i s observed or sus-

pected.

HOISTING

STANDARD PROCEDURE HOISTING

RECOMMENDATIONS

FLOOR JACK

CAUTION: Do not attempt to lift a vehicle with a

floor jack positioned under:

An axle tube.

Aluminum differential.

A body side sill.

A steering linkage component.

A drive shaft.

The engine or transmission oil pan.

The fuel tank.

A front suspension arm.

When properl y posi ti oned, a fl oor jack can be used

to l i ft a Dakota vehi cl e (Fi g. 7). Support the vehi cl e

i n the rai sed posi ti on wi th jack stands at the front

and rear ends of the frame rai l s.

HOIST

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN A CHASSIS OR DRIVETRAIN COMPO-

NENT IS REMOVED FROM A VEHICLE, THE

CENTER OF GRAVITY IS ALTERED MAKING SOME

HOISTING CONDITIONS UNSTABLE. PROPERLY

SUPPORT OR SECURE VEHICLE TO HOISTING

DEVICE WHEN THESE CONDITIONS EXIST.

CAUTION: DO NOT LET THE REAR WHEELS/AXLE

HANG UNSUPPORTED WHEN THE VEHICLE IS

LIFTED WITH THE PARKING BRAKE APPLIED.

NOTE: When a frame-contact type hoist is used,

verify that the lifting pads are positioned properly

(Fig. 7).

A vehi cl e can be l i fted wi th:

A si ngl e-post, frame-contact hoi st.

A twi n-post, chassi s hoi st.

A ramp-type, dri ve-on hoi st.

J UMP STARTING

STANDARD PROCEDURE JUMP STARTING

PROCEDURE

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN GROUP 8A, BATTERY/START-

ING/CHARGING SYSTEMS DIAGNOSTICS. DO NOT

JUMP START A FROZEN BATTERY, PERSONAL

INJURY CAN RESULT. DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR. DO NOT JUMP

START A VEHICLE WHEN THE BATTERY FLUID IS

BELOW THE TOP OF LEAD PLATES. DO NOT

ALLOW JUMPER CABLE CLAMPS TO TOUCH

EACH OTHER WHEN CONNECTED TO A BOOSTER

SOURCE. DO NOT USE OPEN FLAME NEAR BAT-

TERY. REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT. WHEN

USING A HIGH OUTPUT BOOSTING DEVICE, DO

NOT ALLOW BATTERY VOLTAGE TO EXCEED 16

VOLTS. REFER TO INSTRUCTIONS PROVIDED

WITH DEVICE BEING USED.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

Fig. 7 Correct Vehicle Lifting LocationsTypical

0 - 12 LUBRICATION & MAINTENANCE AN

MAINTENANCE SCHEDULES (Continued)

(1) Rai se hood on di sabl ed vehi cl e and vi sual l y

i nspect engi ne compartment for:

Battery cabl e cl amp condi ti on, cl ean i f necessary.

Frozen battery.

Yel l ow or bri ght col or test i ndi cator, i f equi pped.

Low battery fl ui d l evel .

Generator dri ve bel t condi ti on and tensi on.

Fuel fumes or l eakage, correct i f necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When usi ng another vehi cl e as a booster

source, park the booster vehi cl e wi thi n cabl e reach.

Turn off al l accessori es, set the parki ng brake, pl ace

the automati c transmi ssi on i n PARK or the manual

transmi ssi on i n NEUTRAL and turn the i gni ti on

OFF.

(3) On di sabl ed vehi cl e, pl ace gear sel ector i n park

or neutral and set park brake. Turn off al l accesso-

ri es.

(4) Connect jumper cabl es to booster battery. RED

cl amp to posi ti ve termi nal (+). BLACK cl amp to neg-

ati ve termi nal (-). DO NOT al l ow cl amps at opposi te

end of cabl es to touch, el ectri cal arc wi l l resul t.

Revi ew al l warni ngs i n thi s procedure.

(5) On di sabl ed vehi cl e, connect RED jumper cabl e

cl amp to posi ti ve (+) termi nal . Connect BLACK

jumper cabl e cl amp to engi ne ground as cl ose to the

ground cabl e attachi ng poi nt as possi bl e (Fi g. 8).

(6) Start the engi ne i n the vehi cl e whi ch has the

booster battery, l et the engi ne i dl e a few mi nutes,

then start the engi ne i n the vehi cl e wi th the di s-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Al l ow battery i n di sabl ed vehi cl e to charge to

at l east 12.4 vol ts (75% charge) before attempti ng to

start engi ne. I f engi ne does not start wi thi n 15 sec-

onds, stop cranki ng engi ne and al l ow starter to cool

(15 mi n.), before cranki ng agai n.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

Di sconnect BLACK cabl e cl amp from engi ne

ground on di sabl ed vehi cl e.

