Professional Documents

Culture Documents

Diecast Defects Manual

Uploaded by

Praveen CoolCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diecast Defects Manual

Uploaded by

Praveen CoolCopyright:

Available Formats

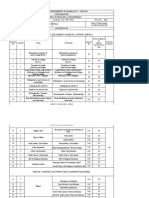

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 1

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 2

CLASSIFICATION OF DEFECTS

Surface defects or

visual defects :

Cold shut

Crack

Drag

Damage

Chip off

Gate blow hole

Shrinkage.

Heat sink mark

Peel off

Blisters

Soldering

Internal defects/ After

machining defects

Blow hole

Inclusion

Pin hole porosity

Non clearance.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 3

Cold shut

Intensifier not put on.

Cycle time more.

Less air spray.

Die

Process

Water leak

Overflow blocked.

Vent blocked

Flash from the die

Machine

Lower metal temperature.

More die coat spray

Less die temperature.

Dragging plunger tip

Low / high first phase velocity

Less/more velocity based on

location

Flash from plunger tip..

Fast shot start position.

Less jumping pressure.

Less Accumulator pressure.

Less / more biscuit thickness.

N2 pressure ~ Acc pressure

Shot not effective.

Man

Material

Low Si content.

Un drossed metal

More diecoat dilution.

High Fe content.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 4

Cold shut

Die

Water leak

Overflow blocked.

Vent blocked

Flash from the die

Crack in insert at

water line area

Water line cut at ejector

pin area

Coating leak from Auto sprayer

Water leak in injection rod

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 5

Die

Water leak

Overflow blocked.

Vent blocked

Flash from the die

Ejector pin broken at overflow area

Over flow gate blocked

Overflow catch up in previous shot

Cold shut

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 6

Die

Water leak

Overflow blocked.

Vent blocked

Flash from the die

Flash catch up at vent

Overflow catch up in previous shot

Cold shut

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 7

Die

Water leak

Overflow blocked.

Vent blocked

Flash from the die

Die matching not proper.

Casting pressure exceeding M/C locking force.

Chill vent area not matching.

Die bulged.

Die Insert is retracted or to the level of housing .

Higher metal temperature.

Worn out toggle link.

Worn out platen shoe.

Cold shut

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 8

More Shot delay time.

More Auto ladle waiting time .

Auto ladle forward speed slow.

Temperature indicator not

working.

Variation in topped metal

temperature.

Coil not working.

No auto switch - on working.

Cold auto ladle.

Cold shut

Process

Lower metal temperature.

Low / high first phase velocity

More die coat spray

Less die temperature.

Dragging plunger tip

Less/more velocity based on

location

Flash from plunger tip..

Fast shot start position.

Loss at

shot sleeve

Loss at

furnace

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 9

Cold shut

Process

Lower metal temperature.

More die coat spray

Less die temperature.

Dragging plunger tip

Low / high first phase velocity

Less/more velocity based on

location

Flash from plunger tip..

Fast shot start position.

More spraying time.

More Quantity of

diecoat spray .

Settling of die coat

.

Time set more

catch up prone area

Less draft area

Less water cooling area

Leaking spray head

More no of nozzles

Application of raw die coat

to avoid catchup

Coat drain hole blocked

Side core area

Horizontal land in die

No effective air spray

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 10

Cold shut

Process

Lower metal temperature.

More die coat spray

Less die temperature.

Dragging plunger tip

Low / high first phase velocity

Less/more velocity based on

location

Flash from plunger tip..

Fast shot start position.

More water cooling

More die coat spray.

Initial startup.

Waterline opened

after stoppage

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 11

Cold shut

Process

Lower metal temperature.

More die coat spray

Less die temperature.

Dragging plunger tip

Low / high first phase velocity

Less/more velocity based on

location

Flash from plunger tip..

Fast shot start position.

Worn out plunger tip.

Worn out shot sleeve.

Less lubricant in plunger tip.

Misalignment between plunger and

injection .

Mismatch between sprue bush and shot

sleeve.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 12

Cold shut

Process

Lower metal temperature.

More die coat spray

Less die temperature.

Dragging plunger tip

Low / high first phase velocity

Less/more velocity based on

location

Flash from plunger tip..

Fast shot start position.

Set in wrong position

Valve getting loosened while runnimg.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 13

Cold shut

Process

Lower metal temperature.

More die coat spray

Less die temperature.

Dragging plunger tip

Low / high first phase velocity

Less/more velocity based on

location

Flash from plunger tip..

Fast shot start position.

Set in wrong position

Limit switch problem

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 14

Cold shut

Process

Lower metal temperature.

More die coat spray

Less die temperature.

Dragging plunger tip

Low / high first phase velocity

Less/more velocity based on

location

Flash from plunger tip..

Fast shot start position.

Wornout plunger tip

Wornout shot sleeve

Wornout sprue bush

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 15

Cold shut

Process

Lower metal temperature.

More die coat spray

Less die temperature.

Dragging plunger tip

Low / high first phase velocity

Less/more velocity based on

location

Flash from plunger tip..

Fast shot start position.

Set wrongly

Poor response from limit switch

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 16

Machine

Less jumping pressure.

Less Accumulator pressure.

Less / more biscuit thickness.

N2 pressure ~ Acc pressure

= 30 kg/cm

2

Shot not effective.

Low nitrogen pressure

Set value not as per standard

Cold shut

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 17

Machine

Less jumping pressure.

Less Accumulator pressure.

Less / more biscuit thickness.

N2 pressure ~ Acc pressure

= 30 kg/cm

2

Shot not effective.

Cold shut

Refer PCM #

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 18

Machine

Less jumping pressure.

Less Accumulator pressure.

Less / more biscuit thickness.

N2 pressure ~ Acc pressure

= 30 kg/cm

2

Shot not effective.

Cold shut

Auto ladle angle variation

Al spill from auto ladle

Cold metal strucjk at nozzle of ladle

Less or more intensification pressure

Loss of Al due to flash from die.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 19

Machine

Less jumping pressure.

Less Accumulator pressure.

Less / more biscuit thickness.

N2 pressure ~ Acc pressure

Shot not effective.

Cold shut

30 Kg/cm

2 (

For eg : If Acc pr = 140

N2 pressure should be 110 Kg/cm

2

)

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 20

Machine

Less jumping pressure.

Less Accumulator pressure.

Less / more biscuit thickness.

N2 pressure ~ Acc pressure

Cold shut

Shot not effective.

Oil in N2 cylinder.

More intensification delay.

Less second phase velocity.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 21

Crack

Die

Process

Soldering in die

Bend ejector plate

Machine

Higher metal temperature.

Less die coat spray

More die temperature.

Biscuit catch up in plunger tip

More gate velocity

Less/More dwell time

More jumping pressure.

Improper machine platen

alignment.

Improper side core sliding.

Die opening speed more. .

Man

Material

Less diecoat dilution.

Low Fe content.

Improper coating

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 22

Crack

Die

Soldering in die

Bend ejector plate

Fe content < 0.8 %

No effective water cooling

Near to gate .

Less die coat spray.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 23

Crack

Process

Higher metal temperature.

Less die coat spray

More die temperature.

Biscuit catch up in plunger tip

More velocity based on

location.

Less/More dwell time

Temperature indicator not

working.

Variation in topped metal

temperature.

No auto switch - on working.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 24

Crack

Process

Higher metal temperature.

Less die coat spray

More die temperature.

Biscuit catch up in plunger tip

More velocity based on

location.

Less/More dwell time

Less spray time

No spray head nozzle focused to

defect

prone area.

Inaccessible area to spray head.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 25

Crack

Process

Higher metal temperature.

Less die coat spray

More die temperature.

Biscuit catch up in plunger tip

More velocity based on

location.

Less/More dwell time

Near to gate area.

No effective water cooling

More wall thickness area.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 26

Crack

Process

Higher metal temperature.

Less die coat spray

More die temperature.

Biscuit catch up in plunger tip

More gate velocity

Less/More dwell time

No water cooling to plunger

tip and sprue bush

Flash in plunger tip.

No forward stroke of

plunger

to push the biscuit.

Length of the plunger tip

less.

Dragging in sprue bush.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 27

Crack

Process

Higher metal temperature.

Less die coat spray

More die temperature.

Biscuit catch up in plunger tip

More gate velocity

Less/More dwell time

More second phase

velocity.

Length of first phase

velocity is below the gate.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 28

Crack

Process

Higher metal temperature.

Less die coat spray

More die temperature.

Biscuit catch up in plunger tip

More gate velocity

Less/More dwell time

More T2 timing setting.

More ejection time after die

opening.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 29

Crack

Machine

More jumping pressure.

Improper machine platen alignment.

Improper side core sliding.

Die opening speed more.

Worn out Toggle links

Worn out platen shoes.

Fixed die platen flexure.

Set value more

Worn out side core guide ways

Worn out core pull rod

Valve setting more.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 30

Drag

Die

Process

Soldering in die

Rough surface after

die polishing

Under cut in die

Heavy heat check

marks

Machine

Higher metal temperature.

Less die coat spray

More die temperature.

More gate velocity

Less/More dwell time

More jumping pressure.

Improper machine platen

alignment.

Die opening speed more.

.

Man

Material

Less diecoat dilution.

Low Fe content.

Improper coating

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 31

Drag

Process

Higher metal temperature.

Less die coat spray

More die temperature.

More gate velocity

Less/More dwell time

Temperature indicator not

working.

Variation in topped metal

temperature.

No auto switch - on working.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 32

Less spray time

No spray head nozzle focused to

defect

prone area.

Inaccessible area to spray head.

Drag

Process

Higher metal temperature.

Less die coat spray

More die temperature.

More gate velocity

Less/More dwell time

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 33

Drag

Process

Higher metal temperature.

Less die coat spray

More die temperature.

More gate velocity

Less/More dwell time

Near to gate area.

No effective water cooling

More wall thickness area.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 34

Drag

Process

Higher metal temperature.

Less die coat spray

More die temperature.

More gate velocity

Less/More dwell time

More second phase

velocity.

Length of first phase

velocity is below the gate.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 35

Drag

Process

Higher metal temperature.

Less die coat spray

More die temperature.

More gate velocity

Less/More dwell time

More T2 timing setting.

More ejection time after die

opening.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 36

Chip off

Die

Process

Catch up in die

Matl projection

in gate.

Machine

Prefilling in Casting.

Low metal temperature.

Ineffective shot

Cold metal from auto ladle

More breaking force

Biscuit catchup in sprue

bush.

Improper trimming.

.

Man

Material

Diecoat matl at gate.

Improper handling of

castings.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 37

Die

Catch up in die

Matl projection

in gate.

Chip off

Less die coat spray

Die chipped off

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 38

Process

Prefilling in Casting.

Low metal temperature.

Ineffective shot

Cold metal from auto ladle

More breaking force

No support in casting

Chip off

First phase velocity ends

beyond the gate

Low die temperature.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 39

Process

Prefilling in Casting.

Low metal temperature.

Ineffective shot

Cold metal from auto ladle

More breaking force

Chip off

More shot delay time

More autoladle waiting time

near shot sleeve

Oxide layer from furnace

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 40

Process

Prefilling in Casting.

Low metal temperature.

Ineffective shot

Cold metal from auto ladle

More breaking force

Chip off

More weight hammer.

Position of holding casting

while breaking.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 41

Process

Prefilling in Casting.

Low metal temperature.

Ineffective shot

Cold metal from auto ladle

More breaking force

Chip off

More Shot delay time.

More Auto ladle waiting time .

Auto ladle forward speed slow.

Temperature indicator not

working.

Variation in topped metal

temperature.

Coil not working.

No auto switch - on working.

Cold auto ladle.

Loss at

shot sleeve

Loss at

furnace

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 42

Process

Prefilling in Casting.

Low metal temperature.

Ineffective shot

Cold metal from auto ladle

More breaking force

Chip off

Oil in N2 cylinder.

More intensification delay.

Less second phase velocity.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 43

Chip off

Machine

Biscuit catchup in sprue

bush.

Improper trimming.

No water cooling to plunger

tip and sprue bush

Flash in plunger tip.

No forward stroke of

plunger

to push the biscuit.

Length of the plunger tip

less.

Dragging in sprue bush.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 44

Chip off

Machine

Biscuit catchup in sprue

bush.

Improper trimming

No proper location for

Casting in trimming die.

Improper alignment of trimming die.

Bend trimming plate.

Bulging in edge of the trimming pin.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 45

Material

Diecoat matl at gate.

Chip off

Less draft

More drag mark area.

Prone to casting catch up.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 46

Peel off

Die

Process

Flash from the die

Less die

temperature

Die surface

roughness

Machine

Oxide layer from metal

Shot blasting current .

Shot blasting time.

Flow marks .

Fast shot starts from gate.

Improper gate velocity.

Intensifer action improper

More second phase velocity

More intensification delay.

.

Man

Material

Less Cu content

More die coat spray

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 47

Peel off

Die

Flash from the die

Less die temperature

Die surface roughness

Die matching not proper.

Casting pressure exceeding M/C locking force.

Chill vent area not matching.

Die bulged.

Die Insert is retracted or to the level of housing .

Higher metal temperature.

Worn out toggle link.

Worn out platen shoe.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 48

Peel off

Die

Flash from the die

Less die temperature

Die surface roughness

More water cooling

More die coat spray.

Initial startup.

Waterline opened

after stoppage

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 49

Peel off

Die

Flash from the die

Less die temperature

Die surface roughness

Soldering in die

Die not serviced after taking

corresponding shots.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 50

Peel off

Process

Oxide layer from metal

Shot blasting current .

Shot blasting time.

Flow marks .

Improper gate velocity.

Fast shot starts from gate.

S1 set value more

More first phase velocity.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 51

Peel off

Process

Oxide layer from metal

Shot blasting current

Shot blasting time.

Flow marks .

Improper gate velocity.

Fast shot starts from gate.

Second phase velocity

More intensification pressure

Block in gate due to cold metal.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 52

Peel off

Process

Oxide layer from metal

Shot blasting current .

Shot blasting time.

Flow marks .

Improper gate velocity.

Fast shot starts from gate.

Metal not cleaned properly

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 53

Peel off

Process

Oxide layer from metal

Shot blasting current .

Shot blasting time.

Flow marks .

Improper gate velocity.

Fast shot starts from gate.

Less shots load to impeller

Filter block.

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 54

Peel off

Process

Oxide layer from metal

Shot blasting current .

Shot blasting time.

Improper gate velocity.

Fast shot starts from gate.

Set timing more

Re shot blasting

Flow marks .

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 55

Peel off

Process

Oxide layer from metal

Shot blasting current .

Shot blasting time.

Improper gate velocity.

Fast shot starts from gate.

Flow marks .

Initial startup water line open

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 56

Machine

Intensifer action improper

More second phase velocity

More intensification delay.

Peel off

Less N2 pressure

PRESSURE DIE CASTING DEFECTS MANUAL

Sheet no : PDCM 57

Machine

Intensifer action improper

More second phase velocity

More intensification delay.

Peel off

Set value more

You might also like

- 10-Qua-15 F01 Deviation Request Format-01.12.2019Document1 page10-Qua-15 F01 Deviation Request Format-01.12.2019Rohit SoniNo ratings yet

- KINIK Catalogue 2018 Us PDFDocument59 pagesKINIK Catalogue 2018 Us PDFAfrianaAghataRahmadiantama0% (1)

- Casting CPDocument2 pagesCasting CPSuraj RawatNo ratings yet

- List of Internal Auditors & Competency - Qms Auditor: For - QMS Audit (ISO 9001:2015)Document1 pageList of Internal Auditors & Competency - Qms Auditor: For - QMS Audit (ISO 9001:2015)Safety DeptNo ratings yet

- Engineering Materials and Metallurgy Notes PDFDocument0 pagesEngineering Materials and Metallurgy Notes PDFSenthilkumar Subbiah50% (2)

- 6.1 Risk - Opportunity AnalysisDocument4 pages6.1 Risk - Opportunity AnalysisSafety DeptNo ratings yet

- Abs - Injection Mould Component Cost EstimationDocument7 pagesAbs - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- An Introduction To ISO/TS 16949:2002: by George TaoDocument91 pagesAn Introduction To ISO/TS 16949:2002: by George Taogerald904640No ratings yet

- IATF16949,2016Document28 pagesIATF16949,2016Vinni WadeNo ratings yet

- Lesson 04 - Environmental AspectsDocument32 pagesLesson 04 - Environmental AspectsAnkit SharmaNo ratings yet

- Polyethylene Bottle Trouble SHooting GuideDocument21 pagesPolyethylene Bottle Trouble SHooting GuideSantino Celedonio100% (1)

- The Quality Improvement Model: Is Process Capable?Document19 pagesThe Quality Improvement Model: Is Process Capable?shafie_buangNo ratings yet

- Audit Checklist 9001 13485 21 CFR 820Document66 pagesAudit Checklist 9001 13485 21 CFR 820Zoli0984100% (5)

- SOP Stack Emission of DG SetsDocument2 pagesSOP Stack Emission of DG SetsPandu BirumakovelaNo ratings yet

- Metric ThreadsDocument35 pagesMetric ThreadsmihaidelianNo ratings yet

- Wholesale & DistributionDocument40 pagesWholesale & DistributionkmagedNo ratings yet

- Reliability Management (Jakarta-Des22)Document87 pagesReliability Management (Jakarta-Des22)Bhaskara AjiNo ratings yet

- Form30TM Advanced Product Quality Planning-APQPDocument1 pageForm30TM Advanced Product Quality Planning-APQPShinichi SuzukiNo ratings yet

- Basic Knowledge of Forging-1Document94 pagesBasic Knowledge of Forging-1UzorNo ratings yet

- Problem Solving Tools: Training Module OnDocument46 pagesProblem Solving Tools: Training Module Onmiso73No ratings yet

- Projects From Unigraphics NX Student ManualDocument34 pagesProjects From Unigraphics NX Student ManualReginato Moschen100% (2)

- 5 S For Shop Floor 01Document52 pages5 S For Shop Floor 01sachinNo ratings yet

- Statistical Process Control: Quality Productivity Management Consultancy (QPMC)Document15 pagesStatistical Process Control: Quality Productivity Management Consultancy (QPMC)Sumeet SainiNo ratings yet

- Pt. NGK Busi Indonesia: Potential End Effect S E VDocument5 pagesPt. NGK Busi Indonesia: Potential End Effect S E VAsrizal asrizal100% (1)

- IBM Insurance IAA Warehouse GIMv85Document23 pagesIBM Insurance IAA Warehouse GIMv85Matthew ReachNo ratings yet

- Forging PDF NotesDocument51 pagesForging PDF Notesaman prasadNo ratings yet

- Aluminium DegassingDocument4 pagesAluminium DegassingJohnNo ratings yet

- Cooper Industries PPAP Manual PDFDocument51 pagesCooper Industries PPAP Manual PDFmuselhakNo ratings yet

- Workflow MCQS For ExamDocument14 pagesWorkflow MCQS For Examphilip abrahamsNo ratings yet

- V3I2IJERTV3IS21239Document5 pagesV3I2IJERTV3IS21239erwindNo ratings yet

- Emd Millipore Contamination Monitoring Product Guide PDFDocument16 pagesEmd Millipore Contamination Monitoring Product Guide PDFManoharar R0% (1)

- QA QC DEPT IntroductionDocument6 pagesQA QC DEPT IntroductionsathiyaprasathNo ratings yet

- Autocad ShortcutsDocument13 pagesAutocad ShortcutsKriscel CaraanNo ratings yet

- Autocad ShortcutsDocument13 pagesAutocad ShortcutsKriscel CaraanNo ratings yet

- Autocad ShortcutsDocument13 pagesAutocad ShortcutsKriscel CaraanNo ratings yet

- 3.annexure 2 Training Manual of Coir Board PDFDocument59 pages3.annexure 2 Training Manual of Coir Board PDFbhuviNo ratings yet

- Impact of Covid-19 On Coir IndustryDocument18 pagesImpact of Covid-19 On Coir IndustryAnand SagarNo ratings yet

- New Operator Training ManualDocument35 pagesNew Operator Training ManualBharat ChakravartinNo ratings yet

- Environment Life Cycle AssessmentDocument4 pagesEnvironment Life Cycle Assessmentshreya royNo ratings yet

- EQ-17 StackDocument6 pagesEQ-17 StackSangam SharmaNo ratings yet

- GM 1927 36 Quality System Basic Marzo 2009 Lpas PDFDocument26 pagesGM 1927 36 Quality System Basic Marzo 2009 Lpas PDFmedi38No ratings yet

- DME Metric ComponentsDocument60 pagesDME Metric ComponentsSyuhadah RashidNo ratings yet

- DME Metric Components PDFDocument60 pagesDME Metric Components PDFSergio OsorioNo ratings yet

- A Guide To Process Capability (CP, CPK) and Process Performance (PP, PPK) - 1factoryDocument10 pagesA Guide To Process Capability (CP, CPK) and Process Performance (PP, PPK) - 1factoryRudra Das100% (1)

- The Sweet Spot To Buy: (Premium Increment) Premium Increase 100 0.90 90Document5 pagesThe Sweet Spot To Buy: (Premium Increment) Premium Increase 100 0.90 90abhijit ghoshNo ratings yet

- NADCA - Aluminum Alloys For Structural Die CastingDocument4 pagesNADCA - Aluminum Alloys For Structural Die CastingFábio CesarNo ratings yet

- Castrol Price List PDFDocument16 pagesCastrol Price List PDFkaushikNo ratings yet

- COPQ Metrics Governance ProcessDocument16 pagesCOPQ Metrics Governance Processarelyta8123No ratings yet

- 5S Audits Check Sheet and Comments Sheet - Issue2Document2 pages5S Audits Check Sheet and Comments Sheet - Issue2PrakashNo ratings yet

- Quality Alert / Flash Note: Photo / Sketch:-Ng Part Photo / Sketch: - Ok PartDocument1 pageQuality Alert / Flash Note: Photo / Sketch:-Ng Part Photo / Sketch: - Ok PartMohit SinghNo ratings yet

- Casting Quality and InspectionDocument11 pagesCasting Quality and InspectionisaacNo ratings yet

- ISO/IEC 17025:2017 Internal Auditor: TUV India Training AcademyDocument1 pageISO/IEC 17025:2017 Internal Auditor: TUV India Training AcademyKamalaNo ratings yet

- Basic Principles of Heat TreatmentDocument4 pagesBasic Principles of Heat TreatmentHarpreet AroraNo ratings yet

- Zero Defects Reference PFMEA IndexDocument2 pagesZero Defects Reference PFMEA IndexMani Rathinam RajamaniNo ratings yet

- Tool Design TerminologyDocument5 pagesTool Design Terminologyanmol6237No ratings yet

- COA Himalayan SaltDocument4 pagesCOA Himalayan SaltMNo ratings yet

- Chemical Compatibility ChartDocument13 pagesChemical Compatibility ChartManuel Mendez GomezNo ratings yet

- Six Sigma Analyse Phase 1Document50 pagesSix Sigma Analyse Phase 1Vinod Yb100% (1)

- Case HardeningDocument28 pagesCase Hardeningdramilt100% (1)

- Rubber Properties Chart PDFDocument1 pageRubber Properties Chart PDFsefaNo ratings yet

- Procedure For New DevelopmentsDocument2 pagesProcedure For New DevelopmentsspdhimanNo ratings yet

- MS-06-117 Tubing Data-Engineered CombinationsDocument6 pagesMS-06-117 Tubing Data-Engineered CombinationsJacques StrappeNo ratings yet

- BoM List of 51 Merged BranchesDocument3 pagesBoM List of 51 Merged BranchesMoneylife Foundation0% (1)

- Final Inspection - Tata Ace DiscDocument3 pagesFinal Inspection - Tata Ace DiscazadNo ratings yet

- Presentation On MSA by TS16949 Auditors From UL IndiaDocument16 pagesPresentation On MSA by TS16949 Auditors From UL Indiavish12321No ratings yet

- 7 QC ToolsDocument8 pages7 QC ToolspremNo ratings yet

- PSWDocument2 pagesPSWLinda G. CordovaNo ratings yet

- Marking Work InstructionDocument1 pageMarking Work InstructionSUBODHHNo ratings yet

- FIR-garments PDFDocument4 pagesFIR-garments PDFTarun PariharNo ratings yet

- Calibration FormatDocument84 pagesCalibration FormatJagjeet SinghNo ratings yet

- Supplier Quality Management A Complete Guide - 2021 EditionFrom EverandSupplier Quality Management A Complete Guide - 2021 EditionNo ratings yet

- CBT UnitII ModDocument18 pagesCBT UnitII ModPraveen CoolNo ratings yet

- 7 Zib Vol2 Issue 1 PDFDocument15 pages7 Zib Vol2 Issue 1 PDFPraveen CoolNo ratings yet

- Workshop Slides SHT 02Document42 pagesWorkshop Slides SHT 02Praveen CoolNo ratings yet

- Ethics in The WorkplaceDocument14 pagesEthics in The WorkplacekiranmesaNo ratings yet

- Component Based Technology 2marksDocument17 pagesComponent Based Technology 2marksjawahar.s100% (1)

- Anti CorruptionDocument41 pagesAnti CorruptionHend AbidNo ratings yet

- Chapter - 3 Composite ManufacturingDocument2 pagesChapter - 3 Composite ManufacturingPraveen CoolNo ratings yet

- The Tsai-Wu Failure CriterionDocument18 pagesThe Tsai-Wu Failure CriterionTeju ThrillsYou100% (1)

- CBT UnitII ModDocument18 pagesCBT UnitII ModPraveen CoolNo ratings yet

- Failure Theories..Document93 pagesFailure Theories..adnanmominNo ratings yet

- Session PlanDocument4 pagesSession PlanPraveen CoolNo ratings yet

- A107411812-Non Conventional Sources of EnergyDocument2 pagesA107411812-Non Conventional Sources of EnergyPraveen CoolNo ratings yet

- CBT UnitiDocument4 pagesCBT UnitiPraveen CoolNo ratings yet

- Composite MaterialsDocument64 pagesComposite MaterialsPraveen CoolNo ratings yet

- A107411812-Non Conventional Sources of EnergyDocument2 pagesA107411812-Non Conventional Sources of EnergyPraveen CoolNo ratings yet

- CATIA V5 Analysis: Design For Real World PerformanceDocument6 pagesCATIA V5 Analysis: Design For Real World Performancemech1212No ratings yet

- AutoDocument20 pagesAutoPraveen CoolNo ratings yet

- Tipsntricks Catiav5-UuidDocument2 pagesTipsntricks Catiav5-UuidPraveen CoolNo ratings yet

- AutoDocument20 pagesAutoPraveen CoolNo ratings yet

- Non Conventional Sources of EnergyDocument8 pagesNon Conventional Sources of EnergyPraveen CoolNo ratings yet

- Non Conventional Sources of EnergyDocument8 pagesNon Conventional Sources of EnergyPraveen CoolNo ratings yet

- A107411812-Non Conventional Sources of Energy (Eee)Document1 pageA107411812-Non Conventional Sources of Energy (Eee)Praveen CoolNo ratings yet

- PPC Organization - Pilani PDFDocument7 pagesPPC Organization - Pilani PDFRavi JainNo ratings yet

- Non Conventional Sources of Energy (Eee)Document8 pagesNon Conventional Sources of Energy (Eee)Praveen CoolNo ratings yet

- 4Document8 pages4Praveen CoolNo ratings yet

- PUREGOLDDocument1 pagePUREGOLDAlwin Glen PapaNo ratings yet

- Consumer Behaviour: Topic 7 Marketing ManagementDocument38 pagesConsumer Behaviour: Topic 7 Marketing ManagementPratik Kumar GhoshNo ratings yet

- Demantra Sales and Operations Planning Fundamentals D55654GC10 - 28 - USDocument2 pagesDemantra Sales and Operations Planning Fundamentals D55654GC10 - 28 - USrichiet2009No ratings yet

- BSR Info Management Supply ChainsDocument12 pagesBSR Info Management Supply Chainsharsh09609003No ratings yet

- Ucmp Detailed PlanDocument13 pagesUcmp Detailed PlanKalai ArasanNo ratings yet

- Chapter 5Document14 pagesChapter 5Cyra JimenezNo ratings yet

- Tactical Marketing Plan (Part of Business Plan)Document5 pagesTactical Marketing Plan (Part of Business Plan)Jevgeni FjodorovNo ratings yet

- Heat Treatment 7Document12 pagesHeat Treatment 7watersoul.nNo ratings yet

- OSM C-1 Prod SysDocument9 pagesOSM C-1 Prod Sysmathurrohit1987No ratings yet

- Business Process ManagementDocument8 pagesBusiness Process ManagementSmart WriterNo ratings yet

- Place and PriceDocument6 pagesPlace and Pricerambo kunNo ratings yet

- Global Marketing: Principles, Insights ChallengesDocument45 pagesGlobal Marketing: Principles, Insights ChallengesAnkit Vohra100% (1)

- Tvi Action CatalogueDocument2 pagesTvi Action CatalogueLloydie LopezNo ratings yet

- Spreadsheet Modeling & Decision Analysis: A Practical Introduction To Management ScienceDocument34 pagesSpreadsheet Modeling & Decision Analysis: A Practical Introduction To Management ScienceAashrith ParvathaneniNo ratings yet

- Kaizen ModelDocument4 pagesKaizen ModelCresel ReposoNo ratings yet

- Business PlanDocument12 pagesBusiness PlanKisshenrau Vijayan ArenaNo ratings yet

- Management and Cost Accounting: Colin DruryDocument18 pagesManagement and Cost Accounting: Colin DruryYasmine MagdiNo ratings yet

- Budgeting Quiz Part 1Document1 pageBudgeting Quiz Part 1Levi AckermanNo ratings yet

- Product Differentiation and ExamplesDocument8 pagesProduct Differentiation and ExamplesApplopediaNo ratings yet

- ETOM ImplementDocument45 pagesETOM ImplementIvanzz coolsNo ratings yet

- Billing PBDocument888 pagesBilling PBRaghu VenkataNo ratings yet

- Cost Chap 6 ContinuationDocument7 pagesCost Chap 6 ContinuationPeter Paul DeiparineNo ratings yet

- Ajay Kumar Dubey April 2023Document2 pagesAjay Kumar Dubey April 2023Ajay DubeyNo ratings yet

- Chap.5. Process Costing - QuestionsDocument10 pagesChap.5. Process Costing - QuestionsLegends CreationNo ratings yet