Professional Documents

Culture Documents

Risk Assessment For Sand Blasting

Uploaded by

Rochdi Bahiri69%(16)69% found this document useful (16 votes)

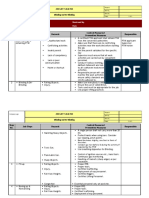

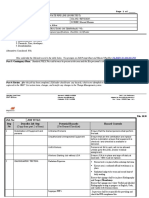

15K views8 pagesRISK ASSESSMENT FORM Location: Terga Date of Assessment: 17-09-2009 ASSESSMENT No: Biman Modak System / Activity: Sand Blasting and Painting. Table below provides a simplified representation of the methodology used and the processes involved in this Hazard Identification and Risk Analysis Procedure (Risk Management) to be undertaken by OCIA and all subcontractors.

Original Description:

Original Title

Risk Assessment for Sand Blasting

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRISK ASSESSMENT FORM Location: Terga Date of Assessment: 17-09-2009 ASSESSMENT No: Biman Modak System / Activity: Sand Blasting and Painting. Table below provides a simplified representation of the methodology used and the processes involved in this Hazard Identification and Risk Analysis Procedure (Risk Management) to be undertaken by OCIA and all subcontractors.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

69%(16)69% found this document useful (16 votes)

15K views8 pagesRisk Assessment For Sand Blasting

Uploaded by

Rochdi BahiriRISK ASSESSMENT FORM Location: Terga Date of Assessment: 17-09-2009 ASSESSMENT No: Biman Modak System / Activity: Sand Blasting and Painting. Table below provides a simplified representation of the methodology used and the processes involved in this Hazard Identification and Risk Analysis Procedure (Risk Management) to be undertaken by OCIA and all subcontractors.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

RISK ASSESSMENT FORM

Location: Terga Date of Assessment: 17-09-2009 Assessment No:

Assessor(s): Biman Modak System/Activity: Sand Blasting and Painting.

P

r

o

b

a

b

i

l

i

t

y

&

F

r

e

q

u

e

n

c

y

Definite 5 5 10 15 20

High 4 4 8 12 16

Moderate 3 3 6 9 12

Low 2 2 4 6 8

Negligible 1 1 2 3 4

1 2 3 4

Minor Serious Major Catastrophic

Severity

Key to Priorities

Medium Priority (5 days) High Priority (2-3 days) Immediate

INTRODUCTION

The table below provides a simplified representation of the methodology used and the processes involved in this Hazard Identification & Risk Analysis Procedure (Risk

Management) to be undertaken by OCIA and all Subcontractors in order to initiate, act on, review and effectively manage project-related risks throughout the Construction

Phase.

IDENTIFICATION - Pre planning , Method

statement , Job safety analysis.

ASSESSMENT Impact, Risk factor,

Mitigation measure, Residual risk

IMPLEMENTATION &

COMMUNICATION

REVIEW & UP DATE

Identify activities , Identify hazards Assess Impacts, Analyze Risk ,

Establish Mitigation Measures.

Communication & Training Audit, Inspection & Up dating of Log.

RISK ASSESSMENT FORM

Hazards Identified (include the exposed groups)

Probability

1 - 5

Severity

1 - 4

Risk

1 - 20

Control Measures to be Implemented

Probability

1 - 5

Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date Action

Completed

Crane / Boom failure 3 3 9 Certified controlled and well maintained

crane.

Licensed competent crane operator.

Complete the crane checklist inspection

Re inspect the crane after each shift

2 3 6

Collapse or rollover of crane 3 3 9 All the service drawings to be inspected prior

to the commencement of any works

Steel plates fitted where appropriate to

provide additional support

All movements to be controlled by a

competent banks man.

A competent trained supervisor to be present

and in control of the works at all times.

2 3 6

Unstable ground of the crane outriggers 3 3 9 Crane operator to assess work and lifting

area before any lifting operations are carried

out.

Outrigger to be fully extended and load

bearing pads to be use during lifting

operation.

2 3 6

Unstable load 3 2 6 Sufficient tag lines to be used at all times.

Trained and competent banks man to be in

control of the lift at all times.

A competent trained supervisor to be present

and in control of the works at all times

2 2 4

Incorrect / Unsafe slinging 4 3 12 Load to be rigged by a trained competent

rigger at all times

A competent trained supervisor to be present

and in control of the works at all times

All movements to be controlled by a

competent banks man.

All slings shall be protected from sharp

objects and edges of the load at all times.

2 3 6

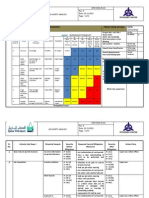

RISK ASSESSMENT FORM

Crush injuries to body parts 3 3 9 No worker under a suspended load.

Experienced steel erectors who will be

inducted in the company policies, safety

procedures, site safety rules, emergency

procedures and environment to only work

aloft.

All crane swing radius to be protected and

highlighted.

All personnel to be vigilant / alert at all times.

A competent trained supervisor to be present

and in control of the works at all times.

All movements to be controlled by a

competent banks man.

2 3 6

Throwing of materials such as : Bolts, nuts

and hand tools

3 3 9 No throwing up or down of equipments, tools

or bolts etc, and all materials to be put in a

suitable container before lowering or

hoisting.

Personnel to be issued with pouches or belts

for ease of carrying hand tools or extra bolts.

2 3 6

Safe access / egress 3 3 9 All access routes to remain clear and free

from obstructions.

Area to be kept tidy at all times.

Adequate access ladders with fall arrest

system installed.

A pre tested and certified man basket and

scaffolding to be used to access difficult

areas.

Man basket to be checked daily by a

competent person prior to use.

The man basket must be checked each time

it is attached to the crane.

Shackles are secured and pinned.

Shackles and rings are not deformed and

pad eyes are not damaged.

Slings and rings in good condition.

Handrails are in good condition.

Floor plating and kick plates are in good

condition.

2 3 6

Grating fixing 3 3 9 All gratings will be secured to the structure,

and also will be secured to each other with

proper fixing materials.

2 3 6

RISK ASSESSMENT FORM

Working at heights with man basket 4 4 16

Sandblasting is a special physical

process that uses a stream of sand

propelled by water or compressed air

and applied on a surface. Texas

sandblasting creates a powerful

abrasive force that can act on any

surface worked on using this air-

propelled material. There are

alternative sandblast materials that can

be used depending on the requirement

of the work. These include iron

globules, emery and powdered quartz.

It is the preparatory process done on different

kinds of surfaces before enameling, painting and

during the process of galvanizing. It is also a

popular cleaning solution for surfaces with hard

to remove grime and other debris that accumulate

in the concrete surfaces of buildings.

2 3 6

Working at heights ( fall ) 4 4 16

It should be noted that sandblast jobs

can be hazardous as workers are

exposed to toxic elements during the

process. There are a wide range of

harmful particles which may include

zinc or lead which are common

components in most commercial Texas

coatings. When you are doing

sandblast operations, steps should be

undertaken to protect yourself from

the harmful effects of the abrasive

materials being used. Protective gears

like goggles and appropriate clothing

are extremely important if you are

going to do sandblasting work. The

potential harm and injury that can be

brought on the person doing the

sandblasting operations makes it

extremely important that safety

regulations are observed before and

during any sandblasting operation.

2 3 6

RISK ASSESSMENT FORM

Rigging , miscommunication between riggers

and crane operators

4 3 12

In any typical sandblasting operation,

the standard air breathing equipment

must be used. This is necessary as the

operators need to have a steady supply

of clean air in a workplace where there

is a heavy volume of toxic and harmful

contaminants. Before any sandblast

operation, it is imperative that you

inspect the air breathing apparatus to

make sure that it delivers a steady flow

of clean air. The operators are strongly

advised to remove the air breathing

equipment after operation only when

they at a safe distance from the work

area as harmful particulates remain

suspended in the air even after the

sandblast operations.

The crew must also wear standard issue gloves

and coveralls while within the sandblasting

workplace. It is also equally important to use the

prescribed footwear when doing sandblast

operations.

2 3 6

Equipment slinging, Part of a body sheared

by the slings and the equipment due to

incorrect slinging

2 3 6 2 2 4

Fall from the access ladders 4 4 16 2 3 6

Unauthorised personnel in the lifting area 3 3 9 2 3 6

Manual handling , temporary support , fixture

are used during assembly, erection activities.

3 2 6 2 2 4

Equipment and tools transportation to and

from storage area .

3 3 9 2 3 6

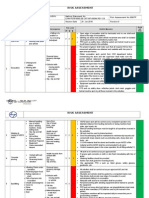

RISK ASSESSMENT FORM

Fire or explosion ( combustible materials, gas

cylinders, etc.)

3 3 9 Area to be checked from flammables before

the commencement of any works and also

area to be checked one hour after work has

ceased.

Gas cylinders must be kept in the vertical

position.

Site emergency plan to be followed in event

fire or explosion.

All personnel to be inducted and aware of

emergency procedures.

Fire blankets and extinguishers to be present

at the work places.

2 3 6

Disc cutting and grinding, Cut/severing by

using the tools incorrectly.

3 3 9 Hand tools are to be inspected and colour

coded by the designated competent person.

Tools to be used by the qualified employees

only. Proper PPE wearing, toolbox talk prior

to starting the activity.

2 3 6

Use of mechanical lifting equipments 3 3 9 All operators will be competent in use of

mechanical lifting equipment.

Equipment will be suitable, sufficient,

maintained and inspected (colour coded)

prior to use.

2 3 6

Irritation to eyes 3 3 9 All personnel to wear appropriate PPE at all

times.

2 3 6

Cut and abrasions 3 3 9 All personnel to wear appropriate PPE at all

times

2 3 6

High noise during bolts tightening 3 3 9 All personnel will be using hearing protection

at / around the origin of high noise.

2 3 6

Irritation to the respiratory track 3 3 9 All personnel to wear appropriate PPE at all

times

2 3 6

Burns, scalds and scars 3 3 9 All personnel to wear appropriate PPE at all

times

2 3 6

Inadequate lighting 3 2 6 Temporary lights to be in place wherever

required

2 2 4

Use of hand tools and equipment 3 3 9 All personnel involved to be competent

All tools to be maintained in good order and

used correctly by trained operators only.

Hand tools will be secured by robe when

used at height and secured to fixed point.

2 3 6

RISK ASSESSMENT FORM

Erection of scaffolding 3 3 9 Scaffolding only to be erected by competent

and trained scaffolders, and will be tagged

green or red.

Avoid working under scaffolds and under

overhead ongoing activities, toolbox talk prior

to starting the activity.

Working at height standards implemented,

safety guard rails mounted and safety

harness worn and secured, toolbox talk prior

to starting the activity.

2 3 6

Torque bolting, Non-ergonomic posture to

carry out certain tasks

3 2 6 Implement good manual handling techniques 2 2 4

Welding at height 3 3 9 All welding operations at height are to be

fully sheeted in with a fire blanket.

The area below the work place to be

checked for flammable materials before

commencing any work cordoned off.

A fire watcher and fire extinguishers to be in

place below the work area.

All equipments to be inspected and left in

safe conditions at break times and at the end

of each shift.

2 3 6

Inclement weather 3 3 9 Wind speed and weather conditions to be

monitored on a daily basis.

2 3 6

Slips and trips and falls 3 2 6 Work area to be kept tidy at all times.

Area to be cleaned of any waste material at

end of each shift.

2 2 4

Temporary storage at height 3 2 6 All temporary storage of material at height

shall be held on a dedicated suitable and

sufficient platform.

2 2 4

Assessor Print : BIMAN MODAK Sign: Date: 25-07-2009

RISK ASSESSMENT FORM

You might also like

- Risk Assessment Form for Sand Blasting and PaintingDocument6 pagesRisk Assessment Form for Sand Blasting and PaintingRochdi Bahiri100% (10)

- RA, COSHH, MSDS Screed & Waterproofing PDFDocument27 pagesRA, COSHH, MSDS Screed & Waterproofing PDFテレブリコ ジェファーソン60% (5)

- Risk Assessment Sand BlastingDocument7 pagesRisk Assessment Sand BlastingRohit Singh100% (7)

- JSA Blasting and Coating KP 69.4Document5 pagesJSA Blasting and Coating KP 69.4shinto Lawrence100% (6)

- JSA - Fire Proofing WorksDocument5 pagesJSA - Fire Proofing WorksAnis Uddin100% (3)

- #15 Activity Based Risk Assessment For Painting of The Terror Club Compound and Roof Washing of T.C. BuildingsDocument14 pages#15 Activity Based Risk Assessment For Painting of The Terror Club Compound and Roof Washing of T.C. BuildingsSathish Insmile100% (1)

- Use of Hand ToolsDocument2 pagesUse of Hand Toolsvictor100% (1)

- Job Safety Analysis (Hydro Jetting)Document4 pagesJob Safety Analysis (Hydro Jetting)rashid zaman57% (7)

- Portable Power Tools - Risk Assessment2Document3 pagesPortable Power Tools - Risk Assessment2Basit Nawaz100% (1)

- JSA For Diesel Filling at Del CampDocument6 pagesJSA For Diesel Filling at Del CampMohammed Minhaj60% (5)

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Dar Al Hijra Painting Risk AssessmentDocument5 pagesDar Al Hijra Painting Risk Assessmentmakdel68% (22)

- Risk Asses 65-Piping Fabricated and Assembly - H03Document11 pagesRisk Asses 65-Piping Fabricated and Assembly - H03Rochdi BahiriNo ratings yet

- JSA Mechanical Activity Risk AssessmentDocument1 pageJSA Mechanical Activity Risk Assessmentjithin shankarNo ratings yet

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRyanNo ratings yet

- ConfinedSpace RiskAssessmentDocument9 pagesConfinedSpace RiskAssessmentrashid zaman100% (4)

- JHA Example Installation of Underfloor Plumbing and DrainsDocument15 pagesJHA Example Installation of Underfloor Plumbing and DrainsShamel Jen FacundoNo ratings yet

- 3-REV.1 - Hot Work - Risk Assessment JHADocument16 pages3-REV.1 - Hot Work - Risk Assessment JHAnaiyar100% (1)

- Reasons for Painting Safety ReviewDocument5 pagesReasons for Painting Safety Reviewnoufal2783% (12)

- JSA Blinding and de Blinding PDF FreeDocument3 pagesJSA Blinding and de Blinding PDF Free최승원No ratings yet

- Steel FixingDocument5 pagesSteel Fixingrishanmulky88% (8)

- Hydro Jetting and Sludge RemovalDocument18 pagesHydro Jetting and Sludge Removalmarvin100% (1)

- Risk Assessment - Backfilling Around Foul Sewer and Storm Warter ManholesDocument6 pagesRisk Assessment - Backfilling Around Foul Sewer and Storm Warter Manholesloveson70950% (2)

- RISK ASSESSMENT FOR 10 VILLA CONSTRUCTIONDocument12 pagesRISK ASSESSMENT FOR 10 VILLA CONSTRUCTIONFrancis Enriquez Tan50% (6)

- Manual Tig Welding (RRC) - Job ProcedureDocument3 pagesManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- JSA-009 Sand Blasting - Coating 2Document6 pagesJSA-009 Sand Blasting - Coating 2Omar DhiebNo ratings yet

- Form JSA Lifting CraneDocument6 pagesForm JSA Lifting CraneYeti Srinurhayati100% (1)

- JSA-049 Valves & Support Installation and DismantlingDocument4 pagesJSA-049 Valves & Support Installation and DismantlingMoaatazz Nouisri75% (4)

- Jsa For Civil Confined Space EntryDocument11 pagesJsa For Civil Confined Space EntryKhuda BukshNo ratings yet

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocument16 pagesSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh60% (5)

- Task-Based Risk Assessment Painting WorksDocument6 pagesTask-Based Risk Assessment Painting Worksvinodhyper100% (2)

- JOB SAFETY ANALYSIS FOR HEAT TRACING REPAIRDocument12 pagesJOB SAFETY ANALYSIS FOR HEAT TRACING REPAIRChung Trịnh100% (2)

- QP Blasting JSADocument6 pagesQP Blasting JSAMohammed Mujahid100% (1)

- Risk Assessment Work at HeightDocument3 pagesRisk Assessment Work at HeightSathi sh0% (1)

- JSA - Sand Blasting & PaintingDocument4 pagesJSA - Sand Blasting & Paintingsurendra behera100% (4)

- Welding, Cutting and GrindingDocument6 pagesWelding, Cutting and GrindingMohammed MinhajNo ratings yet

- Hse Risk Assessment - 006 Ra - Hdpe Duct LayingDocument7 pagesHse Risk Assessment - 006 Ra - Hdpe Duct Layingbinunalukandam83% (12)

- Forklift Risk AssessmentDocument5 pagesForklift Risk AssessmentNii Ashiii100% (1)

- JSA of Pipe Unloading.Document2 pagesJSA of Pipe Unloading.vijay kumar singh100% (1)

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDocument2 pagesJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- (EDIT) F-SAF-0046.11 Bolt Torquing Risk Assessment (Generic)Document10 pages(EDIT) F-SAF-0046.11 Bolt Torquing Risk Assessment (Generic)ainun mardiah75% (4)

- Winch MachineDocument1 pageWinch MachineJomar Rudolph Cabesas100% (6)

- JSA For NDTDocument4 pagesJSA For NDTMohammed Minhaj50% (2)

- Risk Assessment For Mobilization Works DCP 3Document4 pagesRisk Assessment For Mobilization Works DCP 3thomas_196382% (11)

- Jsa-Jha For Using of Hand ToolsDocument2 pagesJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- Working at Heights RiskDocument3 pagesWorking at Heights Riskmyo lwin75% (4)

- PEB Work Risk Assessment 17.4.17Document10 pagesPEB Work Risk Assessment 17.4.17Syed Ali HassanNo ratings yet

- Hot Work TRA Workshop NightDocument3 pagesHot Work TRA Workshop Nightmarvin100% (1)

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEDocument12 pagesRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- Risk Assessment for Pipe ErectionDocument6 pagesRisk Assessment for Pipe ErectionAzhar MushtaqNo ratings yet

- Jsa For Drilling.Document3 pagesJsa For Drilling.Belsyah Nofriyan75% (4)

- JHA Chain HoistDocument1 pageJHA Chain HoistKrishna Patil100% (2)

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedDr AnwarNo ratings yet

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: Facilitywahyu nugrohoNo ratings yet

- JSA Ladders Working at Heights 001Document2 pagesJSA Ladders Working at Heights 001Raman SawNo ratings yet

- DR - Rescue Plan Water Tank Cleaning (002) Rev-With LayoutDocument4 pagesDR - Rescue Plan Water Tank Cleaning (002) Rev-With LayoutSachin DharneNo ratings yet

- JSA For Cutting, Grinding and WeldingDocument4 pagesJSA For Cutting, Grinding and Weldingyc safety100% (3)

- Risk Assessment For Sand Blasting PDFDocument8 pagesRisk Assessment For Sand Blasting PDFOvais FarooqNo ratings yet

- Risk Assessment Form Gaz Turbine InstallationDocument6 pagesRisk Assessment Form Gaz Turbine InstallationRochdi Bahiri100% (1)

- Risk Assesment 16 - Pre - Assembly and Erection ofDocument7 pagesRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriNo ratings yet

- Audit of Power Purchase AgreementsDocument6 pagesAudit of Power Purchase AgreementsRochdi BahiriNo ratings yet

- Project Finance and Merchant PowerDocument76 pagesProject Finance and Merchant Powersimplyanks_5100% (2)

- A Case Study of 3-MW Scale Grid-Connected Solar Photovoltaic Power Plant at Kolar, KarnatakaDocument38 pagesA Case Study of 3-MW Scale Grid-Connected Solar Photovoltaic Power Plant at Kolar, KarnatakaAnant Joshi67% (3)

- Risk Asses23 - Generator RotorDocument3 pagesRisk Asses23 - Generator RotorRochdi BahiriNo ratings yet

- What Is Quadrature Axis Reactance PDFDocument11 pagesWhat Is Quadrature Axis Reactance PDFRochdi BahiriNo ratings yet

- Evaluate economic feasibility of power plant projectsDocument7 pagesEvaluate economic feasibility of power plant projectsfundu123No ratings yet

- Epc Contracts in The Power SectorDocument30 pagesEpc Contracts in The Power SectorIwan Anggara100% (2)

- Risk Asses 116 - Boiler Hydro Test LP3Document5 pagesRisk Asses 116 - Boiler Hydro Test LP3Rochdi BahiriNo ratings yet

- Primavera: Contract Manager Functional OverviewDocument22 pagesPrimavera: Contract Manager Functional OverviewIgor ČučekNo ratings yet

- TSA Appendices State - 16 09 2014 - WPDocument24,221 pagesTSA Appendices State - 16 09 2014 - WPRochdi BahiriNo ratings yet

- Pump Efficiency For Single Stage Centrifugal PumpsDocument8 pagesPump Efficiency For Single Stage Centrifugal PumpsPerrobast100% (1)

- Power Electronics For Modern Wind Turbines-Frede Blaabjerg Zhe ChenDocument68 pagesPower Electronics For Modern Wind Turbines-Frede Blaabjerg Zhe Chennelber_xNo ratings yet

- Readme 1 STDocument1 pageReadme 1 STRochdi BahiriNo ratings yet

- Risk Asses 118-Transformers Oil TreatmentDocument5 pagesRisk Asses 118-Transformers Oil TreatmentRochdi BahiriNo ratings yet

- Financing and Performance Contracting For EE Projects OutlineDocument1 pageFinancing and Performance Contracting For EE Projects OutlineRochdi BahiriNo ratings yet

- Financial Analysis of Projects I - OutlineDocument2 pagesFinancial Analysis of Projects I - OutlineRochdi BahiriNo ratings yet

- Project and O&M CostDocument2 pagesProject and O&M CostRochdi BahiriNo ratings yet

- Dampers ExplanationDocument7 pagesDampers ExplanationRochdi BahiriNo ratings yet

- 308 BeheraDocument6 pages308 BeheraRajneesh VachaspatiNo ratings yet

- Install NotesDocument1 pageInstall NotesRochdi BahiriNo ratings yet

- Risk Assesment 16 - Pre - Assembly and Erection ofDocument7 pagesRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriNo ratings yet

- Primavera Project Planner p3Document300 pagesPrimavera Project Planner p3MARIANO100% (19)

- P6 Reference ManualDocument550 pagesP6 Reference Manualsaluthomas100% (22)

- Lettre Recommandation Orascom ConstructionDocument1 pageLettre Recommandation Orascom ConstructionRochdi BahiriNo ratings yet

- BRD - Lean Manufacturing CaseDocument62 pagesBRD - Lean Manufacturing CaseRochdi BahiriNo ratings yet

- Hawk 4000 Controls: HAWK 4000 Boiler Control System Sample SpecificationsDocument4 pagesHawk 4000 Controls: HAWK 4000 Boiler Control System Sample SpecificationsRochdi BahiriNo ratings yet

- Wmu 2013 - PPT - FinalDocument103 pagesWmu 2013 - PPT - FinalRochdi BahiriNo ratings yet

- Risk Asses23 - Generator RotorDocument3 pagesRisk Asses23 - Generator RotorRochdi BahiriNo ratings yet

- 750-326 OM Blowdown Separator 04-10Document8 pages750-326 OM Blowdown Separator 04-10Rochdi BahiriNo ratings yet

- Boiler Design StepDocument3 pagesBoiler Design StepRochdi BahiriNo ratings yet

- 002 Majnoon Site Specific HSE PlanDocument18 pages002 Majnoon Site Specific HSE Planالحاج راضي راضيNo ratings yet

- Risk management plasma cuttingDocument1 pageRisk management plasma cuttingMyusof MohamadNo ratings yet

- HIRA - DC MaintenanceDocument25 pagesHIRA - DC MaintenanceDEEPAK MALLIKNo ratings yet

- Sop Hse Hul 14092015Document78 pagesSop Hse Hul 14092015Subhranshu Chakraborty100% (1)

- Hierarchy of Hazard Controls: InitiativesDocument2 pagesHierarchy of Hazard Controls: Initiativeskalyan1990No ratings yet

- Safety Data Sheet for Polymer ProductDocument17 pagesSafety Data Sheet for Polymer Producthai nguyenNo ratings yet

- HSE Manager JOB DESCRIPTIONDocument4 pagesHSE Manager JOB DESCRIPTIONsultanius0% (1)

- Chlorine Evaporator PDFDocument34 pagesChlorine Evaporator PDFSreenubabu Kandru100% (1)

- Safety Data Sheet for Cif Cream CleanerDocument3 pagesSafety Data Sheet for Cif Cream CleanersutaNo ratings yet

- Saudi Methanol Company (Ar-Razi) : Job Safety AnalysisDocument7 pagesSaudi Methanol Company (Ar-Razi) : Job Safety AnalysisAnonymous voA5Tb0No ratings yet

- Summative TestDocument2 pagesSummative Testnerissa dollenteNo ratings yet

- Hazardous Substance Fact Sheet: Right To KnowDocument6 pagesHazardous Substance Fact Sheet: Right To KnowBadtzNo ratings yet

- Manual ZTP EngDocument51 pagesManual ZTP Engeeng_nnabil50% (2)

- Safety Data Sheet: in Compliance With OSHA Hazard Communication Standard (29 CFR 1910.1200)Document6 pagesSafety Data Sheet: in Compliance With OSHA Hazard Communication Standard (29 CFR 1910.1200)TanjaNo ratings yet

- JSA Installation-Fire-Alarm-SystemDocument12 pagesJSA Installation-Fire-Alarm-Systemuz9143895No ratings yet

- Safety Guidelines For Chemotherapy and Radiation Therapy: By: Prof. Marites L. RoblezaDocument32 pagesSafety Guidelines For Chemotherapy and Radiation Therapy: By: Prof. Marites L. RoblezaJerry Able100% (1)

- Using Petrol-Driven Chainsaws: FISA Safety Guide 301Document2 pagesUsing Petrol-Driven Chainsaws: FISA Safety Guide 301Garden GrillNo ratings yet

- EZ GUARD CORROSION INHIBITOR EYM English 18-May-2017 SDSDocument7 pagesEZ GUARD CORROSION INHIBITOR EYM English 18-May-2017 SDSSinan ChenNo ratings yet

- Unit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1Document19 pagesUnit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1Abdur80% (10)

- Chemical Terrorism DisasterDocument164 pagesChemical Terrorism DisasterAnshu ShahNo ratings yet

- ICST Cooling Tower Inspection GuidelinesDocument6 pagesICST Cooling Tower Inspection GuidelinesIan FletcherNo ratings yet

- Automotive Welding Technician Level4Document38 pagesAutomotive Welding Technician Level4BalvinderNo ratings yet

- Plant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerDocument6 pagesPlant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerJoypee MacasamponNo ratings yet

- Sulphuric Acid 98%Document8 pagesSulphuric Acid 98%Rino SutrisnoNo ratings yet

- Final Project 2020-21Document50 pagesFinal Project 2020-21Rs 31 Pavan PawarNo ratings yet

- PPE Selection and Use GuideDocument5 pagesPPE Selection and Use GuideJay Vee100% (1)

- Additional Safety Rules For A Drill Presses: 5) ServiceDocument7 pagesAdditional Safety Rules For A Drill Presses: 5) ServiceRoger OrtegaNo ratings yet

- Hazard Identification 2. Risk AssessmentDocument5 pagesHazard Identification 2. Risk AssessmentNoreen Syakireen Binti NormanNo ratings yet

- Reactive Yellow 145Document4 pagesReactive Yellow 145DHRUVNo ratings yet

- Power KiteDocument3 pagesPower Kiterehab1w23efrtggfdghtNo ratings yet