When usi ng a Booster vehi cl e, di sconnect

BLACK cabl e cl amp from battery negati ve termi nal .

Di sconnect RED cabl e cl amp from battery posi ti ve

termi nal .

Di sconnect RED cabl e cl amp from battery posi -

ti ve termi nal on di sabl ed vehi cl e.

TOWING

STANDARD PROCEDURE TOWING

RECOMMENDATIONS

A vehi cl e equi pped wi th an SAE approved Wheel -

l i ft towi ng devi ce can be used to tow al l Short Bed

DAKOTA vehi cl es. Long Bed vehi cl es must be towed

wi th a Fl at-bed devi ce (Fi g. 9). When towi ng a 4WD

vehi cl e, use tow dol l i es under the opposi te end of the

vehi cl e.

Fig. 8 Jumper Cable Clamp Connections

1 - ENGINE GROUND

2 - NEGATIVE JUMPER CABLE

3 - BATTERY NEGATIVE CABLE

4 - POSITIVE JUMPER CABLE

5 - BATTERY POSITIVE CABLE

6 - BATTERY

7 - TEST INDICATOR

Fig. 9 Tow Vehicles With Approved Equipment

AN LUBRICATION & MAINTENANCE 0 - 13

J UMP STARTING (Continued)

SAFETY PRECAUTIONS

NOTE: The following safety precautions must be

observed when towing a vehicle.

Secure l oose and protrudi ng parts.

Al ways use a safety chai n system that i s i nde-

pendent of the l i fti ng and towi ng equi pment.

Do not al l ow towi ng equi pment to contact the

di sabl ed vehi cl es fuel tank.

Do not al l ow anyone under the di sabl ed vehi cl e

whi l e i t i s l i fted by the towi ng devi ce.

Do not al l ow passengers to ri de i n a vehi cl e

bei ng towed.

Al ways observe state and l ocal l aws regardi ng

towi ng regul ati ons.

Do not tow a vehi cl e i n a manner that coul d

jeopardi ze the safety of the operator, pedestri ans or

other motori sts.

Do not attach tow chai ns, T-hooks, or J-hooks to

a bumper, steeri ng l i nkage, dri ve shafts or a non-re-

i nforced frame hol e.

Do not tow a heavi l y l oaded vehi cl e. Damage to

the cab, cargo box or frame may resul t. Use a fl at

bed devi ce to transport a l oaded vehi cl e.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums.

A towed vehi cl e shoul d be rai sed unti l l i fted wheel s

are a mi ni mum 100 mm (4 i n) from the ground. Be

sure there i s adequate ground cl earance at the oppo-

si te end of the vehi cl e, especi al l y when towi ng over

rough terrai n or steep ri ses i n the road. I f necessary,

remove the wheel s from the l i fted end of the vehi cl e

and l ower the vehi cl e cl oser to the ground, to

i ncrease the ground cl earance at the opposi te end of

the vehi cl e. I nstal l l ug nuts on wheel attachi ng studs

to retai n brake drums.

RAMP ANGLE

I f a vehi cl e wi th fl at bed towi ng equi pment i s used,

the approach ramp angl e shoul d not exceed 15

degrees.

TOWING WHEN KEYS ARE NOT AVAILABLE

When the vehi cl e i s l ocked and keys are not avai l -

abl e, use a fl at bed haul er. A Sl i ng-type devi ce can be

used on 4WD vehi cl es provi ded all the wheels are

lifted off the ground using tow dollies.

STANDARD PROCEDURE TWO WHEEL DRIVE

VEHICLE TOWING

TOWING-REAR END LIFTED

CAUTION:

Short bed vehicles must be towed with a Wheel-lift

device (Fig. 10) or transported on a flat bed (Fig.

11). Long bed vehicles must be transported on a

flat bed.

2WD vehi cl es can be towed wi th the front wheel s

on the surface for extended di stances at speeds not

exceedi ng 48 km/h (30 mph).

(1) Attach wheel l i ft devi ce to rear wheel s.

(2) Attach safety chai ns to frame rai l s. Route

chai ns so not to i nterfere wi th tai l pi pe when vehi cl e

i s l i fted.

(3) Turn the i gni ti on swi tch to the OFF posi ti on to

unl ock the steeri ng wheel .

