Professional Documents

Culture Documents

XS-4222 4100XPC Assembly Procedure

Uploaded by

William Quiliche Veraméndez100%(4)100% found this document useful (4 votes)

2K views8 pagesA P&H MinePro Services advisor will be provided for a period of 50 working days. The advisor can provide advice only. The purchaser will be required to provide all tools, equipment and personnel needed to assemble the machine.

Original Description:

Original Title

XS-4222 4100XPC Assembly Procedure (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA P&H MinePro Services advisor will be provided for a period of 50 working days. The advisor can provide advice only. The purchaser will be required to provide all tools, equipment and personnel needed to assemble the machine.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(4)100% found this document useful (4 votes)

2K views8 pagesXS-4222 4100XPC Assembly Procedure

Uploaded by

William Quiliche VeraméndezA P&H MinePro Services advisor will be provided for a period of 50 working days. The advisor can provide advice only. The purchaser will be required to provide all tools, equipment and personnel needed to assemble the machine.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

ASSEMBLY PROCEDURE

With the purchase of your Model 4100XPC electric mining shovel,

a P&H MinePro Services advisor will be provided for a period of 50

working days to assist the purchaser or the purchasers assembly

contractor with the assembly of the machine. The purchaser should

arrange to assemble, test and place the machine into operation during

this 50 day period.

The P&H MinePro Services advisor can provide advice only. He

is available to advise the purchaser or the purchasers assembly

contractor on assembly sequences, commissioning procedures, testing

and other assembly details as requested, but is not authorized to

supervise workers or to direct the assembly, testing or commission-

ing in any way. The purchaser will be required to provide all tools,

equipment and personnel needed to assemble the machine, as well

as supervision of personnel erecting the machine. For example,

the P&H MinePro Services advisor is available to consult with

supervisory personnel on questions such as places to make hitches

on components, but P&H Mining Equipment will not be responsible

for placement of such hitching or for working with lifting equipment.

P&H Mining Equipment will not be liable in any event for any indirect,

special or consequential damages. Purchaser shall indemnify and hold

P&H Mining Equipment harmless for all liability for damage to property

or personal injury (including death) arising out of purchasers assembly,

testing or placing into service of the machine.

The P&H MinePro Services advisor is not authorized to approve

modifications to the machine that are not covered by the machine

data sheet, nor will P&H Mining Equipment accept any back-charge

for any unauthorized modifications made. (See section titled Machine

Modification Procedure.)

The purchaser or the purchasers assembly contractor should contact

the nearest P&H Mining Equipment regional office to schedule the P&H

MinePro Services advisor. We ask the purchaser, prior to the arrival

of P&H MinePro Services advisor, to issue a purchase order covering

the P&H MinePro Services advisor. The first 50 normal working days

will be on a no charge basis. Any days beyond the first 50 days will be

charged against the purchase order at established service rates.

The normal working day for the P&H MinePro Services advisor is

eight hours on site per day. The normal work week is five days per

week (Monday through Friday excluding holidays). Time spent on

site beyond the normal work week or day will be charged against the

purchase order at established service overtime rates.

ASSEMBLY ASSISTANCE

Assembly site preparation is the responsibility of the Purchaser and

should be a flat leveled area, with good drainage, and stable under

footing to support the lifting equipment and their floats or outriggers

during any lift to be made.

The area required is approximately 300 feet (91.4 m) square, with a

tool shed.

SITE AND MATERIAL LOCATION

During the shovel assembly process, the shovel purchaser will

sometimes request alterations to the standard machine design. Some

of the more-commonly requested modifications affect lubrication

systems, walkways, hand rails, lighting systems and guards.

While some modifications might improve the ability of the purchaser

to utilize and maintain the shovel, some modifications might in fact

adversely affect productivity over time or have significant safety impli-

cations not readily ascertainable.

Accordingly, it is imperative that any modifications sought by the

shovel purchaser of the kind noted above (or any other significant

modifications) be discussed with your P&H MinePro Services

shovel project manager. In turn, your shovel project manager will

discuss your requests with P&H Mining Equipment shovel design

engineers to determine if the modifications can be carried out. P&H

Mining Equipment and P&H MinePro Services make every effort to

accommodate the purchasers requests while taking into consider-

ation the machines optimal productivity and mine application, as well

as current design and safety specifications and regulations.

It is most important that any modification to the machine be

documented so that P&H Mining Equipment and P&H MinePro

Services can maintain current drawings and specifications for your

electric shovel. Furthermore, any future service involving the P&H

Mining Equipment engineering staff can be expedited if modifications

are known and documented.

Please be aware that any modification performed without P&H Mining

Equipment and P&H MinePro Services concurrence might void the

warranty.

Some modifications requested by the purchaser can be accommo-

dated at no additional charge. However, some modifications require

additional welding or other services that cannot be absorbed by P&H

Mining Equipment or P&H MinePro Services. The purchaser will be

notified of such costs in advance of the work being performed.

MACHINE MODIFICATION PROCEDURE

The assembly history for the Model 4100XPC indicates assembly

can be made within 5200-5500 man-hours. The history also indicates

that if proper manpower is not available, the 50 working day period of

assembly and placement into operation will be exceeded. We therefore

advise that the following labor types be available at various stages of

machine assembly.

After the initial cleaning and opening of the packing cases, the four

laborers may be replaced by additional mechanics and millwrights, as

the tasks of the mechanics and millwrights will be more prevalent.

We have not included the supervision mentioned previously. The

necessary mechanical and electrical supervision should be present

when the various trades are involved in the assembly of the machine.

This listing does not include crane operators or oilers (if there is a

requirement for their use).

ASSEMBLY PERSONNEL REQUIREMENTS

4 Laborers (for the purpose of

cleaning parts before they

undergo assembly)

4 Mechanics / Millwrights

4 Electricians

3 Welders

SAFETY: All safety related equipment requirements and procedures are

the responsibility of the Purchaser and or designated Assembly

Contractor and should be in accordance with all applicable

MSHA, Local Mine, State Authorities and regulations.

NOTE: The purchaser is to supply all necessary start-up lubrication

materials, oils, greases, etc., per P&H specifications.

4100XPC

Cranes

Two (2) heavy-lift cranes are required at the start of the assembly,

staying on-site until all the heavy lifts are completed and the boom

has been pinned to the revolving frame. After raising the boom, the

balance of the assembly process can proceed with one (1) rough-

terrain crane in the 30-ton to 50-ton (27,216-kg to 45,360-kg) class.

Heavy-lift crane size requirements are based on many factors,

including crane access to heavy lifts, type of crane used, cold

weather capacity de-rating, reach, and pick-and-carry capability.

Therefore, in extreme cold weather environments, two 225-ton

(204,120-kg) cranes are recommended. In moderate weather, one

150-ton (136,080 kg) and one 190-ton (172,368-kg) crane are

recommended for heavy lifts.

Cables / Slings

4 2-

1

/2" x 25' 4 1-

3

/4" x 20' 4 1-

1

/2" x 20'

4 1" x 12' 2 1-

1

/2" x 20' 4

3

/4" x 10'

2 1-

1

/4" x 20' 2

5

/8" x 20'

10 smaller cables (

1

/2" and

3

/8", 15' long) to handle the misc.

material, such as brakes, blower motors, boxes, cab sections,

etc.

Assortment of nylon slings

Shackles and Pins

2 85-ton shackles 4 55-ton shackles

4 35-ton shackles 4 25-ton shackles

Pins six (6) each in the following sizes:

1

/4",

3

/8",

1

/2",

3

/4", 1"

Blocking (Hardwood)

40 ea. 8" x 8" or 10" x 10" in 6', 4', and 2' lengths

Plywood and 2" lumber (available from shipping crates / boxes)

This material is used for setting the various components on

the ground. The carbody is blocked 48" high for side frame

clearance with shoes on.

Optional Time-Saving Equipment

1 10-ton* (9.072 kg.) forklift.

BASIC RIGGING MATERIAL REQUIREMENTS

Basic Hand Tools

2 6" screwdrivers

1

/4" face

2 8" screwdrivers

3

/8" face

2 12" screwdrivers

1

/2" face

2 15" adjustable open end wrenches

2 12" adjustable open end wrenches

4 12" long bastard files

6 4" paint brushes for use with cleaning solvent

1 crosscut saw

3 36" wrecking bars

2 20 lb. sledge hammers

4 2 lb. ball peen hammers

6 putty knives 3" wide

1 heavy-duty mechanics tool set

2 wire brushes

3 each tapered drifts, 12" long,

5

/8" and

5

/8" dia.

2

1

/2" drive socket wrench sets, including two extensions,

ratchet and sockets, from

7

/16" to 1

1

/4", in

1

/8" increments

1

3

/4" drive socket wrench set, including ratchet and sockets,

from 1" to 3", in

1

/8" increments

6 3-ton come-alongs

2 standard bolt tap set

1

/4" to 1

1

/2" in

1

/8" increments

2 drill bit set

3

/16" to

5

/8" in standard increments

1 set of rotary files for pencil grinder

1

3

/4" drive breaker bar

1 1" drive breaker bar

1 1" drive socket wrench set, ratchet and sockets, from 1

1

/16"

through 3

1

/2" in

1

/16" increments

1 1" Swivel

1 1

1

/2" Swivel

1 1 to 1

1

/2" Adapter

1 1

1

/2" to 1" Adapter

1 set of 1

1

/2" drive sockets from 2" through 4" in

1

/16"

increments

Extensions: 2

3

/4" drive by 8", 1

3

/4" drive by 13",

2 1" drive by 8", 1 1" drive by 13", 1 1

1

/2" drive by 12"

BASIC TOOL REQUIREMENTS

6 6 ton come-alongs

6

1

/5 ton come-alongs

4

3

/4 ton come-alongs

2

1

/2" torque wrenches

1

3

/4" torque wrench

1 1" torque wrench

1 torque multiplier 18

1

/2 : 1

1 48" aluminum pipe wrench

2 24" pipe wrenches

1 24" aluminum pipe wrench

1 24" chain wrench

1 24" crescent wrench

1 open end wrenches

5

/16" through 2

1

/2" in

1

/16" increments

1 hammer wrenches 1

1

/8" through 3

1

/8" in

1

/16" increments

1 4" hammer wrench

Basic Power Tools

1 pneumatic air wrench,

1

/2" drive, with sockets from

1

/2" to 1

1

/4",

in

1

/8" increments

1 spray paint gun

1 air powered grinder, 9" right angle disc

1 air powered

1

/4" pencil grinder

1 air powered chipping hammer w/chisels

1 welding machine, 400 amp capacity (portable gasoline or

diesel driven), including 100' long welding cables

1 portable air compressor, 150 CFM capacity, with 2 ea. 100'

long hoses with inline oilers

1 portable light plant or electric power supply if needed

1 electric heated rod oven

2 oxygen/acetylene burning sets with 75' hose

2 50-ton hydraulic jacks

2

1

/2" electric drills

2

1

/2" cordless drills

1

1

/2" angle drill

2

3

/8" electric drills

1 magnetic drill

1 1

1

/2" drive pneumatic impact wrench

2 1" drive pneumatic impact wrenches

1

3

/4" Super-bolt impact wrench

2

3

/4" drive pneumatic wrenches

4

1

/4" die grinders

9 5" grinders

5 7" grinders

2 straight grinders

The above tool listing indicates the basic minimum range and quantity

of tools recommended. The list is not intended to be all-inclusive.

Data Codes

*1 ton = 2,000 pounds (907.2 kg)

10' = 10 feet (305 cm) 10" = 10 inches (25.4 cm)

BASIC TOOL REQUIREMENTS (continued)

Miscellaneous Items

3 tarpaulins, 30' x 30'

2 12' step ladders - straight

2 20' extension ladders

2 barrels of cleaning solvent

20 rolls masking tape 1"

50 sheets of fine emery cloth

50 sheets of medium emery

cloth

2 wooden stairway with

railing for boarding

25 rolls black plastic electrical

tape

25 rolls of friction tape

5 anti-seize lubricant (cans)

5 dye check kits for

checking welds (NDT-PT)

6 fire extinguishers20 lb.

dry chemical type

100 lbs.

3

/32" weld rod

300 lbs.

1

/8" weld rod

200 lbs.

3

/16" weld rod

(low hydrogen, pre-dried)

300 feet manila rope

100 lbs. cleaning rags

2000 lbs. (approx.) dry ice

(the exact quantity

required will depend

upon location of

source and ambient

temperature)

or

Liquid Nitrogen - 4 bottles,

approximately 370 lbs.

of product each bottle

and must have liquid

withdrawal capabilities

3 6-foot step ladder

3 8-foot step ladder

Painting supplies

Assorted-color electrical tape

Basic Electrical Tools

1 knock out punch set

1 hydraulic hand pump

knock out punch kit

1 hole saw kit

2 manual Crimpers

1 hydraulic crimpers

3 heat guns

2 reciprocating saws

1 soldering gun

6 600 amp welders

4 wire feeders

4 air arcs

1 diesel genset - 300 kW

12'-0"

(3.66 m)

22"

(559 mm) 12" (305 mm)

Center Gudgeon

Weight: 9,050 lbs. (4,105 kg)

125,875 lbs.

(57,097 kg)

w/ trans

61,225 lbs.

(27,772 kg)

w/ trans

Crawler shoes:76" (1.93 m)

42 Shoes each Belt - Weight: 165,100 lbs.

(74,888 kg)

Crawler shoes: 87" (2.21 m)

42 Shoes each Belt - Weight: 175,000 Lbs.

(79,379 Kg.)

Crawler (top view shown) w/o Shoes-Weight: 187,100 (84,869 kg)

C Rotation

L

Crawler (top view shown) w/o Trans w/o Shoes-Weight: 163,000 (73,937 kg)

99,000 lbs.

(44,906 kg)

w/o Trans

64,000 lbs.

(29,030 kg)

w/o Trans

Crawler Frame w/o Shoes

7'-8"

(2.33 m)

123.25"

(3.13 m)

16'-3"

(4.95 m)

8'-1"

(2.45 m)

24'-7"

(7.49 m)

16'-8"

(5.08 m)

98,650 lbs.

(44,747 kg)

98,650 lbs.

(44,747 kg)

98,650 lbs.

(44,747 kg)

98,650 lbs.

(44,747 kg)

36'-8"

(11.18 m)

Total Weight:

197,300 lbs.

(44,747 kg)

Includes:

Swing Roller Carrier Ring

Lower Swing Roller Path

}

17'-5"

(5.31 m)

20'-0"

(6.10 m)

76 yd

3

(58.1 m

3

) Bail Type Dipper

175,000 lbs.

(79,380 kg)

Typical values only; there is no standard dipper.

48,025 lbs.

(21,784 kg)

48,025 lbs.

(21,784 kg)

Total Weight

96,050 lbs.

(43,568 kg)

35'-6"

(10.82 m)

13'-0"

(3.96 m)

5'-8"

(1.71 m)

5'-0"

(1.52 m)

31'-10"

(9.69 m)

99,600 lbs.