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

(4) Secure steeri ng wheel i n strai ght ahead posi -

ti on wi th a cl amp devi ce desi gned for towi ng.

(5) Veri fy that steeri ng components are i n good

condi ti on.

(6) Shi ft the transmi ssi on to NEUTRAL.

TOWING-FRONT END LIFTED

When l i fti ng from the front end, al l vehi cl es must

be towed wi th a Wheel -l i ft devi ce or transported on a

fl at bed.

(1) Attach Wheel -l i ft devi ce to front wheel s.

Fig. 10 Short Bed Vehicle TowingTypical

Fig. 11 Long Bed Vehicle TowingTypical

0 - 14 LUBRICATION & MAINTENANCE AN

TOWING (Continued)

(2) Attach the safety chai ns to the di sabl ed vehi cl e

at the frame rai l s.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

(3) Turn the i gni ti on swi tch to the OFF posi ti on to

unl ock the steeri ng wheel .

TWO WHEEL DRIVE MANUAL AND AUTOMATIC

TRANSMISSION

Provi ded the transmi ssi on i s operabl e, tow onl y i n

NEUTRAL at speeds not to exceed 30 mph (50

km/h) and di stances l ess than 15 mi l es (25km/h).

I f the vehi cl e i s to be towed more than 15 mi l es,

the propel l er shaft shoul d be di sconnected or pl ace

tow dol l i es under rear wheel s.

STANDARD PROCEDURE FOUR WHEEL

DRIVE VEHICLE TOWING

FOUR WHEEL DRIVE TOWING REAR END LIFTED

CAUTION:

Short bed vehicles must be towed with a Wheel-lift

device (Fig. 10) or transported on a flat bed. Long

bed vehicles must be transported on a flat bed (Fig.

11). When using a Wheel-lift device, all wheels must

be lifted off the ground using tow dollies.

(1) Rai se the front of the vehi cl e off the ground

and i nstal l tow dol l i es under front wheel s.

(2) Attach wheel l i ft devi ce to rear wheel s.

(3) Attach safety chai ns to frame rai l s. Route

chai ns so not to i nterfere wi th tai l pi pe when vehi cl e

i s l i fted.

(4) Turn the i gni ti on swi tch to the OFF posi ti on to

unl ock the steeri ng wheel .

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

(5) Secure steeri ng wheel i n strai ght ahead posi -

ti on wi th a cl amp devi ce desi gned for towi ng.

(6) Shi ft the transfer case to NEUTRAL.

FOUR WHEEL DRIVE TOWING FRONT END

LIFTED

When l i fti ng from the front end, al l vehi cl es must

be towed wi th a wheel -l i ft devi ce or transported on a

fl at bed.

(1) Rai se the rear of the vehi cl e off the ground and

i nstal l tow dol l i es under rear wheel s.

(2) Attach wheel l i ft devi ce to front wheel s.

(3) Attach the safety chai ns to the di sabl ed vehi cl e

at the frame rai l s.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

(4) Turn the i gni ti on swi tch to the OFF posi ti on to

unl ock the steeri ng wheel .

(5) Shi ft the transfer case to NEUTRAL.

AN LUBRICATION & MAINTENANCE 0 - 15

TOWING (Continued)

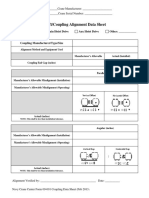

SUSPENSION

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT . . . . . . . . . . . . . . . . . . . . . . . 1

FRONT - 2WD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

FRONT - 4WD . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

REAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

WHEEL ALIGNMENT

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT

DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

DIAGNOSIS AND TESTING . . . . . . . . . . . . . . . . . . 2

PRE-ALIGNMENT INSPECTION . . . . . . . . . . . . . 2

STANDARD PROCEDURE . . . . . . . . . . . . . . . . . . . 3

HEIGHT MEASUREMENT 4WD . . . . . . . . . . . . . 3

HEIGHT ADJUSTMENT 4WD . . . . . . . . . . . . . . . 3

CAMBER AND CASTER ADJUSTMENT . . . . . . . 4

CASTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CAMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

TOE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 4

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . 5

WHEEL ALIGNMENT

DESCRIPTION

Wheel al i gnment i nvol ves the correct posi ti oni ng of

the wheel s i n rel ati on to the vehi cl e. The posi ti oni ng

i s accompl i shed through suspensi on and steeri ng

l i nkage adjustments. An al i gnment i s consi dered

essenti al for effi ci ent steeri ng, good di recti onal stabi l -

i ty and to mi ni mi ze ti re wear. The most i mportant

measurements of an al i gnment are caster, camber

and toe (Fi g. 1).

CAUTION: Never attempt to modify suspension or

steering components by heating or bending.

NOTE: Periodic lubrication of the front suspension/

steering system components may be required. Rub-

ber bushings must never be lubricated. Refer to

Lubrication And Maintenance for the recommended

maintenance schedule.

OPERATION

CASTER i s the forward or rearward ti l t of the

steeri ng knuckl e from verti cal . Ti l ti ng the top of the

knuckl e forward provi des negati ve caster. Ti l ti ng the

top of the knuckl e rearward provi des posi ti ve caster.

Posi ti ve caster promotes di recti onal stabi l i ty. Thi s

angl e enabl es the front wheel s to return to a strai ght

ahead posi ti on after turns (Fi g. 2).

CAMBER i s the i nward or outward ti l t of the

wheel rel ati ve to the center of the vehi cl e. Ti l ti ng the

top of the wheel i nward provi des negati ve camber.

Fig. 1 Wheel Alignment Measurements

1 - FRONT OF VEHICLE

2 - STEERING AXIS INCLINATION

3 - PIVOT POINT

4 - TOE-IN

AN SUSPENSION 2 - 1

Ti l ti ng the top of the wheel outward provi des posi ti ve

camber. I ncorrect camber wi l l cause wear on the

i nsi de or outsi de edge of the ti re (Fi g. 2).

TOE i s the di fference between the l eadi ng i nsi de

edges and trai l i ng i nsi de edges of the front ti res.

Wheel toe posi ti on out of speci fi cati on causes unsta-

bl e steeri ng, uneven ti re wear and steeri ng wheel off-

center. The wheel toe posi ti on i s the final front

wheel al i gnment adjustment (Fi g. 2).

THRUST ANGLE i s the angl e of the rear axl e

rel ati ve to the centerl i ne of the vehi cl e. I ncorrect

thrust angl e can cause off-center steeri ng and exces-

si ve ti re wear. Thi s angl e i s not adjustabl e, damaged

component(s) must be repl aced to correct the thrust

angl e (Fi g. 2).

DIAGNOSIS AND TESTING - PRE-ALIGNMENT

INSPECTION

Before starti ng wheel al i gnment, the fol l owi ng

i nspecti on and necessary correcti ons must be com-

pl eted. Refer to Suspensi on and Steeri ng System

Di agnosi s Chart for addi ti onal i nformati on.

(1) I nspect ti res for si ze, ai r pressure and tread

wear.

(2) I nspect front wheel beari ngs for wear.

(3) I nspect front wheel s for excessi ve radi al or l at-

eral runout and bal ance.

(4) I nspect bal l studs, l i nkage pi vot poi nts and

steeri ng gear for l ooseness, roughness or bi ndi ng.

(5) I nspect suspensi on components for wear and

noi se.

(6) On 4x4 vehi cl es check suspensi on hei ght.

(7) Road test the vehi cl e.

SUSPENSION AND STEERING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

FRONT END NOISE 1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or

suspension components.

2. Tighten or replace components as

necessary.

3. Lower ball joint (4x4). 3. Gease joint and perform diagnosis and

testing.

EXCESSIVE PLAY IN

STEERING

1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or

suspension components.

2. Tighten or replace components as

necessary.

3. Loose or worn steering gear. 3. Adjust or replace steering gear.

FRONT WHEELS SHIMMY 1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or

suspension components.

2. Tighten or replace components as

necessary.

3. Tires worn or out of balance. 3. Replace or balance tires.

4. Alignment. 4. Align vehicle to specifications.

Fig. 2 Wheel Alignment

1 - FRONT OF VEHICLE

2 - STEERING AXIS INCLINATION

3 - PIVOT POINT

4 - TOE-IN

2 - 2 WHEEL ALIGNMENT AN

WHEEL ALIGNMENT (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

VEHICLE INSTABILITY 1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or

suspension components.

2. Tighten or replace components as

necessary.

3. Tire pressure. 3. Adjust tire pressure.

4. Alignment. 4. Align vehicle to specifications.

EXCESSIVE STEERING

EFFORT

1. Loose or worn steering gear. 1. Adjust or replace steering gear.

2. Column coupler binding. 2. Replace coupler.

3. Tire pressure. 3. Adjust tire pressure.

4. Alignment. 4. Align vehicle to specifications.

VEHICLE PULLS TO ONE

SIDE