(45,179 kg)

113,400 lbs.

(51,438 kg)

88,880 lbs.

(40,316 kg)

124,120 lbs.

(56,301 kg)

213,000 lbs. (96,617 kg)

11'-4"

(3.45 m)

Revolving Frame w/Sidestand

Includes:

Upper Roller Path

Misc. Wiring Troughs

Carbody

Counterweight Box

15'-1"

(4.6 m)

Dry ice to freeze center gudgeon (shown above) for

field installation into carbody. The quantity will depend

on location of supplier, and ambient temperature.

The side loading to any welded-on

lifting lug cannot exceed 5 from the vertical.

* Weights are 10%. For actual weight of each component, refer to packing list.

Pick point note:

Use both outer holes of this one

lug when lifting in this position. Pick point note:

Use this one lug when

lifting in this position.

Pick point note:

Use this one lug when

lifting in this position.

Pick point note:

Use both outer holes of this one

lug when lifting in this position.

Pick point note:

Use both lugs

(one each side)

when lifting in

this position.

Pick point note:

Use only top

holes of these

lugs (one each

side) when lifting

in this position.

4100XPC LIFTING OR HITCHING POINTS AND APPROXIMATE WEIGHTS* OF MAJOR ITEMS

13'-11"

(4.24 m)

68'-0"

(20.73 m)

10'-6"

(3.20 m)

7'-7"

(2.31 m)

63,500 lbs.

(28,804 kg)

Bare

82,500 lbs.

(37,422 kg)

Bare

Bare

146,000 lbs.

(66,226 kg)

Fully Dressed

247,500 lbs.

(112,266 kg)

**133,000 lbs.

(60,328 kg)

Fully Dressed

61,330 lbs.

(27,819 kg)

36,170 lbs.

(16,407 kg)

2'-6"

(.76 m)

10'-0"

(3.05 m)

6'-7" (1.96 m)

50,700 lbs. (23,045 kg)

Wing Sections (2)

6'-6" (1.98 m)

49,220 lbs. (22,373 kg)

Inner-Mid P Section (1)

Inner-Mid H Section (1)

5'-0" (1.52 m)

48,800 lbs. (22,182 kg)

Center & Section (1)

24,400 lbs.

(11,091 kg)

24,610 lbs.

(11,187 kg)

25,060 lbs.

(11,391 kg)

18,110 lbs.

(8,232 kg)

32,590 lbs.

(14,813 kg)

24,400 lbs.

(11,091 kg)

8'-8"

(2.64 m)

2'-10"

(.86 m)

24,610 lbs.

(11,187 kg)

25,060 lbs.

(11,391 kg)

10'-0"

(3.05 m)

10'-0"

(3.05 m)

8'-8"

(2.64 m)

7'-0" (2.13 m)

50,120 lbs. (22,782 kg)

Outer-Mid Sections (2)

1'-11"

(.58 m)

4'-10"

(1.47 m)

Bare Boom includes:

Lube material

Fully-dressed Boom includes:

Boom Point Assembly

Crowd Machinery

Hoist Rope Guide

Dipper Trip Machinery

Catwalks

9'-5"

(2.86 m)

* Weights are 10%. For actual weight of each component, refer to

packing list.

The side loading to any

welded-on lifting lug cannot exceed

5 from the vertical.

** Hitch point load encountered when raising a

fully-dressed boom into position.

14'-4"

(4.36 m)

97,500 lbs.

(44,226 kg)

40'-11"

(12.47 m)

Handle Layout

Counterweight Slabs

Note: Use these machined holes as hitch

points. Do not use the welded-on lugs to

raise the boom.

4100XPC LIFTING OR HITCHING POINTS AND APPROXIMATE WEIGHTS* OF MAJOR ITEMS

CRAWLER

SHOES

CRAWLER

SHOES

107

16

15

98

99 41

47

38

31

95

18

30

13

14

60

19

TOOL

CONTAINER

L

U

N

C

H

R

O

O

M

REVOLVING

FRAME

COUNTER WEIGHT

BOX

CARBODY

20

25

30

35

40

45

50

55

60

BOOM

74

115

HOIST

CASE

HOIST

DRUM

GANTRY

GANTRY

TENSION

MEMBERS

PROPEL

MOTOR

BASE

ROLLER

CARRIER

BOOM

POINT

SHEAVES

(67)

5

5

10

15

10 15 20 25 30 35 40 45 50 55 60 65 70

42 43

52

54

69

D

I

P

P

E

R

H

A

N

D

L

E

65

70

75

80

85

90

95

DIPPER

116

S

I

D

E

F

R

A

M

E

S

I

D

E

F

R

A

M

E

METERS

0

106

6

87

34

66

65

65

64

64

63

63

21

82 128

185

145

147 142 138

133

132

131

130

137

136

135

134

152

154

156

127 146

96

22

97

100

183

120 118

119 121

153

102

176

177

182

22

58

103

1

6 5

129

127

105

104

61

37

13

14

29

91

90

76 40

143

112

175

149

150

155

179

178

165

164

163

162

168

170

172

174 173

171

169

166

161

160

159

158

141

112 140

151

144

76

77

85

49 35

25

181

17

24

73

83

10 9 8

11 16

139

113

167

180

44

7

12

34

70

51 26

72 71

110

124

125

122

123

157

36

28

RING

GEAR

23

57

56

55

74

75

78

79

32

33

4

108

93

126

130

184

59

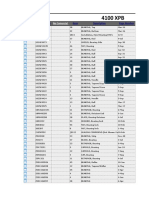

Figure 1 depicts the recommended placement

of parts at the assembly site. Each item shown

is numbered and refers to the Component List

(Tables 1 and 2) which give the approximate

weights of the components. For the actual

weights, refer to the machine packing list.

NOTE

Electrical cabinets, transformers,

AC & DC motors, etc. must be

stored under cover until required.

SITE LAYOUT

Figure 1

Site

Location

Approx Weight*

Description of Contents Lbs. Kg

CARBODY COMPONENTS

129 Cabinet - Control - Lower - Skid 740 336

130 Cabinet - Switch - Lower Disc. - Box 1,042 473

1 Carbody - Lower - Pc 195,000 88452

62 Carbody Stairs Installation - Skid 570 259

18 Center Gudgeon Assembly - Box 13,800 6260

2 Crawler - L/H (w/o Transmission) - Pc 164,400 74572

3 Crawler - R/H (w/o Transmission) - Pc 164,400 74572

xx Crawler Frame Dowel Rod Bolts - Box 2,820 1279

6 Crawler Frame Installation (Bolts) - Box 11,400 5171

14 Crawler Shoe Pin Hardware - Box 1,376 624

13 Crawler Shoe Pins #1 - Box 6,262 2840

13 Crawler Shoe Pins #2 - Box 6,202 2813

14 Crawler Shoe Pins #3 - Box 6,202 2813

Crawler Shoes - Shipped Direct - appx 42 skids @ 8,000 lbs ea

5 Propel Motors & Base Assembly - Pc 43,000 19505

29 Propel Transmission (1 of 2) - Skid 25,000 11340

30 Propel Transmission (2 of 2) - Skid 25,000 11340

37 Propel Transmission Bolts - Hardware - Box 388 176

4 Swing - Ring Gear - Pc 23,000 10433

7 Swing Component Installation - Box 3,112 1412

8 Swing Rollers ( 1 of 3 ) - Box 2,322 1053

9 Swing Rollers ( 2 of 3 ) - Box 2,322 1053

10 Swing Rollers ( 3 of 3 ) - Box 2,310 1048

87 Tools - Hydraulic and Miscellaneous - Box 918 416

179 Wiper Assembly - Roller Circle Inst. - Box 804 365

REVOLVING FRAME COMPONENTS

25 Air Compressor - Box 1,550 703

180 Air Compressor - Duct Bleed Component - Box 274 124

181 Air Compressor Installation - Box 362 164

85 Air Conditioner / Plate Assembly - Box 3,394 1540

182 Brake Removal Kit (Bolts under Platform) - Box 1,400 635

41 Buss Bar Assembly ( 1 of 2 ) - Box 1,460 662

41 Buss Bar Assembly ( 2 of 2 ) - Box 1,020 463

100 Cabinet - Converter - Skid 12,500 5670

98 Cabinet - High-Voltage - Skid 2,850 1293

97 Cabinet - Main Transformer - Skid 25,000 11340

102 Cabinet - R.P.C. - Skid 18,000 8165

101 Cabinet - Transfer - Contactor - Skid 1,514 687

22 Catwalk - Air - Stair - Crate 2,040 925

22 Catwalk - Operators Cab - Skid 2,480 1125

21 Catwalk #1 - Skid 4,080 1851

22 Catwalk #2 - Crate 4,740 2150

147 Control Assembly Filter - Box 450 204

178 Controller - Stair Air R/H Assy. - Box 560 254

177 Counterweight - Flat Stock - Filler - Box 202 92

31 Counterweight - Troughing - Box 3,060 1388

16 Counterweight Box - Pc 98,000 44453

47 Counterweight Mounting Bolts - Box 1,368 621

63 Counterweight Slab ( & ) - Pc 50,000 22680

64 Counterweight Slab ( H ) - Pc 50,000 22680

63 Counterweight Slab ( P ) - Pc 50,000 22680

64 Counterweight Slab Middle Section - Pc 50,000 22680

65 Counterweight Slab Middle Section - Pc 50,000 22680

65 Counterweight Slab Wing Section - Pc 50,000 22680

66 Counterweight Slab Wing Section - Pc 50,000 22680

39 Crowd Motor Blower - Box 694 315

176 Crowd Transmission Lube - Box 729 331

116 Dipper Assembly Variable

141 Dirt Chute - Box 1,168 530

112 Dirt Chute - Hood Assembly - Box 518 235

140 Dirt Chute - Tube Assembly - Skid 256 116

185 Duct Swing Blower Assembly 440 200

130 Electrical - Cable - I/O Profibus Installation - Box 556 252

131 Electrical - Upper Cable Tray Installation - Box 1,005 456

132 Electrical - Wire Installation - Loose ( 1 of 3 ) - Box 458 208

133 Electrical - Wire Installation - Loose ( 2 of 3 ) - Box 1,096 497

134 Electrical - Wire Installation - Loose ( 3 of 3 ) - box 1,090 494

96 Electrical Shipping Materials - Box 373 169

135 Floodlight Installation - 400W - Box 1,218 552

136 Floodlight Installation - 500W - Box 306 139

137 Floodlight Material - Box 336 152

33 Gantry - Tension Members (2 units, each weighing) - Pc 9,800 4445

32 Gantry Assembly - Pc 35,900 16284

28 Gantry Assembly Parts - Box 976 443

175 Gantry Boot Assembly - Box 265 120

36 Gantry Platform Assembly - Skid 2,865 1300

139 Gantry Platform Ladder Assembly - Skid 622 282

73 Hoist Drum Assembly - Pc 53,000 24041

17 Hoist Drum Assembly Cabinet Bracing Box 850 386

51 Hoist Drum Guard Installation - Box 1,300 590

4100XPC COMPONENT LIST - US & CANADA Table 1

Site

Location

Approx Weight*

Description of Contents Lbs. Kg

REVOLVING FRAME COMPONENTS (CONTINUED)

138 Hoist Gear Case - I/O Cabinet Assy - Box 390 177

24 Hoist Gear Case Assembly - Pc 37,000 16783

79 Hoist Motor Assembly Hardware - Box 524 238

74 Hoist Motor Base - Skid 6,070 2753

75 Hoist Motor Base - Skid 6,070 2753

78 Hoist Motor Front - (K1980) - Skid 20,640 9362

78 Hoist Motor Front (K1690) - Skid 19,125 8675

79 Hoist Motor Rear - (K1980) - Skid 20,640 9362

79 Hoist Motor Rear (K1690) - Skid 19,125 8675

145 Hood Half - Rear Roof ( 1 of 2 ) - Skid 4,140 1878

146 Hood Half - Rear Roof ( 2 of 2 ) - Skid 4,140 1878

112 House - Angle, Jacking Installation - Box 884 401

54 House - Center Beam - Skid 4,800 2177

149 House - Center Front Panel - Skid 2,060 934

150 House - Hatch Cover Front - L/H - Skid 1,460 662

158 House - Hatch Cover Front - R/H - Skid 1,460 662

159 House - Hatch Covers - Box 5,765 2615

160 House - Installation Assembly - Box 3,000 1361

161 House - Panel - Front - L/H - Skid 1,000 454

162 House - Panel - Front - R/H - Skid 1,000 454

163 House - Panel - Rear Wall - Box 14,420 6541

164 House - Panel - Side Wall - Box 8,760 3974

20 House - Roof Grating - Box 2,540 1152

165 House - Shims / Covers - Box 382 173

166 I-Beam Framing - Box 10,000 4536

167 L/H Room Assembly - Pc 20,500 9299

58 Ladder - Vertical Pull-down - Skid 1,760 798

142 Light - Interior Installation - Box 922 418

184 Oil Seal Installation Kit - Box 264 120

40 Operators Coop - Pc 11,860 5380

40 Ops Coop - Roof Grating Installation - Skid 420 191

143 Ops Coop - Access Ladder - Skid 750 340

144 Ops Coop - Awning Installation - Box 2,780 1261

168 Plat Mdl. Assembly - Upper - Box 720 327

35 Platform - R/H Room Elevated Platform - Pc 11,200 5080

34 Platform - Rear L/H - Pc 12,000 5443

72 Platform - Rear R/H - Pc 12,000 5443

169 Platform L/H Room - Pc 11,900 5398

128 Pressurization Sys. - Silencer Installation - Box 1,726 783

127 Pressurization Sys. - Truss Hood - Skid 460 209

82 Pressurization System (AirScrubPro) - Pc 34,500 15649

71 R/H Room Assembly - Pc 19,500 8845

21 Railings - Crate 4,520 2050

151 Revolving Frame - Lifting Lugs - Box 764 347

15 Revolving Frame - Upper - Pc 213,600 96889

170 Side Beams - Roof - Box 4,350 1973

171 Sky Light (1 of 2) - Box 374 170

172 Sky Light (2 of 2) - Box 168 76

173 Sky Light Guards - Skid 348 158

49 Slipring Mounting Parts - Box 752 341

174 Stairway - Air / LWR - R/H - Skid 1,280 581

22 Stairway - Air UPR/LWR/RH - Skid 1,996 905

113 Swing Guards - Box 1,380 626

76 Swing Installation Components - Box 3,112 1412

152 Swing Motor Troughing - Box 708 321

76 Swing Motors (3 units, ea. weighing) - Skid 10,000 4536

83 Swing Shaft ( 1 of 3 ) - Pc 5,440 2468

84 Swing Shaft ( 2 of 3 ) - Pc 5,440 2468

44 Swing Shaft ( 3 of 3 ) - Pc 5,620 2549

77 Swing Trans. (3 units, ea weighing) - Skid 12,750 5783

153 Swing Transmission Drain Assembly - Box 438 199

38 Swivel Grease Assembly - Box 5,650 2563

154 Temperature Monitoring Kit - Box 538 244

183 Transformer - Main - Duct Installation - Box 580 263

99 Transformer - Auxilliary Field - Skid 6,532 2963

155 Winch - Elec. - Windshield Install - Box 956 434

BOOM/HANDLE COMPONENTS

95 Boom - Electrical Materials - Box 414 188

156 Boom - Jack Stands - Box 1,134 514

60 Boom - Trip Sheave Bracket Assembly - Skid 792 359

19 Boom Assembly - Pc 148,000 67133

127 Boom Foot Pin Assembly - Box 2,226 1010

67 Boom Point Sheave Assembly - Pc 13,500 6124

157 Cable - Hoist - Guide - Skid 2,186 992

12 Cable - Hoist - Tugger Installation - Skid 2,880 1306

104 Cable - Hoist ( 1 of 2 ) - Pc 6,240 2830

105 Cable - Hoist ( 2 of 2 ) - Pc 6,240 2830

106 Cable - Suspension ( 1 of 2 ) - Pc 11,500 5216

107 Cable - Suspension ( 2 of 2 ) - Pc 11,500 5216

125 Catwalk - Lower Boom Assembly - Skid 1,366 620

Weights are 10%. For actual weight of each component, refer to packing list.

Approx

Weight*

Description of Contents Lbs. Kg

CARBODY COMPONENTS

Cabinet - Control - Lower - Skid 874 396

Cabinet - Switch - Lower Disc. - Box 1,042 473

Carbody - Lower - Pc 195,000 88452

Carbody Stairs Installation - Skid 570 259

Center Gudgeon Assembly - Box 13,800 6260

Crawler - L/H (w/o Transmission) - Pc 165,000 74844

Crawler - R/H (w/o Transmission) - Pc 165,000 74844

Crawler Frame Dowel Rod Bolts - Box 2,820 1279

Crawler Frame Installation (Bolts) - Box 11,400 5171

Crawler Shoe Pin Hardware - Box 1,376 624

Crawler Shoe Pins #1 - Box 6,316 2865

Crawler Shoe Pins #2 - Box 6,316 2865

Crawler Shoe Pins #3 - Box 6,316 2865

Crawler Shoes - Shipped Direct - appx 42 skids @ 8,000 lbs ea

Propel Motors & Base Assembly - Pc 43,000 19505

Propel Transmission (1 of 2) - Box 25,920 11757

Propel Transmission (2 of 2) - Box 25,000 11340

Propel Transmission Bolts - Hardware - Box 388 176

Swing - Ring Gear - Pc 23,200 10524

Swing Component Installation - Box 3,112 1412

Swing Rollers ( 1 of 3 ) - Box 2,356 1069

Swing Rollers ( 2 of 3 ) - Box 2,356 1069

Swing Rollers ( 3 of 3 ) - Box 2,356 1069

Tools - Hydraulic and Miscellaneous - Box 992 450

Wiper Assembly - Roller Circle Inst. - Box 868 394

REVOLVING FRAME COMPONENTS

Air Compressor - Box 1,586 719

Air Compressor - Duct Bleed Component - Box 278 126

Air Compressor Installation - Box 880 399

Air Conditioner / Plate Assembly - Box 3,980 1805

Brake Removal Kit (Bolts under Platform) - Box 1,400 635

Buss Bar Assembly ( 1 of 2 ) - Box 1,960 889

Cabinet - Converter - Skid 12,500 5670

Cabinet - High-Voltage - Box 4,200 1905

Cabinet - Main Transformer - Skid 27,900 12655

Cabinet - R.P.C. - Skid 24,000 10886

Cabinet - Transfer - Contactor - Box 1,766 801

Catwalk - Air - Stair - Crate 3,880 1760

Catwalk - Operators Cab - Skid 2,480 1125

Catwalk #1 - Crate 5,300 2404

Catwalk #2 - Crate 2,040 925

Controller - Stair Air R/H Assy. - Box 560 254

Counterweight - Flat Stock - Filler - Box 221 100

Counterweight - Troughing - Box 3,060 1388

Counterweight Box - Pc 98,000 44453

Counterweight Mounting Bolts - Box 1,396 633

Counterweight Slab ( & ) - Pc 50,000 22680

Counterweight Slab ( H ) - Pc 50,000 22680

Counterweight Slab ( P ) - Pc 50,000 22680

Counterweight Slab Middle Section - Pc 50,000 22680

Counterweight Slab Middle Section - Pc 50,000 22680

Counterweight Slab Wing Section - Pc 50,000 22680

Counterweight Slab Wing Section - Pc 50,000 22680

Crowd Motor Blower - Duct - Box 734 333

Crowd Transmission Lube - Box 768 348

Dipper Assembly Variable

Dirt Chute - Box 1,000 454

Dirt Chute - Hood Assembly - Box 528 240

Duct Swing Blower Assembly - Box 286 130

Electrical - Cable - I/O Profibus Installation - Box 556 252

4100XPC COMPONENT LIST - US & CANADA Table 1

4100XPC COMPONENT LIST - EXPORT Table 2

Site

Location

Approx Weight*

Description of Contents Lbs. Kg

BOOM/HANDLE COMPONENTS (CONTINUED)

122 Catwalk - Platform - Boom - Skid 4,227 1917

123 Catwalk - Sdl Blk / Lower Boom L/H - Skid 3,890 1765

124 Catwalk - Sdl Blk / Lower Boom R/H - Skid 3,890 1765

126 Crowd Drive Assembly - Box 1,442 654

93 Crowd Gear Case Cover - Pc 13,940 6323

108 Crowd Motor and Base - Skid 14,800 6713

61 Dipper Trip Drum & Motor Assembly, R/H - Skid 2,234 1013

23 Handle - Dipper - Pc 99,870 45301

60 Handle - Sheave Bracket Assembly - Skid 782 355

121 Pitch Brace Assembly - Adjustable - Skid 3,365 1526

Site

Location

Approx Weight*

Description of Contents Lbs. Kg

BOOM/HANDLE COMPONENTS (CONTINUED)

42 Saddle Block ( 1 of 2 ) - Pc 11,500 5216

43 Saddle Block ( 2 of 2 ) - Pc 11,500 5216

90 Shipper Shaft - Box 16,600 7530

110 Shipper Shaft Gear - Box 7,600 3447

59 Shipper Shaft Pinions - Box 4,610 2091

118 Snubber Kit (SnubRite) - ( 1 of 2 ) - Box 1,574 714

119 Snubber Kit (SnubRite) - ( 2 of 2 ) - Box 1,574 714

120 Snubber Mounting Kit (SnubRite) - Box 830 376

122 Stairs - Boom - Skid 3,280 1488

Approx

Weight*

Description of Contents Lbs. Kg

REVOLVING FRAME COMPONENTS (CONTINUED)

Electrical - Upper Cable Tray Installation - Box 1,864 846

Electrical - Wire Installation - Loose ( 1 of 3 ) - Box 458 208

Electrical - Wire Installation - Loose ( 2 of 3 ) - Box 1,754 796

Electrical - Wire Installation - Loose ( 3 of 3 ) - Box 878 398

Electrical Shipping Materials - Box 373 169

Emergency Light Installation - Box 272 123

Floodlight Installation - 400W - Box 1,286 583

Floodlight Installation - 500W - Box 490 222

Floodlight Material - Box 404 183

Gantry - Tension Members (2 units, each weighing) - Pc 9,800 4445

Gantry Assembly - Pc 35,900 16284

Gantry Assembly Parts - Box 992 450

Gantry Boot Assembly - Box 270 122

Gantry Platform Assembly - Skid 2,865 1300

Gantry Platform Ladder Assembly - Skid 622 282

Hoist Drum Assembly - Pc 53,000 24041

Hoist Drum Assembly Cabinet Bracing - Box 1158 525

Hoist Drum Guard Installation - Box 1,300 590

Hoist Drum Lock Assembly - Box 2432 1103

Hoist Gear Case - I/O Cabinet Assy - Box 390 177

Hoist Gear Case Assembly - Pc 37,000 16783

Hoist Motor Assembly Hardware - Box 524 238

Hoist Motor Base - Skid 6,070 2753

Hoist Motor Base - Skid 6,070 2753

Hoist Motor Front - (K1690) - Skid 20,240 9181

Hoist Motor Front - (K1980) - Skid 21,840 9907

Hoist Motor Rear - (K1690) - Skid 20,240 9181

Hoist Motor Rear - (K1980) - Skid 21,840 9907

Hood - Rope Guide - Skid 1340 608

Hood Half - Rear Roof ( 1 of 2 ) - Skid 4,140 1878

Hood Half - Rear Roof ( 2 of 2 ) - Skid 4,140 1878

House - Angle, Jacking Installation - Box 908 412

House - Center Beam - Skid 4,950 2245

House - Center Front Panel - Skid 2,060 934

House - Filtration Elec. Installation - Box 366 166

House - Hatch Cover Front - L/H - Skid 1,460 662

House - Hatch Cover Front - R/H - Skid 1,460 662

House - Hatch Covers - Box 5,765 2615

House - Heater Installation Kit - Box 427 194

House - Installation Assembly - Box 2,212 1003

House - Panel - Front - L/H - Pc 1,000 454

House - Panel - Front - R/H - Pc 1,000 454

House - Panel - Rear Wall - Box 14,420 6541

House - Panel - Side Wall - Box 8,760 3974

House - Roof Grating - Box 2,540 1152

House - Shims / Covers - Box 382 173

I-Beam Framing - Box 9,600 4355

L/H Room Assembly - Pc 20,500 9299

Ladder - Vertical Pull-down - Skid 1,760 798

Light - Interior Installation - Box 968 439

Oil Seal Installation Kit - Box 274 124

Operators Coop - Box 13,360 6060

Ops Coop - Roof Grating Installation - Skid 420 191

Ops Coop - Access Ladder - Skid 860 390

Ops Coop - Awning Installation - Box 2,780 1261

Plat Mdl. Assembly - Upper - Box 720 327

Platform - R/H Room Elevated Platform - Pc 11,200 5080

Platform - Rear L/H - Pc 12,000 5443

Platform - Rear R/H - Pc 12,000 5443

Platform L/H Room - Pc 11,900 5398

NOTE: All designs, specifications and components of equipment described above are subject to change at manufacturers sole discretion at any time without

advance notice. Data published herein is informational in nature and shall not be construed to warrant suitability of machine for any particular purpose as

performance may vary with conditions encountered. The only warranty applicable is our standard written warranty for this machine.

XS-4222 PDF408

P&H Mining Equipment Box 310 Milwaukee, Wisconsin 53201 USA

ELECTRICAL TEST EQUIPMENT REQUIREMENTS

Weights are 10%. For actual weight of each component, refer to packing list.

Description P&H Part #

DMM (Digital MultiMeter)

Fluke Model 23 89Z514D12

Alternate DMMFluke, Model 87 1089Z275

Oscilloscope

Tektronix Model THS720A (Hand-held, Dual Trace,

Digital, Storage, Battery Powered, Soft Case) Scope

w/120V / 60Hz Adapter 89Z515D16

120V / 50 Hz AC Adapter (240V Adapters Available) 89Z515D30

Hard Carrying Case 89Z515D26

X10 Probe (1kV) 89Z515D17

R5-232 to 485 Converterfor loading ABB drive

firmware ABB NPCU-01-KIT R49117D1

Megger500V & 1000V Scales (hand-crank /w case)

James D. Biddle Cat. 21158 89Z496

Description P&H Part

#Clamp-On Ammeter1A to 600A AC / 1000A (DC)

Fluke Model i1010 89Z514D15

High Voltage Differential ProbeP5200 89Z515D21

Laptop computerConsult service department

for specs N/A

Drive Communications (hardware and software) R40775D3

RPC Capacitor Test unit 89Z508D1

Voltage Divider R1192F1

Hand-held Drive Programmer, ABB CDP-312R R46072D7

2 Meter Connection Cable R46072D8

SCR (Thyristor) Tester 89Z511D1

Basic Electrical Test Instrumentation Recommended to Commission and Maintain Centurion Digital Drive Mining Excavator.

Recommended Maintenance Test Equipment Available through P&H and other Vendors.

4100XPC COMPONENT LIST - EXPORT Table 2

Approx

Weight*

Description of Contents Lbs. Kg

REVOLVING FRAME COMPONENTS (CONTINUED)

Pressurization Sys. - Silencer Installation - Box 1,748 793

Pressurization Sys. - Truss Hood - Skid 680 308

Pressurization System (AirScrubPro) - Pc 34,500 15649

R/H Room Assembly - Pc 19,500 8845

Railings - Crate 3,900 1769

Resolver Cable Installation - Box 526 239

Revolving Frame - Lifting Lugs - Box 1,198 543

Revolving Frame - Upper - Pc 214,000 97070

Side Beams - Roof - Box 4,350 1973

Sky Light (1 of 2) - Box 404 183

Sky Light (2 of 2) - Box 190 86

Sky Light Guards - Skid 355 161

Slipring Mounting Parts - Box 789 358

Stairway - Air / LWR - R/H - Skid 1,280 581

Stairway - Air UPR/LWR/RH - Skid 1,996 905

Swing Guards - Box 1,380 626

Swing Installation Components - Box 3,112 1412

Swing Motor Troughing - Box 774 351

Swing Motors (3 units, ea. weighing) - Skid 10,750 4876

Swing Shaft ( 1 of 3 ) - Pc 5,556 2520

Swing Shaft ( 2 of 3 ) - Pc 5,556 2520

Swing Shaft ( 3 of 3 ) - Pc 5,556 2520

Swing Trans. (3 units, ea weighing) - Skid 13,500 6124

Swing Transmission Drain Assembly - Box 450 204

Swing Transmission Lube Assembly - Box 1,516 688

Swivel Grease Assembly - Box 5,650 2563

Temperature Monitoring Kit - Box 672 305

Transformer - Main - Duct Installation - Box 596 270

Transformer - Auxilliary Field - Skid 7,461 3384

Winch - Elec. - Windshield Install - Box 956 434

BOOM/HANDLE COMPONENTS

Boom - Electrical Materials - Box 420 191

Boom - Jack Stands - Box 1,134 514

Boom Assembly - Pc 148,000 67133

Approx

Weight*

Description of Contents Lbs. Kg

BOOM/HANDLE COMPONENTS (CONTINUED)

Boom Foot Pin Assembly - Box 2,226 1010

Boom Point Sheave Assembly - Pc 13,500 6124

Cable - Hoist - Guide - Skid 2,186 992

Cable - Hoist - Tugger Installation - Skid 2,880 1306

Cable - Hoist ( 1 of 2 ) - Pc 6,240 2830

Cable - Hoist ( 2 of 2 ) - Pc 6,240 2830

Cable - Suspension ( 1 of 2 ) - Pc 11,500 5216

Cable - Suspension ( 2 of 2 ) - Pc 11,500 5216

Cable Installation - Boom Material - Box 308 140

Catwalk - Lower Boom Assembly - Skid 1,270 576

Catwalk - Platform - Boom - Skid 4,048 1836

Catwalk - Sdl Blk / Lower Boom L/H - Skid 3,890 1765

Catwalk - Sdl Blk / Lower Boom R/H - Skid 3,890 1765

Crowd Drive Assembly - Box 1,454 660

Crowd Gear Case Cover - Pc 14,940 6777

Crowd Motor and Base - Box 15,640 7094

Dipper Trip Drum & Motor Assembly, R/H - Skid 2,310 1048

Handle - Dipper - Pc 99,870 45301

Handle - Sheave Bracket Assembly - Skid 790 358

Pitch Brace Assembly - Adjustable - Skid 3,910 1774

Saddle Block - Wear Plate - Skid 1,268 575

Saddle Block ( 1 of 2 ) - Skid 12,000 5443

Saddle Block ( 2 of 2 ) - Skid 12,000 5443

Sheave Brackets - Box 850 386

Shipper Shaft - Box 16,600 7530

Shipper Shaft - Bushings - Box 2,665 1209

Shipper Shaft Assembly - Box 1,164 528

Shipper Shaft Gear - Box 7,600 3447

Shipper Shaft Pinions - Box 4,640 2105

Snubber Kit (SnubRite) - ( 1 of 2 ) - Box 1,590 721

Snubber Kit (SnubRite) - ( 2 of 2 ) - Box 1,590 721

Snubber Mounting Kit (SnubRite) - Box 852 386

Stairs Boom - Skid 3,280 1488

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- 02 EX5600-6 Shovel Inspeccion Visual EX5500-6 - EX5600-6+Loader-A4Document247 pages02 EX5600-6 Shovel Inspeccion Visual EX5500-6 - EX5600-6+Loader-A4jose0% (1)

- 2010 HD Part Cat. LBBDocument466 pages2010 HD Part Cat. LBBBuddy ButlerNo ratings yet

- ERS - Raptor Wear Product & Dipper Door Solutions PDFDocument12 pagesERS - Raptor Wear Product & Dipper Door Solutions PDFBorisRakelaGonzalezNo ratings yet

- Komatsu PC8000 Hydraulic Mining Shovel AssemblyDocument156 pagesKomatsu PC8000 Hydraulic Mining Shovel AssemblyUki Alfa Romeo100% (1)

- AH15849b PC Hydraulic Cylinders With Metal Guard Rings at The PistonDocument12 pagesAH15849b PC Hydraulic Cylinders With Metal Guard Rings at The PistonfernandojNo ratings yet

- Course Pyh 4100a Electric Rope Shovel Parts Components Systems SpecsDocument76 pagesCourse Pyh 4100a Electric Rope Shovel Parts Components Systems SpecsDarwin Enrique50% (2)

- Crowd System MaintenanceDocument8 pagesCrowd System MaintenanceVentasVarias AntofaNo ratings yet

- Fampc4000 05Document94 pagesFampc4000 05Lucio Valderrama PeredaNo ratings yet

- Komatsu - Mining Division - PC7000-11Document24 pagesKomatsu - Mining Division - PC7000-11Derek VerdejoNo ratings yet

- Extrajudicial Settlement of Estate Rule 74, Section 1 ChecklistDocument8 pagesExtrajudicial Settlement of Estate Rule 74, Section 1 ChecklistMsyang Ann Corbo DiazNo ratings yet

- Pala HitachiDocument75 pagesPala HitachiEdwarthMaza100% (1)

- Dipper Door Assembly Part No R72209F1 PDFDocument3 pagesDipper Door Assembly Part No R72209F1 PDFFrancisco Gonzalez0% (1)

- 4100XPC Mechanical Systems Manual PDFDocument1,048 pages4100XPC Mechanical Systems Manual PDFWendy Kera100% (1)

- XS4921 2300XPC DC BroDocument8 pagesXS4921 2300XPC DC BroRaul Mendoza Subia100% (1)

- KOmatsu P&H-trc-series-dipperDocument2 pagesKOmatsu P&H-trc-series-dipperhidrastar123No ratings yet

- Mechanical Manual ES2800XPB 03 MMDocument730 pagesMechanical Manual ES2800XPB 03 MMAdriano Mendes100% (1)

- Manual Dipper 7495 - Inspeccion en Campo OEM PDFDocument147 pagesManual Dipper 7495 - Inspeccion en Campo OEM PDFjhonatanNo ratings yet

- Dipper P&H 2800XPBDocument1 pageDipper P&H 2800XPBBer Seloque HicisteNo ratings yet

- Bucyrus DetailsDocument15 pagesBucyrus Detailscharanpalsingh95100% (2)

- M20015607902 Rep 1906061300Document122 pagesM20015607902 Rep 1906061300KOMATSU SHOVEL100% (1)

- 28 - Hofmann - Trackpads Brochure - A4Document4 pages28 - Hofmann - Trackpads Brochure - A4Jorge Villalobos100% (1)

- 495HR Electric Mining Shovel ManualDocument46 pages495HR Electric Mining Shovel ManualRonald Mario Kupa Anticona0% (1)

- Electric Rope Shovel Electric Rope Shovel Dipper Parts Manual Dipper Parts ManualDocument71 pagesElectric Rope Shovel Electric Rope Shovel Dipper Parts Manual Dipper Parts ManualWalissonNo ratings yet

- Manual de Partes 495HR2 PDFDocument1,172 pagesManual de Partes 495HR2 PDFYuri Sanderson0% (1)

- 7495 Electric Rope Shovel Parts Manual VOL IDocument1 page7495 Electric Rope Shovel Parts Manual VOL ImohanNo ratings yet

- Double Girder EOT Crane EnquiryDocument3 pagesDouble Girder EOT Crane EnquiryvkNo ratings yet

- Komatsu PC8000 Hydraulic Mining Shovel Assembly Procedure Manual Rev 02 2004Document156 pagesKomatsu PC8000 Hydraulic Mining Shovel Assembly Procedure Manual Rev 02 2004Pablo Andres Cortes Inostroza100% (4)

- Bucyrus 495 Shovel - Main Parts DiagramDocument1 pageBucyrus 495 Shovel - Main Parts DiagramMarcelo Mendoza100% (1)

- GP Rating GSK Exit ExamDocument108 pagesGP Rating GSK Exit ExamMicle VM100% (4)

- Manual de Partes Perforadora DMHDocument804 pagesManual de Partes Perforadora DMHcesar sandon100% (3)

- Curso Especificaciones Mecanicas 7495 HRDocument124 pagesCurso Especificaciones Mecanicas 7495 HRbends1408100% (2)

- Enfoque MecánicoDocument79 pagesEnfoque MecánicoFelipe Gonzalez Jimenez100% (5)

- Parts Book - 49HR - 141373 Lot 122 PDFDocument721 pagesParts Book - 49HR - 141373 Lot 122 PDFMiguel Carlin Jimenez80% (5)

- 4100XPB 4198 Grupo Mexico CananDocument758 pages4100XPB 4198 Grupo Mexico CananWalissonNo ratings yet

- Locking Assembly Crowd 7495HR CATERPILLARDocument4 pagesLocking Assembly Crowd 7495HR CATERPILLARFrancisco GonzalezNo ratings yet

- Dipper Door Assembly Part No R72209F1 PDFDocument3 pagesDipper Door Assembly Part No R72209F1 PDFFrancisco GonzalezNo ratings yet

- 1era Reduccion Hoist P&HDocument3 pages1era Reduccion Hoist P&HMarcel Baque100% (1)

- Manual Operación Pala Eléctrica 495hdDocument102 pagesManual Operación Pala Eléctrica 495hdJose Luis100% (6)

- 495 HR 141185Document836 pages495 HR 141185RAUL ROJAS100% (2)

- Special Instruction 797fDocument600 pagesSpecial Instruction 797fLuisNo ratings yet

- Komatsu Pala Cable PH 4100XPC enDocument5 pagesKomatsu Pala Cable PH 4100XPC enCesar A VargasNo ratings yet

- Pala 495HR PDFDocument1 pagePala 495HR PDFClaudio Andres Zuleta MaldonadoNo ratings yet

- Bearing Part Numbers and DescriptionsDocument12 pagesBearing Part Numbers and DescriptionsFrancisco GonzalezNo ratings yet

- BI011852-00-00-EN CMPL - Parts ER601508Document1,303 pagesBI011852-00-00-EN CMPL - Parts ER601508EdwarthMaza100% (1)

- SH001 - 7495 - ER601508 PartesDocument1,303 pagesSH001 - 7495 - ER601508 PartesDennis Huanuco Ccama100% (1)

- Optima Dipper Systems: Breakthrough Loading SolutionsDocument6 pagesOptima Dipper Systems: Breakthrough Loading SolutionsDiego Vicente75% (4)

- Lewis Corporation Case 6-2 - Group 5Document8 pagesLewis Corporation Case 6-2 - Group 5Om Prakash100% (1)

- P&H 4100xpc DC 9 Lub SystDocument213 pagesP&H 4100xpc DC 9 Lub SystEdgardo Roldan H-E Parts100% (1)

- 4 Influencing Factors of Learners Career Choice Parents Choice Vs Personal DescisionDocument24 pages4 Influencing Factors of Learners Career Choice Parents Choice Vs Personal Descisionmatteo mamaloNo ratings yet

- Parts 1 XPC P&H 4100Document55 pagesParts 1 XPC P&H 4100Frank Azola Araya100% (1)

- 495HR Spec (Lit408)Document2 pages495HR Spec (Lit408)hogfdv5654100% (1)

- MCC, MAIN COMPRESSOR START CABINET PARTS LISTDocument1,096 pagesMCC, MAIN COMPRESSOR START CABINET PARTS LISTFernandoNo ratings yet

- BI010305-Service Manual-141450-Pl002 PDFDocument574 pagesBI010305-Service Manual-141450-Pl002 PDFjlparedesy100% (1)

- Heavy Duty Electric MotorsDocument4 pagesHeavy Duty Electric MotorsMCA100% (1)

- Transmisión Komatsu P&H Recambios, Kit Reparación y PartesDocument12 pagesTransmisión Komatsu P&H Recambios, Kit Reparación y PartesCésar Rodrigo Puentes Arriagada100% (1)

- Procedimiento Alineaci N Tambor Hoist SL-ES-221-Ver03Document60 pagesProcedimiento Alineaci N Tambor Hoist SL-ES-221-Ver03Miguel_Angel_R_2722No ratings yet

- Catalogo 495 HR1Document46 pagesCatalogo 495 HR1Dario Chouger100% (1)

- Electric Mining Shovels: Product OverviewDocument7 pagesElectric Mining Shovels: Product Overviewpaulocouceiro100% (1)

- PH 2800xpc DC Bro PDFDocument5 pagesPH 2800xpc DC Bro PDFMario Zurita CamachoNo ratings yet

- Catalogo Bucyrus 295bii y Stock FiltrosDocument57 pagesCatalogo Bucyrus 295bii y Stock Filtrosjaime_perez_lopezNo ratings yet

- Palas BucyrusDocument19 pagesPalas Bucyrusperfo 49r100% (2)

- Shovels BucyrusDocument8 pagesShovels BucyrusAlexisPereiraVásquezNo ratings yet

- 4100XPC Erection ProcedureDocument8 pages4100XPC Erection ProcedureErick Antonio Cruz CordovaNo ratings yet

- Attachment S1 - Erection Procedure 2800XPBDocument8 pagesAttachment S1 - Erection Procedure 2800XPBjohnNo ratings yet

- Link Ratio MethodDocument18 pagesLink Ratio MethodLuis ChioNo ratings yet

- Annual Plan 1st GradeDocument3 pagesAnnual Plan 1st GradeNataliaMarinucciNo ratings yet

- Master SEODocument8 pagesMaster SEOOkane MochiNo ratings yet

- N4 Electrotechnics August 2021 MemorandumDocument8 pagesN4 Electrotechnics August 2021 MemorandumPetro Susan BarnardNo ratings yet

- Sinclair User 1 Apr 1982Document68 pagesSinclair User 1 Apr 1982JasonWhite99No ratings yet

- Worksheet 5 Communications and Privacy: Unit 6 CommunicationDocument3 pagesWorksheet 5 Communications and Privacy: Unit 6 Communicationwh45w45hw54No ratings yet

- SOP-for RecallDocument3 pagesSOP-for RecallNilove PervezNo ratings yet

- Joining Instruction 4 Years 22 23Document11 pagesJoining Instruction 4 Years 22 23Salmini ShamteNo ratings yet

- Human Rights Alert: Corrective Actions in Re: Litigation Involving Financial InstitutionsDocument3 pagesHuman Rights Alert: Corrective Actions in Re: Litigation Involving Financial InstitutionsHuman Rights Alert - NGO (RA)No ratings yet

- EN 12449 CuNi Pipe-2012Document47 pagesEN 12449 CuNi Pipe-2012DARYONO sudaryonoNo ratings yet

- Evil Days of Luckless JohnDocument5 pagesEvil Days of Luckless JohnadikressNo ratings yet

- CS210 Lecture 32 Magical Application Binary Tree IIIDocument38 pagesCS210 Lecture 32 Magical Application Binary Tree IIIOshoNo ratings yet

- Ailunce HD1 Software ManualDocument33 pagesAilunce HD1 Software ManualMarc LaBarberaNo ratings yet

- Why Choose Medicine As A CareerDocument25 pagesWhy Choose Medicine As A CareerVinod KumarNo ratings yet

- Technical specifications for JR3 multi-axis force-torque sensor modelsDocument1 pageTechnical specifications for JR3 multi-axis force-torque sensor modelsSAN JUAN BAUTISTANo ratings yet

- Endangered EcosystemDocument11 pagesEndangered EcosystemNur SyahirahNo ratings yet

- OS LabDocument130 pagesOS LabSourav BadhanNo ratings yet

- 2021 JHS INSET Template For Modular/Online Learning: Curriculum MapDocument15 pages2021 JHS INSET Template For Modular/Online Learning: Curriculum MapDremie WorksNo ratings yet

- Production of Sodium Chlorite PDFDocument13 pagesProduction of Sodium Chlorite PDFangelofgloryNo ratings yet

- WWW - Commonsensemedia - OrgDocument3 pagesWWW - Commonsensemedia - Orgkbeik001No ratings yet

- Tutorial 1 Discussion Document - Batch 03Document4 pagesTutorial 1 Discussion Document - Batch 03Anindya CostaNo ratings yet

- Ielts Practice Tests: ListeningDocument19 pagesIelts Practice Tests: ListeningKadek Santiari DewiNo ratings yet

- 2021 Impact of Change Forecast Highlights: COVID-19 Recovery and Impact On Future UtilizationDocument17 pages2021 Impact of Change Forecast Highlights: COVID-19 Recovery and Impact On Future UtilizationwahidNo ratings yet

- Cableado de TermocuplasDocument3 pagesCableado de TermocuplasRUBEN DARIO BUCHELLYNo ratings yet

- Assembly ModelingDocument222 pagesAssembly ModelingjdfdfererNo ratings